Flow packaging machines provide convenience and efficiency because they are able to process a large amount of product packaging in a short time. It provides a product with the best packaging solution, and the hygiene level is highly adhered to. This is achieved by using ultraviolet light and ensuring that fewer people handle the packaging.

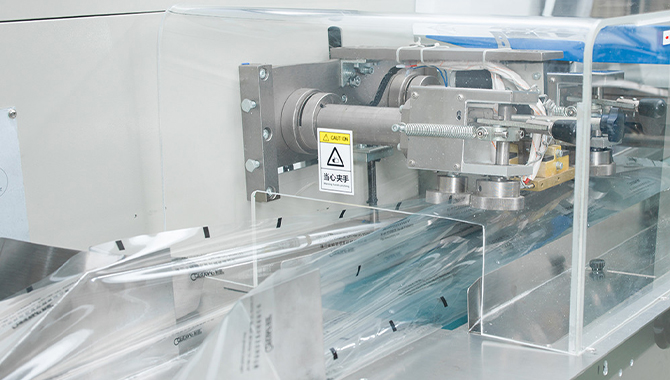

1. What are the components of the flow packaging machine?

The flow packaging machine is available in different sizes and capacities. However, most of them have key components. These components include;

- A very long infeed conveyor belt

- Video from top to bottom

- A shaped bag, usually located at the collar of the machine

- Phone photo

- A display device or touch screen

- Cutting head

- Re-station

- Fin sealing unit

- Unloading belt

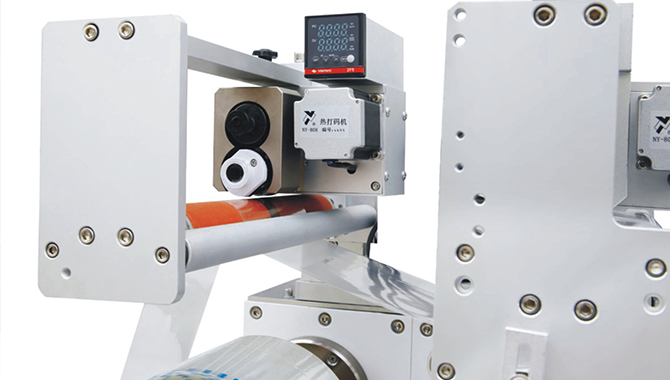

- Optional date printer

In addition, you can request to customize your flow packaging machine from your packaging machine manufacturer depending on the packaging of the product. Household items, stationery and food all attract different changes in machines. Have a clear purpose for your machine, which can help the manufacturer provide you with the best flow packaging machine.

2. What is the working principle of the flow packing machine?

The working principle of the streaming charter is very straightforward. A packaging film driving roller drives the film into the former and causes it to be formed. After that, the material is sent to the conveyor. The product is sealed longitudinally and cut horizontally. Then it passes through the output area of the machine as an output.

3. What is a horizontal flow wrapper?

A horizontal flow packaging machine is a machine used to pack products into its defined packaging. From the name, the product is embedded on the conveyor belt, and the conveyor belt moves horizontally to the sealing head of the machine.

The product follows a flow direction, either to the right or to the left depending on the machine, towards its head. Then, use film for packaging.

In addition, the film usually has a variety of materials to choose from to suit your product packaging needs. Horizontal flow packaging is automatic, thus facilitating high speed in the packaging process. Horizontal flow packaging is very suitable for packaging products such as lollipops, books, pens, and even baked products such as biscuits and pizza.

4. What factors determine the price of the flow packaging machine?

Many factors affect the price of flow film packaging machines. These factors include;

The degree of automation or technical level of a machine. Compared with semi-automatic or manual machines, automatic machines tend to be a bit expensive. The type and size of the machine will also affect its pricing. The bigger the machine, the higher the price.

Finally, the way the machine operates will also affect its pricing. It can use electricity or gas. Their prices are different.

5. Comparison of large and small flow packaging machines?

Large-scale flow packaging machines are suitable for large-scale supply industries that help packaging products. For example, a company that produces food supplies such as chocolate and biscuits will need a large flow packaging machine.

This is because the machine can withstand long hours of work and can also facilitate the packaging of a large number of products. Their power supply is also higher than that of small flow packaging machines. Finally, compared with small flow packaging machines, large flow packaging machines are more expensive.

On the other hand, the small flow packaging machine is suitable for helping to pack the products at a small scale level, just like the name implies. Compared with large flow packaging machines, they are cheaper and consume less power. Nevertheless, both small-scale and large-scale flow packaging machines have automatic functions, which are convenient for smooth operation.

6. Comparison of cold and hot sealing of flow packaging machine?

The sealing type of the flow winding machine depends on the following factors:

- Features

- Material costs

- speed

- Product capacity

- Seal strength requirements

The flow packaging machine is suitable for hot or cold sealing its products. The cold seal is a type of seal that uses a water-based cohesive coating to seal the package.

According to the name, there is no heat involved in the sealing process. Cold sealing only applies pressure to seal the package. Heat sealing is also another type of sealing used to seal packages. For heat sealing, heat must be used on the sealing material. The heating melts the material, and the sealing process is completed under the pressure of the machine.

Heat sealing is more expensive and takes time than cold sealing. The heat that needs to be generated increases the production cost of the product.

In fact, cold sealing provides a speed that is 10 times faster than heat sealing packaging. It is a convenient fact that this machine does not need to wait for heating to seal.

7. Does the flow packaging machine have printing capabilities?

Yes, the flow packaging machine has printing capabilities. This kind of machine is embedded with a photocell, which can print the date and batch number on the package. In addition, they also provide room for added functions to print when the machine lacks a photovoltaic cell.

8. Which industries use flow packaging machines?

Streamlined warp yarn machine has high application value in the following industries

- Detergent and soap industry

- Health industry

- Pharmaceutical Industry

- chemical industry

- Food and beverage industry

9. Which products can be packaged with a flow packaging machine?

The flow packaging machine is suitable for the packaging of different products. These products include

- Food, such as biscuits, candy, chocolate, pizza, lollipops,

- Stationery, such as books and pens.

- Household goods also need to be packaged and packed using flow packaging machines.

- Frozen products

- These machines are now being merged together to help package medicines as well.

- Cosmetic

- Industrial and electronic components

- Drug

10. What is the difference between a flow packaging machine and a folding packaging machine?

The folding packaging machine is convenient for packaging products that need to be folded. These products include chocolate. The flow packaging machine facilitates the packaging of products in a vertical or horizontal manner. In this way, the product is sealed between the two ends of the product.

The flow packaging machine cannot be allowed to be folded during packaging unless it is adjusted to fit the folding packaging specifications. If you buy a folding packaging machine for folding packaging, it will help.

11. What are the advantages of using a flow packaging machine?

The purpose of the machine is to make work easier and achieve efficiency in various tasks. The flow packaging machine improves the packaging efficiency of various products. The following are the various advantages that the flow packaging machine distributes to users;

1) Flow packaging machines increase production.

The flow packaging machine has a high speed, which helps to pack a large number of products in a short time. This is especially beneficial for industries that ship products to different destinations. It helps them deliver on time without delays due to product packaging.

2) Helps to facilitate packaging

The flow packaging machine facilitates packaging by blocking air from entering the packaged product. This helps to extend the shelf life of the product. This aspect is very suitable for food substances such as biscuits and chocolate.

3) The flow packaging machine provides one of the cleanest packaging methods.

This is because the manual handling of the product is reduced. The entire packaging process is mainly completed by the machine. Therefore, any chance of product contamination is eliminated during the packaging process.

The machine also introduced the use of nitrogen to package food. It helps the food to stay fresh for a long time, thereby attracting consumers to buy it. In addition, the flow packaging machine provides space for customized packaging processes.

Some products need to increase the production date and batch number. Finally, the flow packaging machine can be customized to support secondary packaging. For example, the machine can be connected to another machine to facilitate carton packaging.

12. Are there limitations to the use of flow packaging machines?

Flow packaging machines have some restrictions that hinder their operation. These restrictions include:

- They are not suitable for packaging liquid or powdered products.

- Flow packaging machines are limited to helping to pack solid products.

- Any contact with liquid or powder is likely to cause the machine to malfunction.

- In the worst case, the machine may cause serious damage and cause the entire machine to malfunction.

- Another limitation is the expensive nature of the machine.

- They are expensive to purchase and require maintenance.

- Every business person wants to minimize costs. However, this machine imposes an initial cost burden on the user.

- Finally, most flow packaging machines are huge in size.

Therefore, they need a lot of space to train packaging tasks, especially in packaging food products such as biscuits and chocolate.

13. What is the comparison between a semi-automatic flow packaging machine and a fully automatic flow wrapping machine?

When talking about flow packing machines, many people will compare a semi-automatic flow packaging machine and a fully automatic flow wrapping machine, here are their difference.

1) Semi-automatic flow packaging machine

The semi-automatic flow packaging machine is a machine that partially relies on manual intervention although it has automatic functions. For example, in order to start the packaging process- as an operator-you will need to package the machine with the necessary filling materials. After that, you have to set the machine to start packaging, according to the type of packaging you want.

2) Automatic flow wrapping machine

The automatic packaging machine can be operated without manual intervention. In most cases, automated machines only need one machine to utilize packaging materials, and then set the relevant parameters.

In addition, the automatic flow packaging machine is equipped with an automatic touch screen that allows you to input tasks and functions of the packaging. The touch screen serves as an operating point for the user to operate to guide the machine to perform what type of packaging.

You can also add the batch number and date to the product. The automatic packaging machine allows you to enter the batch number and date details, and the rest is processed by the machine. The speed of semi-automatic machines is lower than that of automatic machines. Therefore, automated machines are recommended for industrial use.

This is because its speed provides the efficiency of packaging products on time, allowing the company to supply and deliver specific products on time. In summary, the automatic flow packaging machine is also convenient for large-scale packaging and packaging of products. On the other hand, the semi-automatic packaging machine is very suitable for small-scale packaging of products.

14. How to maintain the flow wrapping machine?

There are some maintenance practices that can help keep your flow packaging machine running for a longer period of time. These measures include;

- Make sure your machine is up to date, especially when dealing with fully automatic machines.

- The spare kit for your machine should be ready at any time and updated in time.

- Minimize the emergency shutdown of the machine.

- Ensure that the utilization rate of the machine is increased.

- Remember to replace and upgrade the drive control of the machine.

Your manufacturer can specify further maintenance features and practices based on the machine model. Ideally, the machine should be accompanied by a manual to guide your various maintenance practices.

15. What are the safety features of the flow packaging machine?

Below are some safety features, you can use the flow packaging machine.

- First, make sure you follow the installation instructions provided in the machine manual.

- Ensure that the factory floor is clean and dry.

- Avoid operating the machine on wet surfaces or conditions. Use the correct tools to operate or maintain the machine

- If the machine malfunctions, make sure you use approved troubleshooting procedures. The operating environment of the machine should be safe. In addition, make sure you have precautions (such as a first aid kit) installed.

16. Is there a warranty for the flow film machine?

Yes, the flow packaging machine has a warranty period. The guarantee helps to verify the quality of the machine, and in case of any inconvenience or operational failure, the manufacturer is held accountable.

The warranty period ranges from 1 year to 5 years. To further clarify the warranty of the machine, it is best to consult the machine manufacturer.

17. What factors should be considered when buying a flow packaging machine?

Here are some factors that you should consider before buying a flow packaging machine.

First of all, we must inquire about the performance of this machine. Some of these features include the shape and size of the machine. Flow packaging machines come in different shapes and sizes to help pack specific products.

Packaging type is another characteristic that needs to be considered. For example, flow packaging machines cannot help package liquid and powdered products. Therefore, it is safe to ensure that you will be exposed to the solid nature of the machine. It is also important to consider package characteristics. This includes the measurement of package width, length and depth.

In addition, the weight and volume of the package should be well known. These measurements help to avoid a reduction in the condition of the product when it is packaged. Another key consideration to make the flow packaging machine purchased before is the speed of the packaging machine. The speed is calculated based on the number of bags per minute.

Therefore, according to the level of efficiency you wish to have, the speed of consulting the machine is important. For example, for flow packaging machines used for large-scale packaging of products, higher speeds are the most impressive.

The type of packaging you want to use is also a factor to consider. There are many types of packaging styles. This includes pillow-shaped packaging, daily packaging, flat-bottom packaging, four-sealed packaging, three-sided sealed packaging, and even pouch packaging.

Having a clear decision on the type of product packaging you want to use can help you buy the right flow packaging machine.

18. Should you buy a new or used flow packaging machine?

Both options are good, and your choice depends entirely on the budget you reserve for purchasing the machine. A second-hand flow packaging machine is a machine that has been used before and is set to resell again.

Some companies specialize in refurbishing these machines to make them work again. Therefore, if you are looking to minimize costs or avoid overspending your budget, second-hand flow packaging machines work just fine.

The new flow packaging machine is a bit expensive on hand. However, the features they provide can be used for a long period of time without too much operation and maintenance costs. Second-hand machines may require some spare parts to replace old ones, thus increasing the operating cost of the machine.

Therefore, if you plan to use the machine for a long time, you can buy a new flow packaging machine if it does not stretch your budget. However, if the need for the machine is not long-term, it is more economical to choose a second-hand flow packaging machine.

19. How to troubleshoot the flow packaging machine?

When the machine breaks down, it is very convenient to troubleshoot. Troubleshooting helps to identify common problems and provide possible solutions to the same problems. The following are some common problems and solutions of flow film machines:

1) Back seal folding

It may appear in the form of wrinkles on the back seal. It is usually caused by the mismatch between the speed of the intermediate sealing wheel and the packaging speed of the machine. To correct this, use the two intermediate sealing wheels between the black rotating handles.

Due to the many turns, there is also the risk of the belt falling off, and the handle is not effective enough. To solve this problem, open the box cover and restore the connection of the belt to the rotating handle if it has dropped.

2) Reduce product

This is also another problem related to flow packaging machines. Product cutting is related to the wrong adjustment of the material level. To solve this problem, just adjust the material level handle.

Products of different sizes and lengths may expose the cutting of the product. Make sure to introduce a measurable size that the machine can handle.

Finally, product cutting can be caused by the speed of the machine. High speeds can result in cutting products. Just adjust the speed of the machine to avoid product cuts.

3) Failed to end sealed encoder

To help resolve this issue, click “Clean”, and then shut down to restart the computer. If the problem persists, move to the lower sleeve of the end-sealed encoder. If the belt on the motor is loose, then this problem is likely to occur frequently. There are many problems in the flow packaging machine, which can be solved by troubleshooting methods.

If further malfunctions occur, it is important to consult your manufacturer for further instructions on how to resolve the problem. In addition, you can also perform a second inspection according to the machine’s manual to help solve the problem.

20. Do you have replacement parts for the flow packaging machine?

Yes. A kind of flow packaging machine, due to the use of too long, some of its parts will be worn out. Therefore, over time, these parts will need to be replaced. Of course, the manufacturer of your machine will have replacement parts for these components. However, before ordering replacement parts, you need to specify the model of the machine and specific parts.

21. How much power does the flow packaging machine use?

The power used by the flow packaging machine depends on the type of flow machine you are using. In addition, the level of automation is a key determinant of the power used by the machine.

For example, a fully automatic flow packaging machine requires more power because most of its operations are controlled by the machine. In addition, compared to smaller flow packaging machines, larger flow packaging machines have higher power consumption.

22. Which type of packaging does the flow packaging machine use?

There are flow packaging machines used for various types of packaging. The main types used include:

- Pouch packaging

- Pouch packaging

- Bag packaging.

Pouch packaging and bag packaging are related and therefore have a high degree of similarity. However, they use different packet sizes.

Small bag packaging is smaller than bag packaging. There, the small size allows them to print on narrow and medium page printing presses.

Bag packaging is suitable for larger products. Pouch packaging is one of the most convenient types of product packaging. The packaging it provides is suitable for buy-and-go products such as chocolates, lollipops and other snacks.