Edge Sealing Machine Supplier

Jochamp has more than 10 years of manufacturing history. We lead in supplying the best, multi-functional edge sealing machines. Complete series is available, ideal for the e-commerce industry, chemical industry, and the commodity industry.

- Accommodate various bag sizes and shapes

- Various models can seal bags weighing 0-50kg

- User-friendly man-machine interface (HMI)

- Offer ODM and OEM services

Custom Edge Sealing Machine Supplier – Jochamp

Edge sealing machine is intended to seal the bag’s end /edge portion. This machine is primarily used to seal filled bags, especially those containing furniture items such as chairs or similar items. It can seal different thicknesses of PE film/bag. With heavy-duty design yet they guarantee low noise edge sealing operation.

Jochamp is the trusted edge sealing machine manufacturer in China. We provide them with compact design, higher efficiency, and heavy-duty. We also offer customization for our OEM customers at affordable Asian rates.

Please contact us for your inquiries!

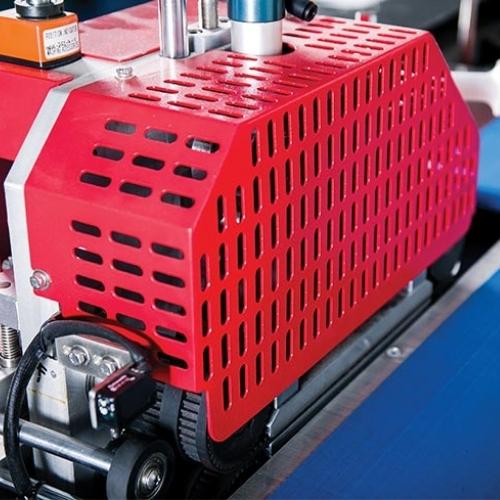

BF-450 Edge Sealing Machine

The side seal of the machine adopts continuous hob sealing and cutting mode, which breaks through the length limitation of packaged products.

- Unlimited pack lengths

- Faster speed than L type

- Save at least 15% packaging material compared to L type

- Acceptable product height over 300mm (customized product)

- Small footprint

- Independent PID temperature control system, precise temperature control, energy saving

- Multi-channel spraying process on the fuselage, corrosion resistance, easy to clean

BF-450

- Technical Parameter

- Features

- Optional

| Model | BF-450 | BF-550 | BF-650 | BF-750 | BF-850 | BF-950 | Shrink tunnel | BS4525N |

| Packing height |

≤150mm |

Power supply

|

380V/50-60HZ

|

|||||

| Packing Width | ≤350mm | Power

|

12KW

|

|||||

| Packing size | width+height≤400mm | width+height≤500mm | width+height≤600mm | width+height≤700mm | width+height≤800mm | width+height≤900mm | Conveyor speed

|

0-15m/min

|

| length No limit | ||||||||

| Conveyor speed |

0-15m/min |

Machinical dimension

|

1900x720x1350mm

|

|||||

| Application film |

POF Folded film |

Tunnel size

|

1500x450x250mm(Width can be customized as customer’s product increase)

|

|||||

| Platform height | 780-850mm

|

Weight

|

130KG

|

|||||

| Power | 1.35kw | |||||||

| Air pressure | 5KG/㎡ | |||||||

| Main material | Carbon steel

|

|||||||

| Weight | 300KG | 320KG | 340KG | 360KG | 380KG | 400KG | ||

Unlimited pack lengths

Faster speed than L type

Save at least 15% packaging material compared to L type

Acceptable product height over 300mm (customized product)

Small footprint

Independent PID temperature control system, precise temperature control, energy saving

Multi-channel spraying process on the fuselage, corrosion resistance, easy to clean

Circulating hot air shrinking furnace makes the packaging film heat more evenly and saves energy

Constant temperature type super-grade aluminum alloy sealing cutter, anti-sticking, fine sealing line, mp coking, no smoking, zero pollution

All conveyor belts are covered with PTFE heat insulating pipes, without ironing hands or damaging membranes.

Conveyor motor adopts VCT motor, which has long service life and low noise.

The size of the package can be adjusted arbitrarily without changing the mould.

Date coding (inkjet, laser, thermal transfer)

Labeling Machine

Round product hemming machine

Feed conveyor belt

export conveyor belt

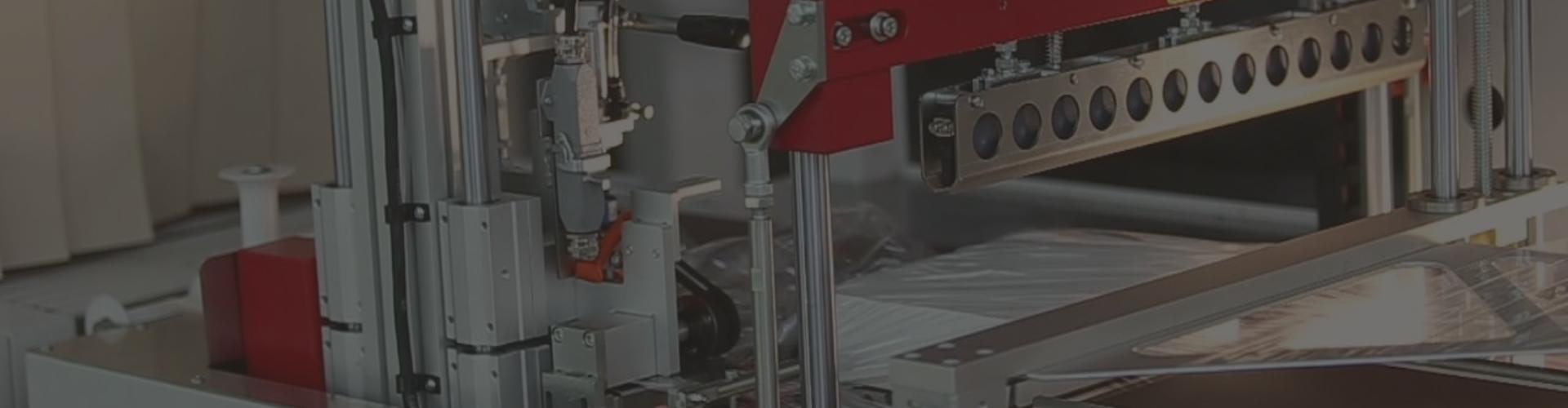

Main Function of Edge Sealing Machine

Jochamp series of edge sealing machines is doing an excellent job of sealing the top and bottom flap edges. They can be used on completely automated, operator-free lines. It is intended to eliminate the need for high-cost hand taping of the 4 edges of random-sized containers.

If you want the best packing solution and an immediate decrease in hand taping expenses, our edge sealing machine is for you. It ensures a unique sealing system, easy to clean, and easier to maintain. For the bulk orders, please contact us.

Work With Us!

All edge sealing machines we offer ensures consistent performance and long-lasting durability. It evenly seals the edge portion of bags in the packaging process. The machines completely passed the required standards such as SGS, ISO9001, and CE quality system.

Whatever industry you are part of, our team is your perfect partner for more efficient, high precision edge sealing machines. We have many years of experience in this field and we guarantee a user-friendly machine, with the maximum speed of 1600 packs/minute.

Related Products

Edge Sealing Machine: The Ultimate Guide

Edge sealing machine plays a critical role in packaging systems. It helps you secure all packaging before shipping or warehousing. This guide will help you choose a reliable and efficient edge sealing machine.

It is often an impulse heat machine that is primarily developed and excellent for sealing cartons or sealing cases’ corners and ends.

Depending on your production line, this equipment is available in manual and automation versions.

Edge sealing equipment is frequently helpful to have on hand if you work with delicate and mass-produced goods.

edge carton sealing machine

Edge sealing machines are typically simple to use, adaptable, quick, and economical.

- Speed Production

The edge sealing machine’s production speed is crucial, mainly depending on the work you currently have to do or the projects you have coming up.

It will impact the edge sealing machine purchase decision.

- Machine Configuration

You may verify the machine’s weight and dimensions right here. The edge sealing machine you buy will depend on your available workspace.

Check the parts’ accessibility because they are essential for upkeep and repairs.

- Energy Consumption

Ensure that the edge sealing machine’s energy usage aligns with its production level. High power usage will raise your total cost of production.

- Safety Features

The ideal edge sealing machine often requires sufficient safety measures. Both the sealing procedure and the operators would be affected by this.

For example, the operator needs a designated area where they can operate the machinery.

Safety features will also maintain the operation safe and reduce production waste at all levels.

- Quality Standards

Ascertain that the edge sealing device satisfies both national and international quality standards.

These requirements must be met to ensure a high-quality, secure, dependable, and long-lasting machine.

- Touch Screen Functionality

It will be simple to monitor and enter production settings once you have a touchscreen.

Additionally, you can modify and save the production processes using the interactive interface.

It makes it simple and hassle-free for you to move up and down every time during the working process.

- Automation

The market offers variants that are semi-automated, completely automatic, and manual.

You must choose the machine that is most appropriate for you based on your production needs.

Although more expensive, fully automatic devices are quicker and more productive than semi-automatic counterparts.

- Accuracy

This element ensures that there are few faults when operating the machine.

Additionally, it is advantageous because waste won’t be made at any point during the production process.

It is an entirely automatic, affordable machine frequently used in the process flow of mass-produced packing material.

It simultaneously incorporates feeding, conveying, packaging, and shrinking.

It most frequently applies to items like electrical goods, photo albums, cosmetics, printing, wood goods, colour boxes, and things that come in sets or a single package.

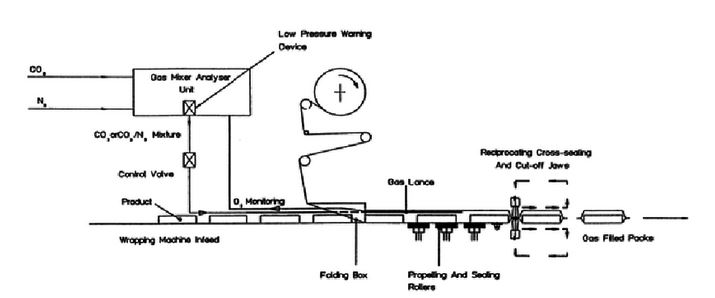

edge sealing machine flow chart

Voltage

Every model typically has a particular voltage; this is the pressure that pushes the electricity.

When choosing a machine, machines with greater voltage typically cause more electricity to flow to the machine.

Typically, they range from 115 to 400 volts.

Production capacity

Depending on the design you decide on, these machines also offer a variety of production capacities. As it affects the cost and income forecast, choose the equipment that will meet your production needs.

Size Of The Machine

Edge sealing equipment is available in a variety of sizes and shapes. Their length, width, and height all show this variance.

The machine you choose must be compatible with the workspace you presently have at your location.

Carton Size

You should take a look at some of the edge sealing machines that are available for carton sizes like (L) 300-600mm (W) 200-500mm (H)180-500mm since they are manufactured to this criteria.

Power

For edge sealing machines to function at their best, a certain amount of electricity is needed.

The machine you choose must operate on the same amount of power that you can provide for it.

Weight

These machines all have varying weights, primarily determined by their designs. Smaller machines will weigh less than larger machines, which weigh more.

Labor Cost Reduction

It takes time to physically seal the carton boxes. When the contents of a package are weighty, it can be challenging to manipulate the box in the necessary ways.

This operation slows down the packaging process, even for light boxes.

High-volume enterprises devote a lot of labour to sealing, but an automated machine may do the task in seconds.

Effective Material Use

An edge carton sealing machine is more efficient in this situation than manual sealing.

When completed manually, sealing calls for more tape to guarantee a job is done correctly.

On the other hand, edge-sealing devices can tape the edges with minimal material, which is more secure.

Since industrial tape requires a significant investment, effective use of the material benefits a corporation.

Product Damage Drops

When sealing with glue and straps, a greater danger of product damage and possibly personnel harm exists.

The machine that applies the staples and glue also needs costly maintenance.

However, you may be assured of fewer product flaws during shipping and lower equipment maintenance costs with an edge sealer machine, which is advantageous to the manufacturer.

However, you may be assured of fewer product flaws during shipping and lower equipment maintenance costs with an edge sealer machine, which is an advantage to the manufacturer.

It Lessens Employee Injuries And Downtime.

Repetitive bodily motions might cause your staff members neck, back, and wrist problems. Equipment for edge sealing machines makes the process easier and relieves employees of this duty: reduced downtime, fatigue, and strain injuries.

Greater Output

Automation’s primary goal is obviously to increase productivity. The number of digital platforms has grown, which has increased competitiveness in the packaging industry.

It just encourages businesses to gain a competitive edge. The most crucial approach is the use of automated devices.

The packing process is accelerated by an edge carton sealing machine, enabling the company to handle high-volume activities.

The Product Safety

It only makes sense to switch out the human process with an edge carton sealing machine as the objective is to deliver products to customers safely.

Operation is Simple

The user guide with the edge sealing machine makes it easy to use. You can quickly seal cartons of various sizes thanks to it.

The machine’s mechanical design will enable you to complete your manufacturing efficiently.

Conveyor

Essentially, it is a device that facilitates the transfer of cases to and from the edge sealing machine. The machine will never be able to work without such a system.

Electric Control Cabinet

The electrical panel is where the significant parts for the edge sealing machine are tapped.

The pneumatic system is powered by an electric system as well. Never forget that the entire machine is connected to the power panel.

Safety Measure

When handling this component, you must exercise the utmost care.

The safety system often has a sensor element that can quickly stop the machine in the case of a risk and will indicate when the machine needs maintenance.

Height And With Adjuster

Its primary function is to turn the handle, allowing for simple adjustment dependent on the breadth and height of the product.

It makes it possible for the sealing to happen very quickly per hour.

Tape Changer

It makes the replacement simple and enables you to change the tapes to any size you require.

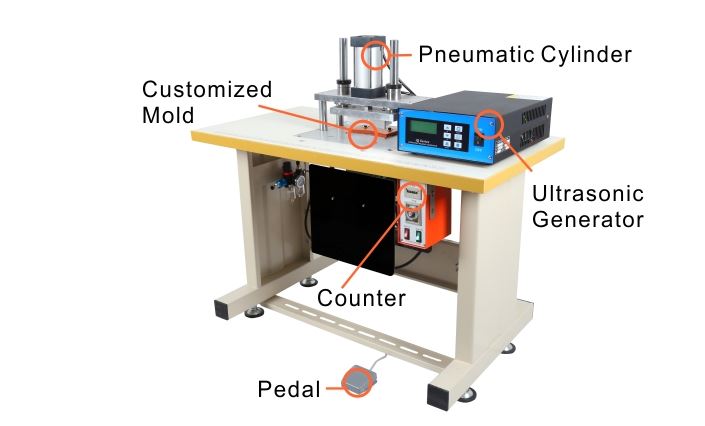

Multiple Cylinders

Fundamentally, these components usually function in concert to guarantee that the edge sealing machine is stale and that the finished product is of higher quality.

Roller

The primary purpose of this component is to facilitate moving boxes from one area to another using a conveyor.

Motor

Commonly, this portion will govern and control how quickly the edge sealing mechanism operates overall.

Pneumatic System

When the sealing process is in progress, this area often assists the machine pressing and aids in moving other components, such as lubrication fluids.

edge sealing machine parts

Sealing Plug

It is one of the critical elements of the mechanism that seals the cartons. Depending on your edge sealing machine, they are available in different sizes and shapes.

Lubrication System

it is among the elements that help to grease the moving parts of the edge sealing machines for easier use.

It lubricates parts like bolts, gears, and rails. The machine will be easier to maintain and less prone to malfunction.

Frame

The shaft sleeve, sliding plate, and machine body make up the mechanical device’s frame. The frame is next welded and later annealed.

PLC Control System

This panel is where the sealing operation’s settings are made.

Control buttons are included on the sealing machine, and an incorporated man-machine connection is included on the high volume completely automated round can sealing machine.

Blade

The primary function of this part of the edge sealing machine is to cut the tapes after sealing is complete.

After the entire operation, the cases benefit from having the same closing cut.

The machine’s operating principle is as follows:

- Check the edge sealing machine to make sure it is in working order for the production process before beginning any process counters.

- The machine’s power system has to be correctly linked. As a second stage, apply the tapes to both sides of the edge sealing machine.

- The manual loading of the cartons into the edge-sealing machine feeder, which takes place at this stage, continues until the feeder is full.

- With the aid of a conveyor and rollers, the edge sealing machine will automatically push the cartons inside.

The carton flaps will then be appropriately folded per adjustments made for the carton size.

- The following step automatically pushes the sealed cartons to the next level on both the top and bottom of the cartons.

- The edge sealing machine progresses automatically to the next phase when the carton edge is pushed out of the machine through the outfeed.

- The final step, optional, involves taking the cartons for inspection to ensure they adhere to the standards before being transported to retailers.

Below are some of the applications for this machine:

- Electrical & Electronic

Electric cables, plugs, lamps, computers, televisions, and refrigerators are just a few of the manufacturers of the products in this sector utilized to edge seal for shipping.

- Automotive Industry

In this industry, components like dashboards, side interiors, windows, bonnets, and dashboards are sealed using edge sealing machines for security reasons from manufacturing to consumer.

- Food Industry

Producers mostly use this machine to secure their products in the bakery and other food industries.

Others include:

- Pharmaceutical Industry

- Cosmetics Industry

- Chemical industry

- Apparel industry

- Hardware industry

As the name implies, a manual edge sealing machine relies heavily on human interaction.

For the manufacturers dealing with small output, this equipment usually ends up being affordable.

However, even though the risk of product mishandling is low, it will raise labour costs and reduce production capacity if edge sealing is done manually.

manual edge sealing machine

While most of the process in an automatic edge sealing machine is computerized and only needs a PLC to operate, it neither requires nor uses the less human interface.

The advantages of an automatic edge sealing machine are speed, suitability for mass production, accuracy, cost-effectiveness, reduction of labour costs, and minimal waste throughout the process. This machine is made in various sizes depending on your needs.

automatic edge sealing machine

Yes, these machines are usually the same since they all have the same function:

seal the sides of cases and cartons, protect the contents, and ease transportation. Additionally, they are both wholly automatic and semi-automatic in design.

case edge sealer

The following are some qualities that make these machines comparable to one another:

Economical

- Labour cost reductions

- Boosts productivity

- Simple and dependable design means zero downtime

- Ready to use, requires simply turning on, and requires little training

- Multiple tape widths can fit on the same machine, resulting in lower costs and higher returns.

Simplicity

- Currently available for use: Plug in and turn on

- It can be equipped with optional casters to make it simple to move around the production.

Safety and Comfort

- Quick access to all moving parts

- No sharp edges, safer for the user,

- protected knife guard on the taping cartridge

- Automatic variants with interlocked safety gates safeguard workers

- They are solid, and the steel frame shields all moving parts.

box edge sealer

Flexibility

- Fitting existing production lines is possible without significant adjustments.

Operating

- Very simple to install and use

- Limited operational experience

- Friendly to users

- Reliable, high-quality components

Maintenance

- In general, a maintenance-free device

- Only belts, springs, rollers, knives, and other wear parts are used.

- Springs should be accessible from the tape cartridge.

- Only routinely inspect the knife and only clean as necessary.

- Belt changes ought to be quick and easy.

You may also want to learn about heat sealer. For all your edge sealing machines, contact us now.