Inverted Flow Wrapper Manufacturer in China

JOCHAMP is the only firm in China that uses the most modern flow wrappers automation. Inverted flow wrappers from JOCHAMP come in a variety of sizes and incorporate a number of typical features. We may customize it for our clients’ needs, and there are several models to choose from.

- Maximum speed 190ppm

- Thick body, less running vibration

- Inverted design is ideal for difficult-to-handle products

- Tool-less operation structure for easier maintenance

JOCHAMP Inverted Flow Wrapper

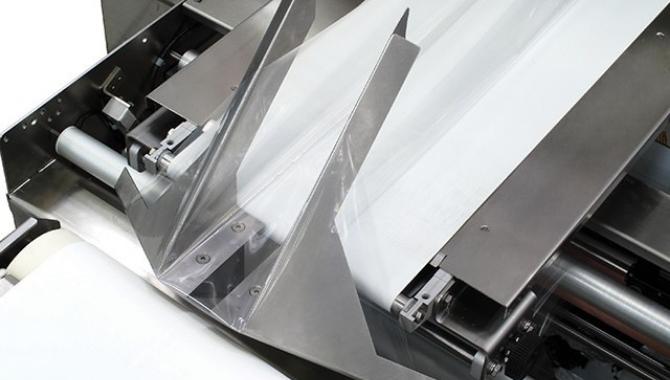

The inverted flow wrapper was created to wrap items that are difficult to handle or package with a standard flow pack machine. And because of its inverted design, the packaging film is supplied from below, allowing the product to be placed on top and gently transported from the feed area to the sealing and cutting stations. Wrappers with an inverted flow can be utilized for a variety of products and purposes. This approach is best for delicate, friction-sensitive, sticky, or loose products.

The high-performance inverted flow wrapper is built for dependability and simplicity. It employs servo motors to provide for rapid and easy changeover and adjustment, as well as a reduction in product and film waste and reduced maintenance costs. Whether it’s for food packaging, medical packaging, or hygiene packaging, JOCHAMP can provide a flexible packaging solution that’s specific to your business.

JCD-280 Inverted Flow Wrapper

The machine uses the packaging film to feed the packaging film from the bottom of the machine upside down. This method is suitable for some special products, such as fragile, sensitive to friction, sticky or loose products.

- Inverted design is ideal for difficult-to-handle products

- The product will be loaded directly onto the packaging film, with no transfer points

- Independent PID temperature control system

- Easy adjustment and switching of products

- More accurate and stable operation

- low noise

- Thick body, less running vibration

JCD-280

- Technical Parameter

- Features

- Optional

| Model | JCD-280 | ||||

| 1 | Max Production Capacity | 50-190 bags/min | |||

| 2 | Packing shape | Various shapes | |||

| 3 | Packing Range | L | 150-450mm(Single Cutter) | 70-260mm(Double Cutters) | 30-130mm(Three Cutters) |

| W | 25-110mm | 35-100mm | 25-80mm | ||

| H | ≤50mm | <50mm | <35mm | ||

| 4 | Max. Dia.of Film | 300mm | 300mm | 300mm | |

| 5 | Max.Width of Film | 350mm | 350mm | 350mm | |

| 6 | Gross power | 3kw | 3kw | 3kw | |

| 7 | Power supply | 220V 50-60Hz | 220V 50Hz | 220V 50Hz | |

| 8 | Gross Weight | 900kg | 900kg | 950kg | |

| 9 | Overall Dimension | 4300×850×1550mm | 4300×850×1550mm | 4300×850×1550mm | |

Inverted design is ideal for difficult-to-handle products

The product will be loaded directly onto the packaging film, with no transfer points

Independent PID temperature control system

Easy adjustment and switching of products

More accurate and stable operation

low noise

Thick body, less running vibration

Tool-less operation structure for easier maintenance

Product contact surfaces for food hygiene and drug safety

Two sets of cold and hot middle sealing system to ensure the sealing is firm

PLC control system with HMI man-machine interface

Maximum speed 190ppm

Passed CE, ISO9001, SGS quality system certification

Free sample packaging test

Siemens, Schneider, SMC, SICK and other internationally renowned brands of electrical appliances and accessories

Standard machine in stock, ready to ship. Customized machine as fast as 15 days delivery time

competitive price

Thermal transfer date printing

stainless steel cover

Automatic feeding system

double knife

exhaust structure

Web/vertical/horizontal sealing

Flat/wavy cut style

End seals with hanging holes

export finishing machine

metal detector

Checkweigher

Inverted Flow Wrapper Working Principles

The inverted flow wrapper is a user interface control with a user-friendly interface. It has stainless steel frames and surfaces for optimal cleanliness and longevity.

- The machine’s memory feature makes it excellent for flexible packing processes.

- Each servo motor has overload-sensing features to protect parts and goods from being destroyed prematurely.

- For increased speed and cost savings, an auto-splicer option is available.

- The manufacturing is versatile due to an adjustable forming box.

- Easy troubleshooting is made possible by the self-diagnosis feature.

- Servo motors are long-lasting. Low noise and good productivity.

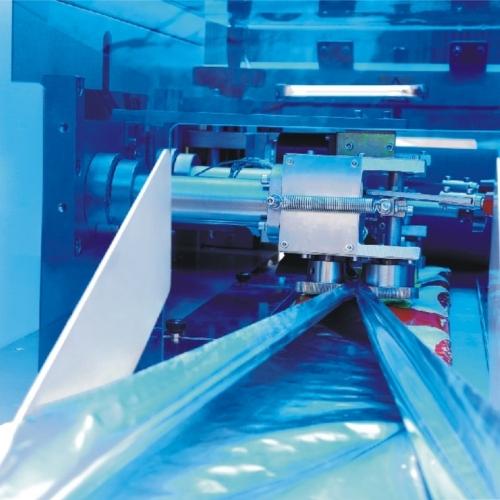

Inverted Flow Wrapper Details

- Inverted design: ideal for items that are suitable for wrapping but are difficult to handle or package. The product is loaded directly onto a moving web of film, eliminating the need for transfer points.

- Advanced and innovative: Capable of high-speed handling of tough items.

- User-friendly software: To make machine operation and navigation easier.

- Automatic bag length detection: If the packing film contains eye markings, the machine determines bag length automatically during operation, eliminating the need for human setup.

- Lower production cost: Labor expenditures, product damage, inventory levels, and packaging costs are all reduced.