With the guidance, you can start the problem-solving process by contacting Jochamp or filling out our online troubleshooting checklist. You may not have an immediate answer to every question; provide as much information as possible. Our technicians will request any additional details they need.

1. Define the problem

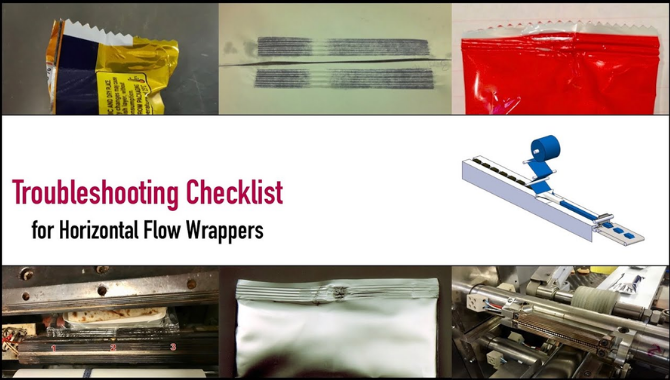

Is there a leaker in your package?

Are there any packaging appearance problems, such as crushed or split end seals, wrinkles, creases, or thermal deformation?

You may have both.

Is the problem isolated to one wrapper, or is it happening on multiple machines?

What is the make and model of each package?

Are the results the same for each shift? Does the problem occur in more than one factory?

Try to determine when the problem started, and pay attention to any changes that might cause the problem.

Has the film structure, film supplier or product changed?

Are there changes in personnel or tools (such as rolls, knives, fins, or heaters)?

Let us further clarify when and where the problem exists.

Do leaks or appearance issues always appear in the same place on the package?

Does the problem occur on every package, or does it occur intermittently?

If you use a multi-coil head, do you have problems with each pair of coils?

Track the problem and see if it appears in the leading seal, trailing seal, or both.

For multi-purpose machines, does the problem occur continuously, or only in one package size, product, or film structure?

2. Determine the cause

Send clear carbon footprint photos-our most important diagnostic tool. They reveal important or otherwise hidden details, machine settings and conditions, crimp and knife design, and other reasons.

Provide photos and samples of the software package running during the production process to prove your problem. If possible, include the film specifications and the name of the film supplier.

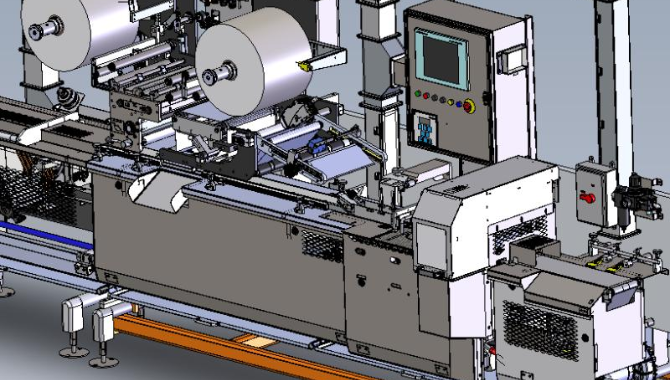

Provide photos or videos of any machine processes or parts related to the problem, such as: crimping machine; using anvils and knives, and sealing and cutting heads.

Is your knife adjusted with screws or washers? After adjusting the washers, what are the number and thickness of the washers under the anvil?

Using a contact pyrometer, provide three temperature readings from the crimped sealing surface in the middle and the face on each side that touches the outer edge of the package.

Provide package control settings, if applicable, line speed, dwell, package length, and temperature of crimper and fins.

3. Develop solutions

We can learn from every detail, even if it seems unimportant, to find solutions that will solve your packaging problems. For technical assistance, please use the troubleshooting checklist on our website or contact Jochamp. We develop and provide solutions on a global scale.