Sachet Cartoning Machine Supplier in China

Jochamp provides sachet cartoning machines that run with low noise yet at fast speed. All machine models are custom-made according to your specific requirements.

- Comes with a 1-year quality assurance

- Great machine qualities at low rates

- Experienced manufacturer for over 15 years

- Perform with stability and efficiency

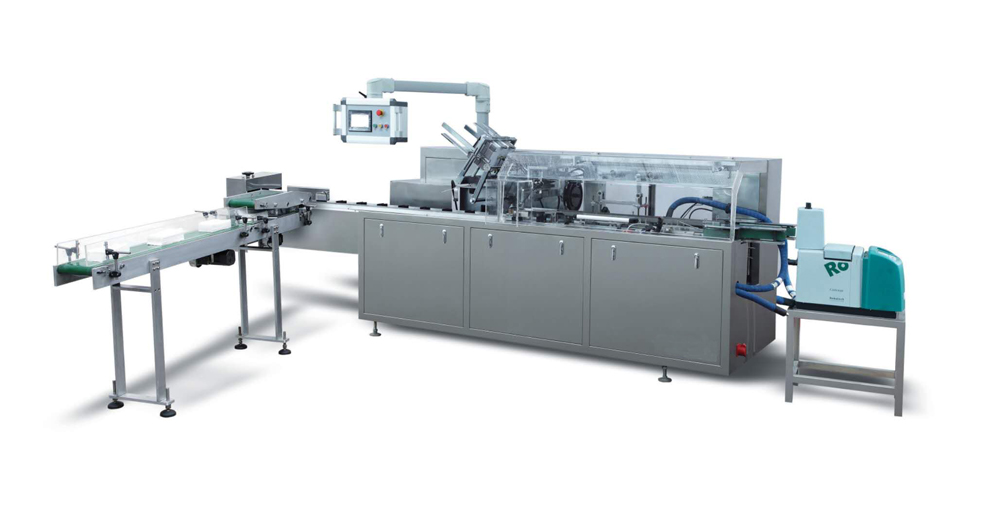

JOCHAMP Sachet Cartoning Machine

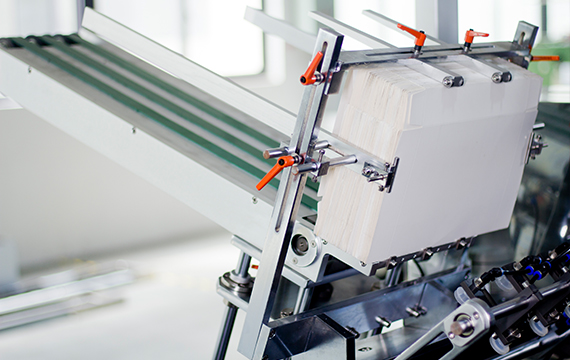

Cartoning machines for sachets are also commonly used in today’s packaging industry. At the same time, they can be split into horizontal and vertical cartoning machines depending on the role where the carton is fed through the machine. As a global manufacturer, Jochamp offers sachet cartoning machines with very good quality, efficiency, and value.

These ideal machines are perfect for cartooning sachet drugs, cosmetics, food products, and further similar sachet items. It generates cartons that are sealed, folded, upright, closed, and side seamed. If you need them for your packaging business, contact us and let us provide them for you.

Types of Sachet Cartoning Machines

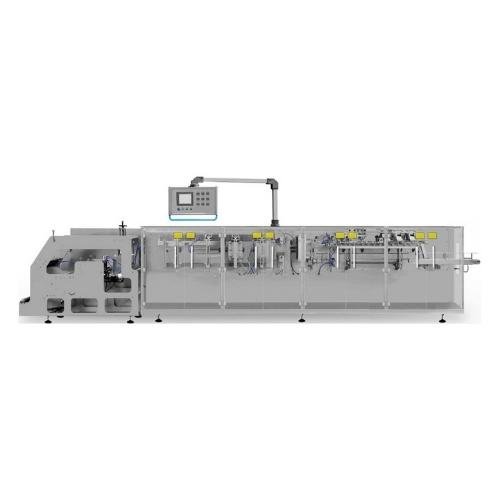

Introducing the Entry-level Sachet Cartoning Machine, an economical and effective packaging solution designed for sachet products.

Tailored to suit the unique characteristics of sachets, this automated equipment ensures precise and seamless cartoning, creating a professional and visually appealing packaging presentation.

With a speed ranging from 30 to 60 packs per minute (PPM), the machine maximizes production efficiency, reducing manual labor and optimizing overall output.

The Entry-level Sachet Cartoning Machine is a cost-effective choice for businesses seeking to automate their sachet packaging processes without compromising quality. Its user-friendly interface enables easy operation with minimal training.

By enhancing packaging efficiency and maintaining consistency, the machine empowers businesses to meet industry standards and leave a lasting impression on customers.

In conclusion, the Entry-level Sachet Cartoning Machine is a valuable asset for companies aiming to elevate their sachet packaging capabilities while ensuring affordability and reliability. Experience seamless packaging and elevated product presentation with this smart investment.

Sachet Cartoning Machine Benefits

We will grant your custom cartoning machine requirements. We can custom-build based on your applications at reasonable rates.

All cartoning machines including sachet cartoning machines are easy to maneuver. It comes with easy-to-follow manuals.

Besides being high-quality machines, they are also reasonable in price. We do not compromise its quality during development.

These machines are built with convenient designs. It means, they are easy to work with – no need for special skills or experience.

Work Flow of Sachet Cartoning Machine

Sachet cartoning machine grabs one carton from a pile, straightens it, and fills it with the sachet item by feeding it sideways by one end, and then closes the box by stuffing the open edges or wrapping it with a designated adhesive. Add the item into the cardboard box using pressurized air. However, because most items are fragile, most cartoner machine manufacturers depend on traditional insertion.

When the cartoning process is done, the machine activates its navigation bar to apply a predetermined amount of sticky tape, shuttering both ends and eventually sealing the carton.

Advantages in the Packaging Industry

Cartoning machines such as sachet cartoning machines are generally inexpensive and provide an exceptional amount of flexibility. These cartoning systems are a prime example of efficiency and adaptability.

To address any packaging issues that arise, you can connect the machine to an upstream packaging system.

Individual machine has a compact design that balances speed and adaptability. That way, you get your money’s worth out of each machine you order.

Specific Designs and Machine Features

Jochamp sachet cartoning machines come with several machine features. It makes them suitable for multiple packaging/cartoning applications.

- This cartoning system is AC- or servo-controlled and provides superior efficiency and ease of machine synchronization.

- Installation period – 5-10 mins, based on the sachet size.

- This system comes with a hygienic design for safer operation.

- Its electronic components are easy to access for quick identification of issues.

- Built-in wheels for convenient operation and mobility. They can be relocated anywhere to any setting.

- Production speed capacity of 50-80 cartons per minute

- Runs automatically or manually.

JOCHAMP –Sachet Cartoning Machine Supplier for 15+ Years

For more than 15 years, Jochamp has been producing a wide range of sachet cartoning machines. Our machines are known for their high precision, good value, and superior efficiency. We manufacture them in compliance with global quality standards such as ISO, CE, cGMP, SGS, and others. We are confident to deliver excellent performance sachet cartoning machines.

Each machine comes with a 1-year warranty. These cartoning machines are perfect for your business needs. For questions regarding our services and machine offers, please contact us directly!

JOCHAMP Sachet Cartoning Machine

- We will send experts to your location to setup and commission machines as well as train your technicians.

- We provide a 1-year warranty on the machine. During the warranty coverage, we will provide free spares.

- We appreciatively welcome client suggestions to help us grow and create good machines, as well as provide quality service to clients and build more value for them.

- Welcome to our manufacturing site to check our machine before placing orders or before shipments. We will pick you up from the airport and arrange your next schedule in our area to ensure that you have a smooth journey all through your visit.

Cartoning machines are classified as horizontal or vertical cartoning machines based on how the carton is fed through the machine.

Sachet Cartoning Machines, Vertical:

Vertical cartoning machines feed the carton vertically through the machine, and the item is placed manually or mechanically. These machines are appropriate for packing “bare” sachet goods that are sold by weight or volume and must be procured by gravity.

Sachet Cartoning Machines, Horizontal:

The item is implanted from the side of the carton on horizontal cartoning machines. These cartoners can perform in constant or occasional mode.

Custom Sachet Cartoning Machines for Any Sachet Products

Jochamp provides a specific cartoning machine for packing standard sachet products. These are cost-effective solutions, with high efficiency, fastpacking speed, and smooth cartoning operations.

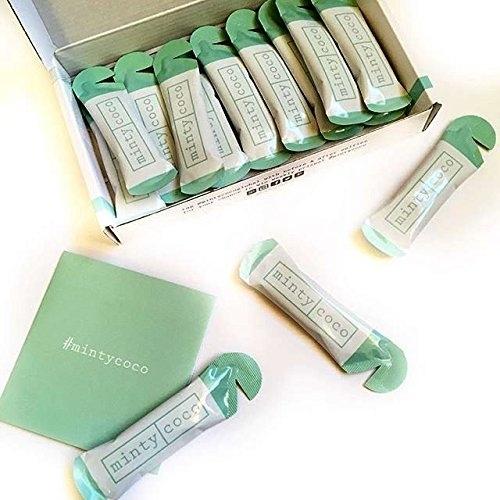

Cartoning machines are a great way to safely packed contour sachet products. This is a unique form of the sachet with a recognizable appearance. They are used for cartoning cream sachets, granules, powders, and cosmetic liquid products. The machines are custom-made based on your applications.

Horizontal or vertical cartoning machines, both work well for packing your tissue sachet products. These cartoning machines are very hygienic, and available in different specific and standard formats.

The certain cartoning machine for onpack sheets aids in securing the product and keeps organized. These machines can be customizable with your brand, size requirements, and so on. Plus, they seal the onpack sachets well for safe delivery.

Related Product

Sachet Cartoning Machine: The Ultimate Guide

If you are looking for the best sachet cartoning machine, read this guide. It covers all vital information about sachet cartoning machine. Let’s dive right in.

It’s a machine-packing process that stacks pre-filled and sealed sachet packs into cartons.

They usually take flat cartons, elevate them to a regular shape, and press the sachet product inside the carton before closing it.

Sachet cartoner comes in a variety of shapes and sizes.

End load, vertical, horizontal, continuous, and top loader sachet cartoning machines are some of the types of machines available.

sachet cartoning machine

It is a technology in which a sachet cartoning machine is combined with a filling machine, loads the product into the sachet to the desired quantity.

It then seals and packs the sachets into their respective boxes.

The sachet cartoning machine subsequently carton and seal the boxes according to the manufacturer’s specifications, ready for shipping or storage.

End Loader Sachet Cartoning Machine

It’s a sachet cartoning machine loads the contents horizontally into the box. In most cases, the product can be slid as a single item.

With either automatic or manual infeed, this equipment can pack up to 35 cartons per minute.

end loader sachet cartoning machine

Standard features include easy format changeover, controlled carton supply, servo drive, hot air and melt system, and excellent accessibility.

Top Loader Sachet Cartoning Machine

In how the confinement is loaded into the carton, this machine matches the vertical cartoning machine for sachets.

Although, it is usually an integrated system that is united by numerous machine sections, robotic loaders, and carton closers rather than a single set machine.

They have a servo drive, easy accessibility, sensor, PLC, and touch screen control, among other characteristics.

top loader sachet cartoning machine

Intermittent Speed Sachet Cartoner Machine

It is a cartoning machine with intermittent motion, as the name implies. Compared to continuous cartoning machines, they have a reduced speed of 150 times.

Typically, sachet products are packed laterally into cartons and sealed with a lock closure during hot-melt gluing or flap insertion.

intermittent speed sachet cartoner machine

It is generally used for large-format cartons and typically includes a motion control module, actuator, and servo drive, improving operating accuracy and reliability.

This machine can also convey and feed sachet items of various specifications.

Continuous Speed Sachet Cartoning Machine

This machine usually is designed with a high speed for large-volume manufacturing lines, such as cartoning hundreds of boxes per minute.

It’s one of the market’s more complex and pricier sachet cartoning devices.

A continuous-speed sachet cartoner machine deals with solid inventory and regular shaped sachets that don’t require special processing.

continous speed sachet cartoning machine

With features such as a barrel cam loader and various inserter-guided inserters.

This to achieve forward and backward movement of the insertion, the track via which the inserter is motion-controlled horizontally is used.

Horizontal Cartoning Machine For Sachet

This sachet cartoning machine erects the carton blacks with the top and bottom facing horizontally and the front and back panels facing up and down.

It is similar to the vertical sachet cartoning machine in terms of innovation.

horizontal sachet cartoning machine

They have manual or automatic loading, tuck closing, and an easily accessible adjustable conveyor.

Learn more about horizontal cartoning machine.

Vertical Cartoning Machine For Sachet

The sachet contents are always inserted into the cartons vertically, directly from the infeed system, and sealed into the folding box with this type of sachet cartoning process.

This machine is designed to pack various sachet products and is especially well-suited to vials, jars, and bottles.

vertical sachet cartoning machine

It primarily offers simplicity, adaptability to format changes, ease of cleaning, and the ability to accommodate additional alterations.

Learn more about vertical cartoning machine.

The merits of a sachet cartoning machine vary for retailers, producers, marketers, and customers. Here are a few of them:

- Because most sachet cartoning machines are automatic, they have the advantage of being simple to set up.

They also provide consistency and uniform sachet cartoning to satisfy client expectations. This machine also includes essential assistance and a user-friendly handbook to help manufacturers understand how it works.

- Furthermore, because it functions mainly by itself, the sachet cartoning machine has the benefit of lowering labor costs in the sector.

It also ensures that stability, accuracy, and speed are maintained.

- For producers, one of the advantages of a sachet cartoning machine is that it saves a lot of space.

Manufacturers frequently seek machines that take up less room to free up floor space for additional equipment while lowering lease costs.

This machine is compact, which is a benefit to the producer.

- It is simple to eliminate necessary faults when using sachet cartoning equipment. During the process, you can expect a low percentage of errors.

- Since less material is required and waste is minimized, sachet cartoning machines are usually cost-effective.

Compared to other machines, it is often less expensive, lowering the cost of sachet products from the producer and increasing client satisfaction.

- Sachet cartoning machines are ordinarily durable, will work at a high pace, and will have a long-life span with adequate maintenance.

This is an advantage in the long term.

Some of the essential features for sachet cartoners are:

Automation Degree

Typically, automation has resulted in significant improvements in the manufacturing of sachet cartoning machines.

This function has fully automated sachet machine cartoners and semi-automated sachet machine cartoners.

In these cases, a fully automated machine is usually suited for high volume sachet cartoning production but at a higher cost than semi-automated equipment.

Therefore this is typically recommended for small sachet cartoning production.

Sachet Carton Machine Production Capacity

The cartoning capacity of the sachet machine is often a significant feature of the machine.

It usually refers to how much cartoning the machine can handle every minute.

There are typically several patterns to choose from regarding sachet machine cartoning.

Because manufacturing is such an important characteristic, you’ll select a machine based on its capacity and production requirements.

Machines with a large capacity are usually the best since their speed is unmatched.

Product Types

Another aspect of the sachet cartoning machine is the product type.

Sachet machine cartoning is commonly employed in a variety of industries for diverse purposes, including the cosmetics, food, and medical industries.

As a manufacturer, you must select the sachet machine cartoning intended for your product and sachet sizes for the sachet cartoning to run successfully.

Additional Equipment and Accessories

Flexible and rigid designs are commonly used in sachet machine cartoning.

The rigid sachet machine cartoning is developed with restricted characteristics for a future update for this function.

It implies you won’t be able to install any more accessories or equipment if you require it in the future.

Flexible sachet machine cartoning, on the other hand, is always built to support any future upgrade features.

As a manufacturer, you have the option of adding any equipment or accessories that you think will benefit your manufacturing process.

Below are the main parts of the sachet machine cartoning:

Electric Motor And Panel

One of the machine’s unique parts deals with power circulation throughout the complete machine system.

All electrical and mechanical systems must be established in this section for the entire machine to work.

Lubrication Automation System

If you want your sachet cartoning machine to last longer, the bearings, gears, and belts should all be lubricated consistently.

Like any other mechanical system, this machine is essentially an electromechanical device.

To get the best performance, ensure the moving parts are adequately greased. If you don’t lubricate your machine, you’ll have to pay a lot for maintenance.

Control Panel

It is the part of the sachet machine cartoning where the on and off knobs or push buttons, circuit, fuse breakers, emergency buttons, and process controller for elements are usually operated.

This section will alert you to any errors that occur throughout the sachet carton processing.

An ink-jet Printer

It is a crucial section that mainly deals with the printing of manufacturing dates, expiration dates, and any warnings for the user.

It usually has a minimum of three rows of writing space.

Safety System

It is vital because a sachet carton machine is an inanimate item. You use extreme caution when handling it.

In general, the safety system will show when the machine requires maintenance and has a sensor element that may promptly stop the machine in the event of a risk.

The cartoner sachet’s principal operation is as follows:

- Step 1: Manually stack the product into the feeder with your hands.

- Step 2: This is where the product will be counted and dropped before being pushed to the conveyor.

- Step 3: This is the point at which the box sucking takes up space.

- Step 4: Leaflets will be folded into 1-4 folds, and the box will be opened and shaped.

- Step 5: This is the procedure of pushing sachets inside the box.

- Step 6: They will be labeled according to the batch numbers, optional, using an ink jet printer.

- Step 7: The box will be tucked in or sealed with hot melting gluing.

- Step 8: Output of the completed sachet product cartoning

A sachet packing machine is a machine that fills and seals pouches with powder, liquid, or granule contents such as palm oil, shampoo, tea bags, cookies, sugar, and cereals, among other things.

sachet packing machine

The most well-known packaging types for the sachet cartoning machine are foreign sachets, stick sachets, four-sided sachets, and three-sided sachets.

A sachet cartoning machine, on the other hand, a machine puts the filled sachet package into cartons ready for transportation and shipment.

Vertical sachet cartoning machines, horizontal sachet cartoning machines, and end load sachet machine cartoning are some of the varieties.

Some of the benefits include:

- One of the advantages of melt closure cartoning for numerous sachets is that the cartons have superior packing quality.

It can withstand temperature and humidity variations in the shipping environment without causing damage to the multiple sachet packs inside the cartons.

- Another advantage of melt closure cartoning for numerous sachets is that it acts as an anti-counterfeiting measure.

This is because it penetrates the carton, and any attempt to open it tears it completely, leaving visible proof.

- An additional advantage of the melt closure is that it is environmentally friendly; it does not harm the environment.

It is because it meets quality standards, making the sachet packs within the carton safe to use.

The significant applications of the cartoning sachet machine are:

- Milk

- Jam

- Tea bags

- Coffee

- Sugar

- Fruit juice

- Honey

- Shampoos

- Powder soaps

- Sanitizers

- Powder medicines

- Tablets

- Liquid medicines.

While choosing a cartoner sachet machine, you may need to consider the following:

- Consider the size of the sachet products you plan to the carton in the industry before selecting a sachet machine cartoning.

- Another factor is the need for sachet cartoning machine size and sachet product turnover.

- A further factor to examine is whether the machine can be upgraded in the future if necessary.

- As a manufacturer, you must understand the type of sachet product you will be dealing with to select the appropriate sachet machine cartoning.

- First, consider how many sachet packages you’ll be cartoning with the machine.

- The speed of the sachet cartoning machine you want to utilize as a manufacturer is another consideration.

Different speed capacities have been built into these devices.

- When selecting a sachet machine cartoning, a manufacturer must consider the area available for installation.

You must know the exact space you have to put the machine so that you do not run out of room or overuse the site for the machine when you choose it.

In a cartoning sachet machine, a delta robot picks multiple or single sachet goods that come in random order and quickly places them into the appropriate cartons.

They can pack different sachet goods in many infeed at the same time.

Advantages

- Due to increased speed and throughput, they enable higher sachet cartoning production rates.

In most cases, it may produce three pieces per second or even 180 parts per minute.

- They have the benefit of taking up less space than other sorts.

It is appropriate for a limited manufacturing area because it has a compact footprint and is often installed overhead.

- You won’t have to worry about quality control with delta robotic in sachet machine cartoning because it’s taken care of during the process.

- Another benefit is that it simplifies cleaning and maintenance because the sachet machine with delta robot automatically detects when service maintenance is required.

For all your sachet cartoning machines, contact us now.