If you are planning to incorporate Alu Alu blister packaging equipment in your production line, then read this guide.

It will help you choose a reliable and efficient machine for all your blister packaging needs. Let’s dive right in:

What is Alu Alu Blister Pack?

It is a kind of packaging that ensures there is maximum protection of products against harsh environments. Products are packaged in blisters made from aluminum material.

Usually, the machine forms blisters cavities using aluminum material where you package the products.

Features to Look for in Alu Alu Blister Packing Machine

The following are features to look for in this blister packaging machine:

Structural design: It should have a rigid structure to enable an operation that is vibration free. It will ensure overall stability during the packaging process.

Packaging speed – usually, the speed depend on the mode of blister packaging technique. You may use either thermoforming or cold forming. For example,

- During thermoforming, blister packs are generated by the use of heat, the speed is 40 cycles per minute.

- 35 cycles per minute is the packaging speed in cold forming and they use thin sheets of laminate film.

Of course, these speeds may vary depending on the Alu Alu Blister Packing Machine.

Operating interface – the operating interface of this machine should be easy to use. The user friendly operator interface should have have a simple human machine interface touch screen.

Feeding system – the machine’s feeding system should be automatic. This is achievable using a programmable logic controller.

Pneumatic operations – pneumatic systems play an integral role in Alu-alu blister packaging machine. However, to ensure efficiency, always check the following:

- Ensure minimal wear and tear for them to be effective

- Guarantee low maintenance cost

How PVC-Alu Blister Packaging Compare to Alu-Alu Blister Packaging

Probably, you are wondering whether to choose Alu-alu blister machine or PVC Alu blister packaging machine. Well, the two machines play an integral role in modern blister packaging.

Here is what you should know.

Cost of the Blister Packing Machines

The PVC – Alu packaging is more favorable in terms of price compared to the alu alu blister packaging. Additionally, more packaging is required on the alu alu blister packaging thus making it more expensive than PVC – Alu packaging.

Remember the PVC prices are relatively low which equates to its cost of production.

Sizes may Vary

Comparing on the sizes of these packaging’s, the alu alu packaging size is larger than the PVC-Alu Blister Packaging. This is due to the sizes of cavities in the different molds.

Plastic usually has excellent properties when it comes to molding hence it produces small cavity sizes. Compared to the plastic molds, the alu alu does not have such properties therefore producing bigger cavity sizes.

Impermeability during Packaging

PVC- Alu packaging has a more water permeability rate compared to the alu alu blister packaging. The alu alu packaging entails a very stable frequency in which vapor can go through the aluminum film.

For this reason under humid conditions, the medications cannot be affected by the water vapor. In the PVC- Alu blister, there is high water vapor transfer rate hence leading to high rates of water permeability.

Stability of the Blister Package

Alu alu packaging is more stable than PVC- Alu packaging. The stability comes in due to its resilience properties to withstand strong external environmental conditions like oxidation.

Through this, they are able to extend the period of drugs on the shelves.

Compared to the PVC – Alu blister packaging is likely affected by the tough unending environmental sceneries like high temperatures. Its poor mechanical strength makes it unable in sustaining these harsh conditions thus resulting into delamination and tearing.

Parts of Blister Packaging for Cold Forming Alu/Alu Blister Packs

Alu/Alu blister packaging machine is an assembly of many parts and components. The part design varies depending on the specific model.

Let’s look at some common components:

Forming Film

This component is responsible for creating cavities. Its selection depends on a variety of factors that comprise of the thickness, its properties and the grade.

All the properties should be in the right state to enable the film to obtain an appropriate level of rigidity. For this reason, its functionality will be guaranteed.

Therefore, the film should neither be too rigid or soft since it may lead to the damage of the products.

Lidding

This part is essential in the machine because while in the cavity, it provides protection to the product. The lidding structures can be categorized into either push through packs or peelables packs.

Push through packs are made to get torn as you pressure into the pocket thus deforming the pockets. To achieve a greater leading, you have to use these appropriate materials which comprise of PET, papers and foils.

For instance, soft aluminum is used during the packaging of hard products like lozenges.

Heat Seal Coating

This component serves the purpose of binding the lidding and the plastic pack together. The lidding and plastic packs are binded by a liquid polymer resin that is applied in numerous ways like spraying.

To create a great sealing that is air tight, an enough and right amount of the coating should be applied. After the application has been done accurately, its time the resin should be left to get dry.

Printing Section

To identify the product appropriately and precisely, printing has to be done on the lidding structures. Flexographic printing is used to print out information on the product’s lidding.

Other parts

Benefits of Alu/Alu Blister Packs

There are many reasons why you should invest in blister packaging such as:

- The packaging offers an excellent resistance against factors like hydrolysis, thermal damage and microbes’ thus enhanced protection of the products.

- Due to its more and larger cavities, the blister is used to package a larger number of products.

- It has low water permeability; leading to a stable WVTR thus it ensures protection to drugs from moisture in humid conditions.

- The packaging has a formability that is superior which is enhanced by the nylon film.

Limitations of Alu-Alu Blister Packaging

Although blister packaging is common in most industrial setups, it has some drawbacks:

Cost

This type of packaging is a bit more expensive because of the laminate material that is used in the process. Also, the cost more during the cold forming process that is always time consuming.

Environmental Impact

This type of packaging has a greater negative impact on the environment. The packing depletes more than 80% of the water resources than the PVC. Moreover, during its manufacturing, the packaging produces more energy.

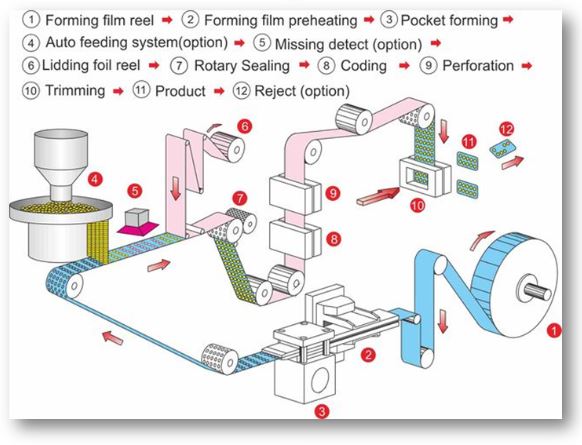

How Alu/Alu Blister Pack Machine Works

Although the working principle of Alu Alum blister packaging may vary slightly, there are certain mechanisms that are common with most machines.

Let’s look at some critical steps:

Step 1: Loading Products you want to Package

Products are transferred into the feeding device by a vibrator through the feeding tubes. These can be tables, or capsules depending on products you want to package.

Step 2: Loading Packaging Materials (Aluminum Film)

You should ensure the machine has the correct size and type of aluminum film for packaging.

Step 3: Alu-Alu Blister Packaging Process

The products from the feeding device are then taken into the sealing roller which has a pocket. Remember, the sealing roller is two tempered. Due to this nature, it is able to seal aluminum films effectively.

On the sealed aluminum film, the horizontal perforation now lines on it. At this point, also, the vertical perforation has to line on the aluminum film that had been sealed initially.

By the end of this stage, the aluminum films are now split at this stage in rows.

Using a drag roller, the strips are tensed to ensure cutting and sealing is appropriate. Next, the aluminum strips are cut appropriately by using the cutter.

Lastly, the cut strips are now fed into the feeding reject system. The system automatically checks and declines a missed feeding strip.

The Alu Alu bister packaged products can be inserted in secondary packaging for storage and shipping.

Applications of Alu/Alu Blister Packing Machine

This machine is widely used in many industries including;

- Packaging of health supplements

- Biotechnology

- Pharmacy

- Nutritional supplements

- Natural food

Does Alu/Alu Blister Offer the Best Protection?

Yes, it offers the best protection.

This is because it is a kind of packaging that ensures there is maximum protection of products against harsh environments. Aluminum foil is used in the covering of the product’s cavities.

Advantages of Automatic Alu Alu Blister Packaging

Below, are some of the advantages of using this machine;

- Automatic Feeding System

The capsules and tablets are automatically fed by the vibrator into the blister pocket at a faster rate.

- Feeding Detecting System

Since it is automated, the machine is able to identify any miss fed blister and thus rejects it hence accuracy.

- Cost

The machine is cost effective since it does not require lots of labor, a single operator is only required.

- Easy to Use

The machine embraces a simple human machine interface touch screen which puts a command on how the machine should operate.

- Packaging Can Be Customized

With this machine, you can achieve a custom design at an affordable rate.

Conclusion

As you can see, Alu Alu blister packaging is efficient and secure. It offers better packaging solution.

At Jochamp, we offer the best blister packaging line for your business.

More Resources:

Blister Packaging Machine – Source: Jochamp

Blister Packaging – Source: IQS Directory

Blister Packaging Line – Source: Jochamp