Lollipop Wrapping Machine Supplier

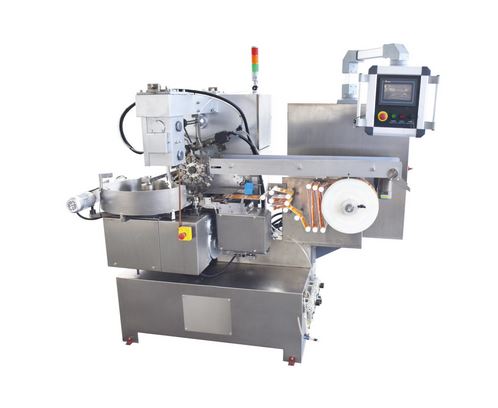

Jochamp commits to delivering hygienic, fast, and high-tech lollipop wrapping machines. Available with a wide range of optional parts and accessories. We can also make lollipop packing equipment to meet your specific market needs.

- Maximum speed 130 – 350ppm

- Adopts Servo motor control

- Full food-grade contact surface

- Siemens, Panasonic, SMC accessories

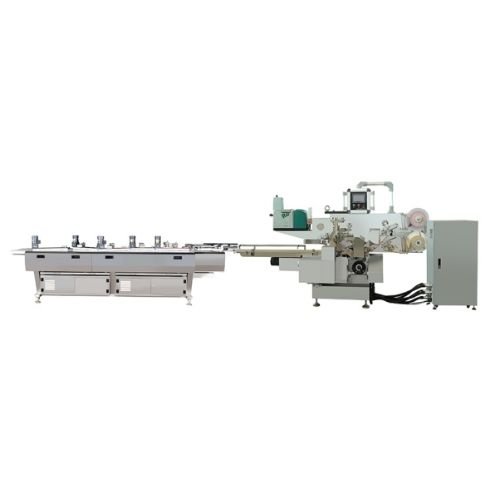

Jochamp Lollipop Wrapping Machine

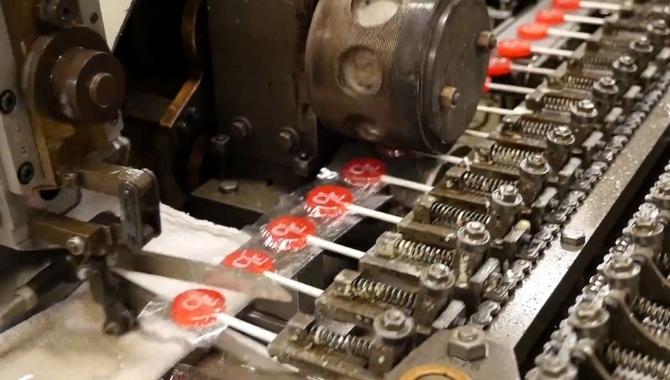

Lollipop wrapping or packing machine is a special device designed for lollipops. There are different unit models which fit various lollipop shapes. Jochamp has special equipment for spherical lollipops and lollipops with irregular shapes. We have a vast selection of machinery that fit your confectionery production line.

JCL-840 ball lollipop twist wrapping machine, JCL-260 flat/irregular lollipop wrapping machine, and JCL-300 automatic lollipop production packaging line are just a few. These series provide maximum speed ranging from 130ppm to 350ppm. You can source the best units for your need. Send us your requirements now.

Various Lollipop Wrapping Machine for Your Choices

Different Lollipop Packaging (6)

Lollipop Wrapping Machine Advantages

The speed of the lollipop packing machine is determined by numerous factors. Hence, it varies from one machine to the next. The speed of the machine can vary from 100 to 350 pieces per minute.

The machine is designed with automatic configuration, easy to operate. Can easily control the packing machine with a touch screen. The error information will be displayed when problems occur.

The lollipop wrapping machine is simple to use and care for. There are a few requirements for upkeep such as ensuring to lubricate all the moving parts and cleaning equipment thoroughly after usage.

Although it is an investment from the start, in the long run the machine save labor cost. Plus, it reduced personnel in operations. That means, cost-saving. Jochamp helps you get lower-priced units.

Main Types of Jochamp Lollipop Wrapping Machine

Jochamp offers four major types of lollipop packing machines. Different model has their features and functions. Among them are:

- JCL-840 Ball Lollipop Twist Wrapping Machine -unique machine for making spherical lollipops. It has a maximum speed of 130ppm.

- JCL-260 Flat/Irregular Lollipop Wrapping Machine – developed specifically for lollipops that have unusual shapes.

- JCL-950 Flat/Irregular Lollipop Twist Wrapping Machine – it twists packaging for lollipops with odd shapes using heat-sealable packaging materials. It has maximum speed of 220ppm

- JCL-300 Automatic Flat/Irregular Lollipop Production Packaging Line – This machine is an irregular-shaped lollipops die-forming, production, and packaging line. It has a maximum speed of 350ppm.

Jochamp Lollipop Packing Machine Major Performance

Lollipop packing machines are ideal for big and small-scale businesses, providing constant performance. The following are its 8 primary performances.

- PLC Controlled System and HMI man-machine Interface

- Intelligent Color Mark Tracking

- Intelligent Compensation System

- Independent PID temperature control

- Adopts Servo motor control

- Equipped with an efficient cooling system

- Full food-grade product contact surface

- Flexible clamping and packaging, no harm to lollipops

Recommended Lollipop Packing Film Materials for Unit

Lollipop wrapping can be done with a variety of film materials. The choice of film material is influenced by many factors, including consumer preferences and shelf life.

You can utilize the following hot-air packaging materials:

- Oriented Polypropylene (OPP). This material is a multi-layered plastic film that can be used to wrap lollipops.

- Polyethylene Terephthalate (PET). This plastic film is made from a thermoplastic resin that can be used to wrap lollipops.

- Cast Unoriented Polypropylene (CPP). Although this is a low-cost and low-density material, it nonetheless performs well.

- Aluminum Film. This is a durable material that provides outstanding barrier properties.

Jochamp: One-Stop Lollipop Wrapping Machine Provider

Jochamp is a professional manufacturer of confectionery machinery. For more than 15 years, we give the ideal solution to meet various customers’ demands. Our team has rich experience and knowledge in lollipop packaging machine production. We have served customers around the world.

Jochamp lollipop packing machine is subjected to rigorous quality control. Our QC team makes sure they meet various safety requirements including ISO, SGS, and CE. Plus, we provide free sample tests. State-of-the-art lollipop wrapping machinery is driven by innovative technology. We utilize Panasonic, Siemens, and SMC for accessories and electrical appliances. Guarantee quality standard yet lower price. We welcome OEM and ODM orders.

If you utilize an automatic lollipop wrapping machine in your production line, You will benefit from the following business advantages.

- Increased final output

- More hygienic and safe

- Neat appearance of lollipops

- Time and energy-saving

- Improve safety and health

- Low noise operation

- Lower cost

When it comes to choosing a new lollipop packing machine for your production line, there are a few things to consider. Below are a few elements to think about.

- Technical characteristics of the equipment

- Wrapping speed according to your product size

- The lollipop wrapping machine’s starting cost

- Labor demand on operating machine

- Lollipop packaging workshop space requirements

- Power requirements of the machine

- Equipment maintainability, serviceability, etc

Why Trust Jochamp for Your Lollipop Wrapping Machine Needs

Jochamp utilizes two main materials to make a lollipop wrapping machine. Stainless steel and aluminum. It makes all food-grade product contact surfaces that guarantee the hygiene and safety of lollipops.

We deploy an expert team in every department. There is more than 15 mechanical engineering team to design machine. 10+ technical sales team, 20+ after-sales service team, and international trade team.

Jochamp lollipop wrapping machines are subjected to stringent quality control. And it meets a variety of safety requirements, including CE, SGS, and ISO9001. These certificates simply verify the equipment’s quality matches your demand.

All lollipop wrapping machines have 12 monthly guarantees since the date of a successful installation. We will replace any parts or send personnel to fix and maintain the lollipop wrapping machinery free of charge, if any issues or defaults occur during the warranty period.

Jochamp offers free assembly and installation of lollipop packing machines. We provide global localized installation of your unit. After-sale support is a lifetime. We give regular after-sales care and give guidance on maintenance.

Related Product

Lollipop Wrapping Machine: The Ultimate Guide

When it comes to choosing lollipop wrapping machines, you may opt for ball lollipop or flat lollipop wrapping machines.

In this guide, you will find all information about these two types of lollipop packaging machines. So, before investing in your next packaging equipment for lollipop, read this guide.

Advantages Of Ball Lollipop Wrapping Machine

A ball lollipop wrapping machine is a piece of equipment you can use to wrap a ball-like type of lollipop.

ball lollipop wrapping machine

The machine cuts the wraps depending on the dimensions of the lollipop then covers it and seals it.

- Using a ball lollipop wrapping machine increases production and this leads to high returns.

With the high returns, you can get larger profits.

- When you use a machine to wrap lollipops, it has features that you can use to decorate the lollipop in many ways.

This improves the look of the lollipop making them attractive.

- With a machine, you are assured the whole process is efficient and accurate.

It is highly unlikely to get products that are not of the required quality.

The machine ensures the wraps are secure and tight.

- A ball lollipop wrapping machine saves time. You can get high output within a short time because the machine is fast.

- It is cost-effective. Buying the machine initially might seem expensive but you will be able to get value for your money within a short time.

- With a ball lollipop wrapping machine, you do not need many employees since the machine does most of the work.

- Using a machine to wrap the lollipop ensures there is no contamination through human handling.

The machine improves hygiene.

- A ball lollipop wrapping machine has an easy layout which is quite easy to operate and clean.

- There are no fumes or smoke with a ball lollipop wrapping machine.

This means the working environment will be clean and there will be no health hazards.

Features To Look For In Ball Lollipop Wrapping Machine

The features of any machine are what will determine its efficiency and effectiveness of the machine.

The following are the features to look for in a ball wrapping machine;

- Power requirements of the machine. You should know its voltage capacity and electricity consumption.

- Ease of repairing the machine and troubleshooting it in case of a problem.

- A ball lollipop wrapping machine should be versatile.

The machine should accommodate several product designs just with simple settings.

- Production capacity of the machine. The machine should be able to have a high production output which translates to high returns.

- A ball lollipop wrapping machine should have a PLC-controlled system.

- Look for one that only requires little labor input.

Most of the machine functions should be automatic.

The machine does everything independently and requires little to no manual labor.

-

- A budget-friendly machine is one factor you cannot ignore. You should make sure you don’t go over your budget.

- Look at the safety features of the machine. This ensures the safety of the operators and the environment.

- The configuration of the machine. It should not be very complicated, especially for a new operator.

Materials To Use In Ball Lollipop Packaging

The ball lollipop packing materials you use will affect the quality of the chocolate.

You should choose the material that will best suit you.

Below is a list of wrappers that you can use to pack ball lollipops;

- Polyethylene terephthalate

- Oriented polypropylene –

- Polyvinyl chloride –

- Cast unoriented polypropylene

Types Of Lollipop Wrapping Machines

Ball Lollipop Flow Wrapping Machine

The ball lollipop flow wrapping machine covers the whole lollipop from the lollipop to the stick.

The whole lollipop is covered in a film securely.

This wrapping machine has few maintenance requirements, and most of the operations are automatic.

The machine also has a PLC-controlled system.

ball lollipop flow wrapper machine

All the types of lollipop wrapping machines have almost the same working principle.

They only differ depending on the wrapping style needed on the lollipop wrapper.

The working principle of the machine includes the following;

- Placing the lollipops in a bucket conveyor. The conveyor will then move the lollipops to the wrapping machine.

- The second step involves weighing the lollipops using a multi-head weigher.

- After weighing them, the machine moves the lollipops to the operating platform. The operating platform is where the most important step takes place.

- A wrapping film covers the lollipops using a revolving chamber.

It then presses the lollipops to the direction where the paper film from the feeder awaits.

- The machine then wraps the lollipops by covering the whole of it and seals the lollipops at the ends.

- The lollipops are then released to a box ready to be packaged.

Ball Lollipop Double Twist Wrapper Machine

This machine wraps the ball lollipop by twisting and tightening the film at both sides of the lollipop resulting in a double twist.

This type of wrapping is common in many lollipops.

The working principle of the machine includes the following process;

- Place the lollipops in a bucket conveyor. The conveyor will then move the lollipops to the wrapping machine.

- The second step involves weighing the lollipops using a multi-head weigher.

- After weighing them, the machine moves the lollipops to the operating platform. The operating platform is where the most important step takes place.

- A wrapping film covers the lollipops using a revolving chamber and then presses the lollipops to the direction where the paper film from the feeder awaits.

- The machine then wraps the lollipops by covering them, then twists and tightens both the top and the bottom of the lollipop.

- The lollipops are then released to a box ready to be packaged.

ball lollipop double twist wrapper machine

Ball Lollipop Bunch Wrapping Machine

This type of lollipop wrapping machine wraps the lollipop in a bunch-like package.

It covers the top of the lollipop and then tightly twists the film at the bottom of the lollipop where it meets the stick.

This machine has a PLC-controlled system, an automatic lollipop settlement, advanced heating process among many other features.

The working principle of the machine includes the following process;

Place the lollipops in a bucket conveyor. The conveyor will then move the lollipops to the wrapping machine.

The second step involves weighing the lollipop using a multi-head weigher.

After weighing them, the machine moves the lollipop to the operating platform.

The operating platform is where the most important step takes place.

A wrapping film covers the lollipop using a revolving chamber and then presses the lollipop in the direction where the paper film from the feeder awaits.

The machine then wraps the lollipop by covering the top parts only and seals the lollipop at the junction where it meets the stick.

Advantages Of Flat Lollipop Wrapping Machine

A flat lollipop wrapping machine is a piece of equipment you can use to seal flat lollipops.

The machine wraps all the lollipops individually in separate wrappers.

- Its operational costs are low.

A flat lollipop wrapping machine uses very high speeds during the whole process hence reducing the operational costs.

- You are assured that your package has been secured well and is airtight when using a flat lollipop wrapping machine.

- When using a flat lollipop wrapping machine materials are utilized well and there is no wastage.

The machine has been configured to know the exact amount of material to use.

- A flat lollipop wrapping machine is very effective, hence will give you value for your money.

It works very well and its production speed is very high.

- Using a flat lollipop wrapping machine reduces labor costs since most of the work is done by the machine.

The machine also does not require supervision, this means you will not have very many people working for you.

- Using a machine to wrap the lollipop ensures there is no contamination through human handling.

The machine improves hygiene.

- When you use a machine to wrap lollipops, it has features that you can use to decorate the lollipop in many ways.

This improves the look of the lollipop making them attractive.

- With a machine, you are assured the whole process is efficient and accurate.

It is highly unlikely to get products that are not of the required quality.

The machine ensures the wraps are secure and tight.

flat lollipop wrapping machine

Choosing Flat Lollipop Wrapping Machine

There are several things you should look into before choosing any machine.

By doing so, you can get the best machine that will suit your needs.

Here are some factors you need to consider before choosing a flat lollipop wrapping machine;

- Look for one that only requires little labor input.

The machine does everything independently and requires little to no manual labor.

Most of its processes should be automatic.

- A flat lollipop wrapping machine should have a digital display system.

This is where all the important information is displayed.

- The machine should be versatile. This means it should be able to accommodate a variety of products with simple setting changes.

- Power requirements of the machine. You should know its voltage capacity and electricity consumption.

- Ease of repairing the machine and troubleshooting it in case of a problem.

It should be easy for the operator to solve problems without necessarily calling for additional help.

- The machine should have a compact built design, high quality, and very fast.

- A budget-friendly machine is one factor you cannot ignore. You should make sure you don’t go over your budget.

- The machine should be made up of advanced equipment construction.

Its parts should be made of materials such as stainless steel. With that, you can be sure of the durability.

- The machine should have an easy structure to clean and maintain.

You can disassemble some parts for proper cleaning and maintenance.

- The machine should have an air-blowing unit that protects the sealing quality.

- A flat lollipop wrapping machine should have a user-friendly interface.

One that anybody can learn to use easily.

Packaging Materials For Flat Lollipops

The flat lollipop packing materials you use will affect the quality of the chocolate.

You should choose the material that will best suit you.

The material you choose should be able to protect the product and maintain the nature of the lollipop.

Below is a list of wrappers that you can use to pack flat lollipops;

- Polyethylene terephthalate

- Oriented polypropylene

- Polyvinyl chloride

- Cast unoriented polypropylene

Types Of Flat Lollipop Wrapping Machine

Flat Lollipop Twist Wrapping Machine

This machine wraps the lollipop by covering it entirely and then securing it at the junction between the lollipop and the stick.

It is a high-speed machine that improves the shelf life of the lollipop.

The working principle of the machine include;

- Place the lollipops in a plastic tool in the conveyor. The conveyor will then move the lollipops to the wrapping machine.

- The machine moves the lollipops to the operating platform.

The operating platform is where the most important step takes place.

- A wrapping film covers the lollipops then the conveyor belt moves then to the twisting section.

- The machine then wraps the lollipops by covering the whole of it and twists the lollipops at the junction between the lollipop and the stick.

- The lollipops are then released to a box ready to be packaged.

flat lollipop twist wrapping machine

Double Twist Lollipop Wrapping Machine

This machine wraps the ball lollipop by twisting and tightening the film at both sides of the lollipop resulting in a double twist.

The working principle of the machine include;

- Place the lollipops in a plastic tool in the conveyor. The conveyor will then move the lollipops to the wrapping machine.

- The machine moves the lollipops to the operating platform. The operating platform is where the most important step takes place.

- A wrapping film covers the lollipops then the conveyor belt moves then to the twisting section.

- The machine then wraps the lollipops by covering the whole of it.

The machine then twists the lollipops at the junction between the lollipop and the stick as well as at the top of the lollipop.

- The machine then releases the lollipops that have been wrapped into a box.

double twist lollipop wrapping machine

Pillow Packaging Flat Lollipops

The pillow packaging flay lollipop wrapping machine covers the whole lollipop from the lollipop to the stick.

The working principle of the machine include;

- Place the lollipops in a plastic tool in the conveyor. The conveyor will then move the lollipops to the wrapping machine.

- The machine moves the lollipops to the operating platform. The operating platform is where the most important step takes place.

- A wrapping film covers the lollipops then the conveyor belt moves then to the twisting section.

- The machine then wraps the lollipops by covering the whole of it including the stick.

The machine then seals the ends of the lollipops ensuring it is airtight.

- The machine then releases the lollipops that have been wrapped into a box.

Pillow Lollipop Wrapping

This type of wrapping style involves covering the whole lollipop including the stick. No part of the lollipop can be seen.

This kind of wrapping style is the most hygienic and offers the best protection to the lollipop.

Top Twist Wrap For Lollipops

This wrapping style involves wrapping the lollipop at the top by twisting the wrapper. The machine will then seal the bottom of the lollipop where it meets the stick.

This is one of the most common wrapping styles.

4-side Seal Wrap For Lollipops

A 4-side seal wrap for lollipops is a wrapping style where the machine seals the lollipop in a square-like wrap.

The machine heats the wrap to form a square shape where it puts the lollipop.

Twist Wrap For Lollipops

This wrapping style is among the common lollipop wrapping styles. The machine wraps both the ends of the lollipop in a twist.

When you unwrap the seal it produces a cracking sound.

You can also learn more about candy packaging machines.

For all your lollipop wrapping machines, contact us now.