Stick Pack Machine Supplier in China

Jochamp manufactures stick pack machines – customized to your specifications. It is perfect for packing any material, such as coffee granule, sugar, salt, milk liquid, powder, coffee granule, and more.

- Conformed cGMP, SGS, CE, ISO

- Asian rates, EU quality machines

- 1-Year quality guarantee

- Long term after-sales support

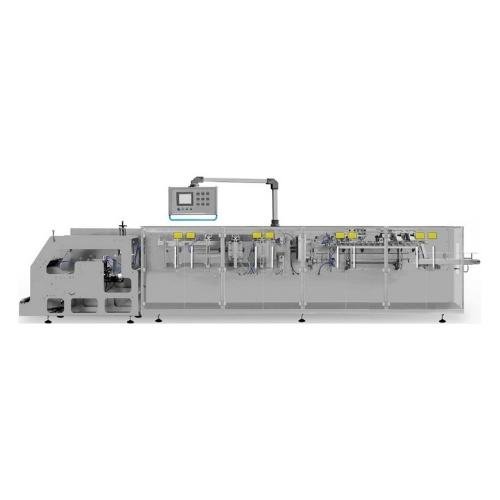

JOCHAMP Stick Pack Machine

Unlike other forms of food packing, stick pack machine offers more benefits when it comes to their convenience and pack size. They are very suitable for liquid products, granular, or powders – specifically spices, sugar, ketchup, milk liquid, and more. Using these machines can guarantee the freshness of all products.

Jochamp offers stick pack machines that are both inventive and technically sophisticated. It uses various packaging materials, such as PE-coated aluminum, plastic, or paper. Thanks to our deep capabilities and knowledge in the field, help us produce comprehensive machines – made in compliance with rigorous GMP and URS standards.

If you need them for your packaging business, contact us immediately!

Types of Stick Pack Machines

Stick Pack Machine Benefits

We always supply cost-efficient yet high-quality machines. You are sure to get your needs that fit your budget.

Choose our stick pack machines and you will get no problem in terms of maintaining them. Very easy to maintain.

Using them for your packing projects is recommended. They are high-speed and can meet your time frame.

All types of stick pack machines we offer are very convenient to operate. It ensures a smooth packing process.

Technology Characteristics

Jochamp stick pack machine delivers numerous technology characteristics. This is to fully satisfy every operator and packaging business needs. These machines are also customizable based on your specific sizes and structures.

- Composed of technological advancements

- Magnificent appearance

- Decent structures

- Fast and smooth operation

- Durable and efficient

- Simple to use

- Energy efficiency

- Fully automated, multi-purpose machine

Filling Systems in Stick Pack Machine

Liquid Filling System – It is the combination of sensitive pumps that fill all fluid types and commodities with a gel consistency into the preferred packages. Suitable for ketchup packaging, olive oil, mayonnaise, corn oil, honey, lemon sauce, jams, and many others.

Volumetric Filling System – This other filling system is perfect for use in free-flowing products (e.g. sugar packaging, brown sugar, white sugar, sweeteners, black pepper, salt, and more).

Auger Dosing Screw Filling – Last filling system ideal for products that are non-free-flowing. Made of stainless steel, an auger dosing screw filling system is used for packing instant coffee, coffee cream, cappuccino, hot chocolate, 3-in-one coffee, powdered pharmaceutical products, and more.

Applicable in Many Industries

Our stick pack machines are the best packaging solutions which can be assembled according to the following industries:

- Industrial sectors

- Food industry

- Beverage industry

- Cosmetic

- Personal Hygiene

- Nutritional

- Veterinary

- Pharmaceutical

JOCHAMP - Reliable Stick Pack Machine Supplier

Jochamp manufactures the most excellent and popular stick pack machines in the market. These machines are designed for optimum efficiency and constructed to last. Clients’ requests can be accomplished and satisfaction is granted with a length of 180mm and advanced features contributed to this equipment.

We provide stick pack machines perfect for packing products such as pharmaceutical powders, coffee, sugar, sauces, 3-in-1 coffee, honey, and many more. All machine types offer benefits such as high speed, simple maintenance, cost efficiency, and compactness.

If you are an expert with stick packs or a newbie in this business world, please get in touch with Jochamp at any time!

JOCHAMP Stick Pack Machine

As one of the leading manufacturers in China, we have knowledge and experience in a diverse variety of stick pack machine solutions. Having these types of machines enable you to create single-use, elegant stick packages. Whether you need to pack free-flowing products or non-free-flowing products, our machine is your good choice.

Free-flowing products: mayonnaise, ketchup, honey, sugar, coffee, milk, liquid chemicals, liquid soap, black pepper, water, and so on.

Non-free-flowing products: coffee cream, milk powder, coffee, and many others.

There are many advantages our machines can offer in the production of stick packages. Some of it includes the following:

- Price advantage for customers nationwide

- Simple fabrication

- Used cost-effective films

- Lowers packaging costs

- Creates 500 sticks per minute

- Eye-catching packages for consumers

- Prominently robust

- Perform 24 hours over 3 shifts

Why Choose Stick Pack Machine For Your Projects

Automatic stick pack machines package products at high speed without requiring manual human assessment. It is singular equipment used to package products in a timely manner.

Stick Pack Machine can be added to your existing packaging line. It overall improves speed and offers efficient productivity. Using them in your packaging projects can help reduce employee risk of injuries and labor costs.

Our range of stick pack machines is designed to secure and neatly package different products. This machine performs the sealing, forming, packaging, and labeling process. Its benefits include labor cost reduction, quick reaching of rising demands, enhanced efficiency, and excellent quality guaranteed.

Jochamp produced quite a wide range of options and sizes of packing machines. It comes in 45mm to 180 mm in length, and 16mm to 50mm in width or customized according to your request. This allows you to produce different-sized machines for various uses. We will provide a reliable custom machine for all of your packaging needs.

Related Product

Stick Pack Machine: The Ultimate Guide

Before buying stick pack machine, you should know the working principle, features, parts, and applications, amongst others.

In this guide, you will find all information you need about stick pack machine – take a look.

Stick packs are a form of flexible pouch distinguished by their narrow shape and compact size.

Typically, they are used to carry dry powder and, on rare occasions, gel, liquids, and semi-solid goods for on-the-go application.

stick pack

Mostly stick packs are an excellent choice for single-serve applications, sizes, and sample items heated at the point of sale.

Compared to other packing pouches, they use 10% to 40% less packaging material.

The pouches require specialized printing film and size and a four- to the six-week turnaround time for art approval.

stick pack machine

Some of the benefits are;

- Stick packs have the advantage of being able to be utilized for a wide range of products in a variety of industries.

- They are usually appealing, with various unique designs for customers to pick from.

- Another advantage is that they avoid product waste by providing the exact amount of a substance.

- You won’t have to worry about spilling during delivery using stick packs.

- It is usually practical and simple to use.

- Stick packs are easy to store and take up less space.

- It also has the advantages of being compact, slim, and easy to pour.

- Stick pack will create a larger potential value for marketing as an industry.

- Compared to other types of packaging on the market, stick packs save a lot of material.

- You shouldn’t be concerned because there is normally a solid barrier between the outside environment and the items within the pack.

- Another advantage is that the freshness of the product inside the stick pack will be preserved.

The stick packing machine components are:

Sealing Unit

Packs are normally sealed once the products have flowed through the stick pack.

The sealing unit’s job is to keep the contents inside the packs from spilling out. It’s usually found near the bottom of the stick sugar machine.

Forming Tube

The hollowness of the packets is formed by this portion of the stick sugar machine. It is the tube that gives the pack its final shape.

Cutting Knife

Cutting the stick packs into separate strips is normally done using a knife. In most cases, the cutting will start with the lane numbers on the stick pack machine.

Feeding Hopper

Stick packs must have substance inside them to be functional for the stick packing machine.

The feeding hopper will feed the content into the machine, which is one of the stick pack machine’s most critical components.

The Dancer’s Arms

It usually has a set of rollers that help maintain the film tension and, in general, keep the sideways from roaming.

Motor

The motor is a component that converts electrical energy into mechanical energy and is used to drive the stick packing machine’s parts.

Conveyor System

It’s a simple stick packing component that deals with moving material from one place to another.

Electrical Unit

It contains all electrical components that aid in providing electricity to the machine, such as fuses and cables in general.

Rolling Stock

Rolling stock is usually a circular element on a stick pack machine that holds the film.

You must position the film in this section of the machine for it to unwind during the stick pack creation procedure.

Control Panel

There is normally a computer-like mechanism on the side of the machine at this area of the stick pack.

It is when you take control of the stick packing machine.

This interface is used to set the parameters, and it can also be used to locate problematic components.

Sensor

It is a machine component that plays a key function in ensuring the stick packing machines’ efficiency.

Typically, the machine contains various sensors that aid in increasing efficiency.

It aids in detecting flaws throughout the stick packing machine’s operation. For example, the sensor will detect if the stick pack is not properly sealed.

They also assist in determining the appropriate amount of content to flow in the stick pack.

Printers

It is an optional component of the stick packing machine for the printer; for machines with this component.

It prints details such as the manufacturing date, expiry date, brand name, and any additional precautions consumers must observe.

The steps on how a stick packaging machine works are as follows:

Step 1: Unwinding And Transporting The Film.

The unwinding and transportation of the film is commonly the initial stage, and the stick packing machine will employ a single film material sheet rolled on rolling stock.

At this point, you must choose the packing film to utilize from a selection of options. Nylon/PE, OPP/PE, and aluminum/PE are some of the film materials.

The film is usually placed on the fill reel at the back of the stick packing machine.

Thanks to the rotating cross seal jaws, the unwinding will occur here.

Step 2: Printing

This stage is usually optional, depending on the design of the stick packaging machine.

Everything depends on the machine’s design; you can use a simple ribbon printer, an inkjet printer, or a thermal transfer printer.

The stamp date can be positioned by feeding the films on the roller registration.

The film will pass over the sensor, detecting marks and placing the horizontal seal simultaneously.

Step 3: Film Tension

If the sick packing machine lacks a printer, the operation will likely go to the film tension step, where a nip roller will feed the film.

By applying even pressure to the film, the nip roller ensures that it remains in continuous tension.

It usually aids in optimum dancer arm operational positioning.

The film will pass to the dancer’s arm, which normally consists of numerous rollers while unwinding from the roll.

The pivot is the dancer’s arm, placed at the back of the stick packing machine.

As the film moves up and down, the dancer’s arm serves to keep the film suspense.

Step 4: Film Cutting

It will be the next stage once you’ve finished with the nip roller. When it comes to film cutting, it’s commonly done at the stick packing machine’s cutting portion.

The number of lanes available in the stick packing machine will determine the cutting.

The film, still under tension, travels through the blades that are in contact with a specific roller.

While moving forward to the next stage, the film is being chopped as it passes through.

Step 5: Stick Pack Formation

The formation of stick packs from the stick packing machines is usually done. The strips will run through several forming tubes.

Here films often form a collar on each tube and fold the tubes into stick pack shapes. In most cases, the shape features two outer edges that overlap.

A lap seal or a fin seal can be formed with a forming tube.

The fin seal is formed when the two outside film edges meet and produce a seal that protrudes like a fin.

In contrast to the lap seal, where the two outer edge films overlap to form the flat seal, the flat seal is formed by overlapping the two outer edge films.

Step 6: Filling And Sealing Of The Stick Packs

The contents are typically filled at this stage, and when the film movement ceases, a forward movement of multiple vertical bar sealers, which are typically hot, occurs.

As the movement continues, the vertical fil will overlap by pressing on the vertical sealers, resulting in the formation of a vertical seal.

On the other hand, the horizontal jaw will bond the top of one stick pack with the bottom of the next.

An auger filler or a liquid pump is typically utilized to ensure exact filling and accurate product measurement during the sealing process.

Step 7: Discharging Of The Stick Packs

The final stage of the stick packing machine process; is when the sick packs have been filled and sealed.

Again the machine pushes them to the outfeed channel, a flap that normally alternates between shutting and opening.

Closing and opening are done at predetermined levels, with the packs being dropped straight into the outfeed conveyor receptacle.

If you want to discharge the stick packs one at a time, you’ll have to change the outfeed channel, and you may choose to pack the stick packs directly into the cartons at this point.

The stick packing machine is a vertical filling and sealing machine that forms stick packs due to film cutting and making a roll, then fills and seals the stick packs.

Sachet machines are comparable to stick pack machines.

They heat seal at the bottom and then fill through the hopper before being heat sealed at the top and cut to create a fully sealed unit.

stick packing machine

Moreover, they are normally heat sealed at the bottom and then filled through the hopper before being heat sealed at the top and cut to create a fully sealed unit.

In general, they have similar uses in:

- Pharmaceutical industries

- Cometic industry

- Food industry

- Chemical industry.

sachet machine

Normally the stick pack machine will vary depending on the design of the machine. Some of the features include:

- It has SS 316 stainless steel, a strong and long-lasting material.

- The Stick pack machine has a fully programmable logic feature with HMI

- Another feature is it has no film alarm that alerts the operators, resulting in less waste.

- It usually has an emergency stop, capacity count, and output pack ready

- Also, the stick pack machine has Filling capabilities for granules, liquids, and powders

- It is a tool-free changeover that is quick.

- The stick pack machine has aided in the integration of equipment.

- The machine has Photocell tracking capabilities with a high degree of precision.

Some of the main filling technologies are:

Volumetric Filling Technology

This filling process is best appropriate for free-flowing products.

You can stick pack brown sugar, sticks sweeteners, salt, paprika, black pepper, and any other mixed spices with this type of stick packing filling choice.

volumetric filler

Auger Filler Technology

It is a stick packaging machine filling solution for non-free-flowing materials.

Generally, the filling of non-free-flowing goods is mostly accomplished by rotating stainless steel screws.

The Servo motor usually provides the rotation of the screws. The number of needed rotations determines the weight of each packet.

auger filler

Coffee cream, instant coffee, hot chocolate, cappuccino, three-in-one coffee, Turkish coffee, powdered pharmaceutical products, or any other powder are good candidates for this filling.

Liquid Filling Technology

It is connected with sensitive pumps for liquid technology filling, which fill products with gel-like consistency and liquids into the desired sticking packs as per their required weight.

Corn oil, lemon source, honey jams, cream sauce, salad sauce, marmalades, and any other particles containing food products are among the products.

In general, it is appropriate for the stick packaging of liquid items.

Various industries use stick pack machines for different productions. Some of them are:

- The Pharmaceutical industries

In this industry, they apply the stick pack machine to package medicines for patients of all ages in various quantities, making them convenient to use and store.

- Cosmetic industry

This industry involves a lot of beauty products, which must be packaged properly and also attractive. Stick pack machines assist the manufacturers in packaging products like dyes, body lotions, and body oil in a visually appealing and portable style.

- Food industry

Stick pack machines are used in the food industry to provide an easy-to-use, appealing, and economical product for all of their clients.

Some of them are glucose, coffee, and sugar, among others.

- Chemical industry

Stick pack machines are used to pack a lot of chemicals. Acids and reactive compounds are among the products.

Normally, it is determined by the individual’s needs.

Choosing a stick packaging machine can be difficult because different manufacturers require different specs for their machines based on their applications.

Here are some tips on how to buy a stick packing machine:

Stick Packing Category

Depending on your product category, you should select a stick pack machine suitable.

Stick packing machines for granules, powder, and liquids are the most common types.

Choose the proper machine with the appropriate categories for your application based on the product line.

Rate Of Packing

Consider the number of stick packs you intend to create per unit when selecting a stick packing machine as a manufacturer.

Compared to semi-automatic stick pack machines, there is an option of a fully automated stick pack machine, which covers a larger volume per unit.

Another thing to remember is that a multilane stick packing machine will provide you with a higher packing rate than a single stick packing machine.

Hooper Capacity Of The Stick Pack Machine

To reduce time throughout the packaging process, make sure the stick packing machine hopper can contain enough products without needing to be refilled frequently.

Seal Type

Typically, the stick pack machine creates fin seals or lap seals.

The lap seals generally overlap the two outside edges, resulting in a flat seal, whereas the fin seal will reassemble a fin by joining the inner sections of the outer edge to form a seal.

Select the machine with the seal type you’ll need for your production.

A lap seal is the most commonly recommended since it uses less material and is more appealing.

Application

As a company, you can select a stick pack machine for your production from the food, pharmaceutical, cosmetic, or chemical industries.

Ensure that the equipment can handle the product you want to pack.

Some of the common types of stick pack machines are:

Semi-Automatic Stick Pack Machine

The operation of these machines necessitates the use of human effort.

Even if the machine is self-contained, some aspects of its operation will necessitate human intervention.

It is adaptable, as you may use human labor to expand your packing capacity.

Fully Automatic Stick Packing Machine

The term “totally automatic stick machine” usually refers to a machine that can perfume all of the packaging functions without the involvement of a human.

It is the ideal machine for stick packs in high-volume production businesses.

This machine has several advantages, including a high level of precision compared to the competition, eliminating human mistakes in packing, and improving production.

Single Lane stick Pack Machine

When using a single-lane stick pack machine, the stick pack normally forms in a single vertical direction.

The single long pack is broken into numerous sizes depending on your size requirements.

This machine is ideal for sectors with limited production volumes or where minimum packaging is required.

Multilane Stick Pack Machine

As the name implies, it usually features numerous vertical stick pack formations simultaneously.

For example, suppose you’re making six vertical stick packs and five horizontal stick packs simultaneously.

The multilane stick pack machine is the best machine to use if you have huge production or high packaging needs.

Related Resource:

Packaging And Labelling Machine

For all your stick pack machines, contact us now.