A packaging machine is widely used in many industries, and there are many Packaging Machine Types. Most people find it hard to tell them apart. A packing machine wraps products to protect them.

These machines can form, fill, seal, wrap, clean, and pack stuff. They also help sort, count, and gather things. Industries like automotive, Chemical, Cosmetics, Food, Garments, Household and even medical use Packaging Machines.

This article will discuss the 18 Best Packaging Machine Types for your Business Growth.

How Packaging Machine Works?

You can seal the bags in different styles like a back seal, 3-side seal, 4-side seal, and even pyramid seal.

Businesses use them for tasks like filling bottles, packing goods in cardboard boxes, and filling and wrapping FF for shipping.

Types Of Packing Machines

Lots of different types of packaging machines exist. Suppliers who offer integration services can help customers blend new equipment into existing production lines or assist in setting up equipment and training employees. Common types of packaging machines include:

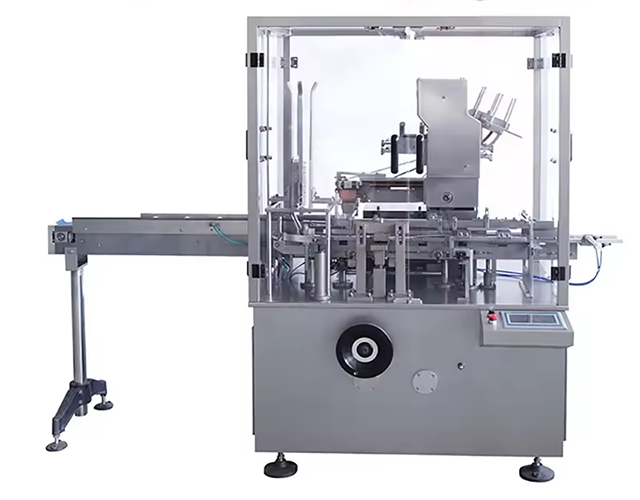

1. Carton Box Packing Machine

This Machine is all you need to automate processes like forming, filling, and sealing cartons or boxes. Industries like food, medicine, cosmetics, and consumer goods prefer this Machine.

Carton Packaging Machines have many benefits. For instance, they increase efficiency, reduce labour costs, continuously pack products, and use high-speed packing that doesn’t damage your products. Moreover, they can make your products look good and more presentable for customers.

2. Cartoning Machine

It can fold, side seam, and seal the contents of a carton. However, depending on its purpose, it can be put together, closed, or folded, and a carton can be side-sewn.

Cartoning machines work best with liquid or semi-liquid materials like milk, juices, etc. They work effectively by producing excellent result-ready product Showcasing. They have a wide range of styles and different sizes depending on what your products need, such as food products, cosmetic product packaging, or any other packaging.

Moreover, It also creates a corner flap for extra security. It’s great for packaging and shipping products of any size. This Machine is crucial in any warehouse or retail operation.

3. Case Packer

Case packers are essential in packaging, especially in automating production lines. They keep products safe during global shipping and long journeys. These case packers are usually made for top efficiency, performance, and flexibility.

This small and all-in-one case packer is made for low to mid-level case packing, prioritizing quality and saving space. It erects the case securely, ensuring complete control of the empty carton throughout the packing process.

4. Case Sealer

A case sealer is a machine used in industrial packaging to seal cartons before shipping. After filling, the case sealer closes the top flaps and tapes the box.

Usually, low-cost case sealers have this problem of strange vibration in sealers. To avoid shaking in Case Sealer, you should understand the tape applicator. They achieve a 99% sealing success rate, cutting down on product damage and shipping costs.

- Semi-automatic: It needs a person to close the flaps before sealing.

- Fully automatic: Closes and seals the flaps without human help

5. Case Erector

Case Ectors automatically make, fold, and seal corrugated cartons from flat boxes. These machines come in semi-automatic and automatic versions and can make between 6 and 20 cases per minute. They are suitable for packing products like cardboard and plastic and can easily be used for different dimensions of materials.

They’re straightforward compared to other packaging gear, featuring automated LxWxD path generation, opposing-cup case opening, and robotic pick and pass for smooth operation.

6. Form Fill Seal Machine

Form Fill and Seal machines, also called FFS, are automatic packaging machines. Fills it with a product and seals it. It begins with a big roll of film shaped into a bag. The Machine fills the bag with your product and seals it horizontally or vertically. Equipment like this stops human errors, ensures consistent quality, reduces labour costs, and makes your process more efficient.

The FFS machine feeds the film roll to the forming section, seals the back side and bottom of the formed film, fills the contents, seals the top of the film, and cuts it. It creates the final product, a pillow bag.

They’re very efficient, cutting down on labour costs and boosting production rates by up to 500 bags per minute. That’s why they are a top choice for many industries.

7. Vertical Form Fill Seal Machine

A Vertical Form Fill Seal Machine (VFFS) is a popular bagging machine used in production lines to pack goods into bags. These machines are remarkable for the reason that they can perfectly pack products like nuts, granules, chips, or powder-like things.

Vertical Form Fill Seal machines can run at very high speeds. Venia’s OHLSON Brand offers system speeds of up to 200 bags per minute on a duplex line. Vertical Form Fill Seal machines achieve speeds of up to 180 bags per minute. At the same time, we provide highly efficient packaging solutions for a wide range of industry products.

8. Horizontal Form Fill Seal Machine

A benefit of HFFS is that it lowers the total cost of ownership and lets manufacturers make pouches in different sizes and shapes more easily. Horizontal Form Fill Seal (HFFS) machines can churn out up to 120 pouches per minute and a remarkable product-filling capacity of up to 1,200 cc.

The film, or laminate, moves through the machine sideways, which is why it’s called “horizontal.” They are so good because of their fast speed, adaptability according to your needs, and ability to work without making a mess. The wrong side of this machine is that it mightn’t work well for non-regular tasks like different shapes or won’t stand straight.

9. Stick Pack Machine

This type of machinery has several main parts. It has a system that unwinds the film and feeds it into the Machine. The Machine shapes the film into stick-type tubes and fills each pouch with the right amount of product. Then, it seals each tube to keep the contents safe.

Stick pack machines churn out a staggering 100,000 stick packs per hour. Additionally, stick-pack machines save money and time by automating packing. The slim design of the product also makes it easy to transport and handle during shipping.

10. Automatic Wrapping Machine

Compared to hand-wrapping, semi-automatic and automatic stretch-wrapping machines save your business money on expensive film. Automatic stretch wrapping machines have two rollers for the film.

The average Automatic Wrapping Machine wraps an impressive 15 pieces per minute. However, This makes the film stronger and cuts costs. Rotary tower automatic stretch wrapping machines are even better at saving time and money.

11. Flow Wrapping Machine

A horizontal flow wrapper is a machine that packages products into their designated packages. Additionally, horizontal-flow wrappers are automatic, so they pack quickly.

It continuously wraps the products with plastic film by using heat sealing, filling the air inside the package. It is mainly used to pack snack food, candles, or baked goods like cake or biscuits at high speed, which saves money. The drawback of the flow wrapping machine is that it is not suitable for products that need solid or more safe packaging.

12. Pouch Packing Machine

A pouch packing machine is automated packaging equipment filling and sealing products in flexible pouches or bags. This Machine fills the pouches depending on your product’s pre-formed pouches. It uses either an auger filling machine or a liquid filling machine.

Pouch packing machines usually have form fill seal (FFS) packaging machines, churning 120 pouches per minute, speeding up a product filling capacity of up to 1,200 cc.

It’s used in many industries like food, pharmaceuticals, cosmetics, etc. These machines handle many products, like powders, granules, liquids, pastes, and solids. Additionally, it has weighing and counting technology for a non-stop working experience.

13. Shrink Wrapping Machine

A Shrink Wrap Machine, also called a shrink wrapper, shrinks material to wrap it. It’s used in many industries, mainly food and beverages. Now, even pharmaceutical companies use these machines a lot. Shrinkwrapping is done with a strong shrink film that looks thin but has multiple layers.

Moreover, it makes packaging compact and catchy, so it stands out on the shelf. The Machine wraps an item in a sleeve or loose shrink film and uses heat to shrink it tightly. Shrink packing machines are helpful for wrapping a lot of items at once.

FshF

FshF

14. Overwrapping Machine

Overwrapping machines wrap products with flexible packaging material to improve their appearance and protect them from theft and dust. There are two types of overwrapping machines: machines for paper products, one for wrapping catalogues and one for copying papers with Kraft paper.

On the other hand, it is used to package household papers like tissues, toilet rolls, and kitchen papers with film. The Kraft paper packaging machine can wrap products like saddle-stitched catalogues, thick non-line stitch catalogues or textbooks and cut paper products like copy papers or leaflets.

15. Blister Packing Machine

A blister packaging machine makes blister packets for different items. It’s fast and fully automatic. It can make up to 70 blister packs per minute, whether oblong or round. The Machine has several features, like servo web indexing, auto feeding, and strong PLC logic. It also has an inspection system to avoid manual work.

Blister pack machines generate a staggering 200 blisters per minute, Which increases packaging efficiency and slashes labour costs.

Blister Machine can pack Cases, Tables and Suppositories from table press and filling. Moreover, it is used to seal tables, ampoules, capsules, and syringes to protect them from damage or changes. Also, with this Machine, you can print information to help patients read instructions.

16. Blister Card Packaging Machine

Even though it sounds the same, it has a slightly different feature. This Machine looks like a regular blister Machine, but they can create small packs for your products. However, it makes a difference when, after making packs, they attach them with sturdy cardboard backing.

This kind of packaging makes the products safe and easy to carry. Also, it gives you a space for your branding and product instruction.

17. 4 Side Seal Packaging Machine

A 4 side seal packing machine is a wise investment for businesses aiming to enhance their sterilization process. Likewise, they are familiar and used in various industries like food, pharmaceuticals, and medicine.

They can seal up to 120 pouches per minute with a product-filling capacity of up to 1,200 ccs.

When paper is placed on one side and plastic on the other, it forms an airtight seal. It also keeps sterilized items in perfect condition. Thus, this packaging is eco-friendly, which is excellent for businesses because it can help them reduce their carbon footprint.

18. Packaging Production Line

A packaging line is a production line used when the products are ready to pack. You can put all the products in a line on this Machine, and then it fills your products. It has brilliant technology integrated into it, which knows what to do. So, it tracks the product, the labels on it perfectly, etc., packs it, and sends it to the next corner.

Sometimes, space can become a bigger problem for your business when using packaging lines. So, for that reason, most marking machines can only fit on the next mainline instead of staying on the same line itself. Despite other packaging machine types like cartons, case erectors, and palletizers, packaging lines use coding and marking devices.

Conclusion

Ultimately, various affordable and easy-to-carry Packaging Machine Types exist for New Business Brands. You can easily change and upgrade them as per your Business Growth. However, Major Companies can use advanced Tech Machines for their Packaging Systems because they can handle Big Projects quickly without much headache.

Machines help you protect the product’s quality. Moreover, they can work smoothly and reduce labour costs. However, with many machines in the market, you must understand what you need.