Automatic Blister Packing Machine Manufacturer in China

JOCHAMP automatic blister packing machines are available in a variety of sizes and include standard features. There are various models available. We can customize it to the demands of our customers’ from manual, semi-automatic, and completely automated machines. JOCHAMP provides the model that will meet your production needs.

- Longer life and higher visibility

- A variety of material packaging forms

- User-friendly man-machine interface (HMI)

- Passed CE, ISO9001, cGMP, SGS, and other certifications

JOCHAMP Automatic Blister Packing Machine

Automatic blister packing machines are perfect for the packaging of oral tablets, capsules, hard and soft gelatin, and ampules in the pharmaceutical business. For increased output, the machine uses flat shaping and rotational sealing techniques. Its design adheres to GMP guidelines and sets the standard in the blister packing industry. The machine is also suitable for packing equipment for big and medium-sized pharmaceutical industries, with advanced functionality, simple operation, and high production.

JOCHAMP is here for you, and with our quick response time, engaging tools, and professional technology, we’ll keep your production line running smoothly. Our certified specialists have an average of more than a decade of experience and are educated to give excellent technical support so that our customers can continue to produce. We are always ready to serve you. Please feel free to contact us with your requirements so that we can provide you with the most appropriate and dependable automatic blister packing machine.

Types of Blister Packing Machines

Automatic Blister Packing Machine Advantages

All in one, it cuts, fills, seals, and labels seminal doses with a simple touch of the screen. The machine is equipped with an emergency stop system.

A simple design with no crevices or gaps prevents the accumulation of dirt. Easy, fast, and simple cleaning. All-inclusive and easy-to-use technology.

Customized products and kinds of machines. As well as logos and many more. JOCHAMP provides related machines according to customers’ needs.

Simple tube replacement, the filler tube is replaced in seconds, without annoying screws. Choose JOCHAMP now for your best automatic blister packing machine.

Automatic Blister Packing Machine for Different Factories

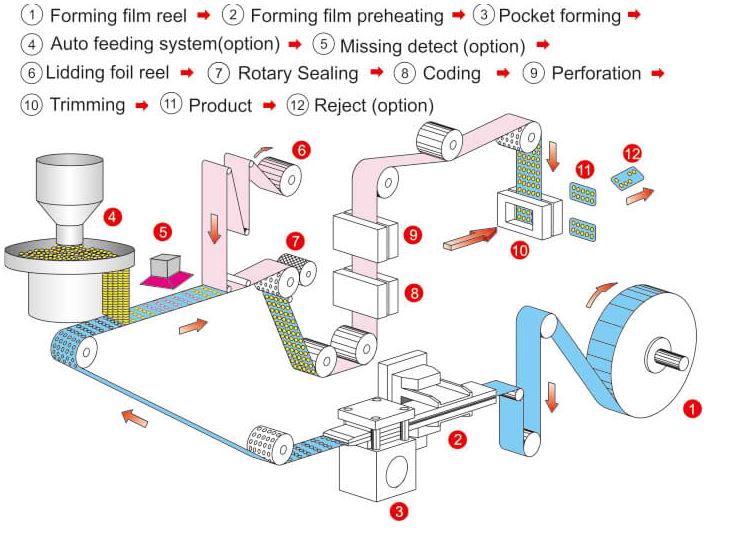

The automatic blister packing machine is widely used in many factories and products, including pharmacy factories, dosage rooms, research institutes, pharmaceutical factories, health products factories, food products factories, hardware factories, etc. PVC feeding, PVC heating, PVC shaping, PTP feeding, PVC and PTP sealing, batch number printing, indentation line creation, and so on are all included in the automatic blister packing machine.

JOCHAMP, innovative equipment, including an automatic blister packing machine, is always being improved. Integral technology is used for speed control and mechanisms. Long shelf life, good sealing performance, attractive appearance, safety, and hygiene are all features of the products that meet GMP production standards.

Automatic Blister Packing Machine Performance Features

- Heat sealing, batch number printing, and indentation are all completed by this machine.

- Conveying automatically, cutting sheets off automatically, stopping and alarming automatically, and so on.

- Good stability, high precision, may be adjusted directly on the touch screen, easy to use.

- The positive gas forming, heat sealing, and indentation molds are fixed at 500 mm by a pressing plate, allowing for precise positioning and easy replacement.

- The machine as a whole benefits from its lightweight, compact structure, simple operation, transport, and maintenance.

- It has good mechanical properties, a smooth transmission, low accuracy, low noise, and no noticeable vibration.

Automatic Blister Packing Machine Details

Material Feeding: Using the proper items, fill the cavities with packaging materials.

Touchscreen Operating Interface: It incorporates a touchscreen human-machine interface that makes managing all the packaging operations simple and straightforward.

Heat Sealing System: In the blister packing process, this is the component that seals the filled spaces.

Foil Feeding System: The material is pushed to the platform for the blister packaging process by this section of the machine.

Waste Material Winder: It’s in charge of winding the waste from the forming material and the sealing machine.

Electric Motor: Controlling the speed of the components to meet the blister packing specification.

Why Choose JOCHAMP for Your Automatic Blister Packing Machine

JOCHAMP automatic blister packing machine is well-known for its mechanical adaptability, sturdiness, and durability. An automatic blister packing machine is specifically built for sectors that require equipment that is both strong and efficient. JOCHAMP employs a technical sales staff of more than 10 employees, each with more than 5 years of professional experience.

Furthermore, JOCHAMP’s highest focus is to meet the needs of all consumers. We’ve been offering significant quantities of fully upgraded, tested, and certified automatic blister packing machines for over 15 years. We can be sure when it comes to personalization. Not only that, but we already had in engineers who will analyze your structural design and provide you with the highest quality machine possible.

JOCHAMP has more than 15 years of professional automatic blister packing machine manufacturer and supplier.

- More than 3000 square meters factory Own R&D Team.

- Free design service, free professional solutions.

- Provide high quality and delivery-guaranteed.

- Professional customer support and after-sales guarantee service.

- Competitive price.

- Excellent technical support.

- Best service, including a professional team and shipping with VIP cooperation.

- 24/7 fast response service and professional business manager answer your needs accurately.

Coating Material: The coating substance should work well with both the substrate and the blister. Furthermore, the temperature should be kept low so that the blister film may be sealed quickly without being damaged.

Substrate: Blister packing is often made of white cardboard. It’s made of bleached Kraft wood pulp, or it can be created from a recycled board with a white paper base layer.

Packaging Film: Because of its sufficient barrier performance to carbon dioxide, oxygen, and water vapor, strong mechanical strength, and high transparency, plastic film can be utilized for blister packing.

JOCHAMP Automatic Blister Packing Machine Professional Services

JOCHAMP automatic blister packing machines have been sold to more than 50 strategic cooperation machinery factories. From a single machine to entire production lines, we’ve got you covered. In this industry, JOCHAMP becomes a household name! We will keep working hard to serve our clients with the best machine and packaging equipment and services.

Before shipment, our inspection engineers will carefully and strictly test the machine, and based on the contract technical requirements, we will create a “pre-shipment inspection list” to check it one by one, ensuring that you receive the correct functional machine. We respond quickly to after-sale service requests by online chat, email, phone number, etc.

Integrated PC controller, PLC touch screen, easy-to-use user interface, connectivity via USB or remotely via Ethernet port. Process control via a pneumatic system (QS 1000). Optical and laser sensing for cutting and filling processes makes filling calibration possible.

The automatic blister packing machine’s other components are constructed of stainless steel or aluminum. Both materials ensure maximum hygiene throughout the packaging process. All of our machines and technological goods are developed, prototyped, and tested in the electrical engineering department of JOCHAMP.

Related Product

Automatic Blister Packing Machine: The Ultimate Guide

There are quite a number of automatic blister packing machines in the market. This guide explores all vital aspects about automatic blister packing machine. So, keep reading to learn more.

A blister packing machine is a piece of equipment mostly utilized in the pharmaceutical industry.

You can pack and seal oral capsules, tablets, ampoules, toothbrushes, and hairbrushes, among many others with a blister packing machine.

The machine packs the tablets in a bubble pack made up of the cold-formed aluminum film.

blister packing machine

Both automatic blister packing machines and strip packing machines are equipment you can use to pack products.

Automatic blister packing machines create cavities on the material and place the products in the cavities.

Strip packing machines from strip packs around the product.

automatic blister packing machine

Both automatic blister packing machines and strip packing machines make packages that protect the integrity of their products.

However, a blister packing machine offers more benefits compared to a strip packing machine.

With an automatic blister packing machine, you can get a package that can protect the product against mechanical damage.

That is not the case with a strip packing machine, its packages cannot protect against mechanical damage.

The packing process using an automatic blister pack is fast compared to using a strip packing machine which is slower.

When using an automatic blister packing machine you do not encounter any difficulties, as compared to a strip packing machine.

There are always some difficulties such as wrinkling of the seal area in a strip packing machine.

An automatic blister packing machine occupies less space compared to a strip packing machine.

strip packing machine

An automatic blister packing machine is an essential piece of equipment in the pharmaceutical industry.

The main advantages of this machine include the following;

1. An automatic blister packing machine is cost-effective. Compared to other packaging types, blister packaging is cheaper.

The equipment itself is affordable, and it is not very complicated.

2. Blister packages made from the machines are tamper-proof. No external factors can destroy it.

If somebody interferes with the package, you can tell.

3. Blister packing machines make packages that one can use to track accurate dosage.

You can know the number of tablets you have taken by simply checking.

4. The material of blister packages protects the product from any interference.

The package ensures the tablets are safe from any environmental changes.

The material also ensures the product’s shelf-life is maintained.

5. Blister packages have all the necessary information on the package.

Details such as the manufacturing date and expiry date are on there.

- Pharmaceutical industry – The industry uses it to pack tablets, capsules, and other medicines.

- This industry widely uses this machine.

- The hygiene industry – uses this machine to pack products such as toothbrushes, combs, hair brushes.

- Battery manufacturing industry – the automatic blister packing machine packs different types of batteries into packs.

You make a few changes depending on the kind of battery you want to pack.

- Cosmetic industry – automatic blister packing machine packs most cosmetic products such as makeup brushes and other personal care products.

- Stationery industry – In the stationery industry, products such as pens are put into their packages using an automatic blister packing machine.

- Food processing industry – an automatic blister packing machine comes in handy in the food processing industry to pack certain foodstuffs.

- Electronics industry – since blister packing protects the products from damage, most manufacturers use this packing method.

- Toy industry – most toy industries use an automatic blister packing machine to pack their toys.

A blister packing machine packs most toy cars and even some dolls.

A manual blister packaging machine is equipment that depends on human labor to function.

The whole packing and sealing process depends on human intervention.

On the other hand, an automatic blister packing machine is fully automated, it does not require human labor during the whole process.

The machine initiates the process and also ends the process on its own.

A manual blister packing machine is best for small and upcoming businesses while for a well-established business, an automatic blister packing machine comes in handy.

The initial cost of a manual blister packing machine is low compared to an automatic blister packing machine which is very high.

A manual blister packing machine takes a little floor space compared to an automatic one which occupies a big space.

Regarding production volume, a manual blister packing machine is very slow, since the whole process depends on manual labor.

However, automatic equipment is fast.

With an automatic blister packing machine, you get very high returns because of the high production volume.

However, with a manual blister packer, production is low, resulting in low returns.

An automatic blister packing machine is very efficient and effective, which is not the case with a manual one.

You should expect some errors when using a manual blister packing machine.

When using an automatic blister packing machine there are no additional costs. However, with a manual blister packer, you have to spend money on the people helping.

Before choosing any product, you have to consider some things.

This will help you avoid spending out of your budget or getting products that do not fit your needs.

To choose an automatic blister packing machine you should consider the following;

- Price – is an important factor to consider before choosing a blister packing machine.

Make sure you get one that is within your budget and will meet your needs.

- Type – there are several kinds of blister packing machines. Each of them meets different needs.

You need to be sure of what kind of machine you want that will fully meet your requirements.

- Ease of use – getting a complicated blister packing machine will only result in a cumbersome packing process.

This may lead to products that are not of quality. You may also spend a lot of time learning how to use it.

- Level of automation – there are different levels of automation. They all depend on the amount of money you have and the market demand.

- Productivity – automatic blister packing machines produce very high returns while manual ones do not produce very high returns.

If you have a huge demand you have to consider the automatic one.

- Dimensions – the size and weight of the machine should meet your needs, and fit on the workstation.

- Material specifications – there are many material specifications that you may need on distinct kinds of products.

Choose a machine that can meet several material specifications by changing a few settings.

- Machine features – you should carefully go through all the features.

The features will help you choose the best machine depending on your needs.

- Touchscreen operating interface – this is one of the essential parts of a blister packing machine. From the operating interface, you can monitor the whole packing process.

- Blister pack tooling system – this is where you can dictate the shape of the package.

- Aluminum foil/ PVC feeding roller – this part is responsible for pushing the material into the machine for packing.

- The heating box – this is the part that receives the material, then heats it to make it ready for forming.

- Guide rail – this part steers the material from one stage to another.

- Electric motor – is responsible for the moving parts.

- Material forming system – this is where the machine forms cavities that will hold the product.

blister packing machine parts

- Turning rollers – help feed the material into the blister packing machine.

- Material feeding system – feeds products into the cavities of the package.

- Heat sealing system – seals the cavities after the machine feeds the products into them.

- Sealing material feeder – this is where the machine holds the sealing materials.

- Pressing mechanical system – presses the material and the sealing to form a permanent seal.

- Waste material winder – part of the machine that holds materials that remain after the whole process is done.

- Tow mechanism – is responsible for the movement of packages that have been sealed.

- Blanking mechanism – this cuts any excess material from packages.

- Product chute – steers the packed packages out of the machine.

- Lubrication system – an automatic part that oils the moving parts of the machine.

Cold forming and thermoforming are both methods you can use to form cavities on the material in readiness for packing different products into them.

Thermoforming uses heat and PVC sheets to form cavities on the material, while cold forming does not involve heat.

The thermoforming process involves heating the PVC sheets by passing them through heating plates.

Passing the PVC sheet through heat makes them soft, you can make any shape.

After that, apply pressure on the heated PVC sheets to form the shape or mold you need.

If the shape of the mold is complex, you can use a mechanical clamp to apply additional pressure.

Cold forming involves aluminum sheets.

The machine turns the aluminum sheets into blisters by forcing a stamp on them to mold them into a shape.

The machine will remove the stamp, the material will maintain the shape that the stamp made.

The material you choose for your package will affect the quality of the products.

There are several kinds of materials that you can use for blister packaging; they all depend on the type of product you are packing.

Therefore, you should consider the following;

- The type of product you are packing. Some products may be light sensitive, but the material you pick should not allow light to pass through it.

- The material you choose also depends on the sealing and blister forming type. You cannot heat some of them, you should avoid the materials if you will be using the heating method.

Automatic Alu Alu Blister Packing Machine

An automatic alu alu blister packing machine is an equipment that is ideal for highly sensitive pharmaceutical products.

Features of this type of machine include;

- Has a user-friendly human-machine interface touchscreen

- The automatic alu alu blister packing machine has a packing speed of 40 cycles per minute and 35 cycles per minute for thermoforming and cold forming respectively

- The machine is easy to use and maintain

- Has minimum tear and wear.

The machine has some benefits which include;

- The machine makes packages that are lightproof

- The machine makes packs that are high barrier

- It is an easier process

Alu Alu blister packing machine

Automatic Blister Card Packing Machine

An automatic blister card packing machine is equipment that packs products into blisters and then attaches them to cardboard.

This is one of the most common blister packing machines.

The features of this machine are;

- You can achieve up to 40 packages per minute with this machine

- It has a design that can fit through a normal door

- The machine has an interface that is easy to use

- The machine can accommodate up to 200 medications

The machine feeds the PVC sheet into the machine, heats them, and then moves the material to the blister-forming unit.

Here the equipment forms the cavities until you achieve the needed number.

A guide rail guides the material to the sealing unit where the machine seals the pack to the cardboard.

blister card packing machine

The benefits of this machine include;

- It is cost-effective since it minimizes operating expenses

- It has an easy-to-use interface

- You can use it for several applications

Automatic Thermoforming Packaging Machine

An automatic thermoforming packing machine uses heat. The machine heats the PVC sheet to make it soft to remodel it into any shape.

Features of this machine include;

- It is low maintenance

- Has a user-friendly design

- It has a longer service life

- The machine has trouble-free performance

Benefits of this machine include;

- The pack and seals from this machine are strong

- The machine is not complicated to use

- It is quite fast

automatic thermoforming packaging machine

Automatic High-speed Blister Packing Machine

An automatic high-speed blister packing machine is a very fast blister packing machine. It is faster than the other packing machines and its returns are quite high.

Its features include;

- High production speed

- Fully automatic operation

- Has a user-friendly design

- Has minimum wear and tear

Benefits of this machine include;

- It is a very cost-effective machine

- It brings back high returns due to high production

- Its production speed is very high

automatic high speed blister packing machine

Automatic Alu PVC Blister Packing Machine

Tablets and capsules are put into packages using the automatic alu PVC blister packing machine.

It has features such as;

- The fully automatic packing process

- Has a universal batch code printing unit

- High-speed and efficient packing production

- Has flexible parts that can be changed when the need arises

It has benefits such as;

- Provides the products with extra protection

- It is a fast and efficient packing process

- Protects the product from light

Automatic Blister Packing Machine For Capsules

It is a machine you can use to pack capsules. It is an efficient and effective machine that provides quality packing.

It has features such as;

- High-speed production cycles

- Easy user interface

- The machine is easy to maintain and use

- It is a fully automatic machine, the whole process is automatic

Benefits;

- The automatic blister packer for capsules reduces workload

- The machine offers high production returns

- This type of blister packing machine is fast

- It is efficient and effective

- The machine minimizes wastage

Automatic Tablet Blister Packing Machine

This is a machine ideal for the pharmaceutical industry. the manufacturer can use the machine to pack the tablets into safe packages.

Features;

- Has a user-friendly human-machine interface touchscreen

- The automatic alu alu blister packing machine has a packing speed of 40 cycles per minute and 35 cycles per minute for thermoforming and cold forming

- The machine is easy to use and maintain

- Has minimum tear and wear

Benefits;

- This automatic blister packer has a long product life

- An automatic blister packer for tablets is effective and efficient

- It has a high production speed.

automatic tablet blister packing machine

For all your automatic blister packing machine, contact us now.