There are many ointment tube fillers in the market today. However, without the right information, choose a perfect machine can be overwhelming.

This guide will help you choose the right machine for your applications – let’s dive right in.

What is Ointment Tube Filling Machine?

A tube filler is a special electromechanical machine you will use to package products in tubes. You can package many semi-liquid products in varying tubes as you will see later in this guide.

Benefits of Investing in Ointment Tube Filling Machine

There are many reasons why you should consider investing in ointment tube fillers for profitable business. They include:

Higher Level of Speed through Production

Using automatic ointment tube filling machines makes it possible to produce countless or limitless products.

Reduce interruptions in Operation

When these manufacturing machines are purchased, the company’s production and labor costs are reduced. Also, the interruptions are mostly non-existent, and this ensures that the flow of work is always on point.

Scalable

Using these machines reduces product waste, which helps ensure tubes are properly filled and the order quantity is correct.

Highly Consistent

With automatic and manual ointment tube filling machine types, there is an assurance that work can go on regardless. Furthermore, these machines can be used for many years before developing a fault.

Versatility in Filling Processes

The versatility and uniqueness of the filling process make it easy for companies to try different products and contents.

Types of Ointment Tube Filling Machines

You can classify tube filling and sealing machines based on many variables. However, some common classification criteria are:

- Fully automatic tube filling machine – they operate with virtually no human interactions. The machines have fully automatic system using PLC integrated with HMI.

- Manual ointment tube filler –They depend on human intervention to work. Although these are affordable to operate, the machines may be prone to errors.

- Semi-automatic tuber fillers – as the name suggests, these machines have both automated and manual functions.

Industries Use Ointment Tube Filling Machine

Tube fillers play an integral role in modern packaging industries. Nearly all pastes or semi-liquid products in tube depend on this machine.

Among the key industries that use this machine include:

- Toothpaste packaging industries

- Pharmaceutical packaging industries

- Food packaging industries

- Cosmetic packaging industries

- Cream making industries

- Chemical industries to package gels and sealants

In fact, the list is endless – as long as you industry makes, gels, creams, or pastes, ointment tube filler is a perfect machine for you.

Ointment Tube Filler Machine Features to Look For

As mentioned earlier, there are many ointment tube packaging machines. However, to choose a perfect machine, consider features that are beneficial to your industry.

A good ointment tube filler and packer should be:

- Easy to use and operate – from software, integration to maintenance

- Guarantee steady functionality – it should have stable structural frame, ensure minimal vibration and possible machine movement during operations.

- High ointment filling accuracy – it will prevent possible wastages thereby optimizing on production

- Easy to adjust operational parameters – these should include ointment filling cycle, number of tubes, filling speed, etc.

- Varying ointment filling capability – it should fill different quantities but still ensure accurate filling

- Offer many functionalities – these many include rejection system, quality inspection, batch coding, printing, etc.

Additionally, you should evaluate the tube filler working mechanism and structure. It should guarantee low maintenance.

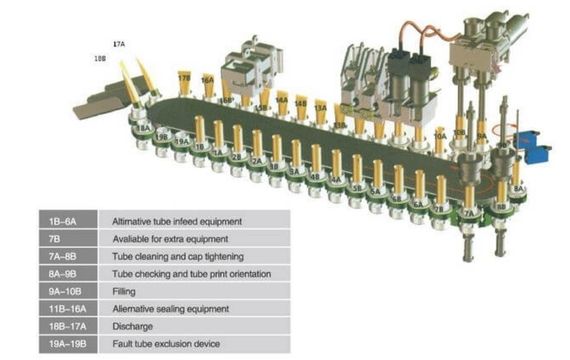

Different Parts of Ointment Tube Filling Machine

The tube fillers are assembly of different parts and components. The main components include:

Nozzles for Filling Ointment or Materials

The moment the liquid stream exists the filler and enters the holder or cylinder, it is directed to the nozzle for controlling its flow. They are connected to the source of the material or item, although the material is moved by a tri-clover.

Tanks

These tanks refer to the storage areas that these machines use to hold ointments or stuff that need to be put into the different tubes. Depending on the design and the item’s capacity for topping off, some machines come with one or several tanks.

Jaws.

Jaws helps in ensuring filling and sealing of variety of tubes can be achieved. These jaws are also essential for ensuring that all components are kept in optimal functioning condition.

Dosing Pump

Dosing pumps are ideally used for displacing in the whole filling process. The substance or ointment flows precisely and efficiently towards the needed filling, thanks to the way the pump is designed. This pump helps users to achieve that ideal and accurate flow rate of filling materials.

Control Unit

This part of the ointment tube filling machine is the most delicate part of the machine. Since this area of the machine contains all of the functioning components, it is primarily used in controlling and regulating various operational parameters. This part is also used in controlling the pace of your production and more.

Tube Holders

Tube holders are used to hold and grasp the tubes when they are being filled with the filling material. The number of tube holders will be dependent on the size and volume of the filling tube.

Again, it determines how much work can be done by the machine during each cycle. Since they work automatically, controlling and handling tubes are very easy.

Hopper

This part is located on the top level of the machine. It is built there to ensure the filling material works smoothly with the tank.

Electronic Box

This component informs users of all electrical features of the machine. It contains all electrical connections that the machine requires to work or operate.

Motor

The motor represents the major power source of the machine. Its main task is to transform electrical energy into mechanical energy.

In short, these are some of the main components in this machines. Of course, there are other components – you can check in the product manual.

How an Ointment Tube Filler Machine Works

The working principle varies according to machine design. From volumetric filling, level filling to pump filling mechanisms – there are many options at your disposal.

Even with the many options available, the tuber filling and sealing machine working principle still remains nearly the same:

Step 1: Choose suitable tube filling and sealing machine

Step 2: Put all tube in position in the machine’s hopper

Step 3: Pour ointment you want to package in the holding tank

Step 4: In case you are using fully automated machine, ensure you configure the right parameters for the tube filler. The machines have PLCs, with fully integrated HMI.

Step 5: Tube filler fill form the tubes, then seal one section (this may vary according to machine design)

Step 6: Fill the tube with right quantity of ointment and seal

Step 7: Label the tube where necessary, inspect for quality compliance. The machine will then discharge the tubes for secondary packaging such as cartoning.

Again, it is important to note that when it comes to filling, process, there are different mechanisms. Some ideal tube filling mechanisms include:

- Volumetric filling process – it depends on the ointment volume to fill tubes. The filling prince depends on a predetermined volume displaced.

- Vacuum–level filling method – while using special nozzles alongside an airtight rim at the top of the tubes. The filling mechanism depends on vacuum suction mechanism and mechanical feeding system by the hopper/auger.

- Piston filling ointments – a perfect choice for thick and viscous ointments. Usually, the piston reattach to the cylinder while at the same time forcing ointment into filling heads in the feed line. They tend to use pump mechanism and are very accurate.

- Servo pump filling mechanism – it precisely delivers ointment to various tube fillers until it reaches the required volume. Each servo pump has a nozzle which is computer controlled.

Note: Therefore, before investing in any ointment tube filler, it is important to know the working mechanism.

Different Types of Ointment Filling Tubes

There are three main tube you can choose for any ointment filling process:

Plastic Tubes

They are designed to be lightweight, leak-proof, long-lasting, and never break. Due to that, they ensure the products or ointments within are protected. Thus, it extends the shelf life of the product.

They can be used in filling products such as tanning lotions, shampoos, cleansing creams, facial masks, and hand creams. It has been made to return back to its original or ideal shape when it is squeezed. This happens without it getting destroyed.

Laminated Tubes

These types are mainly used for toothpaste packaging. However, they have been enhanced in other areas. They are used for other products like oral care products, paints, and medical ointments.

They are very flexible and durable. Their versatility stems from the various ways they are built from plastic and aluminum. This creates the optimal barriers within the tubes.

This type of tube comes in two different categories. They include:

- The Aluminum barrier laminate tube, or ABL and

- The Plastic barrier laminate tube, or PBL

Aluminum Tubes

This tube type has the best protection level provided to its products or contents. This is because it’s manufactured from countless thin layers of pure aluminum (99%). Due to internal lacquering, the product is safe from within.

Conclusion

Ointment tube filling machine types continue to change with new models being introduced. These models come with exciting features to enhance the production process. So, be well informed.

For all your ointment tube filling machines, contact us now.

More Resources:

Tube Cartoning Machine – Source: Jochamp

Filling Systems – Source: Wikipedia

Toothpaste Packaging Machine – Source: Jochamp