High-Speed Shrink Wrap Machine Manufacturer

JOCHAMP is a leading manufacturer of high-speed wrap machines with over 10 years of experience. These machines are designed for durability, efficiency, and long-lasting performance.

- One-year quality assurance

- Unique heat-sealing system

- 250ppm speed

- More beautiful packaging

JOCHAMP High-Speed Shrink Wrap Machine

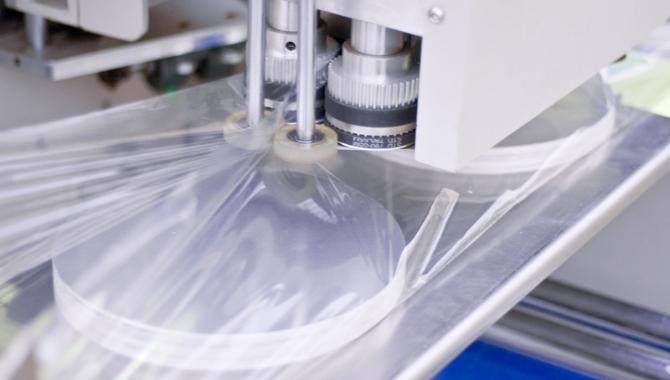

A high-speed shrink wrap machine is a cost-effective solution to make product sealing, longer shelf-life, and waterproof. It makes the product with a beautiful appearance, easy to transport, and smaller volume. JOCHAMP high-speed shrink wrap machine automatically shrinks and forms a heat-shrink bag material around products. As a result, the machine provides uniform, secure packages.

Our high-speed shrink wrap machine is suitable to wrap a huge range of products such as collapsed boxes, picture frames, rolls of thread, food trays, construction materials, windows, and many more. JOCHAMP is a leading high-speed shrink wrap machine provider in China that provides free sample tests. All our machines are guaranteed full certifications like CE, cGMP, ISO9001, SGS, etc.

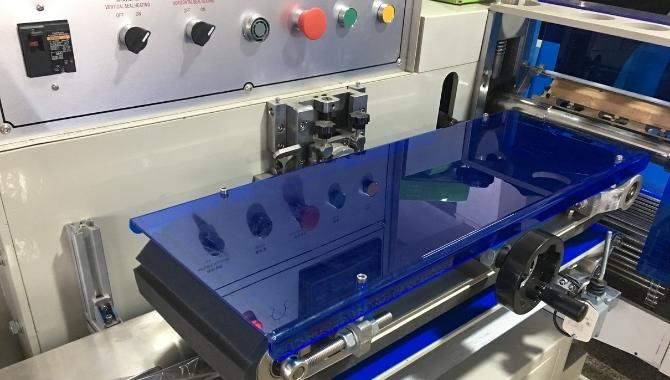

ZWG-590/500 High Speed Shrink Wrap Machine

Horizontal heat shrink packaging machine, the speed can reach up to 180ppm, it is suitable for a wide range of applications, and it is compatible with round and smaller products.

- 50-180ppm speed (depending on product size)

- Accept spherical or smaller products

- At least 20% packaging material savings

- Full servo precise control

- High sensitivity photoelectric eye color mark tracking, mathematically input the sealing position, so that the sealing position is more accurate.

- Temperature independent PID control, better to cut and seal the film

ZWG-590/500

- Technical Parameter

- Features

- Optional

| Model | ZWG500 | ZWG590 | |

|

Packing size |

L | 80mm-450mm | 100mm-450mm |

| W | 20mm-200mm | 10mm-200mm | |

| H | 5-90mm | 35mm-70mm | |

| Packing speed | 30-150pcs/min | ||

| Max film size | ≤590mm | ||

| Film Type | POF PVC Shrink film | ||

| Power consumption | 4.75KW+13.5KW | ||

| Power supply | Front part:220V,50HZ/60HZ: shrink tunnel:380V,50HZ/60HZ | ||

| Front machine dimension | 4900*1130*1500mm | ||

| Shrink tunnel dimension | 2600*600*1750mm | ||

| Weight | 1200KG+600KG | ||

- 50-180ppm speed (depending on product size)

- Accept spherical or smaller products

- At least 20% packaging material savings

- Full servo precise control

- High sensitivity photoelectric eye color mark tracking, mathematically input the sealing position, so that the sealing position is more accurate.

- Temperature independent PID control, better to cut and seal the film

- Location stop function, no sticking knife, no waste of film.

- When cut to the product, automatic inversion, restart directly after boot, more convenient operation.

- Patented hot air circulation shrinking furnace, shrinking more closely, better aesthetics, more energy saving

- Patented waste film recycling system, less interruptions and flatter waste film rolls

- Passed CE, IOS9001 quality system certification

- Omron, Mitsubishi, Siemens, Schneider, SICK, SMC and other internationally renowned brands of electrical appliances and accessories

- The whole system is equipped with HMI man-machine industrial control system as standard, which is easy to operate and powerful.

- Intelligent fault detection system, the fault point and fault cause will be displayed on the screen intuitively

- Patented shrink film forming structure, easy adjustment of shrink film forming, faster product switching

Date coding (inkjet, laser, thermal transfer)

Labeling Machine

Electrostatic sealing structure

easy tear

automatic feeding device

The JOCHAMP Advantage

We own a 3000+ Square Meter factory, 50 strategic Machinery Factories, and an Experienced Technicist.

JOCHAMP has a qualified R&D team, and state-of-the-art equipment, and provides over 100+ solutions.

We adopt branded equipment from Omron & Siemens, advanced testing facilities, and strict quality control.

We support 24 hours online service and pprovides quick-wear parts. Also, overseas service is available.

High-Speed Shrink Wrap Machine Benefits

- Cost-Effective – The machines allow the user to save labor costs.

- Attractive Product Appearance – The protruding corners are minimized while providing slimmer sealing lines.

- Less Waste – The shrink wrapper produces film waste during packaging and sealing products. The sealing knife allows the waste film to reduce by about 15%.

- Online Packaging – Our high-speed shrink wrap machine is more intelligent due to its three servos. The production machine can be attached to the shrink wrapper and serves as a packaging production line.

- Smaller Footprint – The machines allow to change the work of shrink wrappers by 5L.

High-Speed Shrink Wrapper Capability

- Sealing Knife: The machine has a reciprocating cutter and hob design to follow the product movement. Greatly improves the efficiency of the production.

- Feeding Mechanism: Provides a uniform speed through servo control.

- Bottom Sealing Knife: Provides aesthetic and firm packaging and reduces 15% waste film.

- Waste Film Recycling Device: It allows the waste film to be moved on the paper tube during recycling.

- Industrial Control System: It enables the fault to display on the touchscreen and allows the operator to grasp the machine’s operating status easily.

Customized Services

JOCHAMP high-speed shrink wrap machines are great for packaging and feeding solutions for round products like tennis balls, oranges, bath bombs, etc. Here are some of our custom high-speed shrink wrap machines:

- Packaging Solution for Cylindrical Shapes: We can custom wrapper packaging solutions for spherical products such as aluminum foil rolls, toilet paper, wallpaper, plastic wrap, garbage bags, etc.

- Bottle Shrink Wrapper Packaging Solution: JOCHAMP can custom high-speed shrink wrap machines for bottles including shower gel, shampoo, pesticides, beverages, etc.

- Solution for Carton Shrink Wrapper Packaging: Protective packaging or shrink packaging is a common packaging solution for cartons because it is contaminated with dust easily.

If you want a smart packaging solution, please contact us for more customized shrink wrap machines.

Choose JOCHAMP to Custom Your High-Speed Shrink Wrap Machine

If you’re looking for an integrated system solution for your shrink wrap application, JOCHAMP is the right place to come. Our high-speed shrink wrap machines can be customized to match your special applications. Custom high-speed shrink wrapper brings a lot of advantages – minimal graphic distortion, flexible metering and collating, multi-stream capability, and quick changeover.

JOCHAMP is a leading high-speed shrink wrap machine manufacturer in China with 20+ after-sale service teams and 15 mechanical engineers. Our machine is manufactured with branded components from Siemens, Mitsubishi, Schneider, Panasonic, and more. Every detail of the machine is fabricated based on our strict quality control system, from raw materials, assembly, and testing to shipping.

JOCHAMP High-Speed Shrink Wrap Machines

Our high-speed automated shrink wrappers allow you to wrap a product in an efficient and quick manner. Our latest shrink wrap machines include the following:

- Heat Sealers: Enable to seal of the shrink wrap material’s open ends. They come in different forms and sizes depending on production requirements.

- Shrink Tunnels: They are designed for large operations of shrink wrap applications.

- Fully Integrated/Stand-Alone System: It maximizes speed and quickly handles large pack patterns and size ranges.

JOCHAMP high-speed shrink machine can utilize different materials to package products. Mainly are PE, OPP, POF, and PVC. However, POF (polyolefin) shrink film is recommended to use due to its durability and flexibility. These materials are FDA-approved safety materials. POF shrink film has the following properties:

- Low-Cost

- Flexible

- Environmental Hygiene

JOCHAMP High-Speed Shrink Wrap Machine for Different Industry

The transparent appearance of food can make them look fresher. Our high-speed shrink wrap machine is widely used in the food industry using FDA-approved, harmless, non-toxic POF film for longer life.

Our high-speed shrink wrap machine can make beverage packaging more convenient. Most ready-to-eat beverages enhance their sealing performance through these machines.

The household industry has a lot of products. Our shrink wrapper is a great machine to keep the product clean and protected. These machines are also suitable for promotional items.

Protective packaging or shrink packaging is crucial for products in the personal care and cosmetic industry. Their primary use is to improve the product’s appearance and protect the product.

The stationery industry and offices need a clean appearance of products. The greatest use of shrink packaging in the office stationery industry is to protect the products from dust and moisture.

In the electrical and hardware industry, their product contains metal. The shrink packaging allows the product not to be oxidized. JOCHAMP offers high-speed shrink wrap machines for different industries.

Related Product

High Speed Shrink Wrap Machine: The Ultimate Guide

Choosing reliable high speed shrink wrap machine save both time and cost. It guarantees seamless packaging. In this guide, you will find all information about high speed shrink wrap machine.

Guarantees Protection

High-speed shrink wrap forms a highly tight seal when heated, ultimately protecting the contents of the packaged objects.

Once sealed, the artifacts are shielded from damage brought on by moisture, dirt, or dust.

Durable

It is made of robust and long-lasting plastic. It is challenging to tear or pierce.

High-speed Shrink wrap provides more security because, unlike other materials, it does not weaken or become brittle in the presence of adverse weather.

It also does not sag or become loose.

high speed shrink wrap machine

To protect objects from the sun’s damaging rays, some varieties of shrink wrap even have a UV protection feature.

Assists with Branding

High-speed Shrink wrap also can be customized with colors, phrases, images, and logos to help advertise products.

The product carries the brand’s logo from the assembly line to the customer. With this marketing technique, a brand’s visibility to potential buyers can rise.

Affordable

Usually, high-speed Shrink wrapping is a cost-effective solution because it only needs two materials—heat and plastic—to operate.

Although the cost may vary depending on the type of plastic used, the technique is still less expensive than the benefits it provides

Guarantee Convenience

The size of the item to be wrapped does not matter with a high-speed shrink wrapping machine.

To protect the product from moisture, gaming pieces, candies, and other hardware are frequently shrink-wrapped, as well as minor electrical lines.

· Automatic Feeding System

This capability aids in accelerating the machine’s process. Check for a machine with a more extensive automatic feeding system when shopping for a high-speed shrink wrapping machine.

· Fully Integrated PLC And HMI System

Additionally, it’s crucial to opt for a machine that can function more quickly thanks to this aspect.

· Automatic Forming Closure For Packages

With this characteristic, high-speed shrink wrapping machines make work more manageable from the beginning to the operation’s completion.

· Automatic Sealing System

It’s crucial to look for a machine with an independent sealing system that can function without human intervention.

· Easy To Operate Features

Choose a simple machine to run, especially if it has a manual and can be handled without a skilled specialist.

· Reliable And Fast Conveyor System

Since it moves quickly, the high-speed shrink wrapping machine with this capability will aid in boosting productivity.

It is crucial, particularly for enterprises handling high output.

· Sealer Speed, Size, And Voltage

It is essential to consider such functionality because it will be able to predict how quickly your high-speed shrink wrapping machine operates.

· Pneumatic Systems

Another element, which is particularly significant to consider for the high-speed shrink wrapping machine, is transmitting power using compressed air.

· Sensor For Controlled Operations

Look for a machine with this aspect so it can identify any errors or things that need maintenance.

· Tunnel Speed And Voltage

It’s also a good idea to inspect the high-speed shrink wrapping machine to determine how quickly it can operate using minimal power.

According to the length and height of the product, the capacity of high-speed shrink wrapping machines ranges from Low Capacity to High Capacity.

It is commonly measured in packages per minute.

Small Capacity

These manually operated high-speed shrink wrapping machines can produce 5 to 10 packages each minute.

The total packed items per minute produced by these machines depend significantly on the experience level of the operator who operates them.

Medium Capacity

This group includes semi-automatic L sealers. The sealing arm is automatic in high-speed shrink wraps that operate semi-automatically.

The operator can now have the product in the line, ready for sealing thanks to this automatic motion.

The typical output target for semi-automatic shrink wrapping machines ranges from 10 to 25 packages per minute.

A Large Capacity

Fully automatic high-speed shrink wrappers are machines with high capacity.

If desired, these systems can be integrated into your manufacturing process.

They don’t need an operator because they are outfitted with conveyors and several sensors, which maximizes output and reduces costs.

Automatic shrink wrappers can wrap between 25 and 80 packages each minute.

Polyvinyl Chloride (PVC)

PVC is strong and used in various products, including household goods and building projects.

PVC is used in rigid packagings, such as blister and clamshell packaging, and flexible packagings, such as shrink wrap and bagging.

It is advised to use it in spaces with good ventilation.

Polyethylene (PE)

For heavier, bulkier items like multipacks of beverages, utilizing LDPE over the other types of shrink packaging would provide the advantages of greater strength and longevity.

These wraps are also printable, so great graphics can be added while still upholding the necessary image and strength.

Polyolefin (POF)

The “premium” shrink wrap is made of polyolefin, which is incredibly robust and adaptable.

Several polyolefin materials, such as a cross-linked wrap, offer great tensile strength and exceptional clarity for high-speed packaging applications.

Additionally, cross-linked wrap reduces the accumulation of machinery’s sealing parts.

High-speed shrink wrapping machines typically operate without human intervention during each cycle.

The most sophisticated and creative machines have a conveyor system that brings the pallet into place before the shrink wrapper starts wrapping quickly.

high speed shrink wrap machine

Additionally, they may adjust each wrap according to the load’s height and weight utilizing sensors. Conveyorized wrappers will move the pallet once the film has been cut and sealed so that subsequent loads can start the wrapping process.

In contrast to Semi-automatic shrink wrap machine operations, which need a human operator to operate the device.

They are an excellent choice for medium- to low-volume applications.

The shrink wrapper’s operator loads a pallet onto it and arranges the shrink wrap film tail so the procedure can start.

The machine then wraps the plastic film around the pallet load using its automatic features.

The operator needs to make room by removing the pallet for the following load.

Semi automatic shrink wrap machine

I-Bar Sealer

A single sealing bar on an I-Bar Sealer, a high-speed shrink wrapper technology, seals the wrap to encapsulate the product.

I-Bar machines are typically used in processes with smaller output since they perform poorly at high speeds.

L-Bar Sealers

L Sealing Shrink Wrappers are the best high-speed shrink wrapping machine applicator for smaller product sizes.

As goods pass underneath, a heated arm is raised and lowered.

The product is then wrapped with heated shrink film. It guarantees that each product receives the appropriate amount of shrink film.

Foot Sealers.

A good choice for quickly wrapping polybags and shrink bags. There are two types and numerous widths offered.

With foot-operated sealers, a standard flat sealing wire is included.

The film is not cut and sealed simultaneously by the flat sealing wire. It is an excellent replacement for poly bags.

Yes, it is Ideal for activities requiring medium- to high-speed output. There are many different shapes and sizes of shrink tunnels.

Shrink tunnels significantly speed up the production of shrink wrapping.

We advise anyone who wraps more than 150 items each day to think about getting a shrink tunnel.

Below are some tips involved in choosing a system conveyor for the shrink high-speed wrap machine:

Quality

Make sure to conduct thorough research and use a high-quality conveyor system.

The greatest quality will help your high-speed shrink wrapping machine run smoothly throughout the entire process and prevent easy breakdowns during use.

We advise consulting with someone if you’re unsure before making a decision.

Size And Design

More is not always better when it comes to the components that make up a conveyor system; picking your conveyor system.

You must also take into account how much room you have available.

You must pick adequately sized equipment for the available space and function as efficiently as possible.

The Material Type You Are Moving

The material you handle in your operations is possibly the most crucial factor when selecting a conveyor system.

To select the best conveyor system, you must be aware of factors like temperature, moisture content, and abrasiveness of your material.

Operation Type

The sort of operation that impacts the conveyor system style you select. When it comes to material handling operations, there are two primary groups.

One of them is referred to as transfer. Simply put, this entails transferring goods from a pick-up point to the specified drop-off site.

Feeding is the name of the other material handling procedure.

Split Seals

It might be due to a roll of film that is too thin or defective; ensure there aren’t any extra holes or perforations and that the perforations are in the right places.

Ensure your sealing wire is clean and at the proper temperature.

Too Much Time Is Needed To Seal Shrink Bags

The length of time it takes for the film to seal after the seal’s jaws are closed, or dwell time, varies. Increased dwell times signify a low temperature and vice versa.

Angel Hair

These tiny plastic threads connect the product to the plastic film’s sealed area.

This problem is brought on by insufficient heating and can make the finished product ugly:

As unequal clamp bar pressure can result in choppy or incorrect cuts, check the sealing wire or bar for malfunction or temperature concerns.

Hole Resembling A Zipper

On the surface of the shrink film, there are sporadic zipper-like perforations.

Check the sealing machine’s venting device after tearing the shrink film with the venting device; The number of venting holes can be increased because there aren’t enough.

Film Flaps Along The Seal Corners

Increase air evacuation by making sure perforations are located strategically to lessen the appearance of “dog ears.” Reduce the size of your bag as well.

Then reduce the conveyor speed while raising the tunnel temperature and air velocity. Last but not least, direct airflow from the tube to the ends of the package.

Dimensions

It is wise to estimate the sizes of the products that must be packaged in advance. Make sure to measure all of the products accurately.

It will make finding the machine that will satisfy the needs easier.

Take the width, height, and length measurements to ensure that you buy a machine that will function as promised.

Deliberated Method Of Wrapping

The three primary types of wrapping products are as follows. Tubing, center-view, and bags are packaged using a high-speed shrink wrapping machine.

The purchaser should seek advice from the businesses that use this equipment for wrapping or packing various types of goods if they are unsure of the best models.

It will assist the buyer in selecting the ideal machine for their company.

Price

When selecting a high-speed shrink wrapping machine, the machine’s pricing is a crucial consideration that should never be overlooked.

One must purchase a model that is both effective and reasonably priced.

Pay for a simple machine, but be careful to bargain when there are special offers and discounts. However, several manufacturers offer the highest-quality equipment at costs that are likely to meet your budget.

Some of the applications include packaging:

- Honey

- Dry syrup

- Edible oil

- Electrical components

- Stationary

- Rubber adhesive

- Glue

- Dental products

- Shampoo

- Cosmetics

- High performance is made possible by continuous packing that doesn’t use STOP and GO chaotic supply of items of various lengths.

- Simple to use and essentially maintenance-free

- With the Emergency Heating option, there is no downtime. The heating emergency operation can be employed to sustain production during a thermos couple break.

- PLC is not used. Applications with a Windows operating system. Product switching happens instantly.

- Packed in a film bag with precise geometry.

Silicon Seal Strip

Since it comes into touch with the wire when the sealing bar is dropped, this component of high-speed shrink wrapping machines is utilized to seal wires.

The silicon seal strip can be used opposite before being replaced on some wire machines.

A Teflon T ape

Teflon tape is typically used for plumbing, adhesive pipes and backings, and gas connection fittings. However, depending on the machine design, hot knives or sealing wire are used by shrink wrap sealers to fix and heal the film together.

Teflon tape provides excellent protection from temperature to a sealer.

Fuse

Comparable to other electrical devices, Fuse-equipped high-speed shrink wrapping machines are protected from electrical flows.

Transit Channel

The porcelain transit channel is where the micro knives are positioned. The processing of thousands of seals requires that this component be replaced with a fresh one.

On the other hand, if the machine requires a new transit channel if the micro knife can be removed from the transit channel with ease after sealing.

Silicone Sealing Bar

At the base of a wire, a sealer is where you’ll find this component of a shrink wrapping machine.

The silicone sealing bar pushed the hot wire against the shrink wrap if the sealing wire was pushed against the shrink wrap.

The shrink wrapping process consists of 3 steps:

Step One: Product Grouping

The products are grouped.

In slower machines, the product is fed down every single lane, and grouping is accomplished internally by repeating pneumatic or electric pusher strokes (or lifter.)

The product is introduced in multilane or pre-collated outside of the machine in quicker machines.

Step Two: Bundle Forming

The products are bundled together with a sheet of shrink film. Currently, there are two primary methods for packaging the product:

- Through cutting and sealing with two rolls and a heated knife.

- As well as employing a single roll for tunnel sealing while cutting with a cold knife.

Step Three: Heat Shrinking

The bundle moves through a heated area of the high-speed shrink tunnel, where hot air is circulated to shrink the film and mold it to the shape of the products inside.

When the pack is outside, forced air cooling is used to cool it and tighten the film, creating a semi-rigid pack ready to be stacked on a pallet or used in subsequent packing.

For all your high speed shrink wrap machines, contact us now.