Your Case Forming Machine Manufacturer in China

JOCHAMP expertly manufactures case-forming machines that are in demand for most packaging industries. We designed them to form various case packaging sizes that suit specific products. As your business supplier, we ensure extended machine advantages for your distribution and packaging operations.

- Helps decrease staff hours

- Well-established structure and components

- Customizable designs and sizes

- Provides accurate packaging

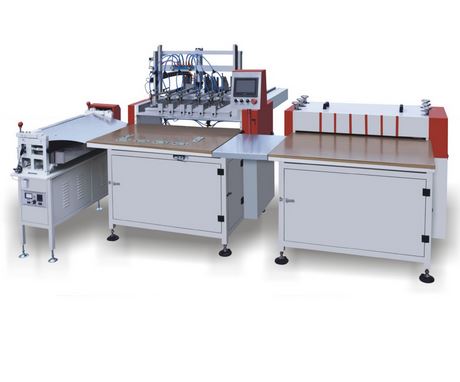

JOCHAMP Case Forming Machine

Case forming machines, widely known as case erectors, are valuable tools that relieve workers of arduous chores like folding and creating cardboard packaging. Whether your cases composes of cardboard boxes or another packaging material type, a case former will save you hours of manual labor. Which typically required pre-form and taping the cases before hand-packing the products.

In addition, the case-forming machine assures a greater output, simplicity of maintenance, and more straightforward operation. It also provides the most appropriate size for binding. Therefore, case erectors or case forming machines are suitable for use in various sectors, such as those that produce hardbound books and clipboards and duplex boards for pasting and pressing.

The packaging solution case forming machine is available in a wide variety of different configurations. It is crucial to have a concrete machine’s functions and capabilities to understand which ones will be packing process appropriate. Get in touch with us to establish which sort of case-forming equipment will best suit your needs.

Types of Case Forming Machines

Case Forming Machine Advantages

Using case-forming machines than hand-form cases indeed increases productivity and efficiency. The workers can only form about three cases per minute, while the device can erect boxes with about ten cases. The workers can use the extra time for other factory operations.

The working case-forming machines reduce human involvement with the packaging. That means there is a decrease in repetitive strains or risk of injuries. Moreover, the mentioned machines are easy and safer to operate. JOCHAMP made them with manuals and directions.

Forming cases using advanced machines achieves consistent results. It helps prevent sloppy erecting outcomes. Having consistent box sizes and forms can reduce shipping damages. The exact form of boxes can endure heavier weight than unformed product cases.

Utilizing case-forming equipment reduces inventory waste. Organizing empty boxes save the floor, walk space, and even storage factory spaces. The workers will never get tired of finding areas for the unused boxes for packaging. JOCHAMP provides the suitable one.

Typical Case Forming Challenges

The following are some typical factors to be aware of when facing forming cases inconsistency.

- Corrugated Material Quality: The properties of your preferred materials, including the age, type, and composition, affect case forming operations. The better the packaging and accuracy, the better the outcome will be.

- Case Designs & Features: Case structural designs is crucial for the case packaging efficiency and delivery. It is recommended to check the box design elements and if they can endure the packaging processes.

- Weather Conditions: The weather condition also affects the performance and quality of materials in forming processes. Examples are: in dry weather, the corrugated materials become more rigid and coarse, while in wet conditions, they become soft.

Consulting the packaging specialists is advisable to ensure excellent packaging results. Don’t hesitate to contact us right here!

Case Forming Machine Reliability

The case erectors improve the case forming machine reliability. The following are the utilized technology to achieve seamless, efficient, and continuous processes.

- Servo Sensors: It helps ensure all steps are entirely done before moving on. This sensor is adjustable, depending on various case forms.

- Case Separation Control: This function ensures that every case is separated before being erected. It helps the case be arranged in a required position for forming, resulting in box consistency.

- Pin-and-Dome System: It is applicable when cases are ready to form. This system erects the boxes even if they are wet, dusty, or on uneven surfaces.

- Hot Melt System: This is the solution for forming case parts reliable bonds. It utilizes compression with hot glue to make the bond. This system results in a stronger bond that everybody desires.

How to Choose Suitable Case Former?

JOCHAMP customizes various designs and capacities of case-forming equipment. To help you decide which types are suitable for your factories, consider the following factors. You need to know:

- The required case material. It may be hard or soft.

- Preferred corrugated paper types

- Brown corrugated paper number of layer

- Carton boxes sizes

- Required open speed

- Adhesive tape measurements

- Industry applications

- Needed core components

- Case forming machine desired process directions

We have a professional design team to customize your desired case-forming equipment.

Customize Your Case Forming Machine with JOCHAMP

JOCHAMP, a company that has years of expertise in the industry, is in the business of making and providing case-forming equipment. Our staff assures outstanding quality control by employing only raw materials of the highest possible quality and the most cutting-edge technology available.

Because of the one-of-a-kind layout of our case-forming machines, we can overcome case variances and prevent jams, allowing your line to remain operational. Because of its uncomplicated design, the device is user-friendly and capable of swift transitions. It always results in square packaging. The safe operation of our machinery is possible through features such as ergonomic magazine loading and safety curtains and shields.

No one can compete with JOCHAMP. Because of our packaging understanding and solution-driven equipment, we are the leaders in this business. The availability of our technical assistance and our best-in-class guarantee will assist in getting your equipment back up and running as quickly as possible. Please send us an email right this minute!

JOCHAMP - Your Expert Manufacturer in China

JOCHAMP manufacturers case forming equipment with various designs and types to suit specific usages. The following defines some of them.

- Automatic Case Forming Machine: You will be able to increase productivity while also reducing the amount of maintenance needed. The machine allows for quick and simple alterations to the case sizes.

- Semi-automatic Case Forming Machine: Manual case packing lines are the best candidates for semiautomatic case formers. The case pre-forming process o for hand packing will become more efficient due to this equipment.

- Forming Products & Materials: They come with tape, adhesives, box materials, and anything required to keep the packing business going optimally.

Packaging plants face several challenges in today’s fast-paced economy, including tight production deadlines and shipment timelines.

- Case erectors that do not jam and result in downtime

- Machines that make cases that are consistently square and have perfect angle integrity of ninety degrees

- Better packing, stacking, and palletizing of the issues.

- Keeping the throughput and transportation flow steady while guaranteeing that no damaged items in transit

Each case-forming machine’s components work together to manufacture solid, square cases without jamming. It results in preventing the machine jams that can occur at the transition points of the machine.

Why Choose JOCHAMP Services

JOCHAMP company is your well-established company specializing in manufacturing various advanced packing machines, including the case-forming equipment. We have 15 years of experience in the manufacturing field. Moreover, we have 100 skilled workers and ten professional mechanical engineers, providing more than 50 sets of packaging machines.

As your professional manufacturer, we provide our customers with a two-year warranty. JOCHAMP has passed multiple patent certifications, including Design Patent, Utility Model Patent, and Inventor’s Patent Right Certifications. We also adhere to SGS and CE certification standards. According to the machine quality, we also provide lifetime after-sale service.

JOCHAMP has a responsible customer assistance department that guides our customers at each machinery project stage. Our team is always ready to accommodate and serve our clients worldwide. We provide services, such as machine installation, commissioning, maintenance, and spare parts supplying. JOCHAMP assures satisfying responses and services.

The JOCHAMP state-of-the-art manufacturing facilities occupy more than 3000 square meters. We organize each manufacturing equipment we use in our facilities. Our production processes are done smoothly with our professional workers and engineers. We make sure of the complete materials and safe storage facilities.

Related Products

Case Forming Machine: The Ultimate Guide

A case forming machine plays an integral role in cartoning machine or case packer machine. Therefore, you must choose a reliable and dependable case forming machine. In this guide, you will find all information about case forming machines – let’s dive right in.

It automatically creates corrugated cartons from flat boxes by folding and sealing them.

Additionally, it typically reduces labour costs while increasing output because of its simple changeover capabilities.

With this machine, operators no longer need to hand made any cases or their products.

Case forming machine

Case forming machines can produce 6 to 45 cases per minute depending on designs and are available in automatic and semi-automatic configurations.

Case forming machines can be used in the following industries:

Pharmaceuticals Industry

Manufacturers typically utilize this technique when creating cases to encapsulate medications used in hospitals for ease shipment and storage to prevent contamination.

Cosmetic Industry

Case forming machines are also used by cosmetics manufacturers. Through case packaging, they improve the appearance of their products, such as fragrances, ointments, and hair sprays, among others.

Food Industry

In this scenario, the employment of forming machines primarily serves to facilitate the preservation of food and its transportation to markets by manufacturers.

Chemical Industry

Most chemical manufacturers find it preferable to employ Case forming machines to obtain the best cases that will fit their products according to their classes.

These chemicals usually range from non-poisonous to hazardous chemicals.

Warehouse And Logistics

Case forming machines are used by this business to create cases for goods of various types and weights.

Also, guaranteeing the goods’ dependability and security throughout transportation.

Electronic Industry

Clients in this sector typically want the best protection at the lowest possible cost and with the highest possible throughput.

They create cases using a case-making machine appropriate for every industrial and domestic electronic application.

Typically, the machines that generate trays include those with lids and slots and can be customized to create other types of trays.

case forming machine

Typically, they work at high speed while using robust adhesive systems. It will always assemble the trays more quickly and consistently.

Case forming machines, on the other hand, is a sort of equipment that deals with the forming, folding, and sealing of the cases with a high changeover.

tray forming machine

This therefore, increases the number of cases produced each minute.

You can learn more about tray forming machines.

Speed Increase

A case former eliminates the time-consuming process of opening and handling the case blanks, which is usually required for all Case forming machine models.

Even with a team working on manual case formation, one employee may create 2–5 cases per minute.

Case forming may make up to 45 in a minute, immediately increasing throughput.

Reduces Backlog

It takes a lot of time and effort to build cases by hand. Workers must first put together enough made cases before packing.

It consumes priceless floor space in addition to lengthening the production process.

As cases are needed, a case-forming machine may create them, freeing up floor space for other uses.

Eases Operation

In contrast to a manual process, Case forming machines involve little to no handling of the corrugated cardboard blanks during production.

The Case’s bottom is opened, squared, and sealed by the machine.

An operator only needs to load the blanks and input the dimensions; the machine takes care of the rest.

Faster Change Over

The requirement for qualified operators to perform a changeover is one reason for holding off on purchasing new equipment.

Additionally, case forming machines are built with quick changeover times in mind.

Executing quick and straightforward changeovers will minimize downtime and give your operators more time to concentrate on other profitable duties.

This is when numerous different-sized cases are required for a given line.

It further reduces your downtime because having fewer parts also means less maintenance.

Reduces Repetitive Strain And Injury

For eight hours at a time, forming and sealing cases can lead to repetitive strain injuries in the hands, wrists, shoulders, and arms.

Repetitive strain injuries over time can lower output, increase time off for treatment and rehabilitation, and lower job satisfaction.

Any chance to reduce the danger of repetitive strain injuries enhances worker productivity and health in the industrial industry.

Case formation machines lower exposure for both people and the business.

Reduce Inventory Damage

Case-forming machines are capable of forming cases and precisely sealing the bottom flaps.

This precision lowers the possibility of crooked case corners and missing adhesive applications.

Boxes manufactured by machines result in straighter stacks and less chance of breakage during shipping.

· Automatic Case Former

Automatic Case forming devices eliminate the need for operator interaction by automatically shaping, folding, and sealing the bottom of corrugated boxes.

automatic case former

To create a comprehensive form, fill, and seal cases, combine an automatic case forming unit with a case sealer.

· Semi-automatic Case Making Machine

Semi-Automatic Case forming machines are often made to handle a variety of box sizes.

semi-automatic case making machine

However, they still need an operator to move the cases through the machine to increase manufacturers’ productivity and efficiency with the Case forming method.

· High-Speed Case Making Machine

It is a case-forming machine type with a robust design that combines characteristics successfully used in production to deliver the best speed and accuracy.

A high-speed case-making machine is typically best.

high speed case making machine

This machine, created to meet the requirements of high-speed lines, features a high-grade, hefty steel frame that is welded and bolted for strength and outfitted with premium parts throughout.

Feeding Unit

You can introduce the cardboard material that needs to be created in this machine at this point. There are essentially different configurations possible depending on the machine’s characteristics.

Folding Unit

It is a separate area where the folding of cases is accomplished with the aid of various components.

A crash module typically makes it easier to fold the base flaps of the Case. The non-hook and hook-based systems are primarily used.

Separating Compartment

The primary purpose of this component is to distinguish between cases with poor form and good ones. It typically has a sensor that aids in precise separation.

Conveyor Belt

In essence, the conveyor belt moves the cases from one segment to the next with the aid of rollers that speed up the operation.

Control Panel

Typically, a set of parameters for the case-making machine’s operation is discussed.

Temperature and speed are two of the variables. One of the most crucial parts you should consider while purchasing the machine.

Electrical System

A case-making machine requires an electrical system to provide electricity for the device to function. This element is effectively the machine’s heart because it connects circuits to produce power.

Pneumatic System

When Case making process is in progress, this area often assists the machine pressing and aids in the movement of other components, such as lubrication fluids.

Lubrication System

It is one of the elements that help to grease the moving parts of the machines that make cases for more straightforward operation. It lubricates parts like rails, gears, and bolts.

Doing this will make the equipment simpler to maintain and less prone to malfunction.

PLC control System

It’s a system with a full touch screen that lets you program, monitor and manage all Case making machine operations from a single location.

This machine works with the following steps:

Step One: The case board is loaded into the Case forming machine’s feeding unit before operations begin. Make sure the case boards are correctly positioned to allow for easy mobility.

Step Two: Position the case boards within the Case forming machine by moving the clamps surrounding it open so they can accommodate the boards.

Typically, a conveyor belt is used to install the case boards because it rotates the cases as they pass along the line.

Step Three: Closing the clamps and joining the case board with glue is a significant step that allows them to create a study case.

Step Four: The cases are taken out of the Case forming machine at this point using the outfeed conveyor that travels farther along the packing line.

Step five: In this optional stage, the cases created are put through a quality control procedure to ensure they adhere to the requirements.

Since they automatically form, fold, and seal corrugated cartons from flat cardboard, case erector machines and Case forming machines are identical.

case erector machine

They both have a high speed and are available in both automatic and semi-automatic varieties, increasing manufacturing productivity.

These two machines are commonly connected to achieve the best results in the secondary packing process.

Integrating Case forming and sealing machines is typically more effective than using one of these machine components.

A case forming machine will shape the case for packaging. Then, the case sealing machine will seal the cases. It ensures complete packaging.

The erecting procedure is divided into easy stages to aid reliability in the Case forming machine. Typically, the Case forming machines use technology to connect the phases and provide a seamless, effective, and continuous Case forming operation.

Before moving on to the next level, the case erector’s servo sensor ensures that every step has been accomplished.

The timing can be adjusted to account for the various types of instances.

Before being erected, the initial case separation function usually ensures that the Case is isolated from the following one.

It will make it possible to prepare each instance for forming in the necessary location, resulting in squared and consistent cases.

Usually, the pin and dome system is employed following the opening of the forming box.

It typically makes up for the factors influencing the corrugated box’s behavior and quality.

Besides, it can build cases on dirty, uneven, or moist surfaces.

A hot melting system is frequently essential for forming a solid bond between the Case’s components.

In essence, compression and hot glue are used to link. Compared to other approaches, this relationship is frequently stronger.

It works with the case-forming machine to provide mechanical and easy solutions throughout the process.

For all your case forming machines, contact us now.