Zipper Pouch Packing Machine Manufacturer in China

JOCHAMP is a professional company dedicated to the development, manufacture, sale, and service of zipper pouch packing machine equipment. We’ve built a reputation for high quality and service by providing customized zipper pouch packing machine solutions for all customers nationwide.

- Linear and stable operation mode

- Rich and other extended applications

- Intelligent fault diagnosis function

- Passed CE, SGS, ISO9001 quality system certification

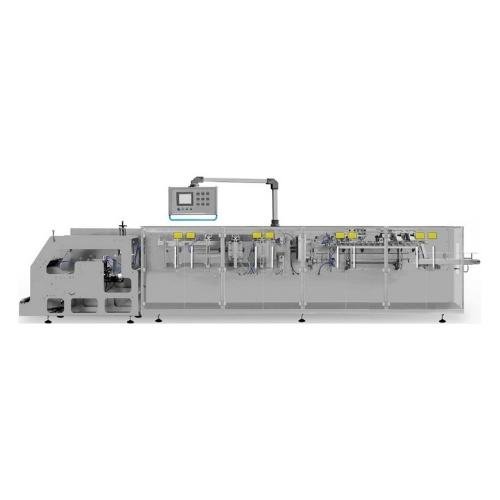

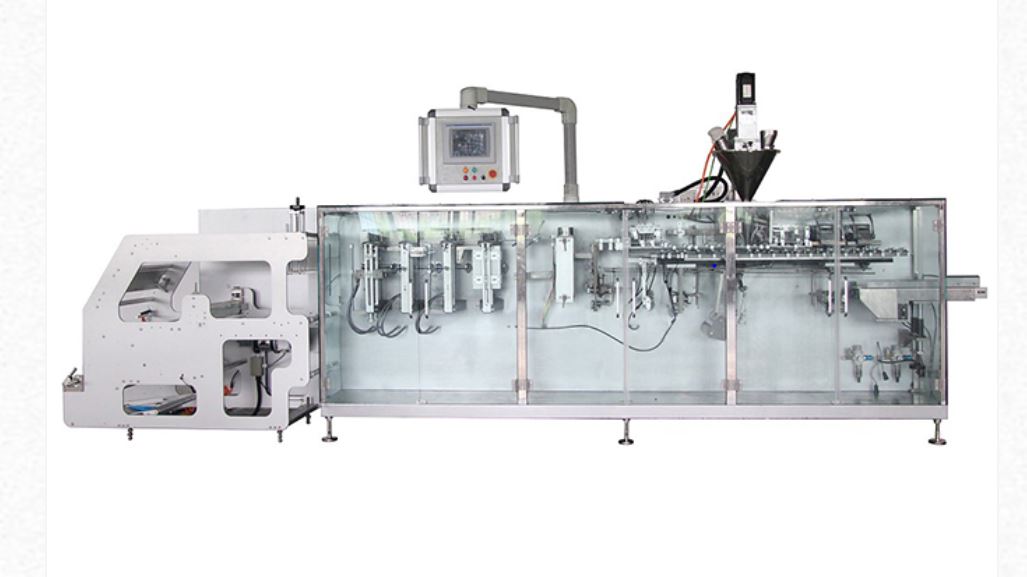

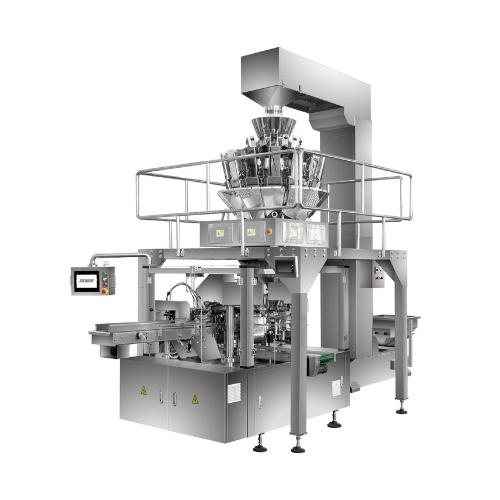

JOCHAMP Zipper Pouch Packing Machine

The zipper pouch packaging machine is an excellent choice for a pre-made zipper pouch because it has zip open and zip-close functions. It has high filling accuracy and fast packing speed and is easy to operate and adjust. To work with automatic pick-up bags, coding batch codes, opening bags, material filling, bag sealing, and output, the support bag width ranges from 80 mm to 350 mm.

JOCHAMP mission is to provide our customers with complete turn-key zipper pouch packing machine solutions and other related machines. By connecting different feeding mechanisms, the machine will be suitable for the vast majority of granules, liquids, pastes, and other products. Send your inquiry now.

Types of Zipper Pouch Packing Machines

Zipper Pouch Packing Machine Advantages

All JOCHAMP machines, including zipper pouch packing machines, have been certified by CE, SGS, and ISO9001. They will be of great quality and dependability, as we guarantee.

The JOCHAMP zipper pouch packing machine is simple to operate. A safety restriction and a doorstop device are included to ensure that the machine runs safely and effectively.

The zipper pouch packing machine by JOCHAMP must be extremely adaptable. The Zipper pouch packing machine has saving pouches, easy-change size, and spout, zip, and vacuum pouches.

JOCHAMP offers packing efficiency and compatibility to gauge the technological content of packaging machinery. It’s also the most important consideration for customers when purchasing packing equipment.

Zipper Pouch Packing Machine Packing Solutions

JOCHAMP will offer you the best solution according to your product mobility, viscosity, density, volume, dimensions, etc. It is widely applied in pharmaceuticals, food, daily chemicals, etc. You have arrived at the right site if you are looking to buy a zipper pouch packing machine from JOCHAMP.

- Powder Packing Solution: Powder filling is specialized for nutrient powder, seasoning powder, flour, medical powder, and other powders.

- Liquid Packing Solution: Fill with liquids such as water, juice, laundry detergent, ketchup, and so on.

- Solid Packing Solution: Solid fillings such as chocolates, nuts, pasta, dried fruit, vegetables, and many more.

- Granule Packing Solution: Chemicals, beans, salt, seasonings, and other granular filling materials.

Zipper Pouch Packing Machine Main Features

Efficient: All the bagging, filling, sealing, cutting, heating, and date/lot numbering are done at the same time.

Intelligent: Without changing any parts, the packing speed and bag length can be adjusted via the screen.

Profession: Different packaging materials are enabled by an individual temperature controller with heat balance.

Characteristics: Automatic stop function, safe operation, and film preservation.

Convenient: Low cost, labor-saving, simple to operate and maintain.

JOCHAMP Zipper Pouch Packing Machine Services

Packaging Solutions: For your convenience, JOCHAMP offers professional packaging and logistics services. Due to our extensive knowledge and meticulous treatment, we ensure that the machine is delivered to you safely and securely.

Pre-sale Service: JOCHAMP sales engineers and electrical engineers will provide pre-sale support, including a complete package of packaging options, professional rationalization proposals, and pre-sale tests.

After-sale Service: One-year quality assurance, lifetime after-sale service. Regular after-sales care, giving guidance on maintenance.

Why Choose JOCHAMP for Your Zipper Pouch Packing Machine

JOCHAMP has been manufacturing zipper pouch packaging machines for more than 15 years. All of our machines are not only technologically advanced but also include completely secure packaging. To verify the quality performance of our zipper pouch packing machine, we also conduct a series of tests and inspections.

We can examine our customers’ needs and requirements and match them with the right machine for their purposes and objectives. Whether you need a zipper pouch packing machine or one of our other packaging machines, we have what you need. Please contact us at any moment if you are interested in our zipper pouch packing machine, and we will respond promptly.

If you’re searching to purchase a JOCHAMP zipper pouch packing machine, you’ve come to the correct place. The best machine attributes such as:

- Faster working speed

- Longer operational life span

- Easy, computerized specification change

- Stable pouch advance with less deviation

- Improved filling accuracy

- An inbuilt batch cutting mechanism

- Noiseless Performance

- Contact parts in Stainless Steel

- Durable Mechanical Structure

- Superior pouch finish

The zipper pouch packing machine is mostly made up of standard components that are closely linked to the production line:

- A PLC and a large-screen touch interface manage the zipper pouch packing machine’s operation.

- Supporting a fault automatic tracking alarm system with a real-time status display.

- More servo control, less noise, and easier operation.

- Bag opening, blanking, and sealing are all possible with the mechanical empty bag tracking and detection mechanism.

- For reliable operation and a low failure rate, the main drive system uses frequency conversion, stepless speed regulation control, and complete cam transmission.

- The entire equipment was made to fulfill GMP requirements and has received CE certification.

JOCHAMP Zipper Pouch Packing Machine For Different Industries Application

Personal hygiene goods can also be packed with zipper pouch packing machines. Consumers are wanting more functionality and more value from items. As a result, single-use or on-the-go flexible packaging is becoming more popular. They benefit both the consumer since they increase sales and brand awareness.

The JOCHAMP zipper pouch packing machine for detergents and home care packaging solutions is very efficient and adaptable to any application. If you need a specific zipper pouch packaging machine for your business, please contact us for more information on how JOCHAMP may help you increase output.

For dairy products, JOCHAMP zipper pouch packing machines provide accurate answers to individual needs. They can be used with a wide range of flexible packaging and allow you to mix a classic product with a modern and appealing package. The cleanliness standards for the JOCHAMP machine are quite strict.

JOCHAMP offers zipper pouch packing machine solutions for coffee packaging, candy packaging, snack packaging, chocolate packaging, and a variety of other items. Some of the most essential features of the JOCHAMP packaging portfolio are the highest standards of hygiene, safety, waste reduction, and flexibility.

The zipper pouch packing machine solutions from JOCHAMP enable laboratories and other producers to ensure that medicines are preserved properly. This ensures the quality, consistency, safety, and efficacy of the product.

Related Product

Zipper Pouch Packing Machine: The Ultimate Guide

Let’s look at some fundamental aspects of zipper pouch packing machine. Whether you want to learn about working principle, features, or sealing mechanism; all information is right here.

It is a machine designed with automatic insertion of a Zip mechanism on the packing bags.

zipper pouch packing

Quality Assurance

Product quality is highly and effectively maintained to avoid any possible contaminations.

High Speed Level

During the process, zipper pouch packing machine can easily be adjusted to different speed levels. Therefore, making it easy to increase the efficiency level of the machine.

Flexibility

It can be used to pack multiple products over a long period at ago.

Efficiency

Over a short period of time, different bags are packed and sealed in large numbers, a factor to reduce number of employees in the company.

It is less costly.

Reliable

It can be used to pack different products. Besides, it can work over a long period of time.

Safety

Made mainly of stainless steel, it is safe as internal moving parts are safely allocated and do not affect the working condition of the operator.

Speed Adjustment

Different frequency level control is used based on the speed needed to make the machine run. It allows reducing or increasing speed based on the number of products to work on within a given period.

Low Maintenance Cost

Cleaning the machine and its components is easily achieved due to its simplicity.

Its parts can easily be accessed and managed based on the deformity included.

Easy To Detect Defect Or Disorder

Gas supply within the machine is detected by the alarm response.

Any defect or disorder is sensed and an alarm response will help the operator to allocated the desired service or task for the affected part.

· Stand Up Zip Lock Pouch Filling And Sealing Machine

It is a machine that automatically seals the pouch after a filling is done by pressing a zip on the pouch.

· Zipper Pouch Horizontal Form Filling Machine

It is a machine that presses the zip to the packing bag at its bottom end. Besides, it is suitable for products that cannot be filled in a vertically erected packing bag.

Zipper Pouch Horizontal Form Filling Machine

· Zipper Pouch Vertical Form Filling Machine

It is a machine that fixes the zip on the packing bag at its top end as the bag remains vertically erect.

Zipper Pouch Vertical Form Filling Machine.

It is suitable for a variety of products.

· Pump Dosing Mechanism

It is powered using an electric motor, the pump, after retaining a weighed amount of liquid in its chamber, is injected into the tank or even a pipe having the fluid dosed.

It controls the flow rate of the fluid being dosed in the process

Advantages

Some of the advantages include;

- Easy to use

- Suitable for all liquids and products are available in doses.

- Fast and accurate

- Flexible in various products

Disadvantages

Suitable for mostly liquid products.

Require a skilled person to run the machine.

· Auger Filling Mechanism

Auger fillers mostly fill powder products.

Powders can be free-flowing for instance salt particles and can also be non-freely flowing product powders like milk powders.

Since free moving powders cannot easily be dispensed, they cannot be pressed further.

Auger fillers use an auger screw part that dispenses the products.

The screw locates materials ahead in a rotating manner.

Settling The Required Parameters

It is done using a controlling mechanism.

Empty Vessels Feeding

Containers in the machine are manually fed for semi-automated auger fillers and manual auger fillers.

Conveyors are used to arranging the empty vessels for filling.

Filling The Containers

A hopper is used for accurate feeding of the drip.

Augers having weighing scales are always exempted as the machine uses volumetric powder filling machines.

The Auger screw is rotated by its drive while feeding powder to the hopper’s tubing.

An agitated blade moves opposite the screw to break inconsistent materials, hence a free-moving powder product.

Advantages

It is suitable for powers

Easy while being used

Faster to use

Flexible for different products

Disadvantages

Require skilled person to operate the machine.

· Net Weight Filling Mechanism

Use of weighing scales is important to measure the exact product before filling it in.

Semi-automated and automated methods are both used.

Semi-automated method places containers below the fillers as a button pressed for the process to start.

The button stops immediately after achieving a given-sized weight.

Process repeats over and over again.

Automated machines are fast and offer reduced operator works.

While using automated fillers, the process starts to the end as the vessels move below the fillers.

The slow nature gives an accurate process, but fast movement offers quick results.

Three alternating set points controlled are the target weight and the dribble weight as the final one is preacted.

Fast movement of the filling cycle moves to the dribble, after which, when it arrives at the preact, the valve closes as the vessel reaches the targeted weight.

A number of nozzle types are used based on speed selection and the type of container to use in the filling process.

Advantages

Easily used

Quality is managed and well maintained.

Disadvantages

It is slow as manual work is involved

Labour increase and costly in the long run.

· Volumetric Filling Mechanism.

Occurs in three types volumetric filling mechanisms.

Pump Filling Mechanism

Pumps transport products from tanks to containers.

It is applicable for highly viscous products hence avoiding clogging pump parts.

Peristaltic nature pumps have flexible tubes and rollers that separate the products from the pump parts in action.

It works best for dangerous fluids and also pharmaceutical fluids.

Gravity Kind Of Feeding System

Gravity being the key factor, forces through the products to the vessels.

It is applicable for foaming kinds of products.

Additionally, it is good for a thin kind of viscosity.

Again, it can also work in different temperature ranges.

It offers a quiet working environment

Piston Type Mechanism

Valves are opened by the piston’s fillers flowing directly from a hopper straight to the cylinder.

A full piston forces the product into the container via the nozzles.

It is applicable in various products of different viscosity and densities.

Advantages

High-quality production level

High-efficiency level

Faster

Easy while using

It is flexible and accurate.

Disadvantages

Require skilled person to run the machine

An intense workload on the machine hence can confuse the operator.

Zip Insertion Point

It is the main point of the machine as the zip is fixed to the packing bag before it is moved to the filling point or sealer.

Control Unit

It controls and monitors all the machine operations effectively.

Any defect or failed part is detected and shown over the screen.

Filling Point

Products to be packed are fed to the packing bag by use of a cup fitted at this point.

Sensor

It has a detector in collaboration withan alarm response to confirm the smooth running process of the machine.

Sensors also detect the presence or absence of fillings in the receiving cup.

Power Point

A given voltage is preferred for the machine to run effectively and efficiently.

Heat is used to seal the capsule for testing and ensure proper tightness is achieved by the machine.

Discharge Point

A conveyor belt is used to expel products that have already been packed and sealed awaiting for transportation.

It is operated vertically in a continuous manner.

A rolling material is a fist fixed on a roller.

A sheet of film rounds the rolling stock.

As the material rolls to the machine, a zip is fixed on the material at the zipper insertion point.

After the zip is inserted, printing can be done to the packing bag based on the client’s choice.

The bag shape is made through the forming tube as the bag edges overlap.

A photo eye is used to confirm all the printings before the bag is passed to the filling point.

A filling is done based on the weight or quantity of the customer’s product.

Sealing is done as the bag is moved to the discharge point to be expelled from the machine by the conveyor belt.

Water Pouch Packing Machines

A pouch packing machine can also pack drinking water to maintain quality and offer low water contamination.

pouch packing machine

Milk Pouch Packing Machine

Milk is packed and sealed using a pouch packing machine that does not require intense actions during operations.

Oil Pouch Packing Machine

Oil is packed and sealed to be transported to the market.

oil pouch filling machine

Masala Pouch Packing Machine

The pouch packing machine can pack Masala in powder and solid forms. This is quite efficient and reliable as different products are packed using the same machine.

Tea Pouch Packing Machine

It is easy to use the tea packed by the pouch packing machine in small bags in offices or other places requiring quick service deliveries.

Pouch Juice Packing Machine

A pouch packing machine is used to pack juices in beverage companies. Different juices are packed and sealed as they are graded based on the juice type or content of the product.

Pouch Shampoo Packing Machine

The liquid shampoo is well packed and sealed within the pouch to maintain its shelf life.

Pharmaceutical Industry

It is used in pharmaceutical industries to pack and seal drugs and other medicinal products for marketing and transportation to various required places.

Cosmetics Industry

Beauty products are packed and sealed in an enclosed vessel that preserves the product through its vase life.

Zipper Bag

The zipper pouch packing machine uses a zipper bag for all activities.

A bag is opened, filled, sealed, and discharged by the machine.

Machine Zipper Strip

The machine comprises a hot zipper bag lamination system that helps fix the pouch bag’s zip.

Tension Controlling System

An extra tensioned control mechanism is installed on the machine to feed the zipper’s strip material to a sealer, hence high quality zipping bag for use.

Specialized Ultra-sonic Design System

The main design offers strength to the zipper striping on the bag.

Punches

Hole punches can be used on specific packing bags based on the client’s desire.

Automatic Slider System

A slider system is optionally done if the client needs one.

Barcodes

If the client requests, an inline barcode can be fixed.

Feeding Material

Material to be fed to the machine is pre-folded onto a roller that rotates to provide the machine.

Cutting Dimensions

Cutting of width and length must be very effective.

Feeding the length will always affect the width; hence accuracy is required to offer a high-quality product.

Film Type Thickness With One Layer

A zipper bag and a sealer must have accurately measured and cut dimensions.

Output Product

A side sealer depends mainly on the length size and the bag thickness.

A zipper depends on the film thickness.

Dimension Of The Machine

Each machine has its dimensions based on the number of feeding materials required and its model based on the manufacturer.

Power Supply

Different machines require a given voltage percentage based on the activity it undertakes.

Conveyor

Automated conveyor helps ease the workload and offer a high-quality working environment.

Air Shaft

It is mainly used for the unwinding process.

Folding Unit

Based on the bag shape to be achieved, a folding unit is designed to fit its shape.

Inspecting Machine By A Technician

A qualified technician should continuously check out any faulty parts.

Proper And Continued Lubrications

Moving parts of the machine must always be well lubricated to avoid friction which causes the wearing of the involved parts.

Lubrications provide effective movement of the movable parts of the machine.

Dry Cleaning The Machine

A coffee capsule packing machine should be kept dry and clean to avoid filthy conditions, which cause corrosion to the main parts of the machine.

Cutting Parts To Retain Sharpness

Cutting parts used to cut film should be maintained sharp to increase the efficiency and performance of the machine in the long run.

Blunt-cutting parts are ineffective for the workpiece, which can create delays in operations.

Replacement And Repair Of Affected Or Broken Parts

Repairing parts that are worn out increases the efficiency of the machine as the operating system is maintained.

Replacing is key to avoiding injuries and offering viable long-term solutions.

Regular Machine Checkups

For any defects based on the machine operations, a regular check-up is required to avoid injuries and poor machine performance.

Skilled Operator

An operator must be skilled to avoid mismanagement of the machines.

Skilled personnel will properly manage the machine, set the machine in a very professional way, and control the unit performance based on the speed prescribed by the manufacturer.

For all your zipper pouch packing machine, contact us now.