Doypack Packaging Machine Supplier in China

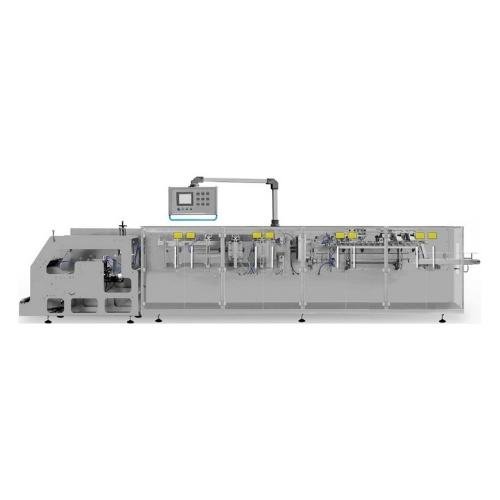

JOCHAMP is a leading manufacturer of doypack packaging machines in China. It is designed for packaging standup pouches. These come with different configurations to meet various demands of bag sizes and shapes.

- Fill products such as granule, liquid, powder

- Certified machines by cGMP, CE, SGS, and ISO

- High speed and corrosion resistant

- Easy maintenance

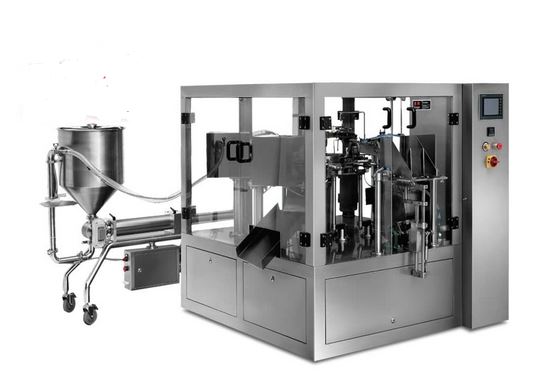

JOCHAMP Doypack Packaging Machine

Doypack packaging machine is a highly automated system for pouch developing, filling, and sealing using a multitude of heat-sealable multi-layer complex films. These machines are designed for packaging standup pouches. Customers who have our filling or dosing system can fill a variety of products such as powder, liquid, or granule.

Jochamp offers doypack packaging machines characterized in a compact design and simple operation. We produce a wide variety of packaging machines to support most packaging companies and supply the most innovative solutions.

Please send us your inquiries!

Types of Doypack Packaging Machines

Doypack Packaging Machine Features

Consistent, non-stop movement for delicate positions. Every pick provides gentle handling.

Flexible machine structure, ideal for synchronously handling a broad array of products.

It adopts a quick changeover and user-friendly interaction for packing processes.

You can save labor costs using our doypack packaging machine since. Human labor is not required.

Doypack Packaging Machine Construction

If you need Doypack bags for the packaging of your high-quality products, the doypack packaging machine is your obvious choice! These are purpose-built by Jochamp engineers to obtain the best value/performance ratio for forming, filling, and sealing doypack pouches. It ensures seamlessly sealed doypack bags in the industry!

Jochamp doypack packaging machine is made of sturdy materials. Construct of rigid stainless steel construction, high-quality materials, and branded components from well-known global manufacturers ensure the machine’s long lifespan.

International Certification

Jochamp received international certifications such as SGS, ISO, CE, ROHS, TUV, and QS. We strictly adhere to global standards, regulations, and customer requirements during the manufacturing process, focusing on quality products, service first, and client first.

Feel free to contact us for further information; we would be happy to discuss your needs and find the best packing solutions for your company. We are eager to work with clients from across the world and cordially invite interested companies to visit our facility.

Good Machines. Better Profits

To ensure trouble-free machine operation, Jochamp provides comprehensive factory services both before and after the sale. On the other hand, our professional team is also experts in maintenance work and global warranty services.

We make sure to improve the performance and cost-effectiveness of all our machines. Adding value to our customers is our constant goal!

Why Choose JOCHAMP for your Doypack Packaging Machine

JOCHAMP is a trusted provider of doypack packaging machines made especially for today’s codes and standards. It performs well in a variety of products depending on the output required.

The doypack packaging machines we offer have a compact size and work quickly. These machines require minimal maintenance and are simple to operate. As a reputable pouch case packer supplier in China, we ensure that all of our machines have met international quality standards such as cGMP, ISO9001, SGS, CE, and others. We strictly enforce quality checks in all aspects of our machines, from raw resources to test results, assembly, and shipments.

If you require dependable packaging machines for your company, please do not hesitate to contact us.

- Adopts PLC and Touch Screen control system is simple to use.

- Stainless steel housing, product contact parts, and bags meet GMP needs, ensuring sanitation and food safety.

- Features Japanese Dry Type vacuum pump with a credible, reduced noise, and easy to maintain vacuum filtration for pouch pick up and opening.

- Changeover is simple for varying pouch lengths. The gripper width can be adjusted automatically via the touch screen panel.

- Packaging materials like aluminum foil, laminating film, and paper laminating film.

- The doypack packaging machine is suitable for a variety of applications and can accommodate any form of a pre-made pouch. It is appropriate for a variety of product widths and bag dimensions.

- It is ideal for a variety of applications including coffee, frozen meals, cookies, cereals, nuts, flowers, candy, and so on.

- To be used in areas with sufficient space, such as factories and warehouses.

Custom Doypack Packaging Machine for Your Product Applications

Jochamp specializes in the production of doypack packing machines for liquid products such as juice, liquid softener, various beverages, ketchup, jam, cocktail, and so on. These machines have distinct and sophisticated features that set them apart from the competition.

Jochamp is your prime source of doypack packaging machines for powders like washing powder, sugar, coffee powder, spice, seasoning, milk powder, tea powder, and more. We will help you with all of your packaging machine needs.

We can custom design doypack packing machines for granules like capsules, grains, nuts, brazil nuts, and so on. It is a fast, automatic process with simple access and control. This machine is strong, high-performance, and made of high-quality stainless steel.

Related Product

Doypack Packaging Machine: The Ultimate Guide

Without the right information, choosing highly efficient Doypack packaging machine can be an overwhelming task. A reason this guide explores all fundamental aspects about Doypack machines such as design, features, parts, working principle, and filling techniques, amongst others.

It provides several benefits across different industries, but its remarkable advantages include the following;

doypack packaging machine

Improves Accuracy

Most functional parameters of this equipment are automated, thus ensures it performs as expected.

As such, it assures precision during product packaging, which is critical in quality control and accountability.

Increases Production Volume

Since the parameters are automated, it implies the machine can easily package numerous products into doypacks within shortest time possible.

Of course, this is beneficial in a typical manufacturing industry where production speed and product delivery are great concerns.

Offers High Reliability

Generally, the design construction of this equipment is quite robust and barely encounters intermittent delays due to mechanical breakdown.

Hence, the high reliability it guarantees is essential, particularly in a large-scale production setting.

Enhances Cost-Efficiency

Ordinarily, this equipment is automated, eliminating the need for human labor since most functions are programmed.

Additionally, it is energy efficient, which means you will always save on utility bills in the long run.

Easy Maintenance

A typical doypack packer is relatively simple, and this makes it easy to maintain it appropriately.

Moreover, its design construction makes it quite reliable and rarely breaks down; thus does not necessarily need intensive maintenance.

Enhances Safety

This equipment comes with a wide range of safety features, and this is imperative because it safeguards the operator from potential dangers.

Also, it provides peace of mind, which is critical in determining productivity.

Eliminates Wastage

The programming aspects of this machine allow it to fill and seal the specific required quantity to respective doypacks.

Hence, it prevents unnecessary wastage, which in the long run, increases productivity.

It is used in a wide range of industries across several sectors in commercial and industrial applications.

But the notable industries that use this equipment include the following;

Food And Beverage Industry

This equipment is used for packing different food and beverage products into respective packages.

Ideally, it provides safety, longer shelf-life, and reliability, which are all critical in obtaining desired packaging solutions.

Medical And Pharmaceutical Industry

Doypack packer comes in handy in packing different medicinal and pharmaceutical products since it is quite versatile.

Such products include capsules and syrups as well as tablets.

FMCG Industry

In Fast Moving Consumer Goods industry, this equipment is relatively dominant because it is helpful in packaging various products into respective bags.

This industry benefits from this packing machine significantly since it offers speedy packaging, which is a considerable concern in ensuring goods get to customers timely.

Personal Care And Hygiene Products

Companies producing different cosmetics and personal care products also use this equipment considerably.

For instance, toothpaste, body lotions, and a wide range of personal care items are packed into respective bags using this machine.

Chemical Manufacturing Industry

Doypack packer also comes in handy in packaging different chemical products, both liquid, solid and powdered.

This equipment is quite versatile; thus, you can use it to pack a wide range of products in liquid, powder, solid, and pellets form.

But the notable ones include the following;

- Meat

- Yoghurt

- Sauces

- Soup

- Rice

- Detergents

- Juice

- Fruit puree

- Baby food

- Pet food

- Breakfast cereals

- Energy bars

- Automotive parts

- Paint

- Body lotion

- Powdered drugs

- Syrup

Most features of doypack machine tend to vary from one model to another.

However, the general critical features you need to consider when shopping for this machine include the following;

- Operation – It should be simple and convenient by adopting an advanced touch screen PLC and POD, human-machine interface, and electric control system.

- Repeatable, speedy, and easy changeovers

- Various metering and infeed mechanisms provide efficient product handling

- Tape or hot glue sealing ability

- Sturdy powder-coated steel framing component

- Synchronized handling of various items

- Faster doypack packing speeds

- Efficient doypack collation system

- Stable performance and durable usage

- Convenient maintenance

- Simple operation

- Easy to integrate into a production line

- Auto-adjustable bag width and rapid change of bag specification

- Single shaft and CAM design

- Advanced design idea to reduce wastage and ensure machine’s stability

- Precise qualitative filling

- Photoelectric sensors revision device

- Automatically adjustable filling quantity

- Wide packaging range for liquid, solid, powder, paste, and granule products

A standard doypack packing machine comes with a wide range of parts and components integrated to perform different roles but offers a single functional unit.

Some crucial parts of this machine that you need to know to include the following;

Bottom Frame – It is the framing component supporting all other parts of this machine and ensuring strength.

Pouch Loader – This component is designed to lay continuous pouches in desired quantity into prepared containers.

Machine Turntable – It is a rotary table designed to clamp the doypack and ensure its indexing positioning.

Dust-Proof Cover – The essence of this part is to protect and save this piece of equipment from dampness, dust, and dropping of any kind.

Pneumatic Control Panel – It is the component that offers the means to actuate valves commonly used in controlling air flow in the machine’s pneumatic system.

Hopper – Also known as a material pump, it is designed for feeding materials into the machine for subsequent packaging processes.

Filling Device Group – It consists of nozzles discharging the products from the equipment into the packaging bags.

Cleaning Device Group – They ensure the packaging is cleaned by removing any spilled or superfluous material from the surface.

Vibrating Tray – It shakes the packaged material to ensure it conveys it to the packaging and sealing stage within the machine.

Plc Touchscreen – It is used for displaying and monitoring numerous machine variables and parameters for easier control during packaging process.

Control Buttons – They are used for triggering or activating, neutralizing, and disengaging the machine’s operating parameters.

Drive System – It is a combination of motor and power systems that ensures the equipment is powered and moves efficiently.

Printer – It prints various information and details on the surface of packaging material at high speed and accuracy.

The design of this packaging machine allows it to utilize different filling mechanisms, which mainly include the following;

Volumetric Filling

It is a type of filling mechanism that enables the equipment to fill doypack bags with a uniform product quantity through a time-based filling principle.

In essence, it implies that volumetric fillers guarantee accurate and consistent product filling irrespective of discrepancies in the containers’ interior volumes.

Auger Filling Mechanism

This mechanism fills the exact product volume in the doypack as desired.

Ordinarily, it is regulated by corresponding pulses from the machine’s auger shaft driven by the servo motor unit.

The filler dispenses a set product volume into the package.

Net Weight Filling

In this doypack packaging mechanism, gravity, vacuum, or pressure play integral roles in determining the efficiency of product filling.

Essentially, the desired product fill level is determined by the equipment to enable filling of doypack packages accordingly.

Pump Dosing

It entails using a pump that draws a predetermined amount of liquid into its chamber and injects the product in the process.

The pump used in this process is driven by an electric motor installed in the machine with a regulator that switches pump on and off to control flow.

The notable sealing mechanisms used in this packaging equipment include the following;

Capping

This mechanism mainly uses chuck cappers that place a cap on doypack container by sending it through the machine to enable the moving parts to spin the cap and seal it tightly.

In this sealing mechanism, the container maintains a continuous motion rather than stopping at a spin station.

Heat Seal

It entails sealing the doypack container using heat and pressure.

This method offers direct material contact that utilizes a constantly heated die or sealing bar to apply heat to a particular path to weld the material.

Ultrasonic Sealing

This sealing technology utilizes acoustic vibrations to produce heat at a molecular level inside the film itself.

Ordinarily, these vibrations formed with sonotrode and an anvil trigger the molecules in the packaging material to start moving.

Primarily, it is the dynamic shear stress created by the ultrasonic vibrations that deform and generate heat due to friction between contact parts.

Here’s the step-by-step process of doypack packaging machine’s working principle;

1) Bag Loading

Preformed doypacks are loaded into the magazine often manually by the operator.

A roller then feeds the bags into the equipment automatically for further processing.

2) Bag Gripping

The proximity sensor detects a bag’s presence at the end of magazine.

An arm grasps the bags using vacuum suction and loads them into the rotary “belly” of the equipment, then the fan sets in.

3) Optional Printing

If the bag needs lot codes, dates, or any other vital information, a printer is set to add the details to each bag as they pass.

4) Zipper Opening And Detection

The vacuum suction pads in this station gently grasp and pull the bottom portion of the bag to open.

An arm grasps top section of the bag and opens it fully.

This station also contains a sensor that detects whether the bag is loaded correctly or at all.

Should it fail to detect a bag, the filling and sealing steps hardly engage for the specific bag.

5) Optional Gas Flush

Most various product manufacturers are concerned with maintaining efficacy, product texture, and extended shelf-life.

Thus, oxygen, in most instances, tend to be the main culprit likely to affect all these elements negatively.

Hence, gas flush station pumps harmless nitrogen gas into the bag to displace ambient oxygen.

The bag is then sealed to suppress the low oxygen level further and create an ideal atmosphere suitable for perishable products.

6) Bag Sealing

The filled bag moves to a sealing station, which has two hot seal bars that come together over top of the bag.

Such seal bars bond and pack the material together and create a sturdy seal.

7) Bag Discharge

The station then conveys finished bags out of the equipment for further processing.

They are available in different varieties, but the main ones include the following;

VFFS Doypack Packaging Machine

The design of this doypack packer is to pack products inside the bags and seal them in a vertical orientation.

In this case, the bag is oriented such that the top is directly above the top.

VFFS Doypack packaging machine

It is best suited for packing liquid, powder, semi-liquid, and paste products.

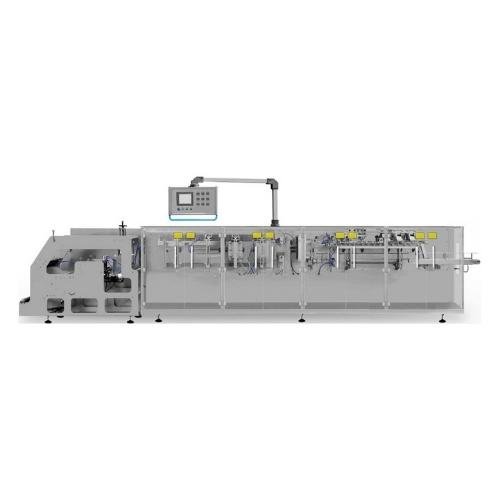

HFFS Doypack Packaging Machine

It is designed to pack products inside the bags and seal them in a horizontal orientation.

The bag, during packing and sealing in this machine, is oriented such that it is parallel to the table.

HFFS Doypack packaging machine

It is suitable for packing solid and semi-solid products.

Mini Doypack Packaging Machine

As the name indicates, this component is relatively compact but designed for a wide range of packaging bags.

It offers a maximum speed of 30 bags per minute depending on type of product and filling weight.

mini doypack packaging machine

This equipment is also quite versatile, and it has a packing system that can handle different products.

Semi-Automatic Doypack Packaging Machine

Most functional parameters of this doypack packaging machine variant are activated and neutralized either manually or automatically.

semi automatic doypack packaging machine

In essence, it means some functions are programmed, whereas others require an operator’s input, albeit a few.

It is moderately faster and relatively affordable than a fully automatic doypack packer.

Automatic Doypack Packaging Machine

All the functional parameters in this type of doypack packing equipment is fully automated.

Simply put, there is limited or no human involvement as far as operation of this machine variant is concerned.

The variables are programmed to deliver predetermined packaging solutions within a specific timeframe.

Automatic doypack packaging machine

It is comparatively fast, efficient, accurate, and highly reliable.

Rotary Doypack Packaging Machine

A multi head weigher dosing mechanism refers to a system offering an accurate, reliable, and speedy weighing machine used in packaging process.

Thus, this machine becomes a suitable option, specifically when packing different granulated items in solid state.

Moreover, you can also consider integrating this mechanism in doypack packing equipment when packing items with irregular shapes into containers.

Multi head weigher dosing system is most suitable for products where the weight of a single piece range from at least 5-6 grams.

This makes it ideal for packaging items such as dry foods, pasta, frozen products, and crackers among others.

At times, doypack filling and sealing equipment tend to portray some malfunction or merely throw a specific error code during or after operation.

Of course, such cases usually arise from the environment, bag, product loading, and other aspects of the machine.

Nevertheless, here are the common troubleshooting techniques you may consider when such issues arise in the machine;

Failure Of Bags To Feed In The Machine

This issue implies that the bags are not feeding appropriately into the machine due to dirty sensors, broken air valves, or vacuum pad breakdown.

Solving this error calls for properly cleaning the proximity sensor and replacing or repairing the broken air valve and vacuum pad.

Bags Failing To Open

This error implies the equipment can never open the bags, or it opens the bags inconsistently for product filling.

Some possible causes of this issue include a worn-out filter, incorrect timing, incorrectly loaded bag, sagging bag, or vacuum pad breakdown.

Troubleshooting this error calls for correct timing, feeding the bags correctly, changing the filter, and replacing or repairing vacuum pad.

Flawed Bag Seals

This error indicates that package seals are uneven, weak, or wrinkled.

Often, it arises from different factors such as scratched or dirty sealing bar surface, incorrect sealing bar pressure, and too high sealing bar temperature.

It may also arise from failure or incorrect centering of the bag.

Some steps to solve the issue include sealing the bar surface, regulating sealing bar pressure, regulating sealing bar temperature, leveling the grippers, and centering the bag.

Different maintenance processes to carry out on doypack packing machines include the following;

Preventive Maintenance

This is primarily routine maintenance tasks conducted frequently to avert machine failures.

It includes routine inspections, changing parts before failing, reporting equipment concerns, etc.

The essence of preventive maintenance is to establish and address minor issues before turning them into major issues.

Breakdown Maintenance

It is only conducted when there is a major break down on the equipment or if it experiences downtime.

However, this is often rare on this machine since it has a simple design structure making it easy to prevent a major unit break down.

Corrective Maintenance

It is a type of maintenance that involves repairing systems with improper functionality.

Mostly, it is common in semi-automatic and fully automatic units, which require occasional software and system upgrades to enhance efficiency, accuracy, and reliability.

For all your Doypack packaging machines, contact us now.