Hot Melt Case Sealer Manufacturer in China

At Jochamp, we offer a wide selection of hot melt case sealers in order for you to select the best suited to your specific needs. Our hot melt case sealers are recognized for their rugged construction, small footprint, operating performance, maximum seal integrity, and safety.

- More than 15 years of experience

- Conforms to cGMP, CE, SGS, & ISO9001 standards

- Offers one-year quality assurance & lifetime after-sales service

- Customizes to your exact details

Jochamp Hot Melt Case Sealer

Jochamp hot melt case sealers can seal boxes or cartons by applying adhesive accurately and consistently. They are ideal if you want to make sure the cases are securely sealed. Mainly, they feature hotmelt glue systems for secure and reliable sealing of cases. And they can provide a stronger and long-term bond compared to the traditional adhesive tape. For that reason, they are ideal for sealing boxes with heavy loads.

In addition, the hot melt case sealers have a fast sealing speed. Because of that, you will save a lot of time and manpower. You will also save costs and ultimately increase profits. Moreover, due to their compact design, the hot melt case sealers take up less space in your facility. They are also designed with an emergency stop device and a protective cover to ensure safety during the operation.

If you are looking for hot melt case sealers, you can select from our wide range of machines below. Our hot melt case sealers are customizable to meet your special needs. You can also contact us if you have questions regarding our hot melt case sealers.

JCE-50H Hot Melt Case Sealer

On the basis of JCE-50 degree, the machine replaces the structure of the tape sealing box with a hot melt glue sealing box.

- Imported advanced parts,electrical and pneumatic components,high quality, stable performance.

- The height and width can be adjustable for different dimension of carton.

- Left and right belt drive design for drive more stable during working process.

- Bigger electrical machine, faster conveyor speed.

- Cutter safety system to prevent hands from stabbed by the cutter.

- Especially suitable for more heavier goods.

- Hot melt glue type

- Simple operation, convenient and easy adjustment, fast sealing speed, high efficiency, strong and durable

JCE-50H

- Technical Parameter

- Features

- Optional

| Mode | FXJ-AT5050 |

| Power | 600W 50HZ |

| Voltage | 110V,220V~240V 1ph |

| Machine dimension | L1840*W1000*H1500mm |

| Net weight | 240KG |

| Conveyor speed | 0 ~ 20m / min |

| Tape width | 36~60mm |

| Max.packager size | L:600*W500mm* H500mm |

| Min.packager size | L:120*W120mm*H120mm |

Hot glue melt

| Technical Parameters | ProBlue 7 |

| Glue Cylinder Volume | 7L |

| Holding Capacity | 6.8kg |

| Melt Speed*2 | 8.2kg/hr |

| Throughout | 10.9kg/hr |

| Max. Pump Rate | 32.7kg/hr |

| Air pressure Range | 48-415kpa(10-60psi) |

| Input Voltage Standard | AC200-240V 1PH 50/60HZ |

| Machine Size | 609*469*322mm |

| Machine Weight | 44kg |

| Ambient Temperature Range | 0-50 C |

| Temperature Range | 40-230 C |

| Max. Working Hydraulic Pressure | 8.7Mpa |

| Levels of protection | IP54 |

- Imported advanced parts,electrical and pneumatic components,high quality, stable performance.

- The height and width can be adjustable for different dimension of carton.

- Left and right belt drive design for drive more stable during working process.

- Bigger electrical machine, faster conveyor speed.

- Cutter safety system to prevent hands from stabbed by the cutter.

- Especially suitable for more heavier goods.

- Hot melt glue type

- Simple operation, convenient and easy adjustment, fast sealing speed, high efficiency, strong and durable

Hot Melter—Norsand Problue 4/7

- *Approximately twenty percent smaller size

- *Approximately fifty percent smaller service envelope

- *Easy-to-use controls

- *High-level noise immunity

- *Rugged,non-handed design

- *Proven Nordson SP dual-acting piston pump

- *Cast-in heater

- *PID temperature control

- *Automatic Pressure Discharge Valve

- *Low-level adhesive indicator

Other brands of hot melt glue machine

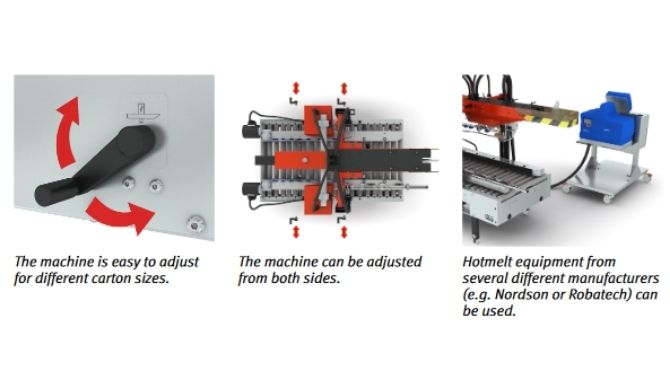

Adapt to different sizes of cartons

Stainless steel rack

Docking case packer

Electric regulator

Up and down drive structure

Automatic folding mechanism

side sealing

strapping

Hot Melt Case Sealer Advantages

The hot melt case sealers can provide stronger and long-lasting adhesion compared to the traditional adhesive tape. They can provide secure and reliable sealing. That is why they are ideal for sealing cases with heavy loads.

Jochamp hot melt case sealers can seal cases quickly, accurately, and gently. For that reason, they can save a lot of time and manpower. In addition, they can improve your productivity and increase profits.

All of the hot melt case sealers from Jochamp are developed in accordance with the standards from international quality management systems. They are certified by the CE, SGS, cGMP, ISO9001, and other quality standards.

Jochamp has the capability to produce custom hot melt case sealers based on your requirements. We are offering customization services in order to complete your specific needs and help you grow your business.

Options for the Hot Melt Case Sealer

- Hot Melt Systems – Other brands or models hot melt glue machine can be integrated for long-term cost savings and greater versatility.

- Outfeed Conveyor – An outfeed conveyor can be integrated since it can provide a location to collect the packed and sealed cases so that they can be transported or palletized for further processing.

- Locking Casters – Locking casters can be added to enable the machine to be movable and quickly transferred to different areas in your workplace.

- Enviroguard Stainless Steel – A stainless steel option is available for environments that need additional corrosion resistance and water resistance.

Other options for the hot melt case sealers that can be added include strapping, side sealing, docking case packer, automatic folding mechanism, stainless steel rack, up & down drive structure, electric regulator, etc. They can be integrated depending on your needs.

Characteristics of the Hot Melt Case Sealer

- Construction – The hot melt case sealers have a premium welded frame with high-quality and corrosion-resistant materials such as stainless steel and anodized aluminum for a paint-free construction.

- Adhesion – Jochamp hot melt case sealers have a hot melt adhesion type. They utilize the standard Nordson ProBlue system for the adhesion.

- Levels of Protection – Our hot melt case sealers have an IP54 rating.

- Components – The hot melt case sealers use imported and advanced pneumatic and electrical components for stable performance.

- Transmission Mode – The hot melt case sealers have right and left belt drive designs for maximum stability during the working process.

- Carton Size – The size of the cartons can be manually adjusted. Their width and height can be adjusted.

Why Choose Jochamp

- Experience – Jochamp has more than 15 years of experience in the production of hot melt case sealers. We have strong research and design capabilities, as well as an excellent management system, which allows us to fulfill your special customization requirements.

- Excellent Services – At Jochamp, we offer lifetime after-sales service, 7×24 hours fast response service, and regular after-sales care. We can also give you guidance on the maintenance of the hot melt case sealers.

- Quality Control – We are following meticulous quality control, from choosing raw materials to assembly and testing of the hot melt case sealers, every production step is controlled by our expert QA specialists. In fact, all of our hot melt case sealers have acquired the SGS, CE, cGMP, and ISO9001 international quality system certification.

Jochamp | Your Trusted Hot Melt Case Sealer Supplier

Jochamp is one of the leading suppliers in China that specializes in the research, development, and production of hot melt case sealers. We have the ability to design the hot melt case sealers in accordance with your exact requirements. Also, we are capable of supplying them around the world.

Most components of our hot melt case sealers are made from high-quality stainless steel for increased durability, excellent corrosion resistance, and extended service life. The raw materials we are using are inspected, carefully selected, and have passed the cGMP standards.

At Jochamp, we strictly implemented quality control in every production process of the hot melt case sealers in order to ensure their quality, safety, performance, and reliability. All of our hot melt case sealers have fulfilled the requirements of SGS, CE, cGMP, ISO, and other international quality management systems. They also have one-year quality assurance.

If you want to know more about our customization services, feel free to contact us!

Jochamp Hot Melt Case Sealer

The hot melt case sealers with Nordson ProBlue 4 or 7 have many features such as:

- Easy-to-use controls

- High-level noise immunity

- Cast-in heater

- Low-level adhesive indicator

- Automatic pressure discharge valve

- PID temperature control

- Proven Nordson SP dual-acting piston pump

- Rugged & non-handed design

- Approximately 50% smaller service envelope

- Approximately 20% smaller size

The hot melt case sealers have a lot of amazing features such as:

- Bigger electrical machine for a faster conveyor speed

- Suitable for heavier goods

- Cutter safety system to avoid your hand from being wounded by the cutter

- Easy and convenient adjustment

- Fast sealing speed

- Easy to operate

- High efficiency

- Strong & durable design

- Quick changeover

- Easy adjustment

- Small footprint

- Low noise operation

Jochamp Hot Melt Case Sealer for a Wide Range of Industries

The hot melt case sealers are used by many automotive part manufacturers since automotive products are commonly heavy. And hot melt case sealers are suitable for heavier or oversized cases. They can seal securely and offers structural strength to heavy boxes.

Jochamp hot melt case sealers are widely used in the food industry for sealing food products. Many snack manufacturers chose hot melt case sealers since they offer total flexibility. They can seal securely and gently. Due to that, they will not damage the food products inside the cases.

The hot melt case sealers can also be used for sealing cases with lightweight medical and pharmaceutical products. They have unique features to make sure that the lightweight cases will be properly and securely sealed.

The hot melt case sealers are also used in the electronics industry since they can provide extra strength to the cases that have heavy electronics and computer parts or products.

The hot melt case sealers are made from high-quality and naturally corrosion-resistant materials such as stainless steel and anodized aluminum. For that reason, they ideal in the beverage industry because they can withstand corrosive plant environments and high pressure washdowns.

Related Products

Hot Melt Case Sealer: The Ultimate Guide

Sealing is an essential part of the packaging process – the reason this guide explores a popular piece of equipment called a hot melt case sealer. It is a unique sealing machine that guarantees the safety of all your products. So, before investing in your next hot melt case sealer, read this guide.

A hot melt case sealer is a machine that uses hot melt glue to seal the already erected cases.

Hot melt glue is a thermoplastic adhesive that can be applied through a hot gun.

hot melt case sealer

A hot gun has a component that melts the glue before it can be pushed out of the gun.

Low Cost

The material used for making the hot melt glue is less expensive when compared to using tapes.

Normally, the amount saved when getting the material could accumulate to high amount of money over time.

Flexibility

There are various material options that can be used for hot melt glue functions.

The machine can also adopt a variety of nozzle sizes.

High speed

This machine works faster and can be used in tandem with other high-speed machines like automatic case erectors.

Rapid set time option is available.

Continuous operation

A hot melt case sealer is automated and the process continuous uninterrupted until all the cases in the line are sealed.

Structural Strength

Seals obtained through hot melt case sealers are strong and stable and can be used with cases that contain heavy weight products.

Long Lasting Bonds

This can be specifically important for cases that are meant to be shipped to long distances.

The seals hold the contents of the case without breaking for a long period of time.

Easy to Open

There is no need for scissors or knives when opening this kind of seal making the customer experience even better.

Neat Appearance

The seal is clean, neat and smart with no folds or cracks and can be trusted by the clients.

Versatility

Hot melt case sealers can create bonds with a variety of substrates such as metals, rubbers, plastics, paper, glass and even wood.

Hot melt case sealers are useful in industries that rely on cases for packing and shipping their products.

Industries like;

Food and Beverage

In the food and beverage industry, manufacturers rely on hot melt case sealers for sealing purposes.

The cases are packed with products like processed foods, soft drinks, , dried food products and frozen food.

Textiles Industry

The hot melt case sealers are applicable in the textile industry and is used to seal cases packed with products like fabrics.

Transport and Logistics Industry

A hot melt case sealer is a required for this industry to seal cases packed with various products.

Consumer Goods

Consumer goods like toys which are packed into cases require the sealing services carried out through hot melt case sealers.

Pharmaceutical Industry

Hot melt case sealers are responsible for creating seals that last for a very long period of time.

This will keep the integrity of the case and even secure the safety of its contents.

Hot Melt Glue Case Sealer

This machine uses an applicator that deposits a synthetic resin melted through heat on to the cases to seal the flaps.

A hot melt glue case sealing machine offers several machine features with different functions including main flap containment, spring loaded belts, HMI control, guard doors.

Some of the benefits of a hot melt case sealer include low cost, structural strength, durability, clean seal and versatility.

hot melt glue case sealer

A hot melt case sealer is not very simple to operate and one can get burns from the melted glue if not handled with care.

Case Sealer With Adhesive Tape

In this case, the sealing machine uses a combination of an adhesive polymer and a plastic or fibre that can be triggered under pressure.

Tape sealers have various benefits including low initial setup cost, flexibility, simplicity and easy maintenance.

case sealer with adhesive tape

One of the limitations of a tape case sealer is that it can only be used with slower production lines.

Case stand

This is where the blank cases are stored awaiting to be formed, folded and sealed.

Caster wheels

This enables the machine to moved from one work station to the next with ease.

Roller conveyer

This is used to transfer the cases from one station to the next.

HMI controls

The machine is equipped with a computer interface which is touch and can be used to monitor and control the sealing process.

Hot melt adhesive applicator

The component that is used to apply the glue on to the cases.

Sealing station

This is when the case is placed and the glue is applied for sealing.

Glue pellets are filled into the hot melt adhesive equipment chamber, once in the chamber.

The machine is equipped with a heating system that melts the pellets.

Additionally, the hot melt glue is now ready to be applied continuously on the cases to be sealed.

Then load the case onto the sealing table, then apply the hot melt glue through a gun to the flaps to create a bond.

Interlocked safety guards – This is to ensure safety of the operators

Corrosion resistant building material – this is meant to ensure that the machine is durable

Excellent accessibility – in order to ensure easy operation and controls

Compact design – this is to ensure stability and savings on space.

HMI controls – machine is equipped with PLC to help monitor and control the process.

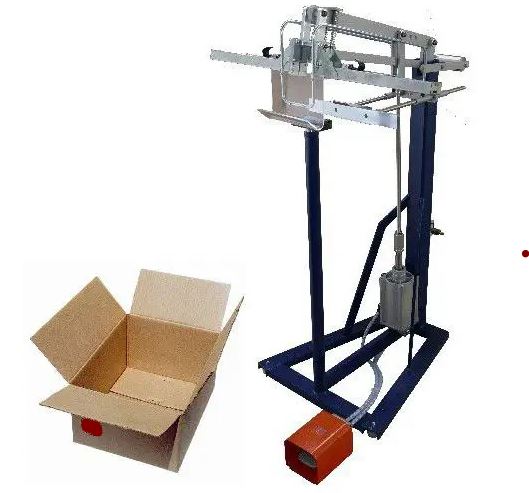

Semi-automatic Hot Melt Case Sealer

This machine works with cases that are pre-opened, the semiautomatic hot melt case sealer seals the flaps automatically.

Normally, the case is filled manually then the hot melt glue is applied by the machine to create temporary or permanent seals.

semi-automatic hot melt case sealer

This machine has high adaptability and can be used in the same production line with other machines.

Fully Automatic Hot Melt Case Sealing Machine

Fully automatic hot melt case sealer has everything automated eliminating the need for extra labour costs.

Meaning the machine can adjust the width and height of the case automatically to meet the requirements of the seal.

automatic hot melt case sealing machine

This machine is recommended for applications like in the food, toys, pharmaceutical, and tobacco industries.

Top hot melt case sealer only seals the top of the case using a hot melt glue.

The machine can only work with cases that have been formed either manually or through a bottom case sealer.

Once the case has been erected and packed with products, it is stationed to be sealed at the top in readiness for shipment.

Top And Bottom Hot Melt Case Sealer

A top and bottom hot melt case sealer is the machine required for sealing both the bottom and top of cases.

This machine uses an applicator to apply hot melt adhesives on the top and the bottom of a case to create seals.

Work is made easier with such a machine when incorporated in a production line.

Bottom Hot Melt Case Sealer

Bottom hot melt case sealer is almost similar to top and bottom hot melt case-sealer except for the fact that it only seals the bottom of the case.

This machine can work adequately when designed with a case packer, weigher and erector in the same system.

The bottom hot melt case packer must be used together with a case erector machine or the cases can be erected manually.

Random Case Sealer With Hot Melt Gluing

Random case sealer is a hot melt case sealer that is made to automatically adjust the size of a case as required for better results.

The machine can handle cases made in the same production line or different production lines connected to it.

This is also a fully automated hot melt case sealer.

Uniform Case Sealer With Hot Melt Gluing

A uniform case sealer is one that is capable of sealing uniform case sizes in a production line.

In this case, it uses a hot melt adhesive to create the seal on the already erected cases.

The machine cannot work with different case sizes and this is one of its limitations.

To avoid clogging, ensure that the filter is cleaned on a monthly basis.

At every six months check the machine to ensure that there is no damage to electrical connections.

The molten filter should be replaced annually and the machine cleaned frequently.

Make sure that you do not disassemble the machine and only experts should do that.

To avoid any electric shocks during cleaning and maintenance, ensure to remove accessories like bracelets, earrings or necklaces.

Stand on a non-conductor material when doing cleaning on the machine.

Disconnect the machine from power supply before handling the protective devise on the machine.

Do not operate the machine if there is any leakage in the pressure chamber.

Do not clean the machine using hard tools or fireworks as these can create punctures that will lead to leakages.

Carton Box Stapler Machine

Carton box stapler machine is a device that is used for joining different or similar materials together using a thing metal called a staple.

This machine is used in production lines to create seals that don’t interfere with labels on the cases.

Additionally, this machine offers various benefits including;

The staples create an overall stable and strong box.

carton box stapler machine

A box sealed using stapler can reused even after removing the staples.

The seal is an anti-tamper feature for the client and producer.

Speed and efficiency are catered for by the machine.

The seal created is not affected by moisture of temperatures.

Hot Melt Case Sealer

Hot melt case sealer is the machine that uses hot melt glue to seal the already erected cases.

Hot melt glue is a thermoplastic adhesive that can be applied through a hot gun.

A hot gun has a component that melts the glue before it can be pushed out of the gun.

Some of the benefits of a hot melt case sealer include low cost, structural strength, durability, clean seal and versatility.

hot melt case sealer

The machine is easy to use but requires prior training for the same.

Hot melt case sealer machine has a high cost during the initial machine equipment set up.

The machine has a potential of creating even higher operation costs.

An operator has to be very careful when working with the hot melt case sealer to avoid cases of injury cause by burns.

Special training is required for one to be able to operate the hot melt case sealer machine with ease and flexibility.

A hot melt case sealer has a complicated cleaning and maintenance procedures.

The seals created through hot melt case sealers may damage the cases during opening and may not be reused.

Related Resources:

For all your hot melt case sealer machines, contact us now.