In this guide, you will find all information you are looking for about ampoule packaging machines.

Whether you want to learn about features, working principle, troubleshooting process or application – you will find everything you are looking for right here.

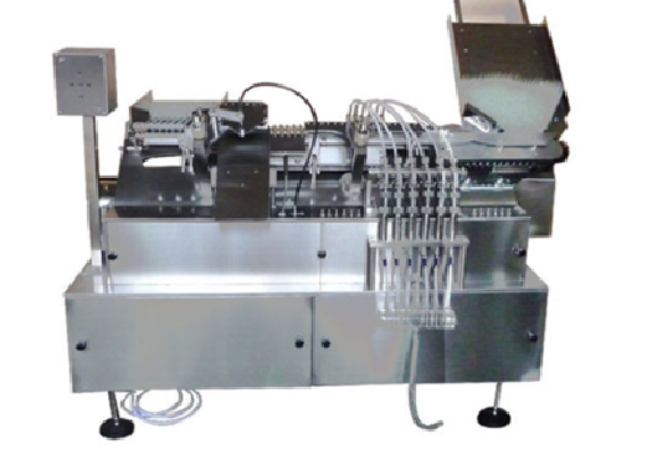

What Is An Ampoule Packing Machine?

An ampoule packing machine fills the ampoule with single dose of liquid medicine and then seals the top of the ampoule by using open flame.

The Salient Features Of Ampoule Packaging Machine

Multiple features play a big role in the popularity of ampoule packing machine. Some of the salient features are:

- Stainless steel structure for unmatched safety and reliability

- Dynamic filling capability

- High speed filling capability

- Nitrogen flushing option

- Support multiple ampoule types: You can fill either the c type or the b type mouth ampoules.

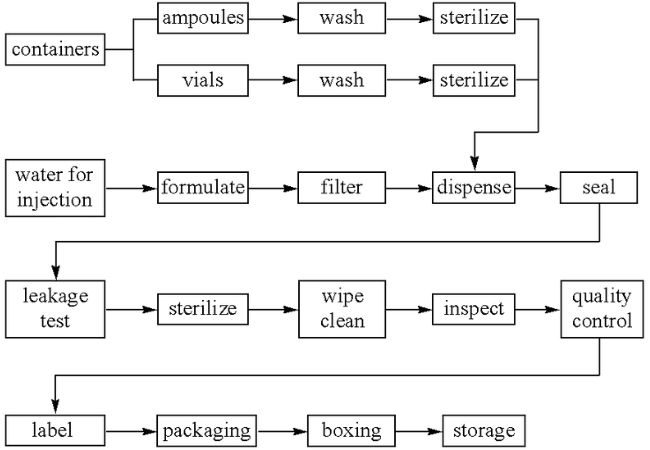

Working Mechanism Of Ampoule Packaging Equipment

The working principle of ampoule machine involve series of actions. Remember, this is an integrated system which ensures container and filling material flow in a specific way.

Step 1: In feeding Ampoules

After sterilization the ampoules move into the infeed conveyor of ampoule packaging machine. This step refers to the in feeding ampoules.

Step 2: Gas Flushing

The next step allows you to flush the gas if any inside the ampoule prior to filling. Normally this step refers to the nitrogen flushing.

Step 3: Liquid Filling

Later the filling takes place with the liquid medicine that you want to fill. The filling device centers the ampoule and fill in the specific volume as per your requirement.

Step 4: Sealing

In this step the heating takes place with an open flame. It heats the top neck of the ampoule for sealing. You can adjust the flame size by tweaking the flow of oxygen or combustible gasses through flow meter.

Step 5: Discharging:

The last step comprises of discharging. You can take the sealed ampoules out in a tray. They are now ready to ship.

Types of Ampoule Filling Machines

The types of the ampoule filling machines exist on the basis of the ampoule heads. This determines the number of ampoules they can handle and fill in a single time.

- 8 head ampoule filler and sealer

- 4 head ampoule filler and sealer

- 2 head ampoule filler and sealer

- 6 to 16 head ampoule filler and sealer

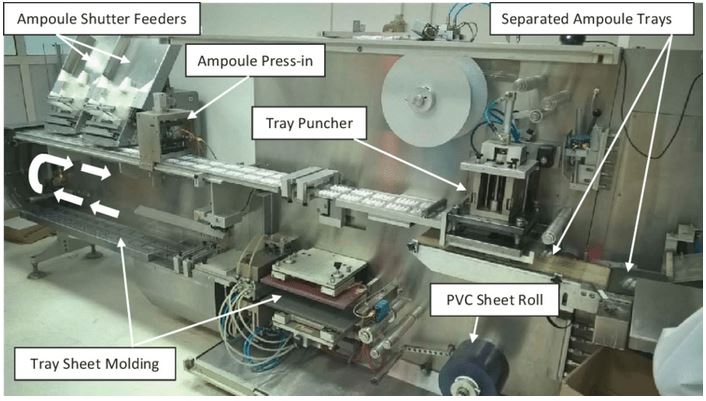

Major Components of Ampoule Packing Machine

Some main parts that an ampoule packing machine consists of include:

Filling Device:

The reservoir act as a source for this filling device. Its main role is to fill ampoules. When there is no liquid medicine inside you can refill it.

Conveyor Belt

Its main role is to carry ampoules from filling, sealing up to discharging.

Pumps

Pumps play a great role in pushing the liquid from reservoir to the filling device.

Volume and Sensor Device

These both components control the amount of liquid that you want to insert in ampoules. The sensor senses the liquid and aids the volume wheel in feeding right amount.

Sealing Device

This device seals the open end of the ampoule using open flame.

Fumes Excavator

The main role is to eliminate the fumes during the ampoule sealing process.

Troubleshooting Tips On Ampoule Filling and Sealing Machine

You can prevent the interruption in ampoule filling and sealing machine. This is possible only if you assess the key issue. Common tips on trouble shooting are as following:

If you experience a failure in sealing system then tweak the angle while sealing. This will increase the efficiency as well as sealing accuracy.

When you observe a delay in ampoule delivery. Then the solution is to adjust the conveyor belts.

Uneven filling can be due to the placement of Ampoule filling machine on a relatively uneven floor. Place it on a flat floor with uniform evenness.

In case you experience a delay in changing ampoules, make sure to use correct spacer in production line.

Head dive failure is another thing you can experience. If it happens then ensure leakage free air lines and proper working air compressor.

Advantages and Disadvantages Of An Ampoule Packer

The advantages of the ampoule packer are various. They key ones listed below:

- Boost production capacity

- Accurate filling as per needed volume

- Easy to operate without special skills needed

- Precise cooling system to ensure optimum heating level

- PLC and sensors for continuous monitoring of each operation

- Latest and Up to date technology

Some prominent disadvantages of ampoule packer are such as:

- If handles improperly may lead to injury or severe contamination

Applications of Ampoule Packer Machine

You can get the most out of your ampoule packer machine in some of industries such as:

Pharmaceutical Industry

It is no wrong to say ampoule is the back bone of the industry. This industry packs up a lot of medicines in ampoule to ensure safe transfer to medical departments.

Chemical Industry

Due to unreactive nature of glass and supreme contaminant protection. Chemical industries using ampoule packing machine to pack different chemicals.

Cosmetics Industry

The cosmetics industry makes use of ampoule packer to pack natural oils, lotion extract etc. They do this in ampoules.

Conclusion

Now you have in depth knowledge on Ampoule packing machine. You can consider the above information while selecting the perfect machine for your needs. In addition, if you want to add some info or needs clearance on some points. Comment down or reach out, we would love to help you out!

More Resources:

Ampoule – Source: Wikipedia

Ampoule Packaging Line – Source: Jochamp