Tablet Packing Machine Supplier in China

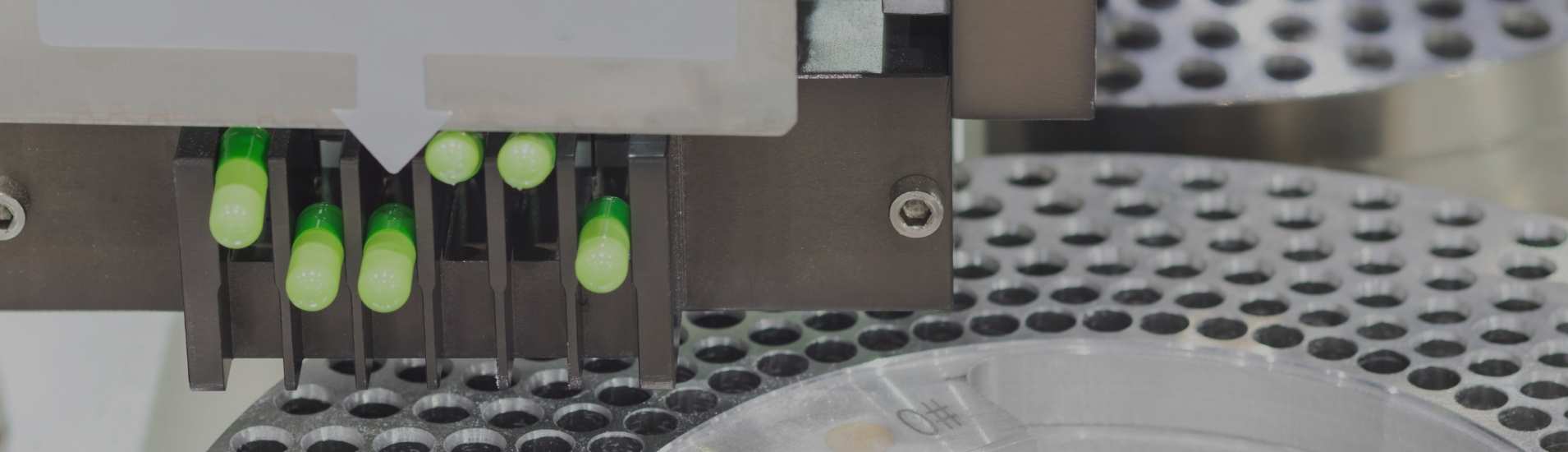

Jochamp is a professional manufacturer of tablet packing machines in China. We supply customized automated packaging solutions to improve your packaging productivity.

- Provides high precision and accuracy

- Complies with international safety standards

- Adaptable packaging solution

- Ensure zero packing error

Jochamp Tablet Packing Machine

Jochamp provides tablet packing machines that are highly efficient, simple to operate and a reliable packaging solution. We construct each machine with excellent flexibility to accommodate different product applications.

With our tablet packing machine, you can save money on labor while boosting efficiency and minimizing error rates. It can handle a variety of applications, from low to high-speed packaging.

We provide high-quality packaging solutions for commodity markets, healthcare, medicines, and other products. Here at JOCHAMP, you can avail a variety of tablet packing machines to meet your needs.

Please contact us as soon as possible with your specifications!

Tablet Packing Machine Benefits

We produce tablet packing machines with added versatility. It is also very adaptable, as it can be designed to meet various packaging requirements.

Our tablet packing machines have a straightforward and compact design. These cutting-edge machines are designed to be low-maintenance.

The speed of JOCHAMP tablet packing machines can be adjusted. It can be set to 5 to 45 cases per minute to improve the wrapping performance of your market.

Tablet packing machines aimed to decrease human labor while enhancing productivity. As result, you can save time, money, and reduce error possibilities.

Fully Automatic and Innovative Packing Machines

At JOCHAMP, we manufacture a diverse variety of fully automatic tablet packing machines. Each machine is creatively designed to meet the needs of the industry. It can be programmed to deal with different box structures or patterns. As a result, you can be confident that it can pack any pharmaceutical tablet products.

Inaccurate loading numbers, foreign body introduction, or other related issues will be excluded by using these machines. Even when used in mass-produced product packaging, tablet packing machines can definitely provide high precision. They can pack approximately 120 cases per minute.

Suitable Films for Tablet Packing Machines

The tablet packing machine is designed specifically for the small pharmaceutical sector and hospitals. It uses several packing materials, such as:

- ALU PVC

- PVC PAPER

The machine is simple to use. It is appropriate for packaging capsules, tablets, softgels, candies, medical supplies, honey, and jam, among other things.

Industries We Serve

If you manufacture capsules, tablets, powder, granules, then the tablet packing machine is right for you. This machine is extensively used in the following industries:

- Drug manufacturing facilities

- Enterprises that provide healthcare

- Food processing plants

- Laboratories

- Pharmaceutical

JOCHAMP –Your Trusted Tablet Packing Machine Supplier in China

JOCHAMP is a tablet packing machine supplier in China that can meet all of your industry or packaging demands. Our machines can help boost the performance of your industry by offering precise, productive, and instant packaging. To ensure high efficiency, each machine is outfitted with sealers and case erectors. We provide various automatic packing machines with customized specifications based on your requirements.

We at JOCHAMP can assist you in locating the best tablet packing machines for your needs.

Send us your concerns right away!

- Jochamp can provide all the tablet packing machine information to determine if you understand the functionalities of the machinery.

- Jochamp’s experienced team will help determine the best machine model to meet your specific production needs.

- Installation, after-sales, and training services are available globally.

- All machines have been guaranteed CE, SGS, ISO9001, and cGMP certified.

- Professional international trade team offering flawless point-to-point trade workflow services ranging from payment to filing a certification to freight and import duties.

- The space on the same flat surface can be easily adjusted for forming, hot sealing, indentation, punching, and other parts. It is appropriate for multiple sizes of drug packaging, has precision, and has a wide range of applications.

- Extendable stroke, automatic material selection, contrary edition heating, proper pressure to form, up and down movement, hot sealing of cylinder, dot number with automatic indentation, mechanism draw, convenience, and operational consistency.

- It uses imported retard with low noise and high durability.

- Placement of the die pressure plate; ease of repair

- The composite mechanism, loading and unloading accessibility, and maintainability.

What JOCHAMP Can Offer for You

We also have our own manufacturing unit to ensure the quality of components used in our machines. The physical frameworks are molded using CNC machining guidelines to ensure overall machine validity and mechanical reliability.

JOCHAMP developed an excellent after-sales service system. Every problem discovered by our customers will be documented in our customer management system, ensuring that every issue raised by our clients is visible in manufacturing, technical levels, and sales. We promise to respond quickly and provide you with a great solution.

As a supplier, we have a large number of professional designers with extensive experience in schematic engineering and error handling. We offer guaranteed machines as well as after-sales technical support. Our sales team can provide technical support both during and after the sale to ensure that the machines arrive in perfect condition.

Related Product

Tablet Packing Machine: The Ultimate Guide

Probably, you are looking for highly efficient and reliable tablet packing machine. In this guide, you will find all information about tablet packing machine such as classification, features, working principle, design, etc.

So, if you want to learn more about tablet packing machine, read this guide.

The following are the advantages of tablet packing machine;

Easy to clean and durable: Machines must be cleaned to increase their durability and prevent them from easily breaking down.

Accurate and speedy: The machine increases the accuracy of the packaging tablets by filling the tubes according to the rotation principle. It can increase production speeds while lowering cost and improving efficiency when the right machine is used for the right process.

Health and safety: Automatic machine allows workers to work less and reduces the amount of heavy lifting which may cause injuries to them.

Meet rising demand more easily: Automatic machine can help you scale up production quickly thus more order means that you satisfied and you can make more profit. Rising demand can also bring problems if you do not have capacity to cope like, staff shortage can lead to less profits.

Reduce labour costs: The machine only requires less operators because it is automatic hence it cut costs but increases production and quality.

tablet packing machine

Here are the industries that uses tablet packing machine;

Pharmaceutical industry: Packaging of Medicines is very important since the medicines may become lethal if they come in contact with external components like water, air and heat.

Food and beverage industry: The machine ensures the food and beverage is filled into the right specifications land in different sizes of tubes.

Nutraceutical industry: The industry prefers to package products in tubes thus the machine helps in filling dietary supplements.

There are many types of tablet packaging machine and here are some of them;

Tablet Tube Filling Machine

A machine that is designed to package tablets into tubes in layers before placing stopper and labelling the package before storage.

The machine ensures there is effective packaging of the best quality of tablets into the tubes thus it does the capping to the filled tubes according to the used specifications.

How Tablet Tube Filling Machine Works

You can easily operate the machine and enhance its efficiency if you understand how, it properly works and here are the steps of how it works;

Stage 1: Preparation

Adjust the hopper according to the filling requirements and load the pre-feeder and load the empty tubes into the tube hopper of the machine.

Set the right filling parameters on PLC control system and inspect the machine before switching it on as any malfunction may affect the machine.

Check the speed of production, reset distance and number of tablets per tube which are the parameter that often comes complete with a touch screen.

Stage 2: Filling Process

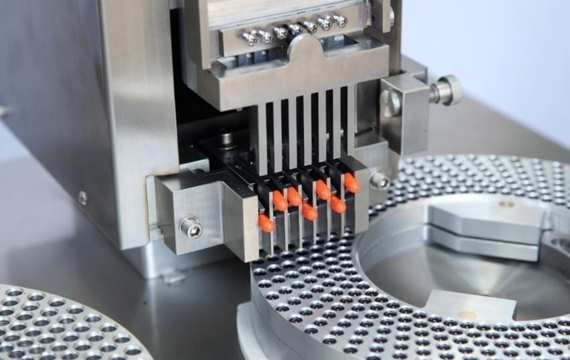

The machine has two channels which automatically forwards the tubes to the table and then fills the empty tubes with the right numbers of the tablets.

When it comes to counting the tablets, the machine has pneumatic stop, which increases its accuracy.

Stage 3: Inspection Process

At this stage, the machine will automatically move the tubes to the inspection stage where the tablets will be confirmed if they are in right number.

If the tubes are not good for filling before capping, they are rejected and exchanged immediately with the correct tubes.

Stage 4: Capping Process

The machine has a sensor which automatically detect if the tube has a cup hence if the tube is not capped, it rejects and allows the capped to move to the labelling stage.

Applications Of Tablets Tube Filling Machine

The tube filling machine is used in the following industries.

Nutraceutical industry: The industry prefers to package products in tubes thus the machine helps in filling dietary supplements.

Pharmaceutical industry: The machine helps in packaging tablets for medical reasons.

Food and beverage industry: This machine ensures the food and beverage is filled into the right specifications land in different sizes of tubes.

Tablet tube filling machine

Benefits Of Tablets Tube Filling Machine

There are many benefits of tube filling machine and some are;

- The machine improves the productivity and efficiency as it works automatically thus it reduces human labor.

- Easy to operate and maintain since it has few parts and depends on the modular concept.

- The machine increases the accuracy of the packaging tablets by filling the tubes according to the rotation principle.

- Tablet tube filling machine is reliable and consistence since it gives you a chance to fill your items in tubes physically and having a good change of volume to each tube.

Disadvantages Of Tube Filling Machine

The following are the disadvantages of using tube filling machine;

- It is expensive to purchase and install the machine which makes the investing in it on a business to become more expensive.

- The material used for packaging may be expensive and difficult to find.

- You must undergo training for you to handle the machine since it is very complex.

- The machine only needs to fill specific sizes of tubes and not all sizes.

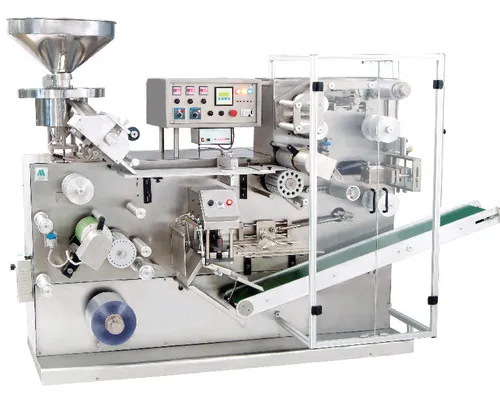

Tablet Strip Packing Machine

Machine used to package coated or uncoated tablets into foil strip hence they give high speed and uninterrupted results at a low cost of maintenance.

The products are automatically fed in between two foil strips that are pressed by a pair of heat-sealing roller to contain the product into air-tight pockets.

How Table Strip Packing Machine Works

The product is fed through the hopper when the feeding machine moves to the heat-sealing roller cavities.

The sealing rollers packs and seals the product continuously after the required laminated foil from the two rollers is drawn.

The desired strip sizes are made when the sealed strip passes through the vertical and horizontal cutters.

Applications Of Tablet Strip Packing Machine

The following companies’ uses tablet strip packing machine;

Pharmaceutical industry: The strip packing process of pharmaceutical products consist of capsules, tablets etc. which are sealed inside pockets created within two moving foil sheets.

The pockets create a strong seal to provide a protection to the items in it

Benefits Of Tablet Strip Packing Machine

- The machine helps in displaying the product hence you can design and print individual packs to strengthen your branding.

- It is simple to use compared to blister packing machine which is a bit complex leading to high cost of labor.

- Has a maximum speed which depends on the size of the product and gravity.

- The machine allows you to fill many different sizes of strip packs with different types of products like tablets, powders and capsules.

Disadvantages Of Tablet Strip Packing Machine

- When packing pharmaceutical products, the machine has a high variation in cost.

- The machine occupies greater space.

- Risk of product damage during handling or prone to mechanical damage.

- Strip pack is difficult to use by elderly and patients with arthritic fingers.

tablet strip packing machine

Vertical Tablet Packing Machine

It is a machine that produces low noise when used and is great for coated tablets, capsule, chocolate bean and any solid product with identical shape.

Application Of Vertical Tablet Packing Machine

Commonly used in the following companies;

- Food and beverages industry.

- Automotive industry.

- Construction industry.

How Vertical Tablet Packing Machine Works

The material used for the film can vary from paper laminates and cellophane laminates thus the machine uses a single sheet of film material rolled around a core.

Forming tubes are used to pull off the film roll and are located at the front of the machine where Film transport belts are positioned.

The film is unwound from the roll by Motor-driven surface unwind wheel and is passed over a robotic dancer arm which incorporates a series of rollers.

Besides, the film then moves to the printing unit where desired printer places dates, logos or graphics and then passes the registration station.

Thereafter, there is a camera that discovers the registration mark on printed film.

A forming tube is set up to immediately make a lap seal or a fin seal when the film enters there and also fold around the tube.

The layers of the film are bonded together by a hot vertical seal bar that moves towards the film to make a vertical overlap on it.

After the product has been released into the bag, it is sealed then dropped when the jaws open and the discharged bag can be discharged into a conveyor and transported.

Benefits Of Vertical Tablet Packing Machine

- It has a robot which pick up bags, print dates and open bag which leads to less risk of danger to workers.

- The machine is easy to use and the consumers appreciate their easy operation and simple storage technique.

- The pouch bags are lightweight compared to bottles and can that make the transportation and distribution to be easy and of low cost.

vertical tablet packing machine

- Tablet packing machine is designed to package tablets into tubes in layers before placing stopper and labelling the package before storage.

tablet packing machine

- Capsule packing machine is designed to fill hard gelatine capsules with, liquid or solid substances and is commonly used in pharmaceutical industries.

- Each machine uses blister packaging due to its safety and efficacy considerations

capsule packing machine

Whereas the output capacity of the machine depends on the product characteristics.

- Tablet and capsule machine reduce the packing cost due to their high application and run-on speed control.

For all your tablet packing machines, contact us now.