Robotic Cartoner Manufacturer in China

JOCHAMP provides high-quality robotic cartoner and other packaging solutions at a competitive price. In order to build stable and long-term relationships with our customers, we include robust technical assistance before and after the installation.

- Fast speeds and offers the ultimate flexibility

- Easy to use with strong stability

- High-quality performance standards

- Noiseless operation

JOCHAMP Robotic Cartoner

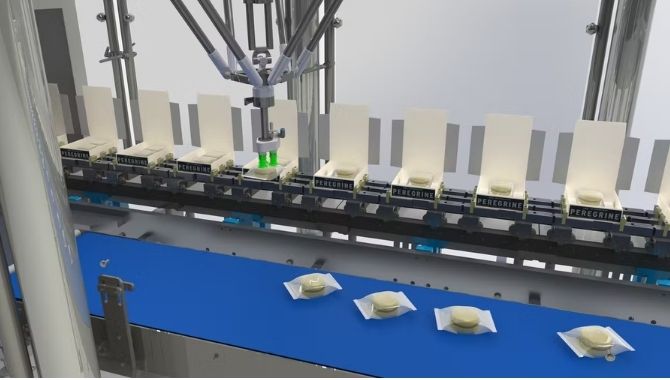

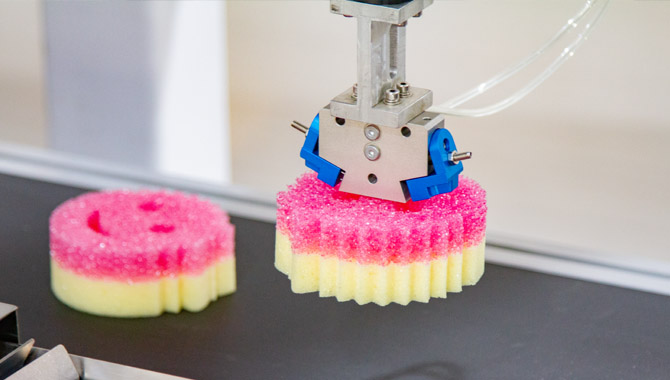

A robotic cartoner is a compact and multifunctional cartoner machine used to flow product packaging into tri-seal or carton style. It utilizes a highly innovative robot arm to pick and top-load products into multiple cartons, cases, trays, or wrappers. A best-in-class cartoning machine, making all classification of products packed securely and safely.

JOCHAMP designs and manufactures an optimized robotic cartoner that reaches the cGMP, ISO, and CE certifications. Whether you are looking for a high-modeled cartoning machine, like the robotic cartoner, JOCHAMP got you! We can assure fast replies and safe deliveries for all your requested machines.

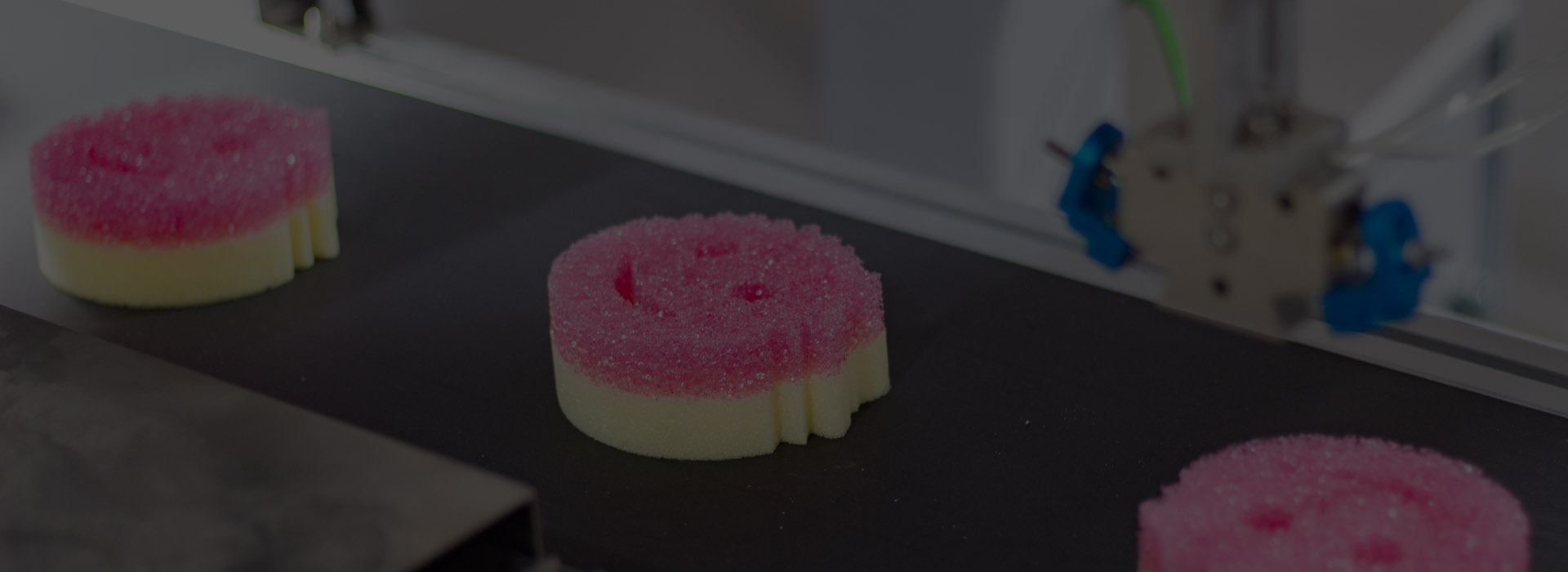

JCZ-120J Robot Cartoner

On the basis of the automatic cartoning machine, we added a set of visual inspection system, cooperated with parallel manipulators, sorted out some scattered products, and automatically fed.

- random product placement

- Single or multiple product feeding can be set

- Product orientation automatic positioning

- Integrated control system

- Seamless butt production line

- Rotary suction box way, faster speed

- Equipped with auxiliary box opening device

- The extended box compartment reduces the frequency of adding paper boxes

- PLC control system and HMI

JOCHAMP Robotic Cartoner Advantages

JOCHAMP robotic cartoner machine adopts advanced software technology and has an advanced international level. This utility model carton packer is used to pack all types of items automatically.

Adopt intelligent HMI to control and display machine running action status and with alarm function in real-time. The robotic cartoner speed is adjustable that controlled by a frequency converter.

A robotic cartoner has an automatic alarm for lack of products, effectively reducing the probability of carton packing error. Equipped with the safety protection function of accidental or faults.

Reliable, long operation time, high precision parts production quality is stable. Strong and durable, suitable for bad production environment. Good generality, flexible integration, and production.

What Can Robotic Cartoner Do?

JOCHAMP robotic cartoner can run at a high-speed rate of up to 400 per minute or 80 cycles per minute. Moreover, our robotic cartoner is capable of:

- To function in both vertical and horizontal applications.

- Provides a convenient method of packaging in an automated way.

- Gives an increased production capacity and output over manual cartoning.

- Offers versatility and high performance in any application.

- Allowing packaging business successors to achieve an easy and accelerated cartoning process.

- Ensures the quality of products with gentle loading, handling, and packaging.

At JOCHAMP, we design and build a robotic cartoner that surpasses your current production needs. Any models and specifications you want are available in our factory!

Robotic Cartoner Outstanding Innovation

The outstanding innovation of the robotic cartoner is beyond effective in performing the comprehensive cartoning and packaging of products faster. Its mechanism configuration and technical setup lead to performing that most crucial operation.

Innovating the robotic cartoner takes place as a replication of industrial needs worldwide. It enables greater flexibility, higher reliability, tracing potential, production demand, and enhanced packaging for all products.

What are the General Uses of Robotic Cartoner?

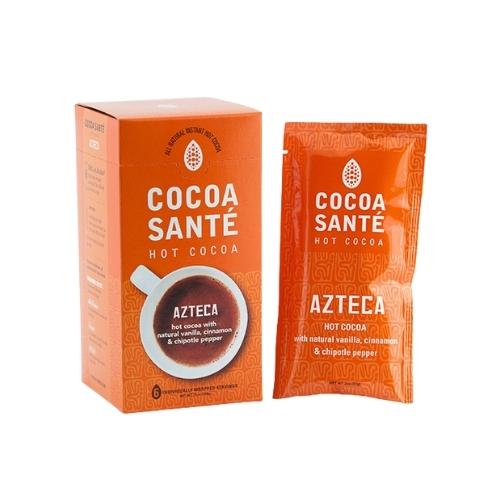

The robotic cartoner is an automated machine used in many marketing sectors and industries, such as:

- Warehousing to manufacturing

- eCommerce packaging

- Small business

- Pharmaceutical industry

- Medical devices

- Cosmetics

- Nutraceutical

- Consumer goods

Why Choose JOCHAMP Robotic Cartoner

Since its establishment, JOCHAMP has become the global leader in designing and producing robotic cartoner. Our production line is immensely expanding along with the most renowned and respected engineers with unmatched R&D capabilities and rich manufacturing experience.

Our robotic cartoner is functional in various chemical applications, daily necessities, foods, beverages, medical, automotive, spare parts, and other industries. These machines are durable and consist of automated controls that are easy to maneuver. However, using a robotic cartoner will make the entire packaging operation runs smoothly, accurately, and efficiently.

Considering the working capacity, features, and advantages of our robotic cartoner will prove that it can give versatility with its performance. We accommodate custom designs and models for robotic cartoner. Please send us your ideas and inquiries now if you have any in mind!

Prestigious packaging sectors and business successors are in favor of using our robotic cartoner due to its versatile features:

- Compact footprint

- Low entry charge

- Push-button redo

- A significant degree of flexibility

- Vision and mission guided

- Re-deployable for other opportunities

- Safely handles random product delivery

- Provides a high-end cartoning technology system

JOCHAMP manufactures robotic cartoner that provides an enhanced working competency such as:

- Highly ideal for projects that require multiple packaging to carton

- Works independently without experiencing any troubles and dysfunctionality

- It ensures that all products are accurately placed in respective cartons, durably enclosed, and sealed

- Has a synchronized control and tracking precision

- Improves the production line more efficiency

- Increases the quality of packaging

Custom Robotic Cartoner Based on Your Applications

Intelligence robotic carton machine is the core of the whole packaging line. It is a piece of machinery that can pack things into cartons in a predetermined order. That is an entirely automatic robotic carton packaging equipment in which the robot controls the bottle’s pneumatic grasping head to accomplish the horizontal and raising movements required for action packing. JOCHAMP can provide high-quality robotic cartons that suit every customer’s requirements.

The tube cartoning machine has automatic feeding, unpacking, sealing, and output systems. The structure is compact and reasonable, and the operation and adjustment are straightforward, as with other packing styles. The tube cartoning machine’s high-quality standards are one of JOCHAMP’s robust features. For modifying purchases, please contact us.

A food cartoning machine features a firm structure, high quality, low noise, and high efficiency. Carton output device, automatic carton output, collecting and piling device, and a counter can be installed to facilitate customer packaging and reduce labor input. The machine is controlled by the PLC intelligent system and can produce complex boxes. JOCHAMP has the best option regarding on food cartoning machine. Inquire now!

The pouch cartoning machine is high-speed and has strong compatibility—automatic leaflet folding, carton opening, forming, and inserting the product into a box. The device can also pack a blister board, bag, or tube into the carton box. Automatic or manual feeding, alarm if no material feeding. For any cartoning machine application, JOCHAMP provides the appropriate solution.

JOCHAMP can provide a robot cartoning machine system especially to meet customers’ requirements. From carton erector to put instruction manual in, tagging, conveying, material arrangement, packaging, weighing and rejecting, sealing, ink-jet printing, labeling, label detect rejecting, and strapping, the packaging process is fully automated. JOCHAMP can customize the packaging line. Each component can be customized to match the needs of each customer.

Related Product

Robotic Cartoner: The Ultimate FAQ Guide

Implementing robotic systems in cartoning machines improve efficiency and reliability. This guide will help you choose a perfect robotic cartoning machine for your packaging applications. Let’s dive right in.

Robotic cartoners are automatically cartoning machines that typically replace human efforts.

While they may not appear human in appearance, they perform human-like functions.

Robotic cartoners are machines that combine electrical, air-light, and mechanical setups to create various cartons for various items.

Robotic cartoner

Typically, they are computer control systems that regulate the entire operation.

Primarily used in food industries, pharmaceuticals/medical industry, auto parts industries, and many more.

Using robot cartoners has benefits like:

Reduce Labor Cost

One of the robotic cartoner is that it saves money on the workforce.

Expensive employee turnover is challenging, leading to inefficiencies, high costs, and compromised product integrity.

It also reduces staff congestion because no human is involved in the process.

Improved Speed And Efficiency

Another advantage of robotic cartoning is that it operates at high speed and efficiency compared to other machines.

The robot cartoning usually features integration and software programmed for faster motions with the least amount of injury or risk.

Reduces Employee Injury

Packing typically necessitates a lot of hard effort, and using various types of machinery can result in many injuries to staff.

However, robotic cartoning can lower many injuries because the system operates without the involvement of any staff.

Flexibility

The adaptability of a robotic cartoner allows it to handle any changes that occur during the cartoning process.

It could need changes to the end effector’s programming and software interface to allow for the execution of numerous formats.

Durability

Manufacturers do not need to be concerned about the robotic cartoner’s longevity because they are typically built of stainless steel, renowned for being durable and long-lasting.

The only thing to be done when employing a robotic cartoner is to maintain it to provide the manufacturer with extended service.

Zero downtime

Another advantage is that robotic cartoners do not require any breaks when the operation begins unless maintenance is required.

With their advanced monitoring system, maintenance can be planned ahead of time to avoid any faults.

It can be determined whether attention is required throughout the robot cartoning process.

As a result, the producer will not waste time cartoning due to breakdowns or productivity delays.

Some of the uses of the robotic cartoners are:

- You can also utilize the robotic cartoner to side seam the carton joints with various items.

- They also used to seal the cartons before transporting and storing them.

- When necessary, they are also utilized to print labels on boxes.

- Typically, the robotic cartoner will place a product or package into the boxes.

- Robotic cartoners also input material and goods into the system, categorize them, and convey and mechanically fold the carton leaflets.

- They’re also used to form cartons from blanks to stand straight for straightforward product packaging.

- The robotic cartoner is used to construct the cartons facing upwards and close the bottom half of the carton.

- They also place a product in the cartons or package the products in the appropriate cartons.

- Another function of the robotic cartoner is to fold the upper sleeves of the cartons appropriately.

Horizontal Cartoner With Robotic Loader

Products are generally put into the cartons from the side with a horizontal cartoner with a robotic loader.

This robotic cartoning equipment may work in both intermittent and continuous modes. They’re primarily used in the food and pharmaceutical industries.

horizontal cartoner with robotic loader

Advantages

- It is simple to use.

- It saves a lot of time due to its fast manufacturing speed.

- Compared to other robotic cartoning machines, it is one of the safest.

- Typically provides a powerful platform for other processes, making it simple to maintain and clean.

- It is inexpensive to manufacturers.

Robotic Vertical Cartoning System

The product and cartons from the system feeding vertical are usually introduced into the robotic vertical cartoning system.

It can usually handle a wide range of products and is great for bottles and jars. Cosmetics, pharmaceuticals, and food industries are the best candidates.

Advantages

- It usually enables simple and reliable formatting adjustments.

- It’s a versatile system that can use both intermittent and vertical cartoning methods.

- It’s simple to customize by adding any new equipment.

- Because it includes an accessible workstation, you can utilize it for additional cartoning tasks.

- Because of its open construction, it is simple to clean.

- It only necessitates a small amount of area.

Side Load Robotic Cartoner

The load on the side of the cartons is usually loaded through the flap openers into the end on top of the carton by a robotic cartoner.

A rapid and efficient robotic cartoner usually ensures a trouble-free operation. Cosmetics, medicines, and the food industry are just a few applications.

side load cartoning machine

Advantages

- It is quicker, resulting in cost savings.

- It’s adaptable

- Helps to avoid a lot of waste

- Can be used for high-volume cartoning

- It is exact and accurate.

You may be interested in side load case packer.

Top Load Robotic Cartoning Machine

A top-loader robotic cartoning machine is multifunction equipment that can load products from the top and move them to an end cartoner’s moving infeed.

It’s adaptable and ideal for high-volume packaging. This machine is usually easy to maintain.

Advantages

- It’s simple to use.

- It has a cheap cost of upkeep.

- The machine is adaptable to different carton sizes.

- It’s quick, with repeatable size changes.

You may also like top load case packer.

Intermittent Motion Robotic Cartoner Machine

It’s almost the same for intermittent robotic machine cartoning as continuous motion robotic machine cartoning.

The only difference is usually the speed, approximately 150 times slower.

The speed slowdown is usually caused by the machine stopping and allowing time for the cartoning cycle to complete.

It’s also suited for various applications, depending on the manufacturer’s needs.

intermittent motion cartoner machine

Advantages

- Allows for the cartoning cycle to occur

- It’s also effective.

- Saves manufacturers money on production costs

- The machine is well-known for its precision.

- It’s simple to alter.

Continuous Motion Robotic Cartoner Machine.

It is best known as high-speed robotic cartoning equipment that may be utilized in a high-speed production line.

It is primarily used for regular-shaped cartons that require little or no additional handling.

Typically, it includes a pneumatic photo electro-mechanics mechanism that helps with all of the machine’s speed functions.

continous motion catoner machine

Advantages

- It is frequently operated at high speed.

- It is well-known for being extremely accurate, resulting in increased cartoning efficiency.

- Lowers the cost of manufacture

- Because of its rapid speed, it saves time.

Below are some of the parts of the robotics cartoner machine

Electric Motors And Panels

It is the power supply for the overall robotic cartoner machine operation system in this portion. Because all mechanical and electrical circuits are configured here, it’s also known as the machine’s heart.

Control Panel

It is a component that allows the robotic cartoner machine’s overall process to be configured and designed for a specific control module.

Also, it is recognized to perform functions such as product numbering according to pack control, print control, fluid and electrical indications, and carton numbering according to control.

Lubrication System

The lubrication consistency of the machine will usually influence the bearing, gear, and belt lifespan. It is where all of the lubrication is done to guarantee that the activities operate smoothly and that no breakdowns occur during the process.

Sensor

It is a component in the robotic cartoning machine that detects any errors or when the machine has to be shut down for maintenance.

It usually sounds an alarm at the exact location where there is a problem.

Guide Rail, Carton Chute, Rollers, And Conveyor

The conveyor is generally interconnected with rollers to promote the transportation of cartons from one area to another.

They usually get their motions from a running engine with a gearbox to set the speed and are directed by the rail defining the runway.

Depending on the machine design, a chute concept will be used to dump the products from cartoning into larger boxes for storage.

An Ink Jet Printer

The robotic cartoning machine is always equipped with an inkjet printer with at least three rows of writing options.

This section lists the manufacturing dates, product precautions, and expiration dates.

Pneumatic System Is A Cartoning Pack Tooling.

The robotic cartoning machine is in charge of the actual cartoning in this part.

The vacuum suction controlled by the pneumatic system always comes into play on the drawing blank to start the process.

A portion where cartons are placed is known as the carton pack tooling. It usually consists of a front and back segment with a front plate in the middle.

The middle of the plate is always moveable and can be changed to the length of the carton.

The robotic cartoning machine works with the following process;

Under The Box Action

It’s usually the initial step at this point when a sucker on the carton feeds mouth the stick carton downwards along the carton line.

Meanwhile the plate pushed to build the rail guide clamping box.

From the upwards base, two screens go ahead. It usually ensures that the carton is delivered at the correct angle to the loading zone.

Loading Zone

It is the filling machine’s stage; typically, the product is inserted reasonably simply using a feeding screw to drive the carton manufacture. It usually only takes a few moments.

Folding Mechanism

It’s the following phase after the loading zone; typically, there’s a plate push that flips up, a lower end flap that closes, and then the upper ears are closed.

The rotational motion folds and presses the cartoning ears as lining along the rail fully. Mechanical rotary motion and chain operation will be meticulous, leaving no stone untouched.

Cover Actions

The final stage will define the robotic cartoning machine process’s integrity. The carton will be folded into a tongue and then forced to bend using plate pressing.

This procedure will entail a succession of components and pieces that will work together to maintain consistency and precision.

Production Capacity of the Robotic Cartoner Machine

One of the features to consider is the robotic cartoning machine’s capacity, which will influence the robotic cartoning machine’s pricing.

It’s crucial to know how many output units the machines can handle per hour.

Robotic cartoner machines are available in a variety of designs and capacities.

If you require a robotic machine with an extensive product line, it will be more expensive than one with a modest production line capacity.

Product Type

It has always been a critical feature, and robotic cartoner machines are commonly utilized in various industries for varied products.

As a manufacturer, you must consider these features with the production line you require.

It will aid in determining the machine’s design and the carton sizes that will be employed throughout production.

Durability

Another vital element for a manufacturer is longevity. No manufacturer in the production business needs a machine that isn’t long-lasting.

Robotic cartoner machines must have a long service life and low maintenance costs. Stainless steel robotic cartoner machines are often the best recommendations.

Additional Equipment And Accessories

As a manufacturer, you should usually think about robotic cartoning machine features that allow you to readily integrate any equipment or accessories, such as robotic gadgets.

This trait is commonly found in robotic cartoners that are both flexible and rigid. Its functionality allows you to upgrade in the future if necessary.

Safety Of The Robotic Cartoning Machine

Another critical characteristic of robotic cartoning machines is their safety, ensuring optimal and precise manufacturing.

This device will detect any machine flaws and protect the technician from damages or injuries during the operation.

The robotic cartoning machine will be chosen depending with:

- As a manufacturer, you must select an automatic robotic cartoning machine based on the product size you wish for the carton.

- You must also select an automatic robotic cartoner machine based on the number of products you plan to package.

There are machines here that manufacture huge volume products and equipment that produce small volume products.

- You must also select a robotic cartoner machine based on the size of cartons to be used during the manufacturing process.

- Another factor to consider is the autonomous robotic machine’s speed.

- As a manufacturer, you should select automatic robotic cartoning equipment based on the area available for installation.

For all your robotic cartoning machines, contact us now.