Before investing in your next toothpaste packaging machine, read this guide.

It has all information you are looking for about toothpaste tube filling and sealing machine. Whether you want to learn about benefits, applications, classification criteria or working principle, you will find all information right here.

Let’s dive right in.

What is Toothpaste Packing Machine?

Toothpaste packer in an electromechanical machine that fills and seals toothpaste in various tubes. It can weight and print necessary information on toothpaste tubes.

Advantages of Toothpaste Packing and Sealing Machine

There are many reasons why you should consider investing in toothpaste filing and sealing machines.

It enhances the efficiency with production

Speed is needed when toothpaste production is concerned. With these machines, you get to benefit from higher yields where production is concerned.

High level of consistency

Toothpaste packaging machines work to perfection and with a high level of consistency, precision, and accuracy. Also, due to their setup, there is no way you will experience issues with the end product’s uniformity. This helps put products out there in the right light.

Simplicity in multitasking

These machines are designed to do several jobs at the same time. So, it can easily fill tubes with toothpaste and have them sealed. This is exciting since no human hands are needed.

Cost of labor is always decreased

With the use of this machine, labor costs are greatly reduced. Since these machines are automatic and work to perfection, production is never a problem.

Also, more workers aren’t needed, which reduces payments going out. All that is required is for experts to be hired to ensure the machine is well kept and maintained.

Product wastage is greatly reduced

Manually packing or filling tubes can never be easy and will lead to a lot of waste. To be safe and know you will make profits, using these machines help. They take away any issues of wastage.

These machines are designed to precisely measure paste. This way, it is able to fill tubes with the right amount that is needed. All of these ensure waste is never something to worry about.

Operating it is very easy

This machine is designed to come with an interface that makes it very easy to use. The interface is perfect for setting the machine’s working parameters.

Industries using Toothpaste Packing Machine for Other Applications

These days, you will find toothpaste packing machines being used in countless industries. These applications include:

- Hygiene – The use of toothpastes to brush the teeth helps in ensuring the right oral care is achieved. This is why these machines are valuable. You can find most companies using these machines to pack other products such as conditioners, hair gels, cleaners, and more.

- Pharmaceutical – Most pharmaceutical productions adore the use of these machines. This helps in simplifying their packing systems. Some of these medicines include ointments, analgesic lotions or creams, syrups, etc. This machine can be used as well to fill into tubes allergy treating and other skin problem creams.

- Food- For the packing of different foodstuffs into their required containers and tubes, these packing machines are used in this industry as well. Some foods that are packed with these machines include sauces, tomato pastes, mayonnaise, and more.

- Cosmetic- For various purposes like filling creams, lotions, and other beauty products into different tubes and containers, toothpaste packing machines are very much used. Even cleansers and other products can be packed with these machines.

- Pet- Pets mostly need different medications for both external and internal care. Well, this is where those that require packing with these machines come in. They are used in food product packing for pets too.

- Stationery- Various stationery products like watercolors, oil paints, and others are packed using this machine. This makes them highly valuable here too.

How to Choose Toothpaste Packaging and Sealing Machine

Before choosing a toothpaste filling and sealing machine, you need to consider the following:

- What is your production about or what does it entail?

This will be engulfed around knowing the amount of work there is to be done. The production size and quantity matter a lot when you consider these choices.

- Easy to use.

Check out the specific features the machine comes with. User-friendly machines will always be perfect since they help operators experience a smooth user experience.

Also, such machines will provide precision, accuracy, and ensure total consistency.

- Reasonably priced.

The best toothpaste packaging machine should be reasonably priced. Buying with a budget helps. So, if the cost is too much and will not benefit production in the long term, you must have that considered.

- Check your space available.

The space where you will be placing the machine makes a lot of difference. Considering the machine’s measurements as well as its dimensions and comparing them to the space you have is important.

- Level of automation.

The machine you invest in should have its automation or speed levels checked. This level should be very high. When it is high, you will love the outcome it brings.

Fully-automatic Vs. Manual Toothpaste Packing or Filling Machine

Simple packaging is assured with this type of machine. To use this type, it needs to be well programmed to ensure it works accordingly.

Such machines work perfectly for businesses on a large-scale. This is due to their need to have more tubes filled within a short period of time.

These machines save a lot of time and allow for higher production levels. Also, human interactions are very little where fully automated machines are concerned. From the process of loading, filling, to packaging, it handles it all.

The interface designed to come with these machines is where all setup and configurations are done. So, you use the interface to suit your needs. With these machines, several adjustments can be made to make it work smoothly.

Manual Toothpaste Packaging or Filling Machine

Workings here or with this type of filling is done manually. There is an operator who physically makes the machine to work.

No main power source is needed to have the tubes filled with this machine. This makes them ideal if electricity or power issues come up.

Comparing the fully-automatic to the manual toothpaste packaging machine, their clear and distinct benefits are easy to realize. However, you need to consider your specific conditions to decide which will work for you.

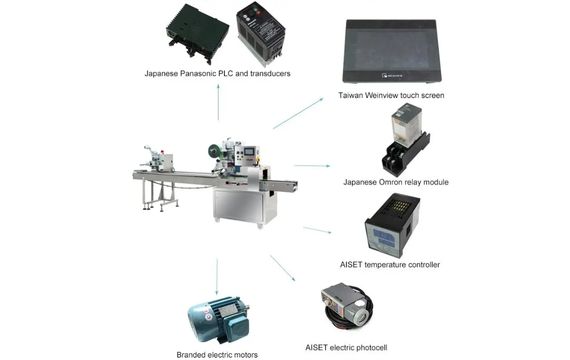

Toothpaste Tube Filling and Sealing Machine Parts

Tube filler for toothpaste are assemblies of various parts and components. Although this machine has hundreds of parts and components, we will focus on some important features.

Take a look:

Frame

Frames are made using very strong materials. This is done to ensure they can hold the whole machine very well together.

Hopper

This is a funnel like part of the machine that works by moving dispensing materials from receptacles to other units.

Tank

Toothpaste and other products need to wait somewhere before they are packed into the tubes. Well, that is the tank.

Filling Nozzle

This component is ideal for controlling the fluid flow into tubes.

Dosing Pump

For accuracy and measurement, this part plays a vital role during the process of filling tubes.

Coding Jaws

The sealing process makes the most of this part of the machine. These coding jaws work interchangeably at specific points in the finishing process to ensure the product gets to the collection unit done.

Tube Holders

The tubes when put in place to be filled need to be supported. Well, that is what this part does.

Tube Container

It is where tubes are kept before they are prepared to be filled.

Sensor

This component spots out the tube and ensure it is filled well. The inability of sensors to detect tubes can draw your production back a great deal. So, this part is very important.

Cooling Unit

This component makes at most 10 degrees of cold water available to ensure the best sealing outcomes are achieved.

Control Unit

This part mostly has the features to ensure the ideal regulations and parameters are well set. This helps to smooth the flow of work.

Motor

Automatic machines especially work on power. This means, they have a motor. It is this motor that helps in sustaining the power and ensuring the machine can work to achieve production deadlines.

Working Principles of Toothpaste Packaging or Filling Machines

Now, let’s look at the main stages in tooth paste filling and sealing process.

Step 1: Tube Feeding

This process has to do with tubes being fed to the machine to pick automatically. This selection is done towards the rotary table.

Step 2: Tube Filling

In this principle, the machine does its job by filling tubes with paste. The nozzle is what is used here. Here, the automation levels come in and will be determined by you and how you set the machine up.

Movement of tubes are made with ease using the conveyor system. This can be done electronically or manually. Under this filling principle, the following are represented more:

Vacuum Fill

This process is well completed with the vacuum pumps. Also, the vane cell feed is used. The hopper is used for filling here. This helps in ensuring consistency in filling.

Volumetric Fill

The gravity and volumetric fill is represented more here.

Gravity Fill

In ensuring measurements are accurate with tube filling, this principle comes in. Gravity does its work here by helping pastes move through these machines.

Piston FIll

Very thick pastes can be difficult to fill if the right principle is not used. This is what makes piston fill the best. Pistons are used to aid pastes reach their destinations which is the tube from the cylinder.

From filling, they go to the capping station. This is where they are capped.

Step 3: Tube Sealing

Movement to the sealing area is the next thing when filling of tubes are completed. This movement is achieved with the rotary table.

Sealing is done using mechanical clamps without delay.

Step 4: Tube Coding

Codes for manufacturing to ensure the product has an identity needs to be printed onto the tubes. This is what this process entails. Printing is done automatically using the coding unit.

When code printing of tube is done, the product is moved to the discharging chute for collection.

Recommended Toothpaste Packaging Material

In order to have toothpaste squeezed to perfection, the right material for packaging counts. Some of these materials include:

Laminated Tubes

Mostly, they come made from plastic. However, they come with a lot of protection and will have some shine, a glossy look, and elegance.

Plastic or Polyethylene Tubes

These tubes mostly come with different levels or grades. So, you need to ensure they are purchased with an understanding of their quality in mind. This will definitely help you.

Aluminum Tubes

This type of tube comes with a lot of safety and they are very unique. That is why they are recommended for products that are very delicate.

FAQs

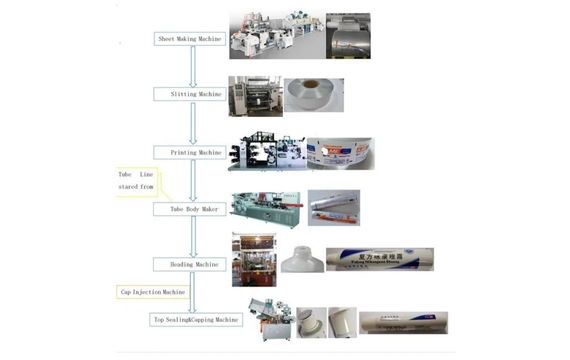

How do you Manufacture Toothpaste Tubes?

Toothpaste tubes are manufactured through the extrusion process. This is a process where plastic particles that are minute are taken and transformed.

How do you Seal Toothpaste Tubes?

There are specific tube sealing machines that can be purchased for sealing toothpaste tubes.

Is Toothpaste Packaging Machine Different from other Tube Filling Machines?

No, actually, they share many features and similarities

Conclusion

Toothpaste packaging machines come with a lot of benefits that are laudable. Their features of being durable, reliable, consistent, and easy to use will make them worthy in various industries for a long time. Hopefully, you will be able to make the right choices now to suit your needs.

Contact us now for all your toothpaste packaging machine needs.

More Resources:

Filling Mechanism – Source: Wikipedia

Ointment Tube Filler Machine – Source: Jochamp