High Speed Blister Packing Machine Manufacturer

High speed blister packaging machine is an automated machine used in hospital and pharmaceutical industry. It is ideal to pack aluminum-aluminum, aluminum-plastic, and paper-plastic material packaging.

- Compact design

- 360 blisters/min or more

- Easy to operate

- High automation and efficiency

JOCHAMP High Speed Blister Packing Machine

Jochamp high-speed blister packaging machine is automatic and ergonomic packaging equipment used for Thermo Forming (PVC/ALU) and Cold Forming (ALU/ALU) blister packs. Suitable for mass production batches in the pharmaceutical industry. It is capable to pack 360 to 600 blisters per minute. This machine covers the industry of food, medicine, agricultural and veterinary medicine, daily chemical and hardware, etc. This is built with outstanding control systems for easy operation and reliable output.

Jochamp provides excellent blister packaging solutions. Various models and types are available thus, we can recommend the machine according to your requirement. We used the best ideas to manufacture a high-speed blister packaging machine. Our company adopts the latest technology and techniques to design the right machine for your needs. If you have a special request, we can custom-built packaging machines quickly and efficiently.

Message us today.

JCDH-260 High Speed Blister Packing Machine

This blister packaging machine is suitable for automatic high-speed ALU-PVC packing of capsules, tablets and other regular shape medicine. It adopts flat pressure forming to form strong and average blisters, and roller type mesh sealing to ensure reliable sealing. The machine is equipped with batching system, embossing device and horizontal boundless punching to achieve high automation and efficiency.

- Fast mould change, push-oriented, without using tools

- Adopt servo traction, simple to set up, convenient to debug

- Push-oriented punch mould installation. If inspection and reject system is equipped and changed, no need to dismantle suck discs

- Long distance between two heating plates of forming when machine stops, to avoid PVC to be excessively heated and softened.

JCDH-260

- Technical Parameter

- Features

- Optional

| Item | Unit | Specification | |||||

| Blanking Speed Standard Card (80mm×57mm)×4 Row | Cycle / min | 100-150 | |||||

| Capacity | Cards / hour | 360Pcs/min | |||||

| Range of stroke | mm | 40-120 | |||||

| Max. forming area and depth | mm | 240×260×12 | |||||

| Power supply | V | Hz | Kw | AC380/220 | 50/60 | 10 | |

| Air consumption | Stere / min | ≥0.5 | |||||

| Packing Material | Pharmacy PVC | mm | 0.25×260 | ||||

| PTP Aluminum foil | mm | 0.02×260 | |||||

| Overall dimension (Length×Width×High) | mm | 4220×1020×1020 | |||||

| Packaging Dimension(Length×Width×High) | mm | 4600×1250×1960 | |||||

| Net weight | Kg | 3000 | |||||

Fast mould change, push-oriented, without using tools

Adopt servo traction, simple to set up, convenient to debug

Push-oriented punch mould installation. If inspection and reject system is equipped and changed, no need to dismantle suck discs

Long distance between two heating plates of forming when machine stops, to avoid PVC to be excessively heated and softened.

Optional configurations include camera inspection and rejection device, mechanical hand structure with suck heads, automatic vibrating guide rail feeder, etc.

visual inspection

Batch number stamping

Rotary suction head discharge

Laser positioning function

Remote system inspection, maintenance, upgrade

Sealing pattern

Punching mechanism

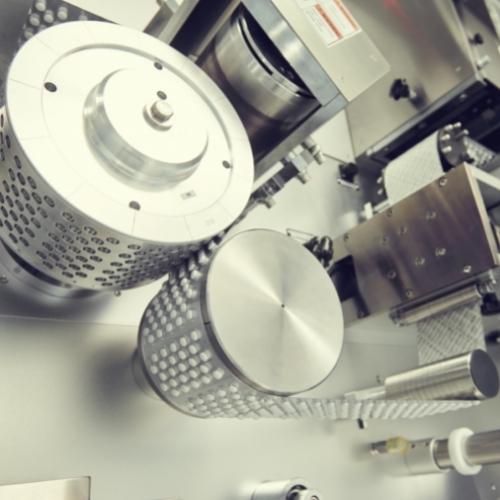

High Quality Construction

High-speed blister packaging machine is constructed from superior grade stainless steel. Designed with a food and drug-grade contact surface. It is rigorously welded and bolted from a durable frame device structure. All the drive parts and complete cabling has installed on the machine with surface treatment. We use internationally renowned brands of electrical appliances and accessories such as Mitsubishi, Siemens, SMC, Mitsubishi, SICK, etc.

The indexing and feeding systems of the equipment are controlled by servo motors. This machine is easy to sanitize due to its adjustable studs. Jochamp offers a variety of seamless automatic feeding mechanisms for this machine, perfect for various product forms. The format sections are simple to mount and detach, utilizing few tools and tackles.

Product Scope

Our range of machines is excellent for packing pharmaceutical products of various sizes with high precision and efficiency into blister packs.

- Capsules

- Tablets

- Softgel

- Candies

- Medical equipment

- Honey and jam, etc.