Automatic L Sealer Machine Manufacturer

For high-volume production, you can trust the Jochamp Automatic L Sealers machine. It has a small footprint that can handle day-to-day operations. This machine secures and protects products of all shapes and sizes.

- Easy to operate and high efficiency

- Reliable control displays

- Provide firm sealing and excellent shrinkage

- Reasonable price guaranteed

JOCHAMP Automatic L Sealer Machine

For higher production rates and increased productivity, use the Jochamp Automatic L Sealers machine. It encases your product in poly bags of heat-sensitive shrink film. The machine work by placing the product on a running conveyor. It passed through the upper and lower layers of film. After the feed is complete the seal bar is automatically lowered. A clean and high-quality seal is created. It can seal 35 packages or more a minute depending on your specifications. Then, the product can be transferred along the conveyor to a shrink tunnel.

Jochamp is your trusted Automatic L Sealer Machine manufacturer in China. We supply high-performance sealer machines compliant with CE, SGS, ISO, and cGMP. These are built-to-last equipment that provides a fast return on investment. Ideal for industries including electronics, medical, pharmaceutical, food, beverage, etc.

If you have a custom request, our team will support and help you through all stages of the process. We ensure that your packaging system is the precise one for your business. Message us now!

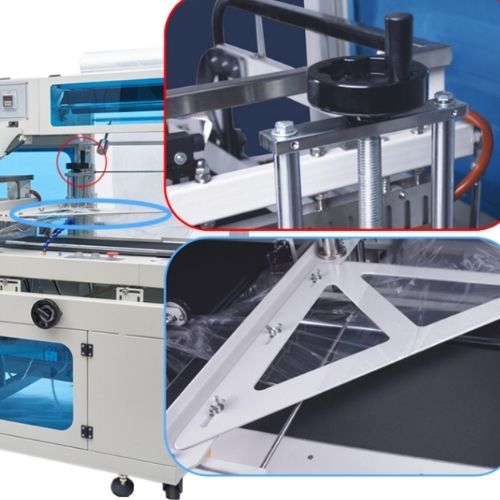

ZWG-450 Automatic L Sealer Machine

The entry-level automatic shrink wrap machine is called L sealer machine because the sealing and cutting structure is L-shaped.

- Small footprint

- Independent PID temperature control system, precise temperature control, energy saving

- Multi-channel spraying process on the fuselage, corrosion resistance, easy to clean

- Circulating hot air shrinking furnace makes the packaging film heat more evenly and saves energy

- Constant temperature type super-grade aluminum alloy sealing cutter, anti-sticking, fine sealing line, mp coking, no smoking, zero pollution

ZWG-450

- Technical Parameter

- Features

- Optional

| Model | ZWG-450 | ZWG-550 | Shrink tunnel | BS45222N | BS5530N |

| Packing height | ≤150mm | ≤150mm | Power supply | 380V/50-60HZ;3Phase | |

| Packing Width

|

≤350mm | ≤450mm | Power | 9.6KW | 12KW |

| Packing size | width+height≤400mm | width+height≤500mm | Conveyor speed | 0-15m/min | 0-10m/min |

| length+height≤480mm | length+height≤580mm | ||||

| Conveyor speed | 0-15m/min | 0-15m/min | Tunnel size | 1200x450x220mm | 1500x550x300mm |

| Application film | POF Folded film. PE | Weigh | 200KG | 230KG | |

| Platform height | 780-850mm | ||||

| Power | 220V/50HZ 1.35KW | 220V/50HZ 1.5KW | |||

| Air pressure | 4kg/㎡ | 4-5kg/㎡ | |||

| Main material | Carbon steel | ||||

| Weight | 300KG dimension | 350KG | |||

| Dimension | 1600x720x1300mm | 1950*1000*1450mm | |||

Small footprint

Independent PID temperature control system, precise temperature control, energy saving

Multi-channel spraying process on the fuselage, corrosion resistance, easy to clean

Circulating hot air shrinking furnace makes the packaging film heat more evenly and saves energy

Constant temperature type super-grade aluminum alloy sealing cutter, anti-sticking, fine sealing line, mp coking, no smoking, zero pollution

All conveyor belts are covered with PTFE heat insulating pipes, without ironing hands or damaging membranes.

Conveyor motor adopts VCT motor, which has long service life and low noise.

The size of the package can be adjusted arbitrarily without changing the mould.

Date coding (inkjet, laser, thermal transfer)

Labeling Machine

Round product hemming machine

Feed conveyor belt

export conveyor belt

How Automatic L Sealers Work?

Jochamp Automatic L Sealers operate on a conveyor system. It can seal up to 35 packages per minute or more. The soft feed conveyors transport items into the system. They are wrapped in folded shrink film.

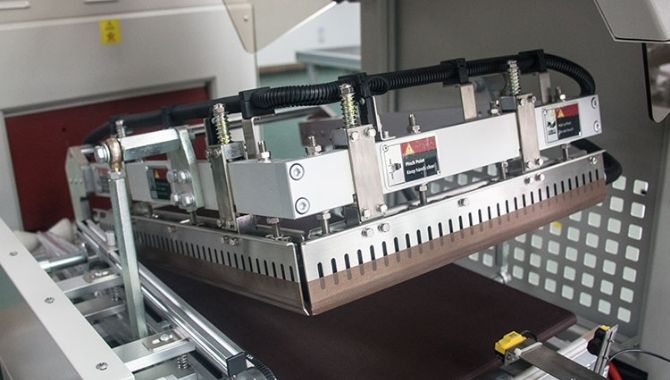

As items travel through the system, an adjustable sealing arm lifts and lowers. After being sealed, the pouch is placed through a shrink tunnel to shrink and tighten the film.

Custom Automatic L Sealers

Automatic L-sealers assist manufacturers with huge product volumes and automate the sealing process quickly and accurately. If you have custom requirements, our team is professional and experienced in the field.

Our range of automatic L-sealers is available in various size and sealing ability configurations. We can supply the right machine for the products you produce. With 15+ years of experience, we are specialized in developing a custom machine with a reliable function that increased productivity and efficiency.

Related Products

Automatic L Sealer Machine: The Ultimate Guide

Automatic L sealer plays an integral role in modern packaging applications. In this guide, you will find all information you are looking for about automatic L sealing machine – keep reading to learn more.

An l sealer machine is a piece of equipment you can use to wrap several products.

The machine wraps measure the length of the product and then the sealing jaws seal the product automatically.

L sealer machine

- Its operational costs are low. An automatic l sealer uses very high speeds during the whole process hence reducing the operational costs.

- You are assured that your package has been secured well and is airtight when using an automatic l sealer machine.

- The machine is easy to clean because of its open design.

- When using an automatic l sealer machine materials are utilized well and there is no wastage.

The machine has been configured to know the exact amount of material to use.

- An automatic l sealer machine is very effective and efficient hence will give you value for your money.

It works very well and its production speed is very high.

- Using an automatic l sealer machine reduces labor costs since most of the work is done by the machine.

The machine also does not require supervision, this means you will not have very many people working for you.

- An automatic l sealer machine has an easy layout which is quite easy to operate.

- There are no fumes or smoke with an automatic l sealer machine.

This means the working environment will be clean and there will be no health hazards.

Automatic L Sealer Machine With Shrinking Tunnel

This is an automatic l sealer machine that has a shrinking tunnel incorporated in it.

The shrinking tunnel is responsible for shrinking and tightening the film.

Automatic L sealer machine with shrink tunnel

The automatic l sealer seals the package and the conveyor belt moves it to the shrinking tunnel.

High-Speed Automatic L Sealer Machine

A high-speed automatic l sealer machine is just the same as the automatic l sealer machine.

high speed automatic L sealer machine

The only difference is the high-speed machine is quite fast compared to the other.

This means it has greater production volume since the system can process up to 40 packages per minute.

Sealing in an automatic l sealer machine is one of the most important steps.

Sealing ensures that the product retains its freshness and it does not pour out of its package.

The most common sealing technologies in automatic l sealer machines are ultrasonic sealing and heat sealing.

Ultrasonic sealing utilizes vibrations to bring about friction.

You should use this type of sealing on products that cannot be used with heat such as ice creams or chocolates.

Heat only comes about in the middle of the film layers when using ultrasonic sealing.

Heat sealing is the most suitable and effective way of sealing a package.

This method uses heat which is the best way to ensure the seal is secure.

The heat sealing method cannot be used on products that are heat sensitized since they may melt.

The following are the parts of an l sealer machine;

- Conveyor belt – helps move the package from one station to another.

- Sealing jaws – seals the package.

- Blade – cuts the film when the required size is achieved.

- Sensors – measure the length of the product.

- Film – is the wrapper you use to seal your package.

- Shrinking tunnel – it is where shrinking and tightening of the package happens.

- A take-up reel – is where the excess film is wrapped so that you can use it again.

L sealer machine parts

An automatic l sealer machine is a very efficient and effective machine that has very high returns, and production volume.

The process of sealing using an automatic l sealer is not very complicated and the system can process up to 25 – 30 packages in a minute.

The first step involves placing the product on the conveyor belt. The conveyor belt then moves the package inside the film.

Using a sensor, the machine then measures the length of the product.

After measuring the length, an adjustable sealing arm raises and lowers the sealing of the product.

After sealing is done, the conveyor belt moves the sealed package to the shrinking tunnel.

At the shrinking tunnel, the shrinking of the film is done and the tightening of the film is also done.

If there is any excess film, it is trimmed then it is wrapped onto the waste film take-up reel.

The whole process is repeated until you get the expected number of sealed packages.

A lot of industries have benefited from using an automatic l sealer machine. Some of the industries include;

- The food industry – this industry uses the automatic l sealer machine to seal products such as frozen food, and biscuits among many others.

- Pharmaceutical industry – an automatic l sealer is widely used in the pharmaceutical industry to seal products such as antibiotics or even vaccines.

- Automotive industry – since the automatic l sealer machine is fast, it benefits the automotive industry.

They can seal a lot of products in a short time.

- Electronics industry – all electronics are very delicate and require a lot of care to avoid damage.

An automatic l sealer machine can seal printers and mobile phones among many other electronics.

- Cosmetic industry – the cosmetic industry is one of the busiest industries worldwide.

An automatic l sealer machine seals hair and body products such as lotions.

- Textile industry – the amount of production from textiles industries in a day is very high.

You should use an automatic l sealer machine because it can manage to seal products such as clothes in a short time.

- Household products industry – household items are used in every house, so their demand is high.

With an automatic sealing machine, you can seal cutleries or cleaners.

- The medical industry – this equipment is vital in the medical industry.

You can seal products such as syringes and also some medicines. Its speed and effectiveness make it quite valuable for the industry.

- Chemical and petroleum industry – you should use an automatic l sealer machine in this industry because of its ability to seal products tightly.

Features of any machine are what determine if the machine is good or not. Therefore you should be careful when going through them.

These are the features you should look for in an automatic l sealer machine;

- Look for one that only requires little labor input. The machine does everything independently and requires little to no manual labor.

- An automatic l sealer machine should have a digital display system.

- The machine should be versatile. This means it should be able to accommodate a variety of products with simple setting changes.

- The machine should have a compact built design, high quality, and very fast.

- A budget-friendly machine is one factor you cannot ignore. You should make sure you don’t go over your budget.

- It should have a PLC with a touch screen control system.

- An automatic l sealer should be made up of automatic sealing parts.

- The machine should be made up of advanced equipment construction.

Its parts should be made of materials such as stainless steel. With that, you can be sure of the durability.

- The machine should have an easy structure to clean and maintain. You can disassemble some parts for proper cleaning and maintenance.

- The machine should have an air-blowing unit that protects the sealing quality.

- An automatic l sealer machine should have a user-friendly interface.

One that anybody can learn to use easily.

An automatic l sealer machine is a machine in that every process is automated and does not require human labor.

It may sometimes require human intervention but not always.

A semi-automatic l sealer machine depends on both human labor and the machine. Some parts of the machine are automated while some are not hence requiring manual assistance.

Automatic L sealer machine

An automatic l sealer machine initiates and ends the whole process on its own.

However, a semi-automatic l sealer, the process starts with a controller and then finishes with the machine.

The initial cost of an automatic l sealer machine is quite expensive compared to that of a semi-automatic l sealer machine.

semi-automatic L sealer machine

Regarding production efficiency, an automatic l sealer machine is recommended.

All the processes in an automatic l sealer machine are automated thus increasing production volumes.

For the semi-automatic, some processes are not automated and this will slow down the production speed.

With an automatic l sealer machine, you can get high returns even though the initial cost is high.

The high production volumes lead to high returns.

On the other hand, the initial cost of a semi-automatic l sealer is low but since its production volume is low you may not get very high returns compared to the automatic one.

- Conduct Regular Maintenance Check On The Machine

A maintenance check means looking at the machine parts and ensuring everything is in order.

Check on the blade, the peeling agents, and the sealing jaws to make sure that everything is in order.

You may expose some parts of the machine to water resulting in rusting, and you can notice this during the maintenance check.

Also, check the oil levels in the machine and add more if needed. This will prevent damage to the machine.

- Regular Lubrication

Machine lubrication is one of the most critical steps in maintaining a fully automatic l sealer shrinking machine.

A machine cannot work well without oil lubrication, mainly done on the moving parts of the machine because of friction.

When a machine goes for long without lubrication some parts may end up breaking or even will not be able to move.

Clean the parts well, then lubricate them with oil.

- Clean The Machine Often.

When using any machine, it is expected to get dirty or accumulate dust.

Parts such as the seals require daily clean-up.

You should dust and clean the machine regularly to ensure it remains clean.

If you use the fully automatic l sealer shrinking machine for a long time without regular clean-up, it might cause issues to the machine and affect its working.

Also, you should ensure the machine is off when cleaning and use machine-friendly cleaners to avoid damaging the machine further.

- Change Machine Parts Regularly.

Anybody working with a machine knows that spare parts are essential.

When a machine has been used continuously for a long time, some parts tend to wear off quickly.

Some features are pretty long-lasting and do not need to be changed frequently.

For a machine to work effectively and for one to avoid excessive damage to the machine, the parts need to be changed.

Always ensure you do an inspection daily before starting the machine and make adjustments where necessary.

A manual l sealer machine is equipment that depends on human labor for it to function. The whole sealing process depends on human intervention.

On the other hand, a fully automatic machine is fully automated and it does not require human labor during the whole process.

manual L sealer

For all your L sealer machines, contact us now.