Stand Up Pouch Packing Machine Manufacturer

JOCHAMP is a trusted stand-up pouch packing machine manufacturer in China. With our professional engineers and expert after-sale service teams, we ensure satisfying quality products and assistance. You can find a series of pouch packing machines in our company. Choose us now!

- Easy to operate and maintain

- Made from durable materials

- Rapidly pack the goods

- Saves time and labor

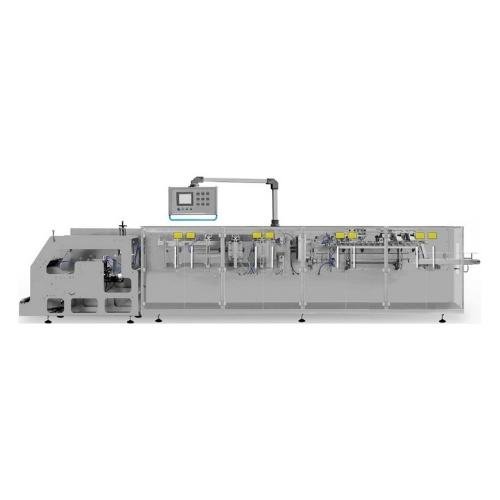

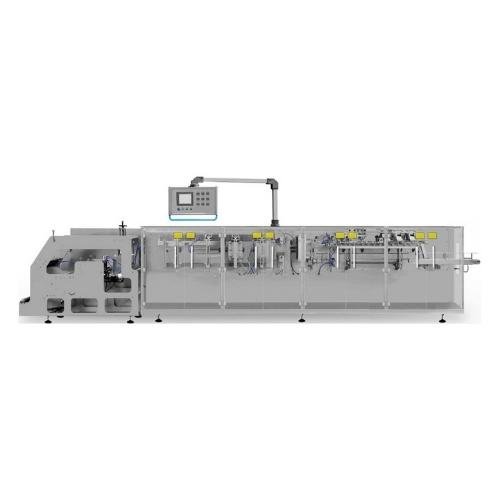

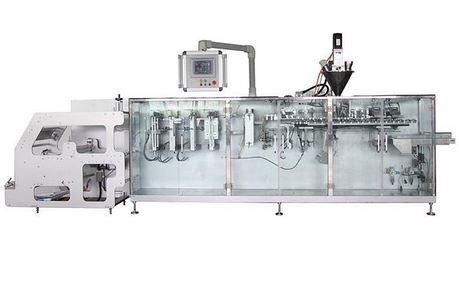

JOCHAMP Stand Up Pouch Packing Machine

The stand-up pouch packing machine is an automated machine that fills and seals the premade stand-up pouches. They have a compact design that saves factory spaces. These advanced packaging machines are easy to adjust, depending on various bag sizes. The packing machine for stand-up pouches is an affordable alternative for intricate filling equipment. They operate by transporting stand-up pouches using bag magazines.

JOCHAMP can provide your required specifications and designs. We are your one-stop automated packaging solution provider. Our skilled workers have extensive experience in manufacturing different packing machines, including stand-up pouches packaging.

Don’t hesitate to communicate with us right now!

Types of Stand Up Pouch Packing Machines

Stand Up Pouch Packing Machine Benefits

A sustainable stand-up pouch packaging machine for business maximizes sales. They provide rigid packaging and use lesser materials than conventional ones, which means less waste and material trash.

The pouch packing machines effectively keep your product secured against environmental contaminations. It ensures a pristine state of packed products as dust, dirt, and other debris don’t penetrate the seal.

Instead of purchasing various packaging machines for different pouch sizes, a stand-up pouch packing machine from JOCHAMP provides adjustable features. It helps save packaging material costs.

Using the advanced packing machines for stand-up pouches packed the products rapidly. They are easy to operate and enhance work efficiency. This machine increases business packaging productivity.

Stand Up Pouch Packing Machine Processes

The packing machines for stand-up pouches come with different stations. And every station also has various packaging tasks. The following tells the processes of how the stand-up pouch packing machines work.

- Pouch loading

- Pouch gripping

- Optional embossing or printing

- Zipper opening and detection

- Pouch filling

- Pouch sealing, cooling, and discharge

Packaging Product Applications

JOCHAMP manufactures automatic pouch packing machines that suit various products for your production factories. The following includes the products ideal for packaging machines.

- Dry & Granular Products: This includes volumetric, scaled, or measured products, like biscuits, sugar, seasoning, pet foods, coffee, teas, tablets, etc.

- Powder: It includes milk powders, caked mixes, sauce, powdered drinks, etc.

- Paste: These products use rotary and spiral pumps and include retort foods.

- Liquid: The packaging machine for stand-up pouch fill and pack detergents, plant foods, shampoo, drinks, etc.

Suitable Stand Up Pouches Designs

The packing machine we manufacture can accommodate different stand-up pouches designs. Below are some stand-up pouches that work well with the pouch packing machine.

- Flat bags

- Zip-lock bags

- Zipper bags

- Three side seal pack

- Resealable

- Heat seal pouch

- PE or a soft pouch

Choose JOCHAMP Stand Up Pouch Packing Machine

JOCHAMP specializes in manufacturing multiple packing machines, including stand-up pouches packing equipment. We have been supplying our packaging machines to numerous clients worldwide. As a responsible supplier, we always ensure the quality and performance of our offered machines. Our high-speed, adjustable, and fully automated pouch packing machines are valuable for your production facility.

We guarantee CE, SGS, ISO9001, and cGMP-certified approved packaging machines. Numerous industries utilize JOCHAMP packing machines for stand-up pouches products, including medical, food, and beverages industries-where machines function for filling, labeling, sealing, and printing.

Contact us now for further information and assistance!

JOCHAMP Stand-Up Pouch Packing Machines

JOCHAMP customizes a series of stand-up pouch packing machines with main accessories. They maximize the operating and packing efficiency of the equipment. You can trust our design team to satisfy your needed specifications.

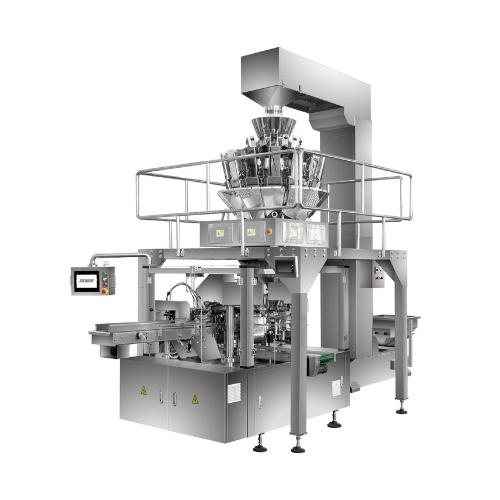

- Multi-Head Scale: The specific product is released to the weighing buckets and starts to weigh.

- Z-Shape Elevator: It features composition flexibility and scrap rate reduction. This accessory has a sealed shell to minimize dust flying.

- Conveyor: It has a simple structure, easy to maintain, affordable, and has stable transportation advantages.

Feel free to communicate and send us your detailed design and trust our services!

JOCHAMP professionally designs advanced packing machines for stand-up pouches with quality structural features. Consider the following:

- Composed of 10 working station structure

- Operated by PLC and touch screen-main control

- Designed with an alarm and direct fault tracking system

- Comes with unfilled bag detection and tracking device

- Primary drive affects frequent speed controls

- Runs flawlessly with a low failure rate CAM drive

- Passed CE certifications

Trust JOCHAMP to customize your needed pouch packing machine characteristics!

Why Choose JOCHAMP Services

We provide our customers with superior packaging solutions and products of the highest possible quality in our area of expertise. All the stand-up pouch packing machine parts are CE, SGS, and ISO9001 certified. Hence, it helps reduce maintenance costs suitable for most businesses.

Customers provide functionality, life span, and regulatory compliance parameters. Our design team will provide outstanding tailored solutions from the beginning of the process. We maintain an effective and efficient quality management system.

To meet your needs, we may provide turnkey automated packaging lines. It is a stand-up pouch packaging machine that utilizes worldwide electrical items and parts. Our goal is to have a quality packaging system that is efficient and effective.

Mechanical engineers and after-sales customer service totaled fifteen in our company. Each team member is skilled in designing and manufacturing all packaging solutions kinds. In addition, we have a well-trained technical sales team on hand that can respond to your inquiries promptly.

Optional

Stand Up Pouch Packaging Machine: The Ultimate Guide

For an efficient stand up pouch packaging, you must get reliable and efficient machine. This guide explores all the vital aspects to look for in stand up pouch packaging machine. Whether you want to learn about features, design, working principle or even troubleshooting these packaging machine, read this guide.

This is a piece of packaging equipment used for filling and sealing premade flat sachets and stand up pouches designed for different consumer goods.

It features a rotary concept design that provides flexibility in type and number of various products to be filled and types of pouches used.

Stand up pouch filler and sealer have existed for a while, but it’s become more popular in the recent past.

stand up pouch packing machine

Hence, if you are thinking of integrating this equipment into your existing packaging line or relatively new to packaging industry, you’ll need to establish more about it.

As such, this article provides comprehensive information regarding all the vital aspects of this equipment and why you should buy it.

A typical stand up pouch filler and sealer is an intermittent, rotating counsel.

Thus, it is used for packaging a wide range of products in various industries hence increasing the production process.

Notably, it is used for packaging both liquid and solid products, thus preferred in different applications.

Some common applications where this machine is largely used include the following;

Food Industry

It comes in handy in packaging a wide range of food products.

Some notable food items packed using this machine include rice, flour, milk powder, cake mixes, pet food, cheese, coffee, snacks etc.

Medical And Pharmaceutical Industry

Several pharmaceutical products are filled and sealed using stand up packaging equipment due to its versatility.

Examples of such products include powdered medicine, tablets and syrups among others.

Personal Care Products

Common personal hygiene products packed using this machine include toothpaste, softeners, shampoo, lotions, facial masks and several detergents among others.

Beverage Packaging

Most companies that process different beverages use this machine to pack their respective products.

For example, juice, milk, and wines can all be packaged using this particular machine.

Cosmetics Industry

A wide range of beauty and cosmetic products are also packaged using a stand up pouch packer.

Chemical Industry

It is also used in packaging several chemical compounds, both liquid and powdered, used in different applications.

This equipment provides several advantages in ensuring you achieve high-quality packaging solutions.

Notable benefits of this machine include the following;

Highly Efficient And Reliable

Mostly, this machine is available in automatic operation option, which makes it immensely reliably and efficient in packaging process.

Improves Production Throughput

It is fast hence can package several stand up pouches within a minute.

In essence, this increases production volume, which is quintessential, especially where high production volume is a concern.

Saves Cost And Time

Since this machine is speedy and reliable, you can be certain of reducing significant running costs and time.

Essentially, this increases profitability, which is vital to business sustainability and growth.

Minimizes Wastage

Ordinarily, this machine has a “no product, no filling” feature, which is integral in reducing stand up pouches significantly.

Improves Safety

The automation features of this packaging equipment protect it and the operator from potential hazards during the packaging process.

Easy To Maintain

It rarely requires in-depth routine maintenance due to its simple design construction, and this saves time, cost and prevents unnecessary downtimes.

The specifications of this machine often vary depending on the actual model you are using or buying.

Even so, the general ideal features of this machine include the following;

- Welded steel framing component that offers incredible durability

- High filling and sealing speeds depending on the required settings

- Accommodates different bag lengths of up to 450 mm

- Simple, compact design construction with a relatively small footprint.

- Hole punching system

- PLC touchscreen with Human Machine Interface for simple operation

- Variable sealing area attachment

- Zipper attachment system

- Gusset system

- Overload protection

- Quick size changeover

- Alarming system

- Spring lock door to automatically stop it based on preset flexible procedures

- Washdown structure for easy cleaning

- Pouch availability detection thus no pouch no sealing

- Production parameter memory

stand up pouch filling and sealing machine

Technically, these two types of machines share a wide range of aspects, including features and working principle.

For instance, both are designed to fill and seal the bags and pouches respectively and ensure the product is safe.

bag filling and sealing machine

Also, they all guarantee high accuracy in packing different products into the respective materials.

Both bag packer and stand up pouch packer can work with belt draw down or draw bar mechanisms in vertical form filling and sealing.

The sealed packets in bag packer and stand up pouch packer are often advanced to an angle to the rotary turn table for assessment and packaging.

Moreover, both machines have special designs to ensure they are compatible to work with different packaging materials.

stand up pouch filling and sealing machine

It consists of numerous parts assembled to create a single functional machine.

Ideally, every part of this equipment is designed to perform a specific function to allow the machine to deliver the desired result.

In most instances, some parts in this machine often vary depending on the specific model you are using.

But the common ones you will always find in most of these machine variants include the following;

Electric eye – It is designed to emit a light beam from the inbuilt light emitting component to allow color marking on surface of stand up pouch.

Electric system – This unit consists of numerous electrical components designed to transmit, supply and utilize electric power within the machine.

Control keys – They are designed for switching different operating variables of the equipment during packaging process depending on the required operation.

Hopper – It is a funnel-shaped component often used for feeding materials or products to be filled inside the pouch into the machine.

Safety guards – They offer machine’s safety by eliminating or minimizing possible dangers likely to arise when machine fills and seals the stand up pouches.

PLC touchscreen – It is used for monitoring and regulating different machine’s operating parameters, and it features an easy-to-understand HMI system.

Printer – It is designed to print different details on the packaging material accurately and at high speed.

Sensors – These devices detect and respond to different inputs from the machine for a particular call for action.

Zipper opening device – It opens the top part of the stand up pouch to allow filling of the product and subsequent sealing of the pouch.

Dusting Unit – This system features different dusting units, including dust suction nozzles and a dust collector for controlling and eliminating dust.

Drive mechanism – It is a combination of power and motor systems designed to drive the equipment accordingly.

Computer unit – It is designed to dictate several production parameters, including memory, sealing temperature, speed, gripper size, filling volume etc.

The working principle of this equipment is quite straightforward.

Often, stand up pouches have a vertical structure and are thus filled through vertical technique, which is usually fast.

Since the pouches in this machine entail intermittent rotary movement in different stations, here is a step-by-step process of how it works;

Pouch Loading

Preformed stand up pouches are loaded into magazine of this equipment through robotic infeed technology.

Vacuum suction pads in robotic arm clutches convey each pouch to the bag grippers.

Pouch Gripping

The pouch is grasped with vacuum suction pads upon detection in the magazine by a proximity sensor and then lifted to a set of bag grippers.

These grippers consistently hold the bag throughout as it moves from each station to another within the equipment.

Printing/Embossing

The encoder-controlled inkjet printer accurately prints different desired details such as lot codes, batch numbers or dates.

This operation is, however, optional depending on the specific products you are packaging.

Pouch Opening

The vacuum suction pads at this stage grasp the exterior of the pouch and open the bag gently.

Where the pouch has a zipper, the vacuum suction opens the bag and allows the opening jaws to clutch its top side to open it.

Product Filling

A pre-specified amount of product is pumped into the pouch by the filling unit that comprises multiple filling heads.

Generally, the product properties are what determine the filler specifications.

If the product contains liquid and solid components, it will be subjected to a second filling.

It is also the same thing that happens if the bag needs a high volume material fill.

Sealing And Deflation

The sealing operation of stand up pouches takes place in two phases.

Before actual sealing, any extra air is squeezed out of the bag using a two-wire deflator component.

During sealing, a pair of heat seal bars close over the sealing section on the upper part of the pouch.

This allows sealant film layers to adhere to one another to form a closed seam.

In other machines, ultrasonic can be used as an alternative, creating more effective seals, albeit costly.

The pouch then moves to the second heat sealing station, reinforcing the seal to ensure the package seam is completely closed.

However, in ultrasonic sealing, the second sealing station is not required.

Seal Cooling And Discharge

A cooling bar passes over the sealed section of stand up pouch to strengthen and flatten the seam.

You can also use the cooling bar to add serrations to the seam if need be.

The finished stand up pouch is then discharged to the conveyor for transportation downline to the other equipment like carton packers.

This machine deploys different filling mechanisms during stand up pouch packaging process, which includes the following;

Auger Filling Mechanism

It is a mechanism that fills the precise product amount in the stand up pouch as required.

This filling mechanism best fits a wide range of powdered and granular products.

Net Weight Filling Mechanism

In this mechanism, gravity, pressure or vacuum are the integral variables that the machine relies on to fill the stand up pouches.

Notably, the required fill level of product is determined by the equipment to allow the mechanism to fill the pouches accordingly.

Also, a vacuum may trigger flow of products at low or medium speeds.

Volumetric Filling Mechanism

It is a mechanism which allows the machine to fill stand up pouches with a uniform product volume through time-based filling principle.

Pump Dosing Mechanism

This mechanism involves the pump sucking a predetermined volume of product into the pump chamber and adding the product in the process.

Pump, in this case, is driven by an electric motor installed in the equipment with a controller that turns the pump on and off to regulate the flow.

The main sealing options used in a wide range of stand up pouch packaging solutions include;

Heat-Sealing

It is used in multiple stages, first during bonding and second after the pouch is filled with product.

You can use direct heat sealing or impulse heat sealing methods in this mechanism.

Ultrasonic Sealing

It used sound vibrations when sealing stand up pouches by producing tight seals and a more appealing final product.

It is an ideal choice to consider when packaging a wide range of granulated products that are in a solid-state.

Besides, you may also choose it for packaging products with irregular shapes into stand up pouches.

Ideally, the multi-head weigher is specifically appropriate for products where the weight of a single piece is at least 5-6 grams.

Hence, it is used for packaging products such as biscuits, sweets, dried fruits, pasta, snack, crackers, blanched fries, jellies, nuts, frozen products etc.

Ordinarily, an automatic stand up pouch packaging machine is quite versatile.

Thus, it means that you can use it to pack different products in a wide range of pouch designs.

The notable types of pouch you can use in this machine include the following;

- Vacuum pouch

- Standard pouch

- Kraft pouch

- Spouted pouch

- Pillow pouch

- Zipper pouch

- Shape pouch

- 3-side seal pouch

- Window pouch

- Paper pouch

- Gusseted pouches

Occasionally, your automatic filling and sealing equipment will throw an error code or simply portray some malfunction during operation.

Mostly, such issues arise from issues surrounding environment, product or bag loading and other factors within the machine.

However, appropriate preventive maintenance ensures such errors and malfunctions rarely occur.

Here are some notable errors and best ways of troubleshooting them when they arise;

Pouches Failing To Feed In The Machine

In this instance, it means pouches are not fed appropriately due to various factors such as dirty sensors, vacuum pad breakdown, and air valve problem.

Troubleshooting it thus requires cleaning the proximity sensor and repairing or replacing vacuum pad and air valve of the machine.

Pouches Failing To Open

It means the machine can hardly or inconsistently open stand up pouches for product filling.

The possible causes of this error include; incorrect timings, vacuum pad breakdown, worn-out filter, sagging or incorrectly loaded bag.

However, to troubleshoot the error, you need to ensure the timing is correct, change filter, load the bag appropriately and repair or replace vacuum pad.

Flawed Pouch Seals

This primarily means that the package seals are wrinkled, weak or uneven.

The error likely arises from incorrect sealing bar pressure, dirty or scratched sealing bar surface, too high sealing bar temperature and failure to center bag.

But to troubleshoot it, you need to moderate sealing bar temperature, regulate sealing bar pressure, clean the sealing bar surface and center the bag or level the grippers.

They are available in four main types as follows;

Horizontal Stand Up Pouch Filling And Sealing Machine

This type of stand up pouch packing machine features a horizontal structure.

It merely means that it is designed to fill and seal stand up pouches through horizontal orientation.

horizontal stand up pouch filling and sealing machine

Thus, it is commonly used for filling and sealing powder, dry products and granules.

Vertical Stand Up Pouch Packaging Machine

It is arguably the most commonly used type of stand up pouch packing machine in many industries.

Ideally, this type of equipment features a vertical structure.

In essence, it implies that the products are filled and sealed inside the stand up pouches in a vertical orientation.

stand up pouch packing machine

This makes it an ideal choice for packing different products such as liquid, powder, dry products, paste and granular among others.

Form Fill Seal Stand Up Pouch Packaging

It is a type of filling and sealing machine that forms a package, fills it with a product then seals it.

This equipment starts with a large bunch of rolled film and forms it into desired shape of the bag.

It then fills the bag with the product and seals it, whether horizontally or vertically.

form fill stand up pouch packaging machine

Ultra Clean Stand Up Pouch Packaging Machine

As the name suggests, this machine is specifically designed to fill and pack fresh and relatively viscous products that are delicate and require high levels of hygiene.

It integrates ultra-hygienic, advanced sanitizing and servo style base technology hence suitable for packing such delicate products.

Common products you can use to pack using this machine include milk, pharma syrups and fresh juices among others.

More Resources:

For all stand up pouch packaging machine, contact us now.