Tube Cartoning Machine Manufacturer in China

JOCHAMP is a tube cartoning machine line manufacturer specializing in development, innovation, and production. We are a skilled and knowledgeable service provider in China with easy access to transportation. All of our tube cartoning machines meet international quality standards and are highly valued in a wide range of countries all over the world.

- The operation is simple and stable

- PLC control system and HMI

- Customization is acceptable

- Certified include CE, IOS9001, and GMP

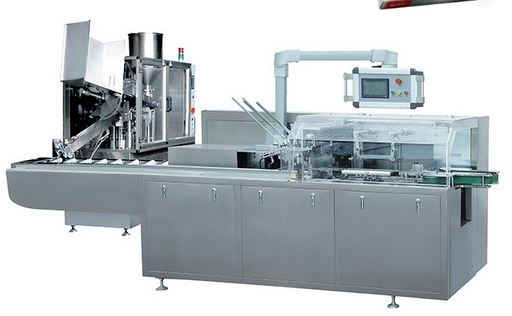

JOCHAMP Tube Cartoning Machine

The tube cartoning machine is designed to feed and pack tubes into cartons automatically. The automatic feeding structure is simple to adapt. Aside from that, the tray cartoner machine is designed to pack tubes of various sizes and shapes into cartons. Every portion uses PLC control and photoelectric supervisory control. It contains a built-in defect detection system. This equipment can be connected to a filling and capping machine upstream.

Furthermore, tube cartoning machines are popular in the market because of their advantages and high efficiency. JOCHAMP has extensive industry expertise, having manufactured, exported, and provided consulting services for tube cartoning equipment. Which are made from graded raw materials, and are known for their sophistication, corrosion resistance, durable construction, and precise filling operation.

Please do not hesitate to contact us if you have any questions about our items or would want to negotiate a special order.

Tube Cartoning Machine Types

The Entry-level Tube Cartoning Machine is a cost-effective and automated packaging equipment specially designed to suit the product characteristics of tubes.

With its optimized design for tube packaging, the machine ensures precise and efficient cartoning, providing a professional and presentable packaging solution for tubes.

Operating at a speed range of 30-60 packs per minute (PPM), the machine delivers efficient and consistent packaging, optimizing production output and reducing manual labor.

This entry-level machine offers a budget-friendly solution for businesses looking to automate their tube packaging processes without incurring significant expenses. Its user-friendly interface allows operators to manage the machine with ease and minimal training.

By enhancing the packaging presentation and protection of tubes, the Entry-level Tube Cartoning Machine empowers businesses to meet industry standards and improve overall packaging efficiency.

In summary, this equipment is a valuable investment for businesses seeking to streamline their tube packaging operations while remaining cost-effective and competitive in the market.

Tube Cartoning Machine Advantages

JOCHAMP prioritizes quality until we achieve a low rate of maintenance. Ascertain that our machine functions properly and provides lifetime after-sale support.

We have built solid business relationships with clients all around the world over the last 15 years, guaranteeing that your company makes a profit.

All of our tube cartoning machines are certified by IOS9001, CE, and SGS. We guarantee that they are of exceptional quality and dependability.

A tube cartoning machines from JOCHAMP are simple to use. To ensure that the machine runs securely and effectively, it has automatic protective devices.

JOCHAMP Manufacturing Services

JOCHAMP offers you a complete choice of products which include an automatic tube filling machine, a double nozzle linear tube filling machine, a single nozzle rotary tube filling machine, a manual tube filling machine, and an automatic linear tube filling machine, and many more.

- Our tube cartoning machine can create the high-quality and unique pack styles you require.

- Deliver the appropriate tube cartoning machine for your project. Our machinery is appropriate for a variety of industries and applications. Customize a machine that’s unique to your company.

Structure Features and Main Performance

JOCHAMP tube cartoning machine has distinct performance and structural characteristics, including:

- All control in one touch screen

- Using PLC microcomputer automatic control.

- User-friendly and easy operation

- The self-lubricating system runs more smoothly.

- The body comprises stainless steel, baked paint, and aluminum of the highest quality.

- Multiple specifications can be adjusted and used within the scope of the same equipment.

- Conversion options include both manual and automatic.

Tube Cartoning Machine Details

High intelligent, cartoning accuracy: Inspection points are densely distributed in the various workstations. Such as feeding inspection, quality inspection, pushing product inspection, and manual inspection.

The feeding part adopts a double servo motor: 120 cartons per minute, which is faster than a single servo motor and works constantly for 24 hours.

All parts are coded and equipped scale adjustment table: Easy to adjust, only 3-5 parts needed to be replaced to pack products of different sizes.

Why Choose JOCHAMP Tube Cartoning Machine

JOCHAMP tube cartoning machines come in a variety of types. It is made in shapes, sizes, kinds, and capacities that are appropriate for specific applications. Other machines linked to the tube cartoning machine are also available.

Apart from that, the tube cartoning machine is highly programmed equipment that is commonly utilized in a variety of cartoning businesses and sectors. The entire equipment has been built to meet modern cartoning standards. Its mechanical structure will provide high automation, high production efficiency, and stable, rapid, and continuous operation at all times.

JOCHAMP has been focusing on R&D and tube cartoning equipment production for over 15 years. All of our cartoning machine technologies have been carefully designed to meet or exceed industry requirements. Allow JOCHAMP to improve your tube cartoning machine’s output while also improving profits. Contact us right now!

The tube cartoning machine has an automatic detection system as well as positioning, halting, and online sub-quality product removal capabilities.

Furthermore, it features a human-machine interface operating system that displays cartoning speed, quantity, faulty causes, and other performance parameters automatically, as well as operation and maintenance procedures.

One tube cartoning machine may handle multiple box sizes.

A sufficient quantity is given to meet the customer’s needs. Customers are given first priority. We provide OEM support for our products in order to meet the specific needs of our clients. JOCHAMP endeavors to deliver the best possible service to our customers nationwide.

- Reasonable and competitive price

- High quality and quick delivery

- Rich production experience

- Strict quality control system

- Flexible MOQ punctual delivery

- Excellent and experienced team.

Custom Tube Cartoning Machine to Syrocket You Business/Project

Get a customized sunscreen carton packaging machine for your projects. It is accessible in various forms and designs, capacities, features, etc. These machines will surely create the greatest value from your investment and time.

For your toothpaste carton packaging machine requirements, you can depend on Jochamp. Our range of cartoning machines has outstanding quality, strictly check and tested before the moving process. We guarantee the machine runs safely and effectively.

Let Jochamp manufacture a high-performance lotion carton packaging machine for your applications. All machines are made from sturdy durable metal and branded components. It has unique voltage capacities and powerful engines.

Our mousetrap carton packaging machine offers consistent performance levels, easy to operate, and has a faster-packing speed. It is energy efficient and can cut down labor costs. Choose the machine size range and construction to fit your projects.

The glue carton packaging machine has stable performance and easy operation. Equipped with a human-machine operation technique, automatically display the device for speed, trouble, detection and rejection, and finished product counting.

Related Product

Tube Cartoning Machine: The Ultimate Guide

If you are in the tube packaging machine, probably, you need an effective cartoning machine. This guide helps you choose best tube cartoning machine for you unique requirements of your application. Whether you want to learn about features, design, working principle, or benefits – read this guide.

A tube cartoning machine is an equipment that one can use to pack tubes into cartons.

There are several types of tube cartoning machines and each of them has different applications.

tube cartoning machine

They include;

- Continuous motion tube cartoner

- Horizontal tube cartoning machine

- Side loading tube cartoning machine

- Bottom load tube cartoner

- Vertical cartoning machine

- Top load tube cartoning machine

- Intermittent motion tube cartoner

- Semi-automatic tube cartoning machine

- Automatic tube cartoning machine

A tube cartoner machine is a very important machine and so many industries use it for various packaging needs.

Just as the states, this is a machine that one can use to package tubes into cartons leaving them ready for shipping.

Below are the uses of a tube cartoning machine;

- A tube cartoning machine feeds and packages tube-like products into a carton.

- The machines also shape or remodel the carton into a tube-like box from a flat carton.

- A tube cartoning machine also seals the carton after the tube has been placed inside.

- A tube cartoning machine ensures the products are safe and secure before they are shipped by wrapping them well.

- The machine is also responsible for joining the seams of the carton before the tube is placed inside.

The joining is done by either using glue or staples.

- The tube cartoning machine is also used to ensure the carton that has the products has been folded properly.

tube cartoning machine

A tube cartoner is one of the machines that is used worldwide because it is applicable in many industries.

A tube cartoner is used to pack tubes into cartons leaving them ready to be shipped.

The following are some of the industries that use the vertical form fill seal machine;

- Food industry

- Automotive industry

- Cosmetic industry

- Pharmaceutical and medical industry

- Detergent industry

tube cartoner

tube cartoner

The parts of a tube cartoning machine include;

- Control panel

- Electric panel

- Lubrication system

- Carton pack tooling

- Conveyor

- Safety system

- Inkjet printer

A tube cartoning machine is an equipment that one can use to pack tubes into cartons.

This equipment is very useful and is utilized in so many industries because of its benefits and its features.

The first process when using a tube cartoning machine is to make the flat carton into a box by erecting it.

Besides, the flat carton is fed into the machine and the guide rails and push plates to ensure they open at the right angles.

Additionally, the carton is then placed into position on the machine and is moved to the loading area where the product is.

At the loading area, the carton is then filled with the product or products depending on how many the box can handle.

The carton is then moved using a conveyor belt to the folding and sealing area.

Furthermore, the carton is then folded well and then sealed by either using glue, staples, or tape.

Finally, the machine then inspects the carton to ensure it has been sealed properly before moving it to the loading area where it is stored.

Every machine in the market today has different features that make them appealing to a buyer.

Every manufacturer makes sure that the machine has top-notch features to make them unique.

The features in a machine are what determine how the machine will work and if you will be able to achieve the intended purpose.

A tube cartoning machine with very good features may be a bit more expensive than the others.

The price may be high but you will get your money’s worth since it will last longer and work very effectively with little to no breakdowns.

Here are some of the features you can find on a tube cartoner;

- Made of a heavy-duty material

- Easy to operate and a steady performance

- Automatically stops when the cartoner is overloaded

- Programmed to automatically display any mechanical issues or any trouble

- Automatically rejects an empty box or a box that has any problem

- Adjustable leg support

- Extended product conveyor

Anybody with a machine knows very well that maintaining the machine is one of the most important things one can do.

Regular maintenance of a machine will result in longevity of the machine.

This will increase the efficiency of the machine, you will also avoid mechanical issues, thus saving costs that were to be used on repairs.

The following are some of the ways one can maintain a tube cartoning machine;

Clean Machine Often

When using any machine, it is expected that it would get dirty or might accumulate dust. The machine should be dusted regularly and cleaned to make sure it remains clean.

If the tube cartoning machine is used for long without regular clean-up, it might cause issues to the machine and affect its working.

Regular Lubrication

Machine lubrication is one of the most important steps in the maintenance of a tube cartoning machine.

A machine cannot work well without oil lubrication which is mostly done on the moving parts of the machine because of friction.

The parts should be cleaned well and then lubricated well with oil.

Do A Regular Maintenance Check on the Machine

A maintenance check simply means looking at the machine parts and making sure that everything is in order.

Some parts of the machine may have been exposed to water which results in rusting and can be noticed during the maintenance check.

Change Machine Parts Regularly

Anybody working with a machine knows that spare parts are very important.

When a machine has been used continuously for a long some parts tend to wear off easily.

Some parts are quite long-lasting and do not need to be changed frequently.

For a machine to work effectively and for one to avoid excessive damage to the machine the parts need to be changed.

Closing Techniques in Tube Cartoner

There are three main ways in which the tube cartoner machine can close the box after the tube has been packaged in it.

First way is by using the hot glue method. This involves sealing or closing the box using glue on the flaps of the box.

Remember, the hot glue method is suitable for heavy products.

The second technique is using the tuck-in method. This closure technique involves the flaps of the box.

You can use this method if the product is not heavy.

Lastly, we have the hot glue and tuck in the closure. This technique involves using both the closing methods.

The hot glue closure is used at the bottom of the carton while the tuck-in closure is used at the top.

Carton Sealer vs Carton Erector Tube Packaging

A carton sealer is a machine that one can use to fold and seal the flaps of a cartoon that had been erected already.

A carton erector on the other hand is used to build up a flat carton and shape the carton then fold and seal the bottom.

A carton sealer can fold and seal the top and bottom of a carton but with a case erector, only the bottom flaps are folded and sealed leaving the top open.

carton sealer

A carton sealer exists in four types while a case erector has two types.

The parts of a carton sealer are not the same as that of a carton erector.

Additionally, a case sealer has parts like a conveyor belt, taping mechanism, and tape holder while a case erector has parts like shafts and taping wheels.

With a case sealer, the box is pushed onto the sealing station via the conveyor belt. This is where one set of holders holds it in place while another shaft lowers down to neatly tape the box’s top.

carton erector tube packaging

With a case erector, the flattened cardboard is pushed on the conveyor belt. This is where tong-like structures help to keep it straight.

They shape it into a box and apply the adhesive tape to the bottom.

- A robotic tube cartoning machine is very fast. This increases the production speed which results in a lot of work getting done.

This means if an order is made, the consumer can get their products in good time.

- The machine reduces the overall production cost because of its production speed.

One can produce a lot of products and get a lot of money for it.

Though it might be quite expensive to purchase the machine, you will get back the money within a short time.

- A robotic tube cartoning machine is very effective and efficient hence will give you value for your money.

It works very well and its production speed is very high.

- With a robotic tube cartoning machine, one can save on time especially if the products are needed within a certain timeline.

The high production speed makes the packaging of the products very quick and effective.

- When using a robotic tube cartoning machine materials are utilized well and there is no wastage.

The machine has been configured to know the exact amount of material to use.

- Using a robotic tube cartoning machine reduces labor costs since most of the work is done by the machines.

The machines also do not require supervision, this means you will not have very many people working for you.

- With a robotic tube cartoning machine, you can avoid a lot of injuries.

For all your tube cartoning machine, contact us now.