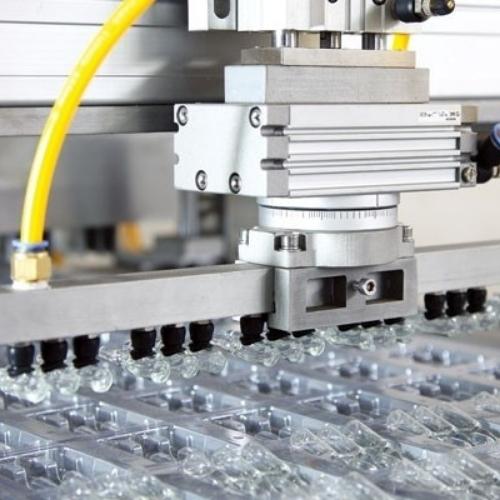

JCDP-260 Blister Packing Machine

Fast processing capacity, higher-end configuration. Thermoforming of general purpose PVC and cold forming of ALU. Suitable for food, pharmaceutical, nutraceutical, cosmetic, stationery and hardware industries.

- Manufactured according to cGMP standards.

- Servomotors ensure accurate and smooth web conveying and punching.

- Photoelectric indexing control.

- Easy and quick changeover without tools

- AISI 304 Stainless Steel cover.

- PLC controlled with Touch Screen Control Panel (HMI) for easy operation.

JCDP-260

- Technical Parameter

- Features

- Optional

| Model | JCDP-260 |

| Main technical parameters | Cutting frequency: 25-50 times/min for Al-Plastic,20-35 times /min for Al-Al |

| Packing material and specification | PTP Al foil: Width 250mm thickness 0.02-0.03mm; Forming material: Width 250mm thickness 0.50-0.15mm |

| Stroke range | Traction stroke: 30-130mm |

| Application range | Western medicine, traditional Chinese medicine pill, herbal medicine pill, veterinary medicine, sugar coated tablet, compressed tablet, different kinds of candy, food and electronic component. |

| Main function | Stepless frequency conversion; blister packing, security detection |

| Max forming depth (mm) | 25mm(Al-pvc) |

| Max forming area (mm2) | 250×130×20mm |

| Power supply | 380V ,3p,50Hz |

| Total electric power (KW) | 5.7kW |

| Compressed air pressure (MPa) | 0.5-0.7MPa |

| Compressed air consumption (m3/h) | ≥ 0.22 |

| Cooling water consumption (m3/h) | Ordinary tap water for circulation cooling |

| Noise (dB) | 70dB |

| Outline dimension (L×W×H mm) | 4700×650×1640mm |

| Weight (kg) | 1500kg |

| Frequency regulation capability of motor | 20-50Hz |

- Manufactured according to cGMP standards.

- Servomotors ensure accurate and smooth web conveying and punching.

- Photoelectric indexing control.

- Easy and quick changeover without tools

- AISI 304 Stainless Steel cover.

- PLC controlled with Touch Screen Control Panel (HMI) for easy operation.

- Electronically monitored individual temperature control for upper and

- lower heating plates, high reliability to meet forming material characteristics.

- Code embossing and slitting or perforation line.

- Pneumatic clamp web indexing system.

- Sturdy construction for prolonged durability.

- Safety interlocked doors.

- Raised output conveyor for easy cartoner integration.

- Vision Checking System for inspection and detection of faulty blisters

- with empty cavities, broken tablets, different

- format, shape, … etc. by means of TV camera.

- Universal or dedicated feeders ensure high feeding efficiency.

- Double rolls system with joining table.

Dispensing machine for tablets and capsules

Liquid Filling Machine

Robotic automatic feeder

batch stamping

Nitrogen flush

Sealing texture

Punching mechanism