Wraparound Case Packer Manufacturer in China

JOCHAMP is a professional manufacturer of wraparound case packers which is an innovative design intermittent running case packer with an output of 30 cycles per minute upward. Our wrap-around case packer is formed in a common end-of-line pack style and can wrap a vast range of products.

- Can group stations for various pack sizes

- In multi-layers form, it has always folding stations

- Offers automatic blank magazine

- It can add modules for labeler, check weigher, etc.

JOCHAMP Wraparound Case Packer

JOCHAMP is a leading provider of wraparound case packers that can place products from the top or side of the wraparound tray blank or harness style. Our wrap-around case packer offers different benefits such as shipment, flat blank storage, and greater case blank capacity magazine.

Our wraparound case packer has a unique walking beam with a dual-sided opposite vacuum to ensure that the case will become square all the way until to closing stations without the need for flight lugs. The rug frames of our wraparound case packer are built for three-shift operations per day and the servo-built drives to provides high-speed operations and ensure quiet.

Moreover, this type has a digital gauge and scale pointers that allow for a quick, no-tool changeover in 5 minutes. It is user-friendly and provides low maintenance.

Send us your inquiry now!

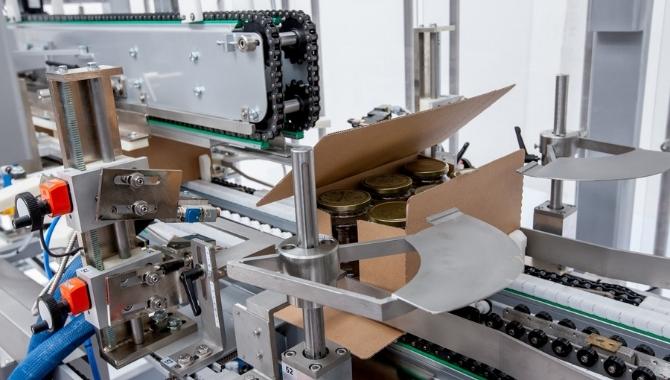

JC-501 Wraparound Case Packer

This machine is suitable for packaging products with a single piece of corrugated paper. Compared with ordinary case packers, it is more compact and can accommodate a wider range of sizes.

- Use a single cardboard to wrap the box, reduce the link of box making and unpacking, and save the cost of box making and unpacking equipment

- Compared with the traditional carton, it can save about 20% of the carton area and save the cost of raw materials

- According to the customer’s packing arrangement requirements, the products are automatically arranged and combined

- Wide range of applications, can meet a variety of specifications product packing

- The use of Nordson hot melt gluer in the United States to spray glue and seal the box ensures the stability of the sealing and bonding, and reduces the downtime caused by the quality problem of the hot melt gluer.

- Control mode: PLC+touch screen+standard control button+signal switch, automatic/manual control mode

- The fault point can be found through the touch screen for easy troubleshooting

JC-501

- Technical Parameter

- Features

- Optional

| Model | JC-501 |

| Power supply | 3Phase,380V, 50/60HZ, 10KW |

| Air pressure | 0.5-0.7MP |

| Machine size | L8145*W2150*H2000mm |

| Suitable carton size | L200-500*W150-500*H100-350mm |

| Packing speed | ≤12cases/min |

| Glue solidify time | 2-3s |

| Machine weight | 2200kg |

- Use a single cardboard to wrap the box, reduce the link of box making and unpacking, and save the cost of box making and unpacking equipment

- Compared with the traditional carton, it can save about 20% of the carton area and save the cost of raw materials

- According to the customer’s packing arrangement requirements, the products are automatically arranged and combined

- Wide range of applications, can meet a variety of specifications product packing

- The use of Nordson hot melt gluer in the United States to spray glue and seal the box ensures the stability of the sealing and bonding, and reduces the downtime caused by the quality problem of the hot melt gluer.

- Control mode: PLC+touch screen+standard control button+signal switch, automatic/manual control mode

- The fault point can be found through the touch screen for easy troubleshooting

Secondary packaging line integration

Labeling Machine

printer

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

JOCHAMP Wraparound Case Packer Advantages

As a manufacturer, we ensure that our wraparound case packer can protect the goods. When you are using our wraparound case packaging machines it will assure that you can encase your products in highly defensive barriers. You can receive more protection than what you get from hand-wrapped operations.

JOCHAMP is always ensured to give high-quality wraparound case packers. You can invest in this that can deliver consistently in a high-quality packaging process. This type of case packer can give integrity to your packaging and can create better protections that help your products looks good all the way through the supply chains.

We provide a wraparound case packer that can save your time in investing in wrapping machines. It gives you faster packaging features with complete and durable results. As a manufacturer, we want to work faster in packaging to increase productivity. Many of our employees dealt with wrapping a very time-consuming process to ensure quality results.

Our wraparound case packer can work through grouping the products together and then bundling them all in the corrugated case. After that, the cardboard start as a flat blank, and then our wraparound case packer machine folds the case around the products and glues all the edges to secure, protect, and increased stability.

Why Choose JOCHAMP Wraparound Case Packer

JOCHAMP always ensures to give you the high-quality type of packer machine including wraparound case packer to help with production. It has a collating system and case extraction system adapted to the natural rigidity and shapes of the products. Our wraparound case packer can help the operator to enhance access to the handling parts.

We manufactured a wraparound case packer that offers numerous benefits such as shipment, flat black storage, and greater case black magazine capacity. By the use of this product, you can improve the palletizing process and can make more squares than a typical RSC type case. It helps to reduce the amount of corrugate overlaps and still provides a strong case that delivers superb strength for distribution and palletizing.

Our wraparound cases offer a good amount of savings on materials and eliminate redundant overlaps. Don’t forget to message us now!

Benefits When Using Wraparound Case Packer

We manufactured a wraparound case packer that offers different benefits. It has the ability to seal cases and either glue them. This machine is capable of handling the wrap-around case blanks, tray blanks, and harness-style case blacks.

- Can provides speed for up to 13 cases per minute depending on the type of products

- It helps to form, seal, and sideloading on a single machine for three types of packaging

- Offers advanced accessibility and ergonomics

- Potential Corrugate Savings

- Multiple Case Style Options

- Inside or Outside Manufacturing Flap

- Increased Case Blank magazine Capacity

- for Positive Product Handling it has Open Case Loading

- Full Over Lapping Flaps Capabilities

Wraparound Case Packer Features

JOCHAMP is a professional provider of wraparound case packers that give you different features and functions when you are using them. Consider the following below:

- Has a group station for different pack sizes

- Multi-layer formats folding stations

- Lid applicator for ready shelf packages options

- High capacity automatic black magazine

- Available in Automatic or manual feeding

- Touch Screen display

- Operation easily and strong stability

- Meet the requirement of GMP

- No need for any molds for size changing

Wraparound Case Packer to Increase Productivity

If you are in the manufacturing industry, owning a wraparound case packer allows you to save money and time. It can significantly reduce time spent on the individual packaging, pallets, and wrapping boxes. With the help of our wraparound case packer, you can boost your business upward. Packing massive bulk orders will become less time-consuming with JOCHAMP wraparound case packer.

The wraparound case packer allows the reduction of human packaging errors and increased production time. To cope with the growing and changing demands of the market, we can provide a wraparound case packer to increase the packaging process speed. It is the right tool for keeping up your business in the market trends.

Provide Room for More Value-Added Labor

For many companies, our wraparound case packer is very useful to maximize productivity. It allows the company owner to increase their productivity by giving work to machines and humans to qualified humans. Our wraparound case packaging machine can let you side on much of your time to consuming work. Meaning by the help of our wrap packer can give the human brainpower to operate the machine, not by self-energy.

Furthermore, wraparound case packers are very useful to feature a higher magazine capacity. All employees with the help of a wrap-around packer in operating don’t need to load new stock corrugated as often.

Save Materials Cost

Our wraparound case packer can help to save your material cost and increased efficiency, opportunity, and productivity. It means that our wraparound case packaging machine uses a corrugated blank to fit the unique dimensions of your products. It helps to minimize the waste materials you used for packaging.

When you are using our wraparound case packer you can save a number of material costs can help you to optimize your budget for production and can help your business to improve.

If you need to purchase our wraparound case packer, message us now!

Improve Pallet Stacking

JOCHAMP manufactured a wraparound case packer to help improve the pallet stacking. It can create stable and optimized pallets that allow you to make the most of your space, ship goods, and streamline transportation. It means that our wraparound case packer can help to improve palletizing and create more stable shipment or inventory. As a result, all cases can create a more stable and consistent pallet.

Moreover, a wraparound case packer can help to improve the integrity and consistency of packages. Meaning each package has the strength to hold up the pallet, provides case strength, and better protections that lead to more optimized pallets,s, and easier stacking.

JOCHAMP – Your Trusted Wraparound Case Packer Supplier in China

As your trusted supplier of wraparound case packers, we create ideas and discover the competitive demand for products for different business owners working in the e-commerce space. Our wrap-around case packer can revolutionize business packaging capabilities. It is used to protect your products, speed up the process of packaging, and lower the production cost which means that these products are very useful for business owners.

In addition, this wraparound case packer can help to separate the products from dust, moisture, and other sources of damage. This means that it can allow you to deliver goods in pristine conditions, preserving your reputation as a supplier and increasing end-user satisfaction.

Message us now!

JOCHAMP Wraparound Case Packer

DUCHAMP offers different case blank magazine options to handle all sizes and types of chipboard blanks and corrugate. We provide many unique features to ensure proper blank.

- Low-level magazine

- Standard 3′ o 6′ case bank magazine

- 4′ case blank magazine (Bottom load only)

- Dual blank style(WA, KD, or Tray)

- Opposing cup set-up

- Vacuum transfer (Bottom load only)

We offer the right product loading options for your product by the use of our wraparound case packer. Below is the complete line of case packers:

- Servo driven overhead loader

- Bottom-up push

- Mechanical gripper

- Robotic

- Cross push

- Vacuum Gantry

The Wraparound Blanks, harness Blanks, and Tray Blanks are the sequence operations when using wrap our wrap-around case packer. Including the process below:

- The 3 blanks are loaded into the case blank magazine to be dispensed into operation.

- Then pulled from the magazine and erected in the set-up station.

- The erected case is then indexed to the load station where the product is loaded into the case

- Then indexes to the gluing station, while manipulating minor and major flaps.

- The case is squared and compressed to allow the glue to set and then the case is discharged

JOCHAMP is the right infeed solution for your business products. We provide a wraparound case packer that is commonly used for packaging applications. Below are the following indeed options:

- Upstacker with the product support

- Flood feed

- Swinger lane divider with grouping

- Indexing paddles

- High-speed rotary stacker with surge/metering belts

- Low-speed bump up stacker

- 90-degree push load

- Race track

High-Performance Wrap Around Case Packer for Different Products

JOCHAMP manufactures an innovative wraparound case packers for beer bottles that feature:

- Up to 6 packs of bottles and cans

- Packs up to 150 bottles per minute

- The carton used has an internal flap

We have wraparound case packers that are used for packaging yogurt tubs that offer:

- Can pack 180 yogurt tubs per minute

- Offers turnkey solutions including palletizer

- Also features a carton with an internal flap

These machines are manufactured with features such as the following:

- Can pack different ice cream tub shapes such as square and round

- Suitable for packing ice cream tubs of different sizes

- Can pack up to 145 ice cream tubs per minute

Related Product

Wraparound Case Packer: The Ultimate Guide

I know you are looking for highly efficient and reliable wraparound case packer machine. Well, this guide explores all details about wraparound case packer such as design, features, parts, working principle, and uses, among other vital aspects.

So, if you want to be an expert in wraparound case packers, read this guide.

A machine that can set up a wraparound case and load it with products from the top, bottom or side.

This is an end of line packing system that offers a wide range of packing solutions.

The wraparound case packer can handle harness style case blanks, case blanks with tear-off perforations and trays.

wrap around case packer

A wraparound case packer machine can be used to perform the following functions;

- Case or tray erection

- Filling the cases and trays

- Closing or sealing the cases

This machine is suitable for companies with large scale production and can package products such as;

- Creating cases for bread

- Packing salt into cases

- Packing dairy products like yoghurt and cheese

- Packing metal jars

- Packing bottles into cases

Reduction in Labour Costs

The wraparound case packer machine has been automated and can do almost everything that was initially done by human labour.

With the wraparound machine, companies around the world have been able to cut on costs that come with labour.

Use of Few Packaging Materials

Using a wraparound case packer machine means reduction in material waste due to accuracy and precision.

Unlike human labour, the machine cannot make mistakes as it works only according to instructions.

Accuracy And Precision

A wraparound case packer machine is only capable of packing the accurate number of products in each wraparound case.

The machine cannot make common errors of accidentally packing excess or a smaller number of products into cases.

Speed And Efficiency

Since the machine has the ability to make, pack and seal the wraparound cases, the process is continuous and very fast.

Product Protection

The wraparound case used for packing the goods offers a protective and defensive barrier for the products.

This protects the products from moisture and other contaminants such as dust.

Creation Of A Good Impression

A machine that delivers high quality packaging maintaining the integrity of the products and giving the package a perfect look.

A wraparound case packer could be one of the reasons why a company has loyal and repeated customers.

Easy You Use Machine

A wraparound case packer machine is designed with a compact PLC controller which makes it easy to use, control and monitor.

Lane Divider

The lane divider is integrated into the wraparound machine for the following purposes;

To be able to detect if there are any missing products.

The lane divider will also detect and reject fallen or faulty products.

At this section, various products can be sorted for packing in the same case.

Grouping Station

At the grouping section, products are handled gently making sure there is no pressure accumulation.

- Several products can be handled of over 1000 products in a minute.

- There is no need for part changes.

- The size change is done automatically.

Product Protection

This is the section that ensures product protection after the wrapping process by applying;

- Layer boards

- Partition boards

Folding Station

At this section, the cases are folded to form a wrapping around the products.

The folding station ensures;

- Tight and properly aligned cases

- Multilayer which can have a layer board

- Wraparound cases with flaps inside or outside

- Various shape options

- All wraps sealed with a hot melt glue.

Lid Applicator

The lid applicator comes with a mechanism that can apply a lid inside or outside the case.

This section ensure;

- A lid is applied inside or outside

- The lid is glued

Automatic Blank Magazine

This section is responsible for holding the blank cases and loading them into the system.

- It is especially suitable for corrugated or solid board

- The automatic blank magazine can store the cases for one hour during operations

- The size change process is automated

The case formation is done through a descender having a platform suction cup which is controlled mechanically.

A frequency converter controls the descender to allow fitting in of the product and case formation.

After the product has been formed and grouped, case positioning takes place to ready it for packing.

The product is dropped into the case through a lift.

After packing, the case wraps the whole product through an automated mechanism.

At the lid applicator station, the case is sealed using a hot melt glue.

Once sealed, it can be discharged from the machine.

Wraparound case packer machines are usually made of heavy-duty steel frames for durability and hygiene.

The machine also features a compact footprint in its design.

Another feature designed within the machine is the sealing procedure which is made possible through a hot melt glue.

Also, it offers flexibility in terms of the loading direction which can be through the sides or the top.

A vacuum assisted walking beam aids in erecting square cases.

The machine is equipped with an in-built and centralized lubrication system that enables smooth operation with low noise.

An HMI interface is provided to ensure accuracy and consistency of the production process.

Low maintenance attributed to the fact that all the components of the machine are easy to reach and clean.

The machine is user friendly and is very easy to learn and operate.

The machine allows for customization of pack patterns and product sizes.

A printer is in-built to aid the batch printing instructions and makes the production speed fast and easy.

Food and Beverage Industry

A wraparound case packer can be used in the food and beverage industry for packing products such as prefilled bottles with soft drinks.

The machine can also pack products such as pet foods, nutritional products and confectionery products.

In restaurants, ready meals can be packed before distribution through the use of a wraparound case packer.

Dairy Industry

In the dairy industry, the wraparound case packer machine can be used for packing products like cheese, fresh milk, yoghurt.

A wraparound case packer made from stainless steel is suitable for handling the packaging needs of a dairy company.

This is because hygiene and safety are paramount for such products and the consumers and manufacturers.

Pharmaceutical Industry

Products such as medicine in bottles, chemicals in bottles, vials, and blisters in capsules can be packed using a wraparound case packer.

Cosmetics Industry

A wraparound case packer is useful for packaging products such skin care products, hair products, make up products.

Agriculture Industry

There are various products in the agriculture industry that can be packed through the use of a wraparound case packer.

Some of these products include cereals, fertilizers, pesticides and many more.

High Speed Wraparound Case Packer

High speed wraparound case packer can also be referred to as fully automatic wraparound case packer.

high speed wrap around case packer

The machine can perform the following processes in a single run within the same compact and integrated machine;

- Wrapround case erection

- Loading of the products into the cases

- Sealing the wraparound carton cases

- Printing the already packed case.

The fully automated wraparound case packer offers the following benefits;

- Lowered material costs

- A compact footprint

- High speed of approximately 35cpm

- Servo control

- Flexibility when it comes to product types and sizes.

Intermittent Motion Wraparound Case Packer

An intermittent motion wraparound case packer is a case packing machine which is operated through a non-continuous motion.

The machine operations and processing movements have to be stopped at intervals to allow the machine to erect cases.

Intermittent motion wraparound case packer can handle a variety of products and can pack up to 28 cases in a minute.

intermittent motion wrap around case packer

Some of the features of an intermittent motion case packer include;

- The ability to work with a wide variety of products and different case sizes.

- The machine can detect fallen containers

- A toolless changeover procedure

- Interlocked guarding

- A well-maintained lubrication system

- Compact footprint

- The machine can easily be used with other equipment

- Detection of any unglued flap through a pneumatic closure.

Continuous Motion Wraparound Case Packer

Continuous motion wraparound case packer is a machine that can function to speed of up to 45 cases in a minute.

This machine minimizes material wastage because it is precise and accurate.

A continuous motion wraparound case packer works well with cans, glass jars, paper cans, glass bottles, plastic jars and bottles.

The system can collate the products, form the cases, load the cases with products and seal them with glue.

continous motion wrap around case packer

Machine is meant to handle various product and case sizes and can also be easily incorporate other equipment.

Wraparound Case Packer

Wraparound case packing machine is the technology through which a case is wrapped around products.

The wraparound case packer can handle variety of products including cans, glass bottles, pet food, coffee and confectionery.

The machine is very efficient and accurate and the changeover time is very fast.

Some features of a wraparound case packer include;

- Adopts a Compact size

- Fast and easy changeover procedures

- Can be used with all full wraparound cases or trays.

- The machine can handle various products with different packing styles.

- Can also be used for multiple layers packing

Some advantages of a wraparound case packer include;

- Product protection

- High speed and efficiency

- High accuracy and precision

- Creating a good impression

- Reduction in labour costs

Disadvantages of a wraparound case packer include;

- The hot melt glue may not be able to stand heavy weight and may give in to pressure.

- The cartons used for making the wraparound cases may not be strong enough to stand the handling processes during shipping.

- The equipment initial set up is quite expensive.

Tray Shrink Wrapping Machine

A tray shrink wrapping machine is a good solution when handling consumer goods that need added structural support.

The machine can be used for all shapes and sizes and can handle different products like cans, or multiple packs.

A tray shrink wrapper is especially good for wrapping products for transit and larger items.

A tray shrink wrapping machine adopts a belt-to-belt transfer which is being controlled by a set of motor inverters.

tray shrink wrapping machine

These machines can create a bullseye wrap around products with lengths above 4 inches.

Some of the features include;

- It has a heavy with a stainless-steel frame.

- Easy and quick changeovers

- It comes with a PLC touch screen interface

- The thready is made easy and quick due to the Low-Level, Side-Mounted Film Position

- A single unit designed with double insulated tunnel that reduces consumption of energy.

Advantages include;

- High through put due to high speed

- Reduction in labour costs

- Can accommodate extended product runs.

Disadvantages include;

- Limited range in equipment choice

- Can only use corrugate or chipboard tray types.

Flow Wrapping Machine

Flow wrapping is the horizontal motion packing procedure for processing cover products in any kind of shape using a polypropylene film.

A flow wrapping machine is the machine that makes a horizontal bag from a roll of film.

The machine uses heat at the bottom and ends of film forming a sealed and flexible package filled with products.

flow wrapping machine

This machine can be used for wrapping various products such as foods, household items, stationary and bake goods.

Features of a flow wrapper

- Temperature of the sealing units can be controlled through a PLC

- It has transparent jaw guards that have an interlock for safety purposes.

- The electrical panel is durable

- It adopts a special type of bag former.

Advantages of a flow wrapping machine;

- The machine creates a wrap that offers protection to the products

- The wrap is tight to ensure that the products inside do not move.

- It wraps with efficiency

Disadvantages of a flow wrapping machine include;

- The machine initial set up cost is high.

Wraparound Case Packer

Wraparound case packing machine is the technology through which a case is wrapped around products.

The wraparound case packer can handle variety of products including cans, glass bottles, pet food, coffee and confectionery.

The machine is very efficient and accurate and the changeover time is very fast.

wrap around case packer

Some features of a wraparound case packer include;

– Adopts a Compact size

– Fast and easy changeover procedures

– Can be used with all full wraparound cases or trays.

– The machine can handle various products with different packing styles.

– Can also be used for multiple layers packing

Some advantages of a wraparound case packer include;

– Product protection

– High speed and efficiency

– High accuracy and precision

– Creating a good impression

– Reduction in labour costs

Disadvantages of a wraparound case packer include;

– The hot melt glue may not be able to stand heavy weight and may give in to pressure.

– The cartons used for making the wraparound cases may not be strong enough to stand the handling processes during shipping.

– The equipment initial set up is quite expensive.

For all your wraparound case packing machine, contact us now.