Swab Packing Machine Supplier

Jochamp is a leading supplier of swab packing machines that can be able to pack swab items efficiently. The machine offers high speed, accuracy, reliable performance, and long service life.

- Ensures high accuracy and precision

- Simple to use during the process

- Equipped with an advanced technology system

- Modular design

Custom Swab Packing Machine

Swab packing machines use a programmable logic controller to achieve high packing precision and accuracy. It is a multipurpose machine that can pack Swabs, Gauzes, Surgical Gloves, Syringes, and other items. The operator interface on this machine is based on a touch screen. It is completely customized and modular in design, allowing it to be linked to other systems.

For many years, we have always ensured that the swab packing machines we manufacture are made from high-quality raw materials. We offer OEM and ODM manufacturing services. In addition, we can provide a 7/24 hour fast response to provide you with quality and the best machine to meet your needs.

Please contact us for your inquiries!

JCB-2040 Automatic Swab Packing Machine

A special packaging machine for cotton swabs, with a maximum speed of 250 packs per minute.

- Adopt PLC programmable operating system, human-machine interface touch screen system

- Adopt servo motor control system and fixed-length photoelectric system

- The host adopts servo motor

- Round pressing round heat sealing mechanism

- Hob cutting bag

- constant temperature heating

- Slatted tensioning shaft coil feeding

JCB-2040

- Technical Parameter

- Features

| Fastest speed | 250 packs/min |

| Swab Specifications | 150mm |

| Packaging bag specifications | 200x40mm |

| Coil width | 200mm |

| Maximum diameter of discharge | 450mm |

| Voltage | 220V |

| Dimensions | 3700x870x1180mm |

| Total Weight | 900kg |

- Adopt PLC programmable operating system, human-machine interface touch screen system

- Adopt servo motor control system and fixed-length photoelectric system

- The host adopts servo motor

- Round pressing round heat sealing mechanism

- Hob cutting bag

- constant temperature heating

- Slatted tensioning shaft coil feeding

Swab Packing Machine Workflow

- Feeding materials

- Automatic stretching

- Film die cutting

- Swab feeding

- Stretching

- Heat sealing

- Auto cutting

- Finish product output

Advantages of Swab Packing Machines

Increased Production Efficiency: Custom swab packing machines allow manufacturers to quickly pack swabs. Its high speed and accuracy increase production efficiency.

Reliable and Consistent: The swab packing machine provides excellent consistency and dependability.

Reduced Labor Cost: Using a swab packing machine eliminates labor costs, making it a more cost-effective solution.

Related Products

Swab Packing Machine: The Ultimate Guide

In this guide, you will find all the information about swab packing machines, such as features, classification criteria, parts, working principles, and uses.

The information will help you choose the best machine for all your production needs – keep reading to learn more.

Swab packaging machine

Swab Packing Machine is an equipment used for packaging cotton swabs. You can use the machine to pack both single- and double-head swabs.

Most modern swab packaging machines apply heat sealing technology to ensure hygienic swab packaging. This is in addition to being multilane equipment having up to 5 lanes.

You should choose a packaging machine that will guarantee high quality packs. Some of the key features of the best swab packing machine include:

- Ergonomic design that enables easy operation

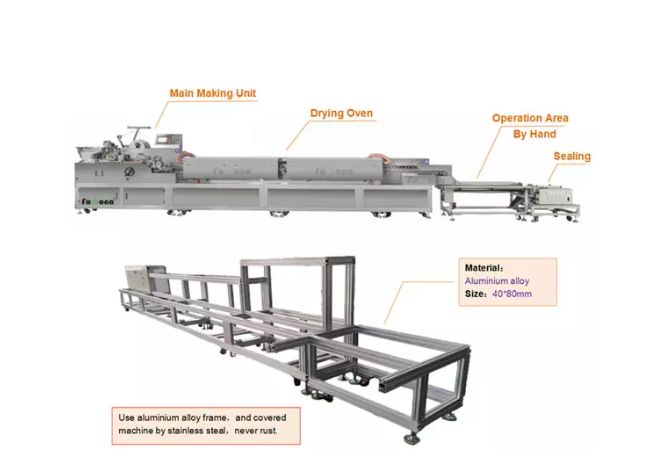

- Stainless steel frame and closed profile to withstand rigorous packaging conditions

- Modular design to allow quick changeover and maintenance

- PLC control system

- Touchscreen control panel

- Servo motor driven system

- Automatic failure diagnosis system that reduces maintenance time and ensures steady production

- Heat sealing technology to guarantee sterile condition during swab packaging

- PID temperature controller suitable for all types of swab packing materials

- Removable safety covers to allow easy access and cleansing

- Allows integration of optional labeler/code printer like thermal coder or inkjet printer.

There are different types of cotton swab packing machine that you can choose from. Often, the main difference between these equipment is their level of automation.

Cotton swab packing unit

1. Semi Automatic Swab Packing Machine

Here, you feed the swabs and pack final products manually. But the packaging assembly does the rest of operations automatically.

Semi-automatic swab packing machine has a production capacity ranging between 500-1000 pieces/minute. This packaging equipment comes in different dimensional and functional specifications according to your requirements.

2. Automatic Cotton Swab packaging Equipment

Automatic swab packaging machine functions based on PLC system to achieve high efficiency and precision. Moreover, the equipment comes with a smart device integrated in it that helps in automatic counting of swabs during packing.

The machine is notable for its user friendly operation, high speed production, low energy consumption, and high precision. It undergoes various quality and performance testing before approval for use.

3. Mini Automatic Swab Packing Machine

Mini automatic swab packing machine features a compact design that makes smaller than standard versions. It is the best choice if you are operating a start-up or small packaging business.

You will find this type of swab packing machine at highly affordable prices and in varying designs based on production needs.

4. Swab Pouch Packing Machine

Cotton swab pouch packaging machine packs a bunch of swabs in one pack. It uses infrared heating technology to dry and sterilize the products. There is also an automatic counter integrated within the equipment to eliminate possibilities of error.

Swab packaging material requirements vary based on the use of the swab. The commonly used materials for swab packaging include:

- Plastic Film

You will find some personal hygiene swabs packed in a transparent blister pack fixed to a fiberboard lining.

- Paper

The other type of packaging material used in swab packing machine is paper sleeves. We use this material for swabs employed in microbiological applications. It is effective in keeping the cotton swab sterile before use.

Cotton swab packaging machine

Swab packing machine is notable for its easy to understand operating interface and high production rate. What makes the packaging equipment achieve the efficient performance are its interconnected parts that work as one system.

Let’s look at the key swab packaging machine components that will ensure smooth operation of the equipment.

PLC Controller

Programmable logic controller enables you to control the swab packing machine from one central location. This industrial digital computer system enables you to control all the production processes and parameter.

Touch Screen Control Panel

The touch screen HMI allows you to control the packaging parameters. Some of the process variables you can control include temperature and speed of the swab packing machine. This intelligent micro-computer facilitates convenient, quick and accurate swap packaging process.

Film Handling System

Swab packing machine has an integrated material handling mechanism that feeds film used for packaging. Most film handling systems are compatible with all film types.

Conveyor System

The conveyor system enables quick and safe transportation of the cotton swabs from one point to another. Most packaging machines have stainless steel conveyor panels to ensure hygienic handling of items.

Sealing Assembly

Here is where the swab packing machine seals the packages. The sealing assembly gives a long continuous vertical or horizontal seal. You can choose between pneumatic sealers and heat sealers depending on the packaging material.

Microprocessor

Automatic swab packing machine come also fitted with a microprocessor. This device assists in accurate counting of swabs during packaging.

PID Temperature Controller

PID temperature controller is a device that the machine uses to control temperature. A temperature sensor in the instrument sends signals to a control element. As a result, the element controls the temperature within the set limits.

Photoelectric Sensors

Photoelectric sensors are also called photo eyes. They emit a light beam that helps in detecting the presence or absence of cotton swabs on the machine.

Package Labeler

Some swab packing machine come fitted with a product labeling device. The labeler can either be an inkjet printer or thermal coder.

These optional devices helps you in tracking and printing the batch number, date of production, and manufacturer name among other information.

As we have already explained, the primary application of swab packing machine is to package cotton swabs. It is a fast, precise, affordable, and adjustable solution that automatically improves productivity and profitability.

Therefore, it is important to understand the step-by-step process of how swab packaging machine works.

Step 1: Feeding Packaging Material

You place the packaging material in the film handling assembly. Typically, swab packaging machine uses a film roll wound around a core known as rollstock.

Step 2: Stretching of Film

The rollers of film handling system pulls the film off the rollstock and stretches it to the required tension. Both the bottom and top materials get stretched in readiness for swab placement.

Step 3: Optional Printing

If necessary, you can integrate a printer device for printing codes, dates, and graphics among other details on the swab packages.

Step 4: Swab Feeding

Next, you can manually or automatically introduce the swabs into the. The conveyor system then transfers and places the cotton swabs onto the stretched film.

A pair of grippers on the conveyor holds the swabs as the machine passes them from one station to another. Also, there are photoelectric sensors station on either side of the conveyor system to ensure that each gripper has a cotton swab.

Step 4: Heat Sealing

First, the sealing assembly applies bottom and top seals to each cotton swab pack. After that, a horizontal sealing mechanism seals both margins of the film as it moves to the cutting system.

The sealing mechanism applies uniform heating due to presence of an automatic temperature controller.

Step 5: Automatic Cutting of Swab Packs

This is the final step in the operation of swab packing machine. Here is where the cutting mechanism cuts the swab packs into individual packages.

After cutting, the system discharges the packs onto another conveyor for secondary packaging process.

Different types of cotton swab

Sterile swabs are safe from virus, bacteria or any other living microbes. Therefore, cotton swabs need to undergo thorough sterilization process. This is because swab sterilization prevents contamination and infection.

For that matter, let’s look at the best sterilization methods you should apply to ensure aseptic swab packaging process.

Ethylene Oxide Gas (ETO) Sterilization

ETO sterilization is a low temperature gaseous procedure broadly applied to sterilize medical products including swabs. Using vacuum-based process, ethylene oxide gas penetrates the swab packs surface and sterilize them efficiently.

Also, being a low temperature sterilization technique makes it compatible with swab packing machines.

Gamma Irradiation Sterilization

Gamma rays are a kind of electromagnetic radiation similar to x-rays though with higher energy. The rays penetrate through plastics and eliminate bacteria by splitting the covalent bonds of their DNA. This is the best method for swab sterilization because gamma radiation is highly penetrating.

Autoclaves Sterilization

In autoclave sterilization, the device blasts cotton swabs with hot steam to kill microorganisms and germs. This sterilization method uses pressure and steam to raise the temperature between 121-132 degrees Celsius. Basically, autoclaves function is a similar way as pressure cookers.

The production rate of swab packaging machines ranges from 200-2500 pieces/minute. But, high-speed designs can produces up to 3000 pieces per minutes. You can adjust the production rate according to your requirements.

You can easily integrate swab packing machine in your production line. This is because of its modular design that allows for seamless integration with other systems. The design offers you the capacity to modify production lines and/or upgrade existing machines as needed.

Collaborating with your swab packing machine manufacturer can help in ensuring proper maintenance schedule and spare parts inventory. This promotes durability and efficiency of the packaging machinery.

We have a team of experienced engineers who are able to customize swab packing machine based on your product features. You can customize the level of automation, control systems, and speed of the machine according to your specifications.

Swab packing machine commonly find use in cosmetic and medical industry. The machine is essential in packaging of sterile cotton swabs used as:

- Throat swabs

- Specimen collection swab

- Medical nasal swabs

- Anal swab

- Oral swabs

Conclusion

With the information in this guide, I hope you can choose the best swab packing machine for all you production needs.

At Jochamp, we have a range of swab packing machines. Contact us now for all your packing machine needs.

Related Resource: