Vial Cartoning Machine Manufacturer

JOCHAMP provides automatic and semi-automatic vial cartoning machines with full certifications such as cGMP, SGS, CE, and more. JOCHAMP vial cartoning machine is designed for cosmetic, pharmaceutical, and medical industries.

- Precise Structure

- Low Noise Operation

- Customized Support for different mechanical structures

- Free Sample Packing Test

JOCHAMP Vial Cartoning Machine

JOCHAMP vial cartoning machine enables all types of cartons to produce, including sealed cartons, side seamed, folded, close, and erect. These machines allow the product to be packed safely. That’s why vial cartoning machines are an essential tool in any industry.

JOCHAMP can provide an automatic and semi-automatic vial cartoning machines that will match your applications. It can guarantee less damage to the products when shipped to your place. Additionally, the machine accommodates more than one product to be packed in a unit carton.

Types of Vial Cartoning Machine

The Entry-level Vial Cartoning Machine is an economical and automated packaging equipment designed specifically to suit the product characteristics of vials.

With its optimized design for vial packaging, the machine ensures precise and efficient cartoning, providing a professional packaging solution for vials.

Operating at a speed range of 30-60 packs per minute (PPM), the machine delivers efficient and consistent packaging, increasing production output and reducing manual labor.

This entry-level machine offers a cost-effective solution for businesses looking to automate their vial packaging processes without incurring substantial expenses. Its user-friendly interface makes it easy for operators to manage the machine with minimal training.

By enhancing the packaging presentation and protection of vials, the Entry-level Vial Cartoning Machine empowers businesses to meet industry standards and improve overall packaging efficiency.

In summary, this equipment is a valuable investment for businesses seeking to streamline their vial packaging operations while remaining cost-effective and competitive in the market.

Why JOCHAMP Vial Cartoning Machine

The entire machine is fully drug-grade and food-grade.

The body is made from 304 stainless steel and applied metal surface treatments.

The integrated control of the machine is simple and powerful for ease of operation.

It has protective features like a cover and movement mechanism that open up the emergency stop functions.

Vial Cartoner Machine Application

JOCHAMP produces vial cartoner machines that are high-speed, automatic, and high-performance. These machines are perfect for packaging various products like round & square medicine bottles, health care products, and cosmetics.

JOCHAMP vial cartoning machine is an ideal carton packing tool for the pharmaceutical industry. It allows mass production of ampoule and vial carton packing. We ensure that our vial cartoning machine strictly meets the requirements of international certifications.

Vial Cartoning Machine Technical Features

JOCHAMP cartoning machine is manufactured with the following features:

- If the machine has no product, the instruction will not suck. If there is no instruction, the machine will not suck cartons.

- Automatically operate after the product supply is returned.

- The machine will stop if there is no carton supplied.

- The machine will alarm and stop when there is low vacuum negative pressure and low air pressure.

- Rear pushing structure material to save more machine space.

- Human-friendly design for convenient operation and maintenance.

Working Process

The working process of a vial cartoner machine involves the transmission of the following:

- Medicine bottle

- Medicine instruction (automatic stacking and folding of 1-4 folds)

- Automatic expansion

- Carton transmission

Both folded instruction and medicine bottles are loaded together into the carton to complete the complex process of packaging. The vial cartoning machine is full of stainless steel. To ensure the safety of every operator, the machine has a man-machine video screen operating system and overload protection function.

Choose JOCHAMP Vial Cartoning Machine

JOCHAMP provides high-speed vial cartoning machines that is automatic and semi-automatic. The main purpose of the machine is to achieve excellent packaging of vials. It has the ability to seal cartons, fold, erect, close, and side seam. We can provide vertical and horizontal cartoning machines to meet your demand applications.

Mainly, the JOCHAMP vial cartoning machine can maximize efficiency, and production, and make the cartoning process easy in possible way. Being a leading manufacturer in China, we aim to provide our customers with vial cartoning machines that are more precise in structure, lower failure rate, and low defective rate.

We can have custom and standard vial cartoning machines in stock. Mostly, we can deliver your customized machines within 15 days. JOCHAMP can guarantee compact design machines with a smaller footprint.

JOCHAMP Vial Cartoning Machine

- Product Checking

- Carton Pick-Up

- Code Embossing

- Carton Erection via Knife Blade

- Leaflet Pick-Up

- Product Insert

- Carton Closure

- Carton Discharge

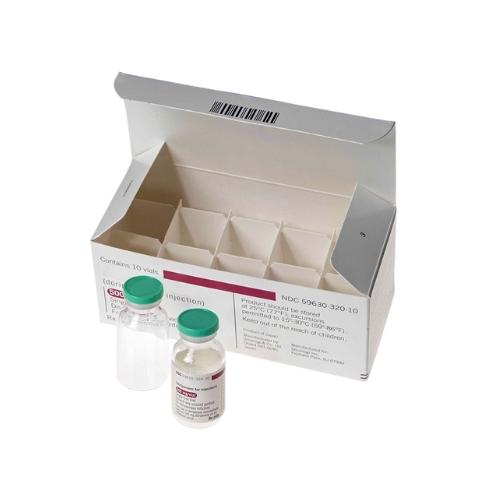

Today, the vial cartoning machine is demanded due to the production COVID-19 vaccine. And it needs reliable and quality packaging. JOCHAMP vial cartoner machine is intentionally manufactured for vial packaging. The machine is connected to the vial filling or the vial labeling and capping machine.

JOCHAMP manufactures a vial cartoner machine with a speed of 55 cartons/minute to pack ten vials. We also have a vial cartoning machine type that can pack 1 vial/carton. Also, we support customized solutions. Our machine is manufactured based on your requirements.

Custom Vial Cartoning Machine

We manufacture a vial cartoning machine that is used for packaging multiple vials. This machine is manufactured to provide safety to glass vials. It also allows the vials to be readily accessible and secured. Hence, our vial cartoning machine can provide a safe drug supply chain.

JOCHAMP manufactures a vial cartoning machine that can pack vials in a plastic tray. These machines have robotic stations to feed the vials in the plastic tray. Each plastic tray can be provided according to customers’ specifications.

Our vial cartoning machine is widely used for single vial carton packaging. It features fast operation, labels prescriptions, and quickly dispenses vials to the carton. These machines have high productivity in every pharmaceutical industry.

The vial cartoning machine from JOCHAMP is also suitable for eyedrop carton packaging. It can accommodate different shapes of eyedrop packaging such as cubical, long-shaped, and rectangular. These machines can also print specific product information to the carton packaging.

Our E-Liquid carton packaging is manufactured with top quality. It also allows customization of box shapes according to the customer’s requirements. E-liquid carton packaging provides high performance and accuracy during the operation.

JOCHAMP can provide a one-stop solution to your CBD hemp oil carton packaging needs. Rest assured that it can offer a professional look packaging that will suit your requirements. These are offered at a fast turnaround time and real-time access.

Related Product

Vial Cartoning Machine: The Ultimate Guide

In this guide, you will find all information about vial cartoning machine. Whether you want to learn about features, designs, parts, working principle or classification criteria, you will find all information right here. So, keep reading to learn more.

Vial cartoning machines are high-tech that integrate light, electricity, gas, and machinery to make sure that pharmaceutical cartons are opened and formed completely.

A vial cartoning machine is mainly used for different vials of different doses as well as different instructions that are used to load into the cartons of vials.

The machines are manufactured according to the pharmaceutical requirements of the GMP.

Good vial cartoning machines have a production capacity of high efficiency as well as good performance.

vial cartoning machine

The technologies the machine employs are related to instructions for folding and also conveying.

Its carton forming and material pushing structure at the rear have met the required standards both in European and the State countries.

The vial machine’s compact appearance design and its continuous material pushing structure at its rear end simplify its operation and maintenance.

Being that the vial cartoning machine is automated, it reduces labor costs while maintaining speed, stability, and precision.

Also, the machine improves labor productivity, and the speed of the vial cartoning machine is much faster than when using manual packaging.

The machine can effectively guarantee the quality of packaging, there are settings on the machine that ensure the quality after packaging.

Vial cartoner machines are protective of the body of workers, like radioactive and corrosive products unlike when you use manual cartoning machines.

Most vial cartoning machines have a service life of 6 to 10 years, this saves a lot of production costs for the company.

Vial cartoning machines will save the company in terms of time, as well as mistakes that can be controlled to prevent unnecessary losses to the company.

The automatic cartoner for ampoules and vials does not suck instructions nor suck cartons without instructions.

This machine will idle and not push products when you do not provide it with a product or the product provided is not in a set.

It will then automatically operate when it returns to its normal supply of products.

Your machine will stop if not provided with products or when you are continuously when not provided with instructions many times.

automatic cartoner for ampoules and vials

When the compressed air of the machine is too low, the machine will stop and alarm you.

You can always change the product specifications easily through the dial hand wheel.

This machine can display cartoning speed, alarm errors if any, and count automatically.

The main transmission system will always have an overload protection device that secures the machine and its operation.

The machine has a material pushing structure at the rear which saves more space for the machine front.

This design is human-friendly and makes the operation and maintenance by operators more convenient.

The main parts of the vial cartoner machine are;

- Control segment; the whole cartoning process is managed and regulated from the control segment.

It can be termed as the brain of the machine in a layman’s language.

- Electric panel; here the mains for the cartoning machine are tapped here.

This electrical system also powers the pneumatic system to ensure that it functions.

- Lubrication system; for the bearing, belts, and gears to have a longer lifespan, lubrication is very important.

The vial cartoning machines are designed with a lubrication system that is automatic and this ensures processing operations are well run.

- Ink-jet printer; this has writing options with at least three minimum rows.

It prints important information like the date of manufacturing, expiring date, and any disclaimer the public needs to be informed of.

- Safety system; it is emergency buttons that are placed in intervals along the cartoner sections for ease of access just in case of an emergency call.

Most vial packaging machines are designed and installed with three entrances.

The entrances are the machine package box entrance, manual entrance, and vial entrance.

You set the carton in a position by the guide rail before a push mechanism by the push plates which leads to the carton opening up.

The bottom of the carton is stuck to a vacuum suction that is driven by the pneumatic system, this ensures that the box gets to the loading bay at a right angle.

When the carton gets to the loading area, the product is inserted into the carton through mechanical effort.

After it is filled, the carton is directed to the folding spot by the chain conveyor.

Here, the vial cartoning machine will target the ears of the cartons, this process is done simultaneously on the left and right sides of the rail by rotary movement.

A vial cartoner machine can be used in the pharmaceutical industry to package medicinal products.

The machine can package the medicines in vials with ease when you use the appropriate vial machine.

Also, you can use the vial cartoning machine in packaging sweets and chocolate.

You can put artistic printing and shapes on their cartons and this help creates an expensive look.

Vials cartoning machines are also designed for the food industry in the packaging of food products.

They can delicately handle food products and still maintain the quality and hygiene of the food.

Most food products that are packaged using the vial cartoning machines are pastries and even spices.

The ampoule cartoner machine, its products are smaller when compared to products packaged by the vial cartoning machine.

There is no major difference in the cartoner machines used for packaging the ampoules and the vials.

Both machines are mainly used for pharmaceutical packaging.

Since the ampoules are smaller, the cartons used in packaging them will be of a smaller size.

One can achieve this by manipulating the setting of your cartoner machine.

If one is using an ampoule cartoner machine, then its production is higher compared to the vial cartoning machine.

vial cartoner machine

Also, the ampoule cartoner machine is more automated compared to the vial cartoner machine.

Top loading vials cartoning machine simply means that the products are introduced into the carton vertically.

Hence the name top-loading cartoning machine is attributed to its mode of product insertion.

The machine comes with vast flexibility and compact dimensions as its main features which makes it very adaptable and can meet almost all industrial challenges.

The side-loading vial cartoning machine introduces the products by the lateral drawer.

Besides, the products enter the machine horizontal shapes cartons from the stack of blanks.

This machine is mostly automatic in its operation.

The top loading vial cartoning machine is easy to clean due to its open structure when compared to the side loading machine.

Also, it provides accessible workstations to its operators, unlike the side loading vials cartoning machines.

The auto load vial cartoner machine is a more elaborate innovation compared to the hand load vial cartoner machine.

Auto load vial cartoner machine is built in a manner that helps reduce too much human involvement when it is in operation.

All its packaging processes are solely controlled and regulated by the control unit of the machine.

Also, the machine can check on the integrity of the carton after the cartoning process and decide if the products are damaged or in good condition.

For the hand load vial cartoner machine, the in-feeding system is not automated and this lowers the production speed and the throughput.

In addition, it will require many operators for you to get the most effective and efficient production output.

The biggest advantage the hand load vial cartoner machine has over the auto load one is its lower maintenance cost.

The intermittent motion vial cartoning machine stops to allow the boxing cycle while in operation.

When you compare it to the continuous motion vial cartoning machine, it is way slower, slower by almost 150 times.

The continuous motion vial cartoning machine is designed mainly for high-speed production lines.

Both intermittent and continuous motion vial cartoning machines are designed to pack products laterally into cartons.

They seal the cartons by lock fastening during flap insertion also referred to as hot melt glue.

Insertion of the product is done either by electronic or a synchronized mechanical device.

For all your vial Cartoning machines, contact us now.