A salt packing machine is an equipment that you will use to fill and seal salt into bags or sachets.

In this guide, you will find all information you are looking for about salt packing equipment.

Whether you want to learn about parts, working principle, classification criteria or applications – you will find all information right here.

So, keep reading to learn more.

Applications Of A Salt Packing Machine

A salt packing machine has several applications in different industries such as:

- Food and beverage industries

- Pharmaceutical industries

- Personal care industries

- Cosmetic industries

Quality Standards That A Salt Packing Machine Should Comply To

A good salt packing machine needs to comply with certain quality standards.This is to ensure the salt packing machine is safe for use and will provide the best quality packing.

Some of the quality standards a salt packing machine should comply to include the following:

- SGS certificate

- CE mark of quality

- International Standard Organization [ISO] quality standard

- Food and Drug Administration [FDA] quality standard

- Physical Agent Directive [PAD] certification

- MSD certification

- CO certification

Types Of Packages You Can Make With A Salt Packing Machine

There are different types of packages that you can make when packing salt with a salt packing machine. These include the following:

Three-seam pillow package

This is a type of package that producers widely use when packing salt products.

Flat bottom package

This is a stable and convenient type of package that has an aesthetic shape.

Briquette

This practical method of packaging salt offers safe storage and transportation.

Doypack

This is a flexible and stable type of package. Doypacks will protect the salt product from moisture due to their airtight features.

Big size bags

This type of package is suitable when packing large volumes of salt products. Big size bags are suitable for producers who will sell to wholesalers.

Sachets

A sachet is a single-use type of package. The sachet will offer four seams which provide extra protection to the salt product from environmental impact.

Sticks

This is a popular type of package that is suitable for single-use situations. Sticks are economic and have a compact design.

Also, they protect the salt product inside to ensure there is no contamination.

PET jar

This is a versatile package type and has a suitable design.

Technology Behind A Salt Packing Machine

The majority of salt packing machines have a programmable logic controller [PLC] unit. This technology will offer a convenient and effective process. It ensures the whole salt packing process happens seamlessly in the production line.

The programmable logic controller allows you to automatically control the salt packing process from a central station. Furthermore, the control is real-time.

This means that when you enter a command, the salt packing machine will respond instantly.

A Proportional Integral Derivative [PID] controller will assist you in maintaining the temperature of the salt packing machine. Depending on the feedback control, you can maintain a specific operational temperature by constantly modulating the system.

Furthermore, these technologies produce no noise and will offer suitable output levels. They make the salt packing machine simple and efficient to use.

Comparison Between A Valve Salt Packing And Open-Mouth Salt Packing Machine

An open-mouth salt packing machine will pack salt on a bag that has an open top side and three closed sides. Once you finish filling the salt into the bag, you will sew or heat seal the open top section.

Also, the cost of an open-mouth bag is lower than that of valve bags.

A valve salt packing machine will enable you to limit salt spillage to the surrounding environment. This ensures that the workstation remains clean at all times and improves the health of your workers.

Furthermore, when you use a valve bag, it will effectively drain air out of the bag. His means the bag fills more and has a regular shape, making it suitable for palletizing.

How A Salt Packing Machine Works

First, you need to ensure the salt packing machine is in suitable operating conditions. Thereafter, you will feed the salt through the hopper from the feeding tank.

The flow of the salt-filling process is controlled by frequency-changing units.

This means you will adjust the speed according to the production needs. Once the bag is full, the machine activates a clamping device.

This will compress the salt in the package. Finally, the package undergoes a sealing process to protect the contents in the package.

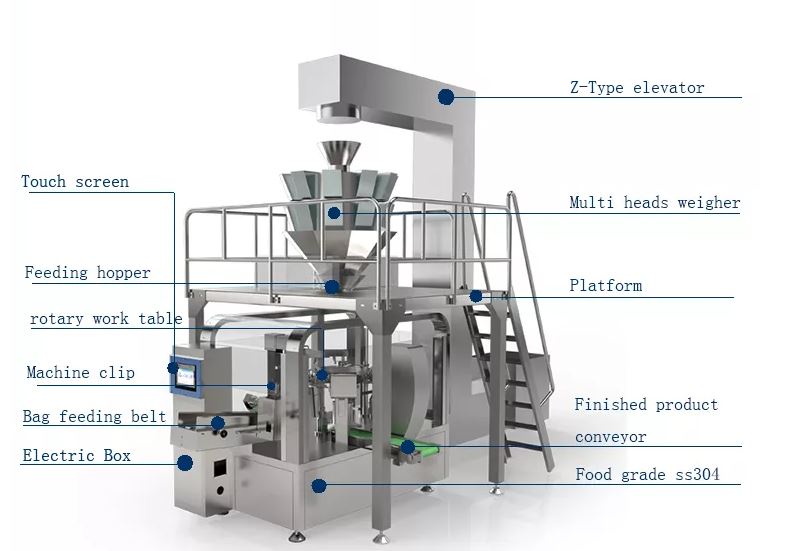

Parts Of A Salt Packing Machine

There are several parts you can find in a salt packing machine.

All these parts work together to deliver an efficient packing process.

The core parts of this machine include the following:

Feeding Unit

This is the part that will feed the salt product into the machine. There are different feeding techniques you can use.

These include auger, impeller, air, and gravity, among others.

Feeding Sprout

This is an important component that sits outside the salt packing machine. It has the main purpose of directing the salt into the package during the packing process.

Weighing Unit

The main part of the weighing unit is the load cells. It will control the feeding timing, detect the weight of the salt product, and ensure the quantity is the same on the packages.

Control Unit

This part of the salt packing machine enables the operator to control the machine from a central spot. It comes with a programmable logic controller and a human-machine interface that allows for easy control.

The control unit can also receive and relay electrical signals to give feedback.

Clamping Unit

This device will hold the packaging and the feed spout together. It will tightly hold these two elements and form a closed space.

This is to ensure the salt materials do not leak during the packing process.

Bag Chairs

These parts offer support to the packing bag when you are filling salt. This allows you to move the bags quickly.

Storage Hopper

This component serves as a storage for the salt product.

Bag Loading Unit

This is an optional component available in automatic salt packing machines. The bag-loading machine automatically loads the bag through the filling spout.

Since it does this process automatically, there will be no manual involvement. This ensures that you always receive a high level of the automation process.

Types Of Salt Packing Machines

There are several types of salt packing machines in the market. These machines can be categorized on the level of automation available.

Manual Salt Packing Machines

These machines cannot operate without human involvement. For this reason, it has a limited packing capacity.

Besides, when the operators are not present, no salt packing can happen. Manual salt packing machines are the most affordable of these three machines.

Also, your operators need to understand how to operate the machine for you to have a successful packing process.

Semi-automatic Salt Packing Machines

These salt packing machines have some level of automation in them. They contain fewer automatic features than the fully automatic version though.

Semi-automatic salt packing machines can operate with minimal human involvement. They are relatively affordable and suitable for small to medium-sized industries.

Fully Automatic Salt Packing Machines

These machines have the highest level of automation and technology. This means they can operate the whole day without suffering production loss.

As long as they are in good working condition, they can operate continuously.

Besides, they are costly to purchase but will save you a lot of money in the long run. They are usually large and heavy and are suitable for large industries that need to meet high salt packing needs.

What To Consider When Selecting A Suitable Salt Packing Machine

Here are factors that you can consider when choosing a salt packing machine:

Level of Automation

If you need to ensure the safety of your operators and the salt packing process, automatic salt packing machines are the way to go.

They may be costly but will save you recurring overhead costs. Besides, they can operate at all times as long as they are in good operating condition.

Speed

If you have a large order to fulfill, you need a salt packing machine with a high filling rate. This will allow you to pack salt quickly within a short time frame.

Compatibility

Not all salt packing machines can work with other machines in the production line.

If you need to integrate a salt packing machine with other support equipment in the production line, you should choose the automatic version.

This will allow you to fulfill the entire salt production process under one roof.

Dimension

If you have a small work area, you should choose smaller versions of salt packing machines. On the other hand, large salt packing machines are suitable if you have a large floor space for installation.

Cost

As the level of automation increases, you will spend more when purchasing a salt packing machine.

If you have a small budget, you can only afford the smaller salt packing machines. Also, you should not only consider the cost when purchasing a salt packing machine. This is because other factors come into play.

Price Of A Salt Packing Machine

There are different types of salt packing machines in the market.

Driving factors of the price include size, production output, and automation levels, among others.

This means the price can go anywhere from a few thousand dollars to hundreds of dollars.

Advantages Of Using A Salt Packing Machine

Some of the benefits include:

- Increased levels of efficiency as most can operate with less human intervention

- Minimal waste since they are accurate

- Product protection as it packs the salt to prevent contamination

- High packing output which depends on the speed of the machine

- Easy to maintain and clean

Disadvantages Of A Salt Packing Machine

The main disadvantage of a salt packing machine is the high initial cost depending on the level of automation.

Troubleshooting A Salt Packing Machine

These include:

- Pouches failing to feed

Possible causes include:

- Dirty sensors

- Trouble with the vacuum generator

- Breakdown of vacuum pads

- Troublesome air or solenoid valves

- Packages not opening

Possible causes include:

- Breakdown of vacuum pads

- Incorrect timing

- Trouble with air valves

- Sagging packages

- Defective seals

This happens when the package is uneven, weak, or wrinkled.

Possible causes include:

- A high sealing bar temperature

- Incorrect sealing bar pressure

- The package is not in a central location

- Dirty or scratched sealing surfaces

Ensure you clean and conduct regular maintenance to prevent such issues.

Conclusion

Salt packaging machine plays an integral role in modern packaging. With the information in this guide, you can choose a machine that meet your unique specification requirements.

Related resource:

Powder Packaging Machine – Source: Jochamp

Granule Packing – Source: Jochamp

Powder Filling Techniques – Source: Wikipedia