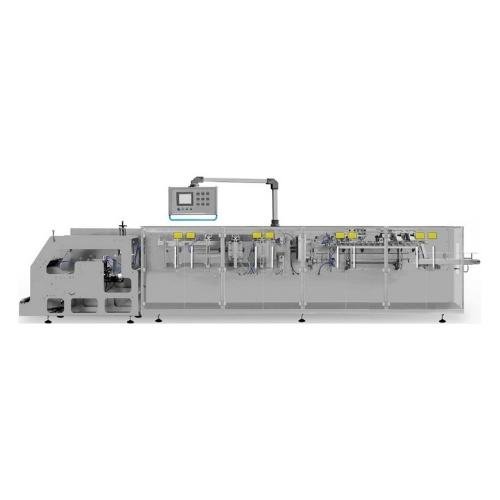

JOCHAMP Yogurt Packaging Machine

Jochamp is a manufacturer of yogurt packaging machines in China. The machines are designed for high precision, speed, and ease of use. It can be used to pack yogurt safely to avoid damage during transportation.

- Long working hours

- Low-power operation

- Setting that is easily adjustable

- Less upkeep is required

Custom Yogurt Packaging Machine

Yogurt packaging machine is exactly designed to pack yogurt products into different container sizes. It has a capacity from 1200 pcs up to 1800 pcs per hour and can be customized to your requirements. The machine details are absolutely visible and have premium quality.

Jochamp develops a yogurt packaging machine equipped with digital controllers. It includes cutting-edge technology such as an automatic shutdown function, a PLC system, and more. The machine is also constructed of 304 stainless steel grade which makes them highly corrosion-resistant. With us, you can get low-cost yogurt packaging machines. Please contact us right away.

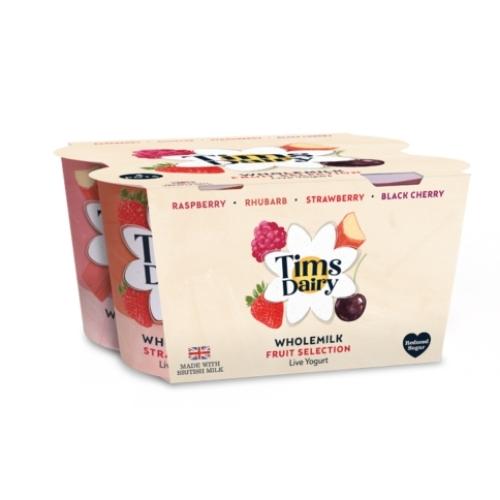

Different Yogurt Packaging (3)

Working Flow of Yogurt Packaging Machine

- Falling cups: The cups fall down one by one.

- Filling material in the cup

- Applying pre-cut film to the cups

- Two heat sealing lids: 0-400 degrees, adjustable.

- The output of finished cups: Push finished cups to a platform.

Features of Yogurt Packaging Machine

Jochamp created a cutting-edge technology yogurt packaging machine. They are well-known for their unrivaled qualities, such as sturdiness, longer shelf life, and ease of maintenance. Special features include:

- Touch screen panel for PLC control

- Sealing cut with servo control

- A one-of-a-kind film tension control system

- Temperature control module on its own

- System for detecting and rejecting empty bags

- Smaller footprints due to the compact size

Related Products

Yogurt Packaging Machine Guide

In this guide, you will find all information about yogurt packaging machines. Whether you want to learn about features, specifications, classification, working principle or applications – all information is available right here.

yoghurt packaging machine

Pillow Bag

A container which is 3-sided with flat surfaces in the shape of a pillow poach meant for products like drinking yoghurt.

pillow bag

Bucket

Bucket container is made in the shape of a bucket using lightweight plastic material and sealed through a tight lid.

bucket

Bucket containers can be used for cottage cheese, yoghurt, sour cream and mayonnaise.

Doy-Pack

A plastic poach container with a bottom that can support it while standing upright.

Doy-pack container is most preferred for use by children and it also allows printing of nice images that are attractive to children.

doy pack

Gable Top

Gable top containers come in different shapes depending on your taste and they are also bright, attracting users.

gable top

Branded content and other promotional content can easily be printed in its surface and is suitable for drinking yoghurt packaging.

Cup

Cup containers for yoghurt offer a shatterproof package that can protect the contents from the environment.

yoghurt cup

Such containers have a small footprint and offer stability.

PET Bottle

PET bottle containers are meant for packaging drinking yoghurt offering durability and lightweight.

A branded shrink wrap or paint can be done on the surface easily.

Plastic Containers

Plastic containers are stable and can be used for packaging yoghurt offering two compartments with a topper.

Temperature Considerations

Ensure that the packaging solution of choice will offer the right temperature conditions suitable for yoghurt.

This is because it is sensitive to extreme temperatures.

Hygiene Requirements

Consider getting a yoghurt filling solution that will ensure that your product is safe from contamination.

Yoghurt packaging machine should be one that offers ultra-clean surfaces and can be decontaminated at various levels during packaging.

Requirements During Operations

Filling speed, maintenance requirements and other operational factors are some of the most important factors to consider when getting packaging solutions.

Speed will be determined by the intended output for the company.

Operational Costs

Some yoghurt filling solutions are designed for short runs with quick changeovers while others are meant for long runs.

Your choice should best fit your needs also considering the cost of operating the machine.

Sustainability

Consider getting a machine that will be able to recycle packaging containers to keep the environment safe and also save money.

Flexibility

A yoghurt filling solution that can handle different types and shapes of containers is a better choice.

However, this choice will be determined by the needs of a given company.

Container Quality

Yoghurt being a consumable product, should be packaged in quality containers hence the need for a machine that will offer quality.

Yogurt Pouch Packaging

Yoghurt pouch packaging can be done manually, semi-automatically or automatically.

Apart from yoghurt, the machine can also package fine food products, health and beauty products, home care products, baby food etc.

Some of the features of yoghurt pouch packaging include;

- Able to handle various pouch shapes that can match company needs to increase shelf appeal.

- The machine offers easy pouring services which ensures tamper evidence ensuring consumer trust in the product.

- Yoghurt pouch packaging can handle different container sizes from approximately 50ml to 5L.

- Sterility is assured through aesthetic finishes like gloss, matt etc.

- Yoghurt pouch packaging also offers packing requirements like oxygen, moisture, aroma and UV barriers.

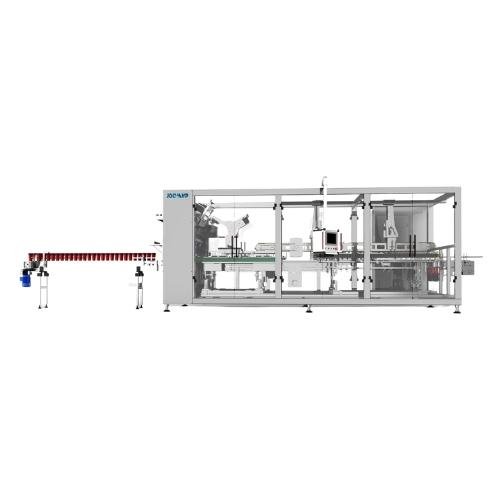

Automatic Rotary Cup Filling Machine For Yogurt

Automatic rotary cup filling machine for yoghurt can perform functions from feeding to weighing to filling to sealing to ejecting automatically.

Apart from yoghurt, the machine can also package products like ice cream, honey, buttermilk and curd.

rotary cup filling machine

The machine is made of stainless-steel to offer sterile conditions for yoghurt with a simple control panel.

Yogurt Cup Sealing Machines

Yoghurt cup sealing machines are packaging machines that can weigh, fill and seal products manually or automatically.

The machine can also handle other products including powdered products, putty snacks, sugar, rice etc.

yoghurt cup sealing machine

Some of the features include; PLC control, serve control film dragging technique, pneumatic seal mechanism, smart temperature control mechanism, alarm system.

Automatic Yogurt Filling And Sealing Machines

Automatic yoghurt filling and sealing machine can perform various functions such as filling, capping, sealing and ejection.

Some of the features include stability and efficiency, PLC control with a touch HMI interface, handling different sizes, stainless steel structure.

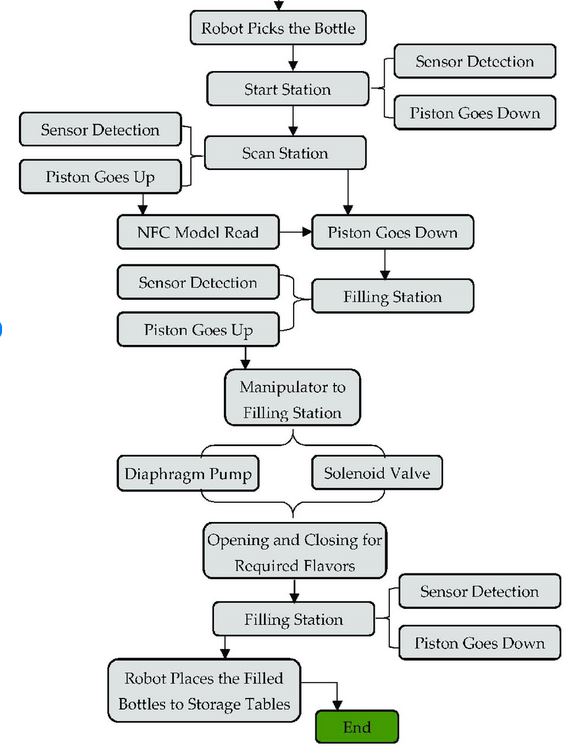

Yoghurt Bottle Filling Machine

Yoghurt bottle filling machine works efficiently with a feature of no bottle no fill.

This feature makes the machine to automatically stop when there are no bottles to fill.

The machine can automatically feed and eject bottles from the system.

yoghurt bottle filling machine

Some of the functions performed by this machine include bottle forming, bottle filling with yoghurt, labelling, sealing and ejecting.

Yoghurt Box Filling Machine

Yoghurt box filling machine is designed to pack yoghurt into containers in the shape of a box.

The machine functions by feeding in the cartons, forming them, filling the boxes with yoghurt, sealing them, labelling and ejection.

Other products that the machine can handle include sauce, ice cream, seasoning etc.

Hygiene Maintenance

Every yoghurt filling machine is designed to ensure that the product is safe from contamination and that the consumer is safe.

To achieve hygiene, manufacturers use materials such as stainless-steel to coat parts that get in to contact with the product.

Simple And Convenient Operation

Operators are provided with a PLC control and an HMI touch interface for easy control and monitoring of the whole process.

Easy Maintenance

Yoghurt filling machine is built in a way to ensure easy cleaning and the whole machine is easy to maintain.

Compact Design

Yoghurt filling machine with a compact design ensures stability and small footprint creating more space within the work area.

Accuracy

Since the machine comes with a PLC control with a touch HMI interface, the packages are more accurate compared to manual operations.

Flexibility

Yoghurt filling machine is flexible in terms of the types of containers it handles, container sizes and shapes.

Also, apart from yogurt, the machine can also package other products like plain milk, vegetable oil etc.

Automation

The machine can perform all the functions including container feeding, container filling, sealing, product ejection.

PLC Touch Screen

Through the PLC touch screen, the operator can control all the processes including container falling, film loading, filling, sealing and ejection.

Automatic Container Dropping System

A pneumatic system at this point controls the dropping of the containers.

Gear And Pull System

Gear and pull system control the movement of the containers from one station to the next through drive motor and speed reducer.

Filling Station

The filling system can be either single or double head outlets for filling the yoghurt into the containers.

Film Loading Station

At this station, the system automatically places film over the container getting it ready for sealing.

Sealing Station

Sealing takes place at this station and the product is pushed into the conveyer belt for discharge.

Product Discharge System

The product is automatically discharged from the system at this point.

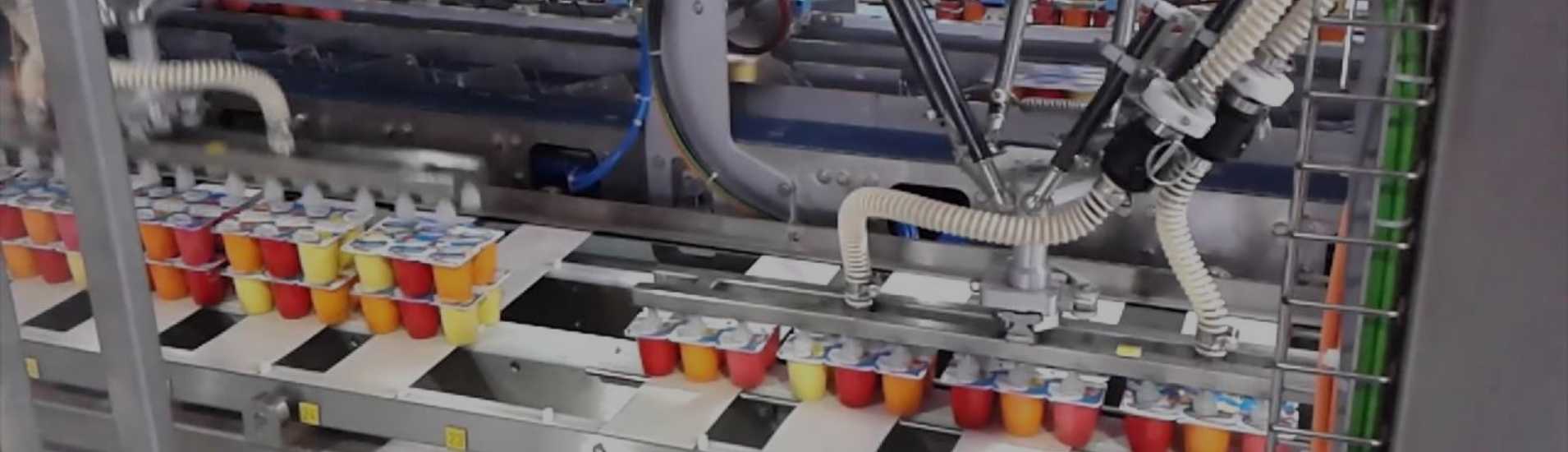

Once all the parameters have been set through the PLC touch screen and the operator switches the start button, packaging begins.

The machine, through a pneumatic system, drops the containers into the system getting them ready for filling.

This is followed by a gearing and pulling process that aids in the movement of the containers to the filling station.

At the filling station the product has already been filled into the hoppers.

Immediately the containers are in place, the valves open and yoghurt flows in.

The amount of product that flows into each container was preset through the PLC touch screen.

Once the containers have been filled, the conveyer belts move the containers to the film putting station.

Film placing on the container, covers the top getting it ready for sealing.

At the sealing station, the containers are sealed through heat to create a tight and durable seal that will protect the product.

After sealing the product is pushed to the discharge station through the conveyer belt where it is ejected from the system.

The product is now ready to be tray, carton or case packaged before being shipped or distributed into the market.

yoghurt filling process

Power requirements range between 220V to 1200W but can change depending your requirements.

A Packaging speed of about 800-900 cups in one hour for single outlet and 1600-1800 cups for one hour for double outlet.

Approximated Air pressure requirement of about 0.5 to 0.75 Mpa.

The Maximum amount of air consumption at approximately 0.45m3/m

Container Dimension at about 100*80*120cm

Product Weight should be approximately 350kg.

Note that these parameters can change depending on the requirements of a production line and the machine can actually be customized.

Simple Operation

A PLC touch screen makes machine operation very simple.

All the operator has to do in control and monitor the whole process through a screen.

Reduced Labor

Since the machine can literally do all the functions automatically from feeding to ejection of the product, labor costs are reduced.

Reduced labor also leads to improved efficiency leading to high output.

Advanced Design

Continuous yoghurt packaging machine is compact and offers high automation and a performance that can be relied on.

Food hygiene and Safety Standards

The whole continuous yoghurt packaging machine is made up of materials like stainless steel or aluminum alloy or copper etc.

These materials don’t corrode hence keeping the product from contamination.

Container Shape Can be Modified

Continuous yoghurt packaging machine is very flexible and can handle various container shapes including round, square, triangle, rectangle etc.

Photoelectric Eye Detectors

Every manufacturer is interested in accuracy and precision and features like photoelectric eye detectors ensure that this is achieved.

Adjustable Production Pressure and Speed

This is to ensure that each production cycle is given the appropriate working conditions for best results.

Flawless and Smooth Edges

Continuous yoghurt packaging machine uses film for sealing which gives the edges the smooth appearance making the product more attractive.

Yoghurt packaging line can also handle several other products apart from yoghurt.

Therefore, a yoghurt producing or packaging company can also package various other products using the same packaging machine.

Such products include milk, beverages, coffee, coffee creamer, juice, ice cream, soy milk, plum syrup, jelly, rice wine, sauce, jam etc.

However, the packaging machine must be designed to accommodate various filling stations for every product.

A yoghurt packaging line can handle different types of container materials including paper, plastic, aluminum etc.

Various container sizes can be handled by the yoghurt packaging line depending of the parameters set through the PLC touch screen.

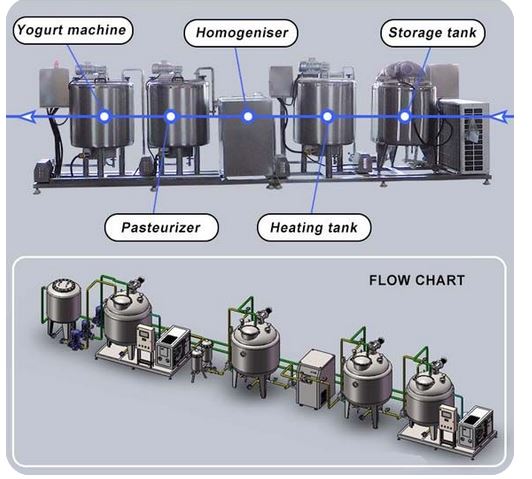

yoghurt production line

The device used for filling the containers can be in various volumes including 1-10ml or 10-100ml or 5-50ml or 50-500ml or 30-300ml to 500ml.

The device volume is determined by the needs of a packaging cycle.

Capping

Capping yoghurt containers uses the concept of creating a roof over a hat.

Before the cap is placed, a flat seal is created to create a seal that will ensure that the contents of the container are not exposed.

The cap is usually made with bright colors allowing the branding on the first flat seal to be seen through it.

Die Cut Lids

Die cut lids can be used for covering yoghurt containers, however, they must be laminated using a plastic film or glue coating.

Die cut lids can be used with plastic containers made from PS, PP, PET or paper laminated using a plastic film.

Yogurt Packaging Lids

Yoghurt packaging lids come in different shapes and most of them are made of paper but laminated using plastic.

They can non-stackable or stackable, clip on or domed clip on.

Heat Seal Foil Lids

Heat-seal foil lidding is mostly suitable for businesses that are just starting up.

Product shelf life and freshness is better preserved through the use of heat-seal foil compared to snap-on lids.

Foil Lids for Yogurt Packaging

Foil lids are usually used for yoghurt packaging because they are cheaper compared to plastic lids, they are also easy to use.

Yogurt Lid

Yoghurt lids are mostly made of aluminum foil laminated using plastic to aid during sealing to create a strong and cost-effective lid.

Yogurt Lidding Foil

Yoghurt lidding foil is also used more often because it does not corrode hence protecting the product from contamination.

Volumetric Filler

Volumetric filler is useful for filling the yoghurt containers with yoghurt with measurement in volume.

Gravity Filler

Gravity filler works through gravity where the hopper above the nozzles is filled with yoghurt.

Once the containers are in place, the opening of the valve allows the yoghurt to flow into the containers.

Piston Filler

Piston fillers are also used to give volumetric fill to containers accurately.

Pump Fillers

Pump fillers enables you to pump only what you need into the containers.

Net Weigh Fillers

These are designed to ensure that all containers in a production line have the same amount of product.

Inline Fillers

Inline fillers are designed for filling yoghurt containers in a single line within a conveyer system.

Rotary Fillers

Rotary fillers move containers in circular stages where some containers are filled, others capped and others sealed.

Case Packaging For Yogurt

Once yoghurt has been produced and packed into containers and sealed through the yoghurt packaging machine, they are packed into cases.

Cases allow for easy distribution and also ensure the safety of the products.

Packaging cases are usually made of carton which are formed by the packaging machine before packing the yoghurt containers into them.

Carton Packaging For Yogurt

Carton packaging for yoghurt can be incorporated into a production line or used independently.

The containers or cups are first filled with yoghurt, sealed and then moved to the cartooning station to be packed into cartons.

After being packed into cartons that were previously made or erected by the same machine, they are sealed and ejected from the machine.

Tray Packaging For Yogurt

Tray packaging is fully automatic but slow because it has to go through the processes of filling the containers with yoghurt.

This is followed by organizing the containers into trays before being sealed and ejected from the system.

For all your yogurt packaging machines, contact us now.