Rotary K Cup Machine Manufacturer

JOCHAMP provides a wide selection of k-cup machines, from rotary filling machines, nitrogen sealers, k-cup weighing and measuring equipment, and many more. It is built with all stainless-steel construction which makes them easy to clean.

- 15 years of manufacturing experience

- ISO and CE-certified

- European quality and Asian price

- 24 hours fast response

JOCHAMP Rotary K Cup Machine

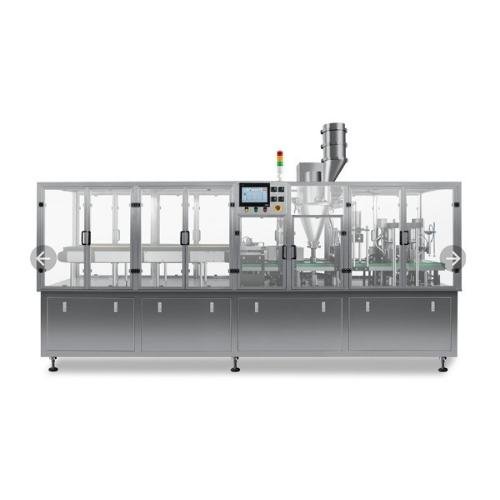

The rotary K cup machine is a kind of professional sealing and filling k-cups equipment. It is great for small-sized and medium-sized enterprises or start-up businesses. This rotary type k-cup machine can accommodate 50 to 70K cups per minute. The machine is manufactured with higher speed, a small footprint, full automation, and complete functions.

At JOCHAMP, you can find a reliable rotary k-cup machine that will meet your quality and daily production requirements. Our machine is manufactured with a high-standard design to provide you with more convenient, faster, and more stable rotary k-cup machines. JOCHAMP rotary k-cup machine is manufactured with high-end electrical parts to ensure long life and reliable operations. With 15 years in this field, JOCHAMP is glad to share with you our experience and provide you with suitable and customized solutions.

JCK-1R Rotary K Cup Machine

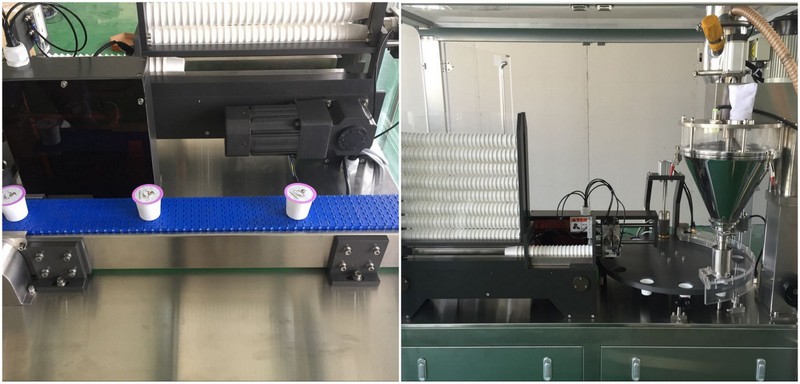

Rotary k-cup capsule coffee packaging machine. Its design is relatively compact and has good space utilization. It is suitable for coffee powder, espresso, cream, ketchup, peanut butter, jam and other products.

- Very compact design to maximize space utilization

- Simple and easy to use design, almost 0 training

- Fast mold changeover for changing products

- no cup, no filling

- no lid, no seal

- Servo motor drive to maintain stable and precise operation

- All stainless steel, aluminum alloy body cover, corrosion resistance, easy to clean

- Full food-grade contact surface to ensure hygiene

JCK-1R

- Technical Parameter

- Features

- Optional

| Model | JCZ-1R |

| Filling Heads | 1 |

| Filling Range | 0-20 gram, adjustable |

| Filling Accuracy | <=+/-0.05g |

| Filling Speed -cups/hour | 2700-3600 |

| Power Requirement | AC 380/220V 50Hz |

| Power Consumption-KW | 1.5 |

| Compress Air Required-Mpa | 0.6-0.8 |

| Compress Air Consumption-m3/min | 0.15 |

| Approximate Weight -kg | 850 |

| Dimension ( ‘mm ) | 1600*900*2000 |

- Very compact design to maximize space utilization

- Simple and easy to use design, almost 0 training

- Fast mold changeover for changing products

- no cup, no filling

- no lid, no seal

- Servo motor drive to maintain stable and precise operation

- All stainless steel, aluminum alloy body cover, corrosion resistance, easy to clean

- Full food-grade contact surface to ensure hygiene

- Passed CE, IOS9001 certification

- Omron, SICK, SMC, Mitsubishi, Siemens and other internationally renowned brands of electrical appliances and accessories

- security door system

- High strength anodized aluminum rotating plate

- Horizontal cup magazine for empty cup mass loading

- Mechanical cup clamping instead of vacuum sucking

- Mechanical lid sucking and positioning

- Mechanical driven rotating cup edge cleaning after filling

liquid filling machine

Flavor Drip Pump

Checkweighing system

Connect the cartoner

batch printing

Nitrogen flush, fill

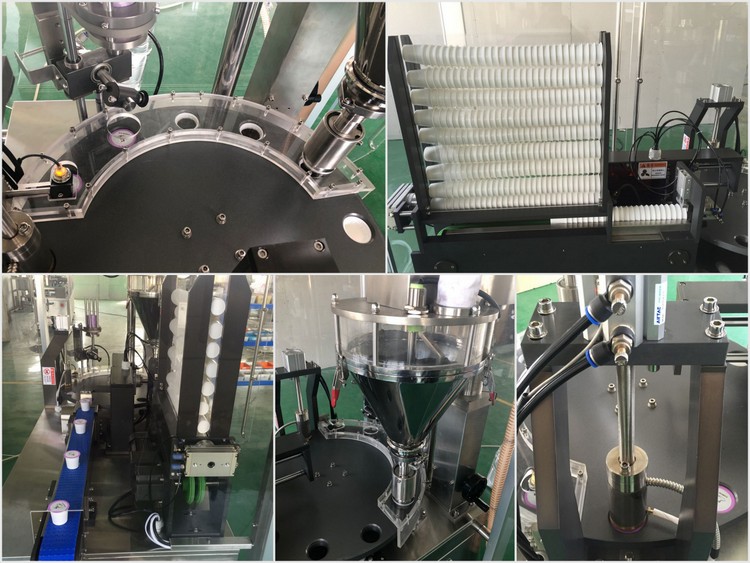

Rotary K Cup Machine Feature

- Capsule dropping

- Vacuum feeder

- Empty cup detection

- Lid detection

- Servo-driven filling

- Finished product output and heat sealing

- High accuracy

- Tamping and edge cleaning

- No capsule no filling detector

- Adjustable sealing

- Conveyor optional output

Advantages of Rotary K Cup Machine

- Accurate Movement: The disc movement is operated by the motor. So, the machine provides smooth operation and is more stable.

- Rapid Production: The disc machine’s production speed is notably faster due to its shorter moving stroke. It can also complete each station operation faster.

- Easy to Change Molds: Our rotary k cup machine can change molds easier to create a large number of coffee capsules by changing 10 to 20 mold cores only.

- Simple to Use and Maintain