Pyramid Tea Bag Packing Machine Manufacturer in China

Jochamp supplies high-speed pyramid tea bag packing machines for medicinal tea, loose tea, tea leaves, and other small granular products.

- Suitable for outer & inner bag packaging

- 15+ years of production experience

- Can be customized as per your requirements

- Comes with 1-year quality assurance

Custom Pyramid Tea Bag Packing Machine from JOCHAMP

Pyramid tea bag packing machines are used for a wide range of loose tea, fruit tea, flower tea, herbal tea, and other kinds of tea products. They can make a pyramid or triangular bags with optional tags and cotton thread. Also, they can feed, measure, seal, cut, and do other functions automatically.

Jochamp offers different kinds of pyramid tea bag packing machines that have a compact design, a PLC control system, and intelligent packaging material detection. Our pyramid tea bag packing machines comply with the cGMP, SGS, ISO9001, and CE standards. We can also customize them to your exact specifications.

For more information about our pyramid tea bag packing machines, feel free to contact us!

Packing Machine for Tea

Different Tea Packaging (5)

Pyramid Tea Bag Packing Machine Advantages

To ensure the safety and hygiene of tea products, the product contact surface of the pyramid tea bag packing machines is made from corrosion-resistant and food-grade 304 stainless steel.

In order to get the perfect pyramid tea bag packaging, the outer and inner sizes of the bags can be adjusted based on the different needs of the operators or users.

The pyramid tea bag packing machines adopt ultrasonic sealing system. They can seal pyramid tea bags tightly and safely. Also, they can reduce the extra edge of the bags.

Our pyramid tea bag packing machines are completely controllable and ease to operate. You can control every single move of the machine using the PLC control system.

Packing Materials

For making inner bags, a variety of materials is suitable such as:

- bio mesh

- nylon mesh

- bio NWF

- non-woven fabric filters

- other types of filter paper that is suitable for ultrasonic sealing

Also, the suitable materials for the overwrap are different types of laminated films such as PE, PP, and many more.

Bag Style Options

The pyramid tea bag packaging machines can make pyramid and rectangular tea bags. You can freely switch between pyramid and rectangular shapes in just one click on the pyramid tea bag packaging machines. Below are some of examples of the tea bag types:

- pyramid tea bags

- rectangular tea bags

- pyramid tea bags with labels and cotton threads

- rectangular tea bags with labels and cotton threads

Pyramid Tea Bag Packing Machine Options

The pyramid tea bag packing machines can be added with optional systems and devices such as:

- Metal detector

- Easy tear

- Z type elevator

- Export sorting

- Nitrogen filling

- Different filling systems

- Docking cartoner

- Date & batch printing

- Checkweigher

Your Professional Pyramid Tea Bag Packing Machine Supplier

Jochamp is a professional supplier of automatic pyramid tea bag packing machines for more than 15 years. Our pyramid tea bag packing machines are designed with unique ultrasonic sealing and cutting technology for beautiful sealing. This technology also reduces the width of the bag’s extra edge in order to minimize the packaging material waste.

Our pyramid tea bag packing machines are made from materials that meet the GMP standards. Their body cover and whole product contact surface is made from durable and corrosion-resistant 304 stainless steel to ensure safety. They have surpassed the food safety and health standards.

For your inquiries, do not hesitate to contact us!

The pyramid tea bag packing machines have many features such as:

- adopts ultrasonic sealing method for safe, smooth, tight, and firm sealing

- with independent PID temperature control system for high energy efficiency and accurate temperature control

- intelligent packaging material detection, shutdown, and alarm before running out

- opto-located bags and labels

- ±0.1 grams of weight accuracy

The pyramid tea bag packing machines are used for packing various kinds of tea products such as:

- long leaf teas

- loose tea leaves

- flower tea

- fruit tea

- herbal tea

- black tea

- oolong tea

Why JOCHAMP is a Trusted Pyramid Tea Bag Packing Machine Supplier

Jochamp has been focused on providing high-speed and high-performance pyramid tea bag packing machines for over 15 years. We have been providing quality and safe pyramid tea bag packing machines at competitive rates to many countries around the world.

Our pyramid tea bag packing machines make triangular and rectangular tea bags neatly and firmly. They can make pyramid tea bags that:

- are accurately 3-dimensional

- have the same length on each side

- have no unfolded edges

Jochamp is an ISO-certified supplier and has obtained certifications such as:

- ISO9001

- cGMP

- SGS

- CE

Our pyramid tea bag packing machines are offered with 1-year quality warranty. We have an expert after-sales service team that can help you with the installation, maintenance, or operation of the pyramid tea bag packing machines.

Related Products

Pyramid Tea Bag Packing Machine: The Ultimate Guide

Choosing highly efficient and reliable pyramid tea bag packing machine requires in-depth understanding of the design, features, working principle, and applications, just to mention a few. This guide explores all information you are looking for about pyramid tea bag packing machine.

It refers to a form of tea pouch packaging machine widely used in packing a wide range of tea products into a defined package.

In other instances, it is referred to as a nylon tea bag packing machine owing to its material in packing the tea leaves.

This machine is commonly used to provide beautiful and intricate packaging and to preserve the freshness of the tea leaves.

pyramid tea bag packing machine

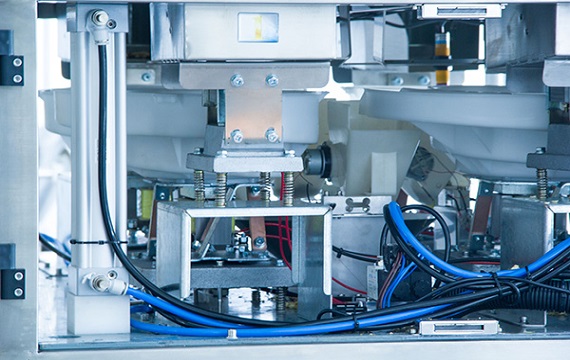

The design of this machine allows it to complete different functions such as feeding, weighing, filling, sealing, and cutting processes.

Pyramid tea bags and regular tea bags are the most popular tea variants used in various households and commercial spaces.

However, they vary in a few aspects, such as the following;

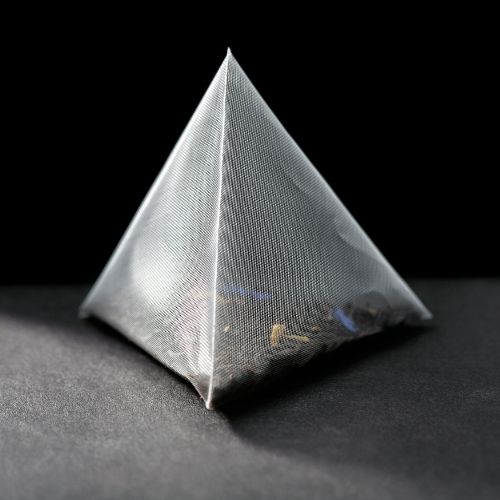

Material

Pyramid tea bags are made from a relatively strong material than regular tea bags.

The former is made using a nylon material that enables the tea leaves to expand and move around freely.

pyramid tea bag

On the other hand, regular tea leaves are made from PET material, which is seemingly cheaper and easy to produce in mass.

Reliability

The nylon material reduces the chances of pyramid tea bags tearing or leaking, making them more reliable than regular tea bags.

PET material used for making regular tea bags can easily tear and leak, making this tea bag relatively unreliable.

Design Structure

The design of pyramid tea bags has additional space provided that allows the tea leaves to move around freely and fully expand.

As such, these tea bags infuse more flavors allowing tea manufacturers to incorporate large high-quality tea leaves in pyramid tea bags.

On the other hand, PET hardly allows tea leaves to expand, and this is likely to lead to a weaker flavor.

Quality

Pyramid bags are spacious hence allowing addition of quality additives to enhance the overall flavor of the tea bags.

Regular bags, on the other hand, have limited space thus commonly contain low-quality tea leaves broken into smaller pieces leading to a weaker aroma.

regular tea bag

The notable advantages of using this type of tea bag packing equipment are as follows;

a) Enhanced Efficiency – The design of this machine allows it to fill tea bags efficiently and faster with the accurate amount of tea leaves.

b) Increased Safety – It is equipped with several safety features like guards and emergency stop buttons to protect employees from injuries when operating the machine.

c) Increases Products’ Shelf-Life – This machine ensures the tea bags are sealed tightly, and this is fundamental in enhancing the shelf-life of the tea leaves.

d) Enhanced Hygiene – The design of this machine allows it to fill each bag with a precise quantity without necessarily coming into contact with other surfaces.

e) Improved Quality – Automation of the tea bag packaging process enhances quality since each bag is filled with exact quantity as predetermined.

f) Customizable – You can select a wide range of features and options when packing tea leaves using this machine.

Hence, it allows you to attain the best results possible that suit your needs.

Different nylon tea bag packing machines come with various design features depending on the specific model.

The notable design features you will likely find across the popular models include the following;

- Faster packing speed ranging from 20, 40, and 60 bags per minute.

- Total weight of between 200-400 kgs

- 220V/2KW electric power rating

- Air consumption of 0.6m³ per minute

- Weighing range of 1-7g

- Dimension of 1200 x 920 x 2060 mm

- 2 sets of sealing and cutting devices

- Length of bags ranges from 50, 60, 70, and 80 mm

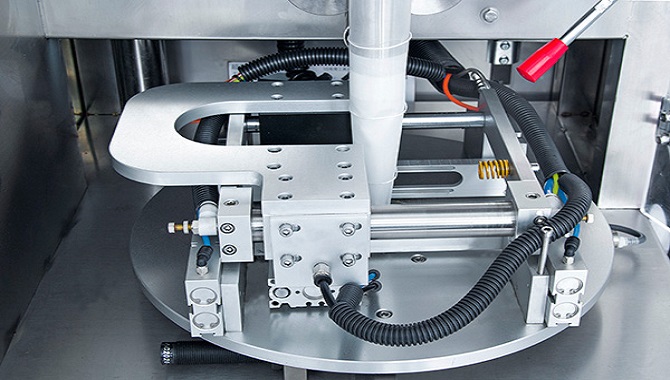

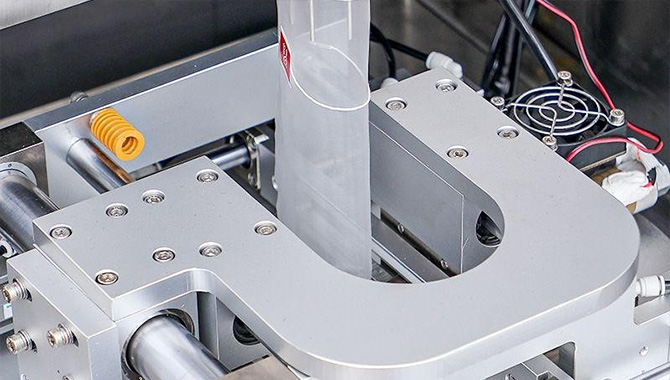

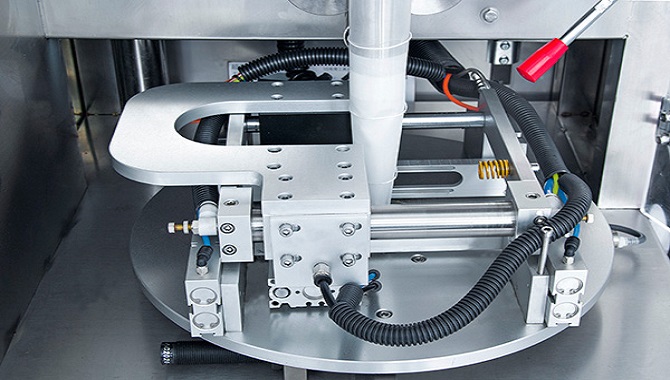

The main parts of this pyramid tea bag packing include the following;

- Hopper – This is an elongated funnel-shaped component designed for feeding tea leaves into the equipment for subsequent packaging process.

- Stainless Steel Frame – It is the structural component where all other parts of this machine are affixed as it ensures stability and efficiency during tea bag packaging.

- PLC Touchscreen – It displays various operations used during the packaging process. You can also use it to monitor the different pyramid tea bag packaging parameters.

- Pneumatic Control Unit – This component provides means to actuate valves often used in regulating airflow in this equipment’s pneumatic system.

- Control Keys – These are buttons used to activate different control parameters of the machine during the pyramid tea bag packaging process.

- Precision Optical Sensor – It measures the physical quantity of light and translates it into readable form to enhance tea bag filling accuracy.

- Feeding Conveyor – It is a panel that ensures movement of the packaged pyramid tea bag from one station to another.

- Universal Wheels – They are attached to the bottom of the machine to enable convenient movement from one point to another.

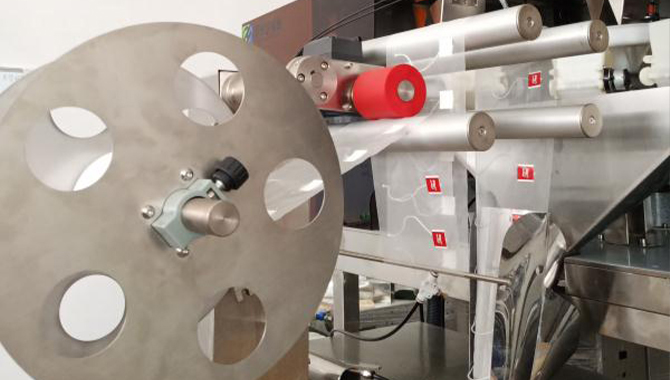

- Film Roll Holder – It is designed to hold and discharge pyramid tea bag packaging material into the machine for subsequent tea leaves’ loading.

pyramid tea bag packing machine parts

- Servo-Motor – This refers to a rotary actuator, which enables accurate control of velocity, acceleration and angular position.

The functional mechanism of this equipment is quite straightforward and usually entails the following steps;

- This machine comes with a tea weigher or linear weigher, which fills the pyramid bags with tea leaves.

An electric tea weigher or any tea weight measurement device is used with the tea leaves filling hopper.

- The conveyor unit of this equipment transfers containers to the specific tea filling component. This component discharges the tea into available nylon sachets that are being created.

Hence, the sachets end up as the tea bags, which will handle the tea directly.

- The device responsible for internal nylon bag sealing and cutting seals and cuts the tea bags respectively and form into paper filter sachets resembling a pyramid.

Even so, some machines enable the design of tea bag adjustment to give rectangular bags.

- Next, bucket elevator links the pyramid tea bag packing equipment to the envelope tea bag packer.

The former machine has a foil roll stock with the nylon material it uses to create envelopes.

It contains an external bag where packaging of tea bags takes place for supplementary cleanliness.

- Then, the external foil bag forming device forms the external bags.

The devices for external bag cutting and sealing are then actuated to seal and cut external bags filled with tea bags.

It attains high accuracy through a device referred to as optoelectronic positioning unit.

The cutting device for external bag counts the quantity of tea bags, which are being packed in a single external bag.

- The pyramid tea bags are discharged through an output conveyor to allow extra packaging process.

When buying this machine, it is advisable to consider a few critical elements to ensure you meet your industrial packaging demands.

Such considerations include the following;

- Budget – Establish whether your business can sustain the procurement of the specific machine and ascertain its feasibility.

Also, determine whether you can obtain machine financing from investors or other financiers where applicable.

- Packaging Demands – Ensure you know the actual packaging requirements upfront before buying the machine.

Know the tea categories and the tea character to enable you to acquire a tea packaging machine that meets the specific requirements.

- Available Floor Space – The essence here is to ensure you buy a specific machine with dimensions that can fit your space.

Most automated pyramid tea bag packing machines are usually compact. However, you need enough space for other processes like storage and operators’ area.

- Usability – Automatic pyramid tea bag packing machines often come with a human-machine interface making them quite user-friendly.

However, it’s important to ensure the HMI is clear and straightforward.

- Brand – The specific manufacturer or supplier you purchase from should be of good reputation, authentic, verifiable, and certified.

Determine the technical user support you attain from the vendor, detailed manuals, and after-sales support offered.

- Features – Ensure you look into the features and establish they can enable you to attain the packaging demands accordingly.

When purchasing this tea type of tea bag packaging equipment, it is vital to ensure it has certifications authenticating it has passed required quality tests.

These tests are fundamental since it guarantees the machine’s efficiency, reliability, and overall performance.

The notable tests for this machine include the following;

- Idling Test – It entails powering the machine for at least 24 hours in an idling mode to establish whether it is fit to withstand a longer operating duration efficiently.

- Trial Packaging Test – This primarily involves carrying out a test run to determine how the machine undertakes the packaging process.

- Durability Test – It is a test where all the key components of the pyramid tea bag packing machines are tested to establish their endurance.

This machine comes in handy in packing a wide range of tea bags of different flavors and aroma.

Some notable applications of this machine include the following;

Food Packaging Industry

Different food companies can use this equipment to package a wide range of food products in smaller pieces.

It is important in this industry because it enhances the packaging efficiency and accuracy of such food portions.

Pharmaceutical Sector

It is also used in different medicinal drug manufacturing companies to pack a variety of doses into respective sachets.

The essence of this equipment in this industry is to enhance dosage accuracy, packaging speed, and quality of the specific drug.

Chemical Manufacturing

Some powdery chemical substances are also packaged into smaller pouches using pyramid tea bag packing machine.

It offers precision in packaging such substances, which is fundamental when used in different applications.

The suitable maintenance process of pyramid tea bag packing equipment is as follows;

- Always repair and replace worn-out parts with genuine or recommended OEM components to maintain and enhance efficiency, reliability, and consistency.

- The machine must always be clean by dusting numerous components and devices like sensors to eliminate unnecessary errors and downtime.

- Diagnose the machine using the right tools and software to determine and fix the different programming errors accordingly.

- Use recommended lubricants to lubricate all the moving parts frequently to prevent them from friction.

They include the following;

1) Too Fast Longitudinal Sealing Speed of Outer Bag

Mostly, it indicates a damaged speed detector and position proximity switch. It could also mean the cursor point is not detected during photoelectric tracking.

Solving this error requires replacing the speed detector and position proximity switch.

You may also set the cursor to be detected during photoelectric tracking.

2) Failed Main Motor

It happens due to failure of PLC to send the signal to an inverter, a damaged motor, improper inverter setting, and a blown fuse.

The ideal way to solve this issue includes replacing the motor, setting the inverter correctly, and replacing a blown fuse.

3) Incorrect Label Sealing

Usually happens due to inadequate pressure, flawed or damaged label, and insufficient temperature.

Troubleshooting this error requires you to ensure the machine attains enough pressure, the labels used are in good condition, and the machine supplies enough sealing temperature.

Other Related Machines:

For all your pyramid tea bag packing machines, contact us now.