Horizontal Flow Wrap Machine Manufacturer in China

JOCHAMP is a professional and one-stop solution provider of horizontal flow wrap machines in China for more than 15 years. We can assess the needs and requirements of our customers by providing them with a machine that is befitted to their applications and purposes.

- Passed CE, ISO9001, SGS quality system certification

- Unique sealing system to ensure excellent sealing

- A simple industrial control system, a more friendly operation

- Various types of flow wrappers to deal with various products

JOCHAMP Horizontal Flow Wrap Machine

The horizontal flow wrap machine has rich extended functions such as labeling, date coding, weighing, metal detection, empty bag kicking waste, image detection, etc. It is among the most necessary machine in the packaging industry. This equipment uses a single roll of film to individually wrap a high volume of small to more oversized products before they are placed into multi-product form fill packages for sale.

JOCHAMP horizontal flow wrap machine is developed from the finest materials and contemporary techniques. It is accessible in various mechanical units and models, and each one comes in a variety of versions with wide-ranging options for different product packaging. That offers a very high-speed operation and performance consistency, making it a perfect choice for massive applications and to increase packaging productivity.

We customized our horizontal flow wrap machine based on our customers’ specific needs and requirements. Receiving our machines is satisfying due to their sturdy construction and perfect surface finishing. If you find interested in some of our machines, you are welcome to contact us anytime.

Types of Horizontal Flow Wrap Machines

JOCHAMP Horizontal Flow Wrap Machine Advantages

Over 15 years of manufacturing and exporting experience. A variety of automatic feeding mechanisms are suitable for most products.

Guaranteed, advanced technology supports high packaging speed. More user-friendly adjustment structure, faster switching of packaging products

Complete production line and large capacity, offering a competitive price. Reduces labor costs, product damage, material inventories, and package costs.

A professional team helps you from design to installation. More servo applications to ensure packaging accuracy, ease of use, and stability.

Horizontal Flow Wrap Machine Performance Impact

JOCHAMP horizontal flow wrap machine has a compact configuration that matches any product packaging requirements, material characteristics, packaging sizes, shapes, and texture. It specializes in having a flexible and open design that enables quick packaging tasks and ensures a higher safety process and production outputs.

The mechanical construction of JOCHAMP’s horizontal flow wrap machine gives outstanding overall performance effectiveness, flawlessness, reliability, and sustainability, making it a perfect choice for small start-ups to larger packaging companies.

Horizontal Flow Wrap Machine Fundamental Features

Due to the high degree of versatility, JOCHAMP’s horizontal flow wrap machine has become essential in the wrapping and packaging industry. It consists of splendid features that make it among the most valuable machine in the industry:

- Adopts the advanced machine interfaces, system formats, and parameter settings.

- User-friendly machine.

- Any function troubles can be read easily.

- No adhesive and no waste issues.

- High sensor photoelectric tracking chart.

- The software operates all control.

- Consistent function adjustment and technical upgradation.

Horizontal Flow Wrap Machine Operation Proficiency

JOCHAMP horizontal flow wrap machine carries out advanced technology and design to achieve the best quality and efficient operations. The professional concepts of our horizontal flow wrap machine guarantees of giving an upgraded performance delivering the optimal function and high overall equipment effectiveness.

In addition, JOCHAMP horizontal flow wrap machine has the potential to handle and withstand heavy-duty wrapping jobs. Due to its high-speeding competence, it can wrap hundreds of various products in a minute. Our horizontal flow wrap machine is a custom-built machine that improves the degree of automation and production capacities.

Why Choose JOCHAMP for Your Horizontal Flow Wrap Machine

JOCHAMP gained a remarkable position being the world-best horizontal flow wrap machine manufacturer. In 15+ years in this industry, we actively participated in our large-scale packaging machines’ research, development, manufacturing, and marketing.

We designed our horizontal flow wrap machine for ease of use and fast product changeover. It has integrated system units that successfully wrap single products, even the oily, and sensitive products. The packaging style of our horizontal flow wrap machine has constantly matched the product and brand image.

JOCHAMP, also undertake a set of testing and inspection to ensure the quality performance of our horizontal flow wrap machine. Whether you require our horizontal flow wrap machine or one of our packaging machines, don’t hesitate to contact us, we can give the ideal solution for you.

JOCHAMP horizontal flow wrap machine is built intended for high established industries; some of them are:

- Food Packaging Products and Food Industries

- Dairies and Ice Cream Plants

- Drinks and Beverages

- Cosmetic Industry

- Distilleries Industry

- Pharmaceuticals & Health Care Industries

- Agricultural Industries

- Chemical and Pesticide Industries

- Every Packaging Products

Developing and innovating our horizontal flow wrap machine also gives any packaging business sector splendid advantages.

- Sturdy and ideal system ergonomics

- Maximum accessibility and efficiency

- Designed for ease of use and control

- Increased operational performance and gives desirable outputs

- Low power and energy consumption

- Long serviceable life and less maintenance

- Accommodate various product dimensions

- A variety of automatic feeding mechanisms, suitable for most products

JOCHAMP Horizontal Flow Wrap Machine Professional Advanced Services

Horizontal flow wrap machines are an automated, high-speed alternative to traditional bagging. The machines are ideal for product packing. The maximum speed is 1600 packs per minute. Reliable packing machines can aid in the detection of empty bags and the preservation of packaging materials.

Flow wrapping equipment is easy to change over from one packaging size to another. The integrated conveyor system has easily adjustable guides that adjust quickly to the needed width. Flow wrap film rolls use corrugated cores that make swapping film sizes simple. The on-board computer systems can store multiple pack specifications that can adjust trim lengths and belt speeds at the touch of a button.

High accuracy and ease of operation are ensured by precise inductors, self-regulating control systems, and sophisticated user control panels. Packing solutions that are automated to save labor expenses and increase efficiency. Stable, intelligent, and premium-quality design are the highest standards for exceptional reliability.

Improve packing aesthetics and bag length consistency with a simple and friendly tension adjustment method. Servo motors with a name brand perfectly control the speed and action commands. User-friendly software for machine operation and navigation. Highest hygienic standards: cleaning is simple and time-saving at extended intervals.

Related Product

Horizontal Flow Wrap Machine: The Ultimate Guide

Horizontal flow wrap machine is one of the many packaging equipment available today. Depending on your production requirements, flow wrap machine offer robust and reliable packaging solutions. So, before investing in your next horizontal flow wrap machines, read this guide.

A horizontal flow wrapper machine is used to seal and wrap many products in a pillow or an envelope form of plastic film at a high-speed using heat.

This helps the products in the wrapped bag increase life durability and offers protection from any risks and damage.

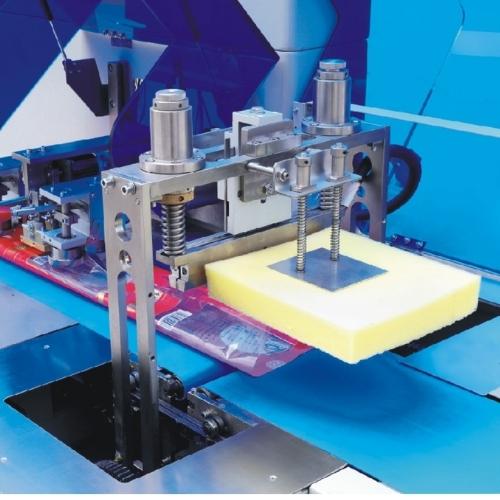

horizontal flow wrapper machine

Any product that can be put into a bag and pushed along a horizontal belt, such as a scratch card, a pack of biscuits, a chocolate bar, or a pack of tissues, is suitable for flow wrapping.

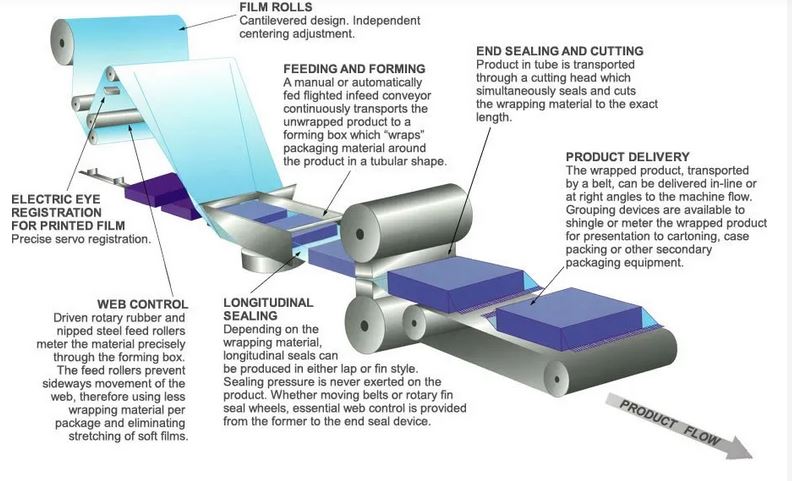

Flow wrap machine has parts that ensure high-speed rapping to an enormous range of products in large quantities, and they are as follows;

Parts of horizontal flow wrapper machine

Rotary Heat Sealer

It ensures the package is protected from any risks or damage; thus, it provides enough film sealing.

Converter Splice Detection

After detecting them on the reel, the part rejects all the markers at the belt of discharge.

Splicer

Ensures there is an automatic connection between two film reels, one that is new and the empty reel.

Pushers

They move products to be wrapped in a forward direction into the former.

Former

It is where products pass through so they can be wrapped using a sealing material layer.

Back Stand

Ensures there is flexibility in the process; hence it is made up of two spindles or reel holders.

Powered Feed Roll

The part is located on the back stand acting as a driven roller; thus, it supports the film’s movement.

Fin Wheels

When the mating edges are passed through, they are sealed and folded over to allow them to enter into the jaws of the end seal.

Infeed Conveyor

Has pushers or lugs that move products automatically or manually in the flow wrap machine to be sealed.

Film Cutting Device

It ensures the efficiency of the process of the Spicer by minimizing the number of packages that are rejected.

Self-centering Film Reel Holders

It unites the center of the film reels line to the machine by removing the mechanical adjustments of the operator.

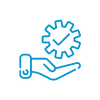

The working principle of flow wrapper machine is quite straight forward.

Horizontal flow wrapper machine has an in-feed system or conveyor systems.

It is this conveyor system than lines up individual products for packaging.

These products will move to the forming box.

Next, the forming box will create a continuous tube of film around the product you want to package.

With the help of rotary heat sealer and cutter, it will separate the items you want to package.

The machine will then seal individual items using wrappers.

Finally, all products will then exit the machine for quality inspection and shipping.

How horizontal flow wrapping machine works

Here are some of the features to look at for a reasonable horizontal flow wrap machine;

Easy To Operate

It is more convenient to modify the parameters, which is easy for the workers and the maintenance of the machinery.

Packaging Speed And Efficiency

The speed continuously improves the output, production of the enterprise, the quality of the product, and the operating cost of the enterprise is reduced.

However, the average speed of the horizontal flow wrap machine can reach 30-150 packs per minute.

All Software Control

This controls all the systems; hence they adjust the functions and upgrade the technology according to the market’s needs.

Material

The material can be stainless steel or aluminum; hence it should be durable, resistant to harsh weather, and resistant to corrosion.

Purpose

You should know what you want the wrapping machine to do; hence you should consider this as it helps you to evaluate the required qualities.

Size

The machine can be small or big depending on the work you want it to do; hence the size of the device should be enough for the function your device will work.

The bigger the machine, the higher the production, while the smaller the flow wrap machine, the lower the product production.

Cost

Ensure the flow wrap machine that you choose is of high quality and it reaches your budget limit since some can be expensive but of poor quality.

The horizontal flow wrapper machine is widely used in many industries, such as;

- Food industry.

- Household products.

- Medical and pharmaceutical industries.

- Paper products.

- Personal care products.

- Automotive and industrial.

- Frozen products.

- Toys industries.

There are many advantages when using a horizontal flow wrap machine, and some are;

- The device hinders the disturbance of the products by ensuring there is a movement of products in the package.

It creates a protective barrier that seals out harmful things that may damage the package items, like sealing out oxygen to help preserve food for a long.

- The machine helps at a high-speed packaging of the products efficiently and ensures that the life span of your products is improved to higher lengths.

More efficient packaging process increases businesses demands and make the business more attractive to potential customers.

- It reduces the resources required to help ship the products by sealing and wrapping them in few quantities.

Therefore, films can also be printed with your branding for the product to stand out on retail.

- Sealing and wrapping the products provides protection and protects them from any risks and damage.

- A horizontal flow wrap machine reduces the labor costs and increases margins, thus ensuring that the precise bag length is used.

This is every time and making sure less film Is left over.

Money saved on waste and labor can be used to invest costs and help to add to profit.

- The flow wrapped products are easy to pack thus they take up less space when stored and can safely be stored and displayed on retail.

Here is the process of installing a horizontal wrap packaging machine;

Step 1;

Select suitable width film according to product size, load the correct film roll, and fasten it on the carrier tightly.

Load the film, and fasten the holding wheel by rotating clockwise.

Therefore, the wheel should be secured closely, and the cone shape part of the inside hold wheels should carry the inner film roller.

The film’s center point should be at the same place as the film carrier’s center point so that the machine’s eye mark sensor will keep registering film marks successfully.

Step 2;

Pass the film though rollers correctly since wrong film threading will cause film wrinkle problems when running.

Step 3;

Adjust the former bag width, height, and angle position to make the film tube and let the film run very smoothly.

Adjust the former bag according to the product width with a little gap to let the product go through.

If the fin seal area is too big or the film bursts out during the process, adjust its height.

The bag former is not installed horizontally but with a 15–20-degree angle to the left-up position so that the film can be fed smoothly from the film roller to the bag former.

Step 4;

Adjust the film rolling bar’s position to make an L shape; thus, the film rolling bars can be wagged for different parts.

This makes the film have muscular tensions between the film roller and bag former.

Move the product guiding plates to the film pulling wheel place so the product can be fed into the film tube with protection from the side.

Step 5;

Use the different sizes of the bag on former plates for wrapping other size products to let the film have muscular tension during feeding.

Pass film through the fin and end seal units, and then run the machine to check which place has the wrinkle or block problem.

Put the product on the packaging machine’s conveyor for test packing.

Step 6;

The temperature should be increased with high packaging speed according to film materials and thickness.

Set machine track on, which means the machine will cut bags according to film marks, and track off, which means the device will cut bags according to to set length.

Move eye mark registration sensor to film mark’s place to set machine screen display track on instead track off.

When on film mark go through, the sensor’s light should be flashed once, and if not, adjust the sensor’s sensibility.

Click the right-side or left-side button to stop the machine and move the film place.

Step 7;

Adjust the film pulling wheel position since the standard work is not horizontal but a little left-down side; thus, the film can be pulled down and not burst out during the running process.

If the position remains horizontal, the fin seal will probably overeat film; hence, adjust by wagging the left and right sides.

Adjust iron plate closing gaps with different film kinds of film, and if the film is blocked before the iron plates, it means the plate closing gap is too narrow and needs to be adjusted.

Step 8;

Connect two cone shape parts with a synchro belt to adjust the speed between the fill pulling wheel and the sealing wheel, making the seal line straighter.

Take a packing test after the machine makes an empty bag smoothly; hence put a product on the infeed conveyor and run the engine to check the product position inside the film tube.

After adjusting the pusher’s position hand wheel, run the machine with the product sample to recheck the product position until the product can be fed to the correct place

The following are types of horizontal flow wrap machines;

- On-edge flow wrapper.

- Side seal flow wrapper.

- Inverted flow wrapper.

- Fin seal flow wrapper.

- Shrink flow wrapper.

- Dual lane flow wrapper.

- Wet wipe flow wrapper.

- Flow wrapper basics.

A horizontal flow wrapper machine is used to seal and wrap many products in a pillow or an envelope form of plastic film at a high-speed using heat.

An overwrapping machine is a machine that uses heat folded film to fold a single item or a bundle of products around.

- The Overwrap machine is designed to over wrap the products by wrapping flexible packaging material, while the horizontal machine is intended to cover developments at the bottom.

horizontal flow wrapper machine

- The Overwrap machine is suitable for every application, which needs longitudinal sealing at the bottom of the product.

A horizontal flow wrapper machine is suitable for every application, which requires flat sealing at the bottom of the product.

- Both machines are versatile and flexible; hence they are used to wrap around a group of products like food, bakery, and many other products.

- The Overwrap machine uses less heat than the horizontal flow wrapper machine and produces enclosed bundles using cheap film.

overwrapping machine

- A pouch packaging machine is used to automatically seal and fill pouches of granule products like tea, powder, and milk powder.

A horizontal flow wrapper machine is used to seal and wrap many products in a pillow or an envelope form of plastic film at a high-speed using heat.

flow wrap packaging machine

- Both machines help fill and seal products which helps to protect them from any external interference that can tamper with their weight or quality.

- Both pouch machines and horizontal flow wrap machines are easy to use, versatile, and flexible devices; hence they fill and seal products in bags or cartons for shipping.

- Most pouches are easy to carry, thus making them more versatile than single-use bags and other packages.

pouch packaging machine

When you perform regular preventive maintenance inspections, you will have enough time to make corrections and save money for repair.

Good maintenance cannot only extend the machine’s service life but will also reduce the occurrence of failures.

Let’s talk about how we can maintain a horizontal flow wrap machine.

- Check the components of the machine before starting the packaging process; hence make sure they are intact and tighten the screws and nuts of each part if they are loose.

- Use clean water or compressed air to blow out dust and clean the unloading screws if there is any blockage.

- Replace the toolset of the horizontal flow packaging machine if it is not sharp enough; hence add the oil to the tool transmission part using the dipping method.

- You should stop the machine and notify the maintenance personnel if there is any abnormal phenomenon like a loud sound; the vibration is strong.

- Lubricate various parts of the packaging machine after use to ensure the functions can typically work again to prevent damage to the elements.

- Record the machine’s malfunctions whenever repairing the appliance hence facilitating future needs.

- Set product carriers and discharge guides properly as they move through and exit the cutting and sealing head.

Some of the main limitations include;

Not Suitable For Vacuum Packaging

Vacuum packaging usually uses a bag-type or stretch film packaging machine; thus, the flow wrapper machine is unsuitable for this.

Manual Feeding Is Required

The manually packed products are placed on the conveyor belt and packaged even though the horizontal flow wrapper machine has packaging speed.

Bandwidth Is Not Adjustable

It can take a lot of time to adjust the machine since the bandwidth adjustment can be inconvenient, making it difficult to change.

As you can see, horizontal flow wrap machine plays an important role in packaging and labeling applications.

For all your horizontal flow wrap machines, contact us now.