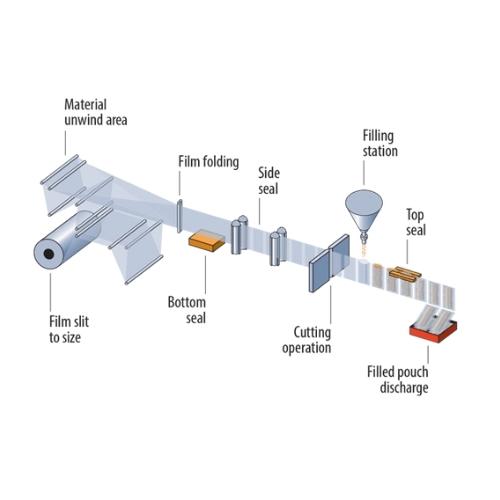

JCH-180 Flat Pouch Horizontal Form Fill Seal Machine

Entry-level horizontal roll film bag packaging machine. Suitable for flat pouch, shaped flat pouch.Through different forms of feeders, it can be used in food, beverage, condiment, pharmaceutical, hardware and other industries.

- Up to 30% bag cost savings compared to prefabricated bags

- Fully enclosed operation, safe and clean

- Cold and hot double sealing system, the sealing is more firm and beautiful

- Double servo traction film system, more accurate and stable film running

- Equipped with auxiliary bag opening, secondary bag expansion system

- Unopened and unfolded bag incomplete detection system to reduce waste

JCH-180

- Technical Parameter

- Features

- Optional

| Specification | 180N | 180NP | 180ND | 130N | |

| Packing

parameters |

Min bag (W*H) | 75×85mm | 70×85mm | 70×90mm | 60×80mm |

| Max bag (W*H) | 180×225mm | 180×225mm | 90×180mm | 130×180mm | |

| Max filling | 400ml | 400ml | 100ml | 160ml | |

| Speed (ppm) | ≤70 | ≤60 | ≤140 | ≤70 | |

| Film thickness | 60-140ų | 60-140ų | 70-130ų | 60-130ų | |

| Max roll diameter | 500mm | 500mm | 500mm | 500mm | |

| Inner roll diameter | 70-80mm | 70-80mm | 70-80mm | 70-80mm | |

| Specifications | Machine size (L*W*H) | 3500×970×1450mm | 4000×970×1450mm | 3500×970×1350mm | 2850×920×1460mm |

| Total weight | 900kg | 1000kg | 950kg | 800kg | |

| Working condition | Temperature Celsius | -10℃—+55℃ | -10℃—+55℃ | -10℃—+55℃ | -10℃—+55℃ |

| Relative humidity | ≤85% | ≤85% | ≤85% | ≤85% | |

| Power voltage | AC380V、50Hz | AC380V、50Hz | AC380V、50Hz | AC380V、50Hz | |

- Up to 30% bag cost savings compared to prefabricated bags

- Fully enclosed operation, safe and clean

- Cold and hot double sealing system, the sealing is more firm and beautiful

- Double servo traction film system, more accurate and stable film running

- Equipped with auxiliary bag opening, secondary bag expansion system

- Unopened and unfolded bag incomplete detection system to reduce waste

- High-strength processed cam structure for longer operating life

- Low noise operation (70 decibels within 1 meter)

- Optional automatic adjustment of the clamp function, 15 minutes to switch bags of different specifications

- Self-diagnosis function, faults are displayed directly, reducing downtime and maintenance costs

- Compact design with as little footprint as possible

- The whole machine is covered with 304 stainless steel, and the components are surface treated with advanced technology, which has stronger corrosion resistance and longer life.

- All food and pharmaceutical grade product contact surfaces, and have aseptic production conditions

- Horizontal operation mode, more friendly to granule, powder, liquid, paste

- PLC and HMI, ensuring stable operation and easier operation

- Independent intelligent tension control system

- Seamless connection to various automatic feeding mechanisms, such as multi-head weighing machines, elevators, liquid filling machines, screw filling machines, etc.

- Friendly docking secondary packaging system

- Unique sealing system, stronger sealing and lower defective rate

- Passed CE, ISO9001, SGS, cGMP and other quality system certifications Mitsubishi, Siemens, Schneider, SMC, SICK and other international brand electrical appliances and accessories

Automatic circulating lubrication system

Date printing (thermal transfer, inkjet, laser coding)

Nitrogen flush system

Electric clamp adjustment function

2-4 station customization

Automatic feeding mechanism (multi-head scale, auger filler, liquid filler, linear scale, vibrating plate, etc.)

visual inspection

Water cooling sealing system

Packaging film deviation correction system

top aligned cut

easy tear

hole punch

Vacuum system