Pouch Cartoning Machine Manufacturer in China

JOCHAMP is a professional manufacturer and supplier of pouch cartoning machines and other cartoning machine equipment in China. In a trusted design institute, we have a well-experienced team to manufacture pouch cartoning machines. JOCHAMP welcomes inquiries worldwide.

- Advanced technology

- High efficiency

- Flexible operation

- Stable performance

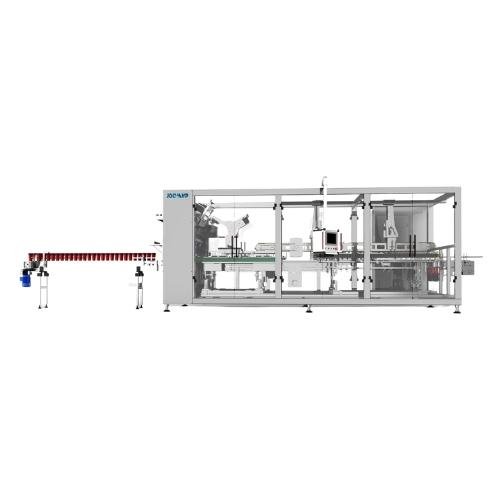

JOCHAMP Pouch Cartoning Machine

A pouch cartoning machine is a packaging machine that puts all kinds of pouch products ranging from solid, liquid, granules, and powders into respective cartons automatically. It offers more benefits regarding packaging efficiency, convenience, and endurance.

JOCHAMP is excellently the smartest in designing and producing pouch cartoning machines. This packaging unit consists of high-powered operation components such as connecting belt conveyor, climbing conveyor, no-power taking off conveyor, weight checker, carton opening, filling, sealing machines, etc.

JOCHAMP pouch cartoning machine guarantees to provide the most satisfying packaging output and have the ability to withstand heavy-duty operations. If you are interested in our machines, please send us your request immediately!

Types of Pouch Cartoning Machines

The Entry-level Automatic Pouch Cartoning Machine is an economical and efficient automatic packaging equipment that has been specifically improved to cater to the product characteristics of pouches.

With its design tailored for pouch packaging, the machine ensures smooth and precise cartoning, providing a professional and presentable packaging solution.

Operating at a speed range of 30-60 packs per minute (PPM), the machine delivers efficient and consistent packaging, optimizing production output and reducing manual labor.

This entry-level machine offers a cost-effective solution for businesses looking to automate their pouch packaging processes without incurring significant expenses. Its user-friendly interface makes it easy for operators to manage the machine with minimal training.

By enhancing the presentation and protection of pouch products, the Entry-level Automatic Pouch Cartoning Machine empowers businesses to meet industry standards and boost their packaging capabilities.

Overall, this equipment is a valuable investment for businesses seeking to streamline their pouch packaging operations and improve overall packaging efficiency while remaining cost-effective.

The Advanced Automatic Pouch Cartoning Machine utilizes a highly efficient and stable three-head rotary suction box method for operation. This innovative approach allows for smoother and more reliable cartoning.

With its adaptability to smaller cartons, the machine ensures precise and secure packaging for various pouch sizes.

Operating at an impressive speed of 50-100 packs per minute (PPM), the Advanced Automatic Pouch Cartoning Machine significantly boosts production output, reducing manual labor and increasing overall efficiency.

This advanced machine is designed to cater to the specific needs of pouch packaging, delivering a professional and polished presentation.

In summary, the Advanced Automatic Pouch Cartoning Machine is a cutting-edge investment for businesses seeking to streamline their pouch packaging processes with efficiency and precision. Experience seamless operation and elevated packaging performance with this advanced solution.

The Large Carton Automatic Pouch Cartoning Machine features a relay-type unpacking method, ideal for handling larger cartons effectively. With this innovative approach, the machine ensures smooth and efficient cartoning operations.

Designed to accommodate bigger carton sizes, the equipment guarantees secure and precise packaging for a variety of pouches.

Operating at a speed of 10-50 packs per minute (PPM), the Large Carton Automatic Pouch Cartoning Machine optimizes production output, reducing manual labor and enhancing overall productivity.

This advanced machine is tailored to meet the specific demands of pouch packaging within larger cartons, delivering professional and reliable results.

In summary, the Large Carton Automatic Pouch Cartoning Machine is a valuable asset for businesses seeking to streamline their pouch packaging processes with efficiency and accuracy. Elevate your packaging capabilities and experience seamless performance with this specialized solution.

The High-Speed Pouch Cartoning Machine, also referred to as the continuous cartoning machine, is a marvel of efficiency and precision. Operating seamlessly, this cutting-edge equipment ensures a smooth production process. With an astounding speed of up to 300 packs per minute, it outperforms traditional cartoning machines, revolutionizing packaging lines across various industries.

This state-of-the-art machine is designed to handle pouches and other similar products with utmost care, ensuring the integrity of the contents throughout the packaging process. Its high-speed capabilities significantly enhance productivity, reducing production time and costs, while maintaining exceptional quality.

Experience the power of innovation and witness unparalleled performance as the High-Speed Pouch Cartoning Machine transforms your packaging operations. Embrace the future of cartoning technology and take your production efficiency to new heights with this remarkable equipment.

The Semi-Auto Pouch Cartoning Machine boasts a user-friendly design, ensuring effortless operation. With a straightforward structure, it allows for swift manual product loading on the top. Its remarkable efficiency shines through, achieving a commendable speed of 10-30 packs per minute. Streamlining packaging processes, this machine becomes an indispensable asset in any production line. Experience enhanced productivity and seamless cartoning with this reliable and efficient solution, catering to diverse industry needs. Embrace simplicity, speed, and precision in packaging with the Semi-Auto Pouch Cartoning Machine.

The Vertical Pouch Cartoning Machine is a versatile packaging solution that excels in handling scattered or irregularly shaped products. By employing the top-loading method, this machine ensures efficient and precise product placement into the cartons. This feature makes it particularly well-suited for packaging various items that may not have a consistent orientation or alignment.

The vertical orientation of the cartoning process enables smooth integration with upstream and downstream packaging systems, optimizing production line efficiency. Additionally, its adaptability allows for easy customization to accommodate different pouch sizes and shapes, providing flexibility for diverse product packaging requirements.

With the Vertical Pouch Cartoning Machine, manufacturers can confidently package their scattered products with ease, speed, and reliability. Experience streamlined operations and enhanced productivity as this advanced cartoning machine elevates your packaging process to new heights.

JOCHAMP Pouch Cartoning Machine Advantages

JOCHAMP has carried out a strict inspection of every part and product, trying to have no quality problems in the hands of our customers. The speed of the machine is fast and working stable.

Pouch cartoning machine electronic components using well-known brands, stable performance, and high efficiency. High-quality corrosion-resistant, stainless steel, in line with GMP standards.

Pouch cartoning machine power supply is provided with over-current protection, the power supply exceeds with normal use range. The fuse will automatically protect the safety of the machine.

The pouch cartoning machine has a touchscreen and PLC control system, simple operation, intuitive and convenient, complete function, stable performance, long service life, and durable.

Technical Properties

JOCHAMP pouch cartoning machine has unique technical characteristics and working competency that outshines large-scale pouch application and packaging. It can function consistently and hygienically and is highly worthwhile as optimum support in any packaging business needs.

- Can be manually or automatically operated

- Compact and durable structure

- Stable and advanced performance

- Easy and convenient operation

- Energy and time-consuming

- Advanced operation devices, components, and systems

Wide Range of Applications

A pouch cartoning machine is applicable in a multi-piece of thin and thick products. A high technological machine that speeds up all the processes of product packaging. Moreover, the pouch cartoning machine integrates cartons’ unpacking, folding, lading, and sealing. This cartoning machine is the best-class packaging solution that is used in different industries:

- Cosmetics

- Pharmaceutical and medication

- Food, confectionery, and beverage

- Chemicals

- Nutritional and personal hygiene

- Industrial and automotive sectors

State-of-the-art Machines

JOCHAMP pouch cartoning machine is innovated and designed according to cGMP, CE, and ISO requirements. It is made from high-quality metal with high-precision components that ensure persistence, improvement of working efficiency, and automation packaging.

All pouch cartoning machine from JOCHAMP is made that runs for an extended period. It thoroughly adopts the HMI control and photoelectric detention to certify that it runs stably and accurately. Our team will exert enough effort to create a brand-new and top-quality pouch cartoning machine based on your needs and request.

Why Choose JOCHAMP Pouch Cartoning Machine

Our pouch cartoning machine is highly-esteemed due to its mechanical strength and versatility. It comprises explicit qualities and features, making them highly renowned in prestigious machine markets and packaging businesses.

The pouch cartoning machine is wholly powered and has an advanced mechanical control system, allowing for safe, easy, and consistent operation that perfectly corresponds to any packaging process. Additionally, a wide range of our pouch cartoning machines has an entirely stainless steel machine body design covered with sturdy surface coatings to achieve long-lasting strength.

As a pioneering manufacturer of pouch cartoning machines, JOCHAMP warmly welcomes all customers on different continents. Reach us to discuss further and to seek joint development!

Many packaging business successors remain on using pouch cartoning machine due to its spectacular features, including:

- Adopt a human-machine operating system

- Automatically displaying device for trouble, speed, and finished product counting

- Meet the requirement of cGMP

- Stable performance, the operation is easy.

- Corrosion-resistant

- Less maintenance

JOCHAMP has the best production line for pouch cartoning machines. It delivers outstanding advantages from a wide-ranging packaging process:

- Capable of excluding and rejecting any defective products

- Spontaneously stops if incorrect position of product into carton

- Adjustable type of cartoning machine

- Increased packaging production opportunity

- Effectively saves labor costs

- Can continue to work all-day

Why 1000+ Clients Trusted JOCHAMP Pouch Cartoning Machine

We manufacture pouch cartooning machine that has a complete system including a climbing conveyor, carton opening machine, carton filling machine, carton sealing machine, and no-power taking-off the conveyor.

Our pouch cartoning machines offer exceptional working processes including conveying bags through connecting conveyor, sending the carton automatically through a climbing conveyor, automatic carton opening, filling the carton automatically, sealing the carton automatically, and superior finished result.

We offer a pouch cartoning machine that can accommodate different types of pouch such as stand-up pouches, gusseted pouches, pillow pouches, three-side seal pouches, sachets, and liquid pouch packaging, and more. Rest assured that all your requirements are met.

Related Product

Pouch Cartoning Machine – The Ultimate Guide

At times, choosing pouch cartoning machine can be overwhelming task without the right information. A reason this guide explores all vital aspects of pouch cartoning machine. So, if you want to learn more about these machines, read this guide.

This is a machine that is used to place products in pouches and processing them until they are packed in boxes.

Various products including pharmaceuticals, cosmetics and food can be packaged using this machine.

pouch cartoning machine

The components of a Pouch Cartoning machine can give us a clear understanding of how the machine operates. They include:

a) Film Pulling System

This type of system is made of a tensioner that works in conjunction with an unwinding roller.

The unwinding roller is normally placed at the machines rear and is the one that holds the laminates of thin film.

A combination of the tensioner and a servo motor guarantees that the film is accurately unwound and introduced into the system.

b) Printer

The printer is responsible for printing the batch number and the date of production on the laminate or film.

This is however optional in some Pouch Cartoning machine the laminates have the dates and batch number printed with their respective labels.

c) Pouch Former

A pouch is formed immediately after printing using the pouch former by overlapping the laminate edges.

Afterwards, the filling jaws are used to perform both vertical and horizontal sealing of the pouches.

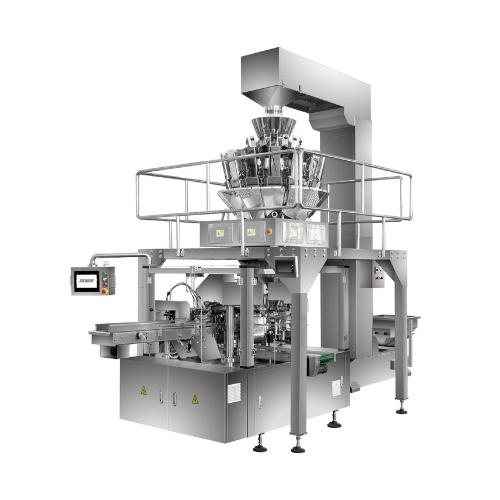

d) Filling and Sealing Machine

A multi-head scale is connected to the bagging machine in order for it to fill the pouches. Alternatively, other filling machines such as a volumetric filler or an auger can be connected to the bagging machine to fill the pouches.

Automatic electronic synchronization between the machines ensures that the product is filled in the pouch as soon as the pouch is ready.

filling and sealing machine

Sealing jaws are used to seal the pouch using heat once the product is inside the bag.

e) Pouch Cut

After the pouch is filled and sealed, it is cut in such a way that the first bags top seal is the second bags bottom seal.

The process is repetitive with the already cut pouch proceeding to the conveyor as a point of collection before packaging.

f) Control Panel

This type of panel is located on the Pouch Cartoning machine’s vertical side and contains the machines electrical parts.

Other components contained in the control panel are electrical low-pressure parts, PLC and the pneumatic cylinder, solenoid valves and servo motors.

Pouch packaging is a very important process for various products and understanding the procedure ensures proper product packaging.

The laminate is pulled from the film pulling system and introduced into the process using a combination of tensioners and a servo motor.

The laminate is then passed through a printer where details such as the date of manufacture, expiry date and batch numbers are printed.

Pouches are then formed using the pouch former by having the laminate edges overlap.

Sealing jaws are then used for sealing both vertical and horizontal seals and the pouch then forwarded for filling.

The pouches are then filled with the target product using either a bagging machine or a volumetric filling machine placed on the top side.

Heat is used to seal the pouches although other methods like ultrasonic sealing can also be applied.

The pouch is then cut after filling in a manner that makes the top seal of the first pouch also being the bottom seal of the subsequent pouch.

The pouches proceed to a conveyer where they go to their final packages for eventual shipping.

The Pouch Cartoning Machine is widely used in many industries to pack various products. Such industries include:

i) Cosmetic Industry: products such cosmetic creams and body creams are packaged in pouches using this machine.

ii) Agricultural Industry: many chemicals and various types of seeds are packaged using the Horizontal Form Fill Seal Machine.

iii) Pharmaceutical Industry: the machine is used for packaging medicinal cream, gauze bandages, blisters and syringes.

iv) Food Industry: a variety of foods including snacks and paste products are packed using the Pouch Cartoning Machine.

The Pouch Cartoning machine poses a lot of challenges especially when it comes to the market entry of new producers.

The advantages can however assist in making well informed investment choices.

Some of the benefits include:

i. Marketing Advantages

A variety of finishes can be achieved using The Pouch Cartoning machine in addition to good quality ink.

The pouch offers a well exposed surface area while at the time occupying a very small storage space.

ii. Varied Customer Base

Pouches have a very diverse custom and functional variations such as spouts zip closures that improve their use.

This has resulted in wide use of The Pouch Cartoning machine in various industries such as pharmaceuticals and food industries.

iii. Consumer Demand

The flexible way in which the packaged pouch looks like is very much appealing to various consumers.

It can be easily transported since it takes very minimal storage space and is easy to transport.

iv. Protective Barrier

Pouches filled using The Pouch Cartoning machine usually contain a foil within used to avert damage to the product from UV Rays.

They also protect the product from contamination, damp conditions and oxygen that may lead to oxidation of the material.

v. Lower Cost

The Laminate or thin film used by The Pouch Cartoning machine is very light weight compared to other materials.

This significantly lowers its transportation cost thus lowering the cost of production.

vi. Environmentally Friendly

The packaging mainly made of Polyethylene used in The Pouch Cartoning machine has environmental advantages.

Being the main raw material, it can biodegrade in 18 months compared to other rigid packaging plastics.

vii. Retailer Demand

The fact that the pouches use up very little storage space makes it very appealing for retailers to display in shelves.

Recent advancement concerning the pouch stability have greatly assisted in their adoption by retailers.

This type of machine has glue that is used in sealing the pouches by means of an advanced gluing machine that is automated.

The pouches containing the product are manually loaded onto the machines and sealing of the side flaps, top and bottom is done using glue.

semi automatic pouch cartoner

Fully Automatic Pouch Cartoner

This is a Pouch Cartoning Machine that operates autonomously using PLC. All the processes are automated and they require minimum human interaction.

automatic pouch cartoner

Horizontal Pouch Cartoner Machine

This type of machine is mostly used to package products having regular shapes into pouches such as biscuits or medicine.

horizontal pouch cartoning machine

The process of filling the pouches is fully automated and hot melt glue is preferred for sealing the pouches.

Vertical Pouch Cartoner

This type of machine is designed in such a way that the product filling side has a vertical inclination. It is ideal for packaging of products into pouches that don’t require vertical loading since the front and rear panels are horizontal.

vertical pouch cartoner

Continuous Pouch Cartoning Machine

This type of machine is made up of several barrels of cam loaders used specifically to load the pouches.

Their motion is usually in the horizontal direction for ease of movement of the pouches.

They operate at maximum speeds with their prices high compared to other Pouch Cartoning Machines.

continous pouch cartoning machine

Intermittent Motion Pouch Cartoner

This is an Automatic Pouch Cartoner with an intermittent motion as its mode of operation.

They are normally operated at intermediate or lower intermediate speeds and are suitable for fairly large pouch packaging.

When sourcing for a The Pouch Cartoning machine, certain features need to be present to enhance safety and efficiency.

Some of these features are automatic while others require human input to actualize.

Some of these features include:

i. An emergency push button that is normally located in the machines electric panel.

This but instantly stops any machine operations in the event of any emergency to prevent damage and harm.

ii. In the event that the laminate or polyethylene package is not in line, the pusher should cease to work.

This will help in avoiding losses by filling in pouches that are non-existent hence saving costs.

iii. To prevent damages for electricity to the machine, it should be equipped with overload shutdown mechanism.

This is normally an automatic protection that shuts down the machine in the event of a surge.

iv. The machine can have two working stations for swing feeding.

This ensures that in case the main stock does not fill up the pouches, ancillary stock will automatically cover and fil the pouches.

v. The Pouch Cartoning machine should have a mechanism that stops its operation due to low ancillary product level.

This is made possible by level sensors in combination with the Programmable Logic Controller.

i. It saves up space since two various operations are carried out at once.

ii. It saves up production turnaround time by eliminating the need to transfer pouches to another machine for forward processing.

iii. Automation is fully exploited by integrating both machine technologies in one.

iv. Easy maintenance of both machines since they can be serviced at the same time.

v. Safety is guaranteed with full automation of both machines.

The sealing options available in the Horizontal Form Filling Machine include:

a) Ultrasonic Sealing: vibrations of high frequency are used for package sealing brought about by vibrations of molecules in the film.

b) Heat Sealing: electric resistance in sealing jaws is used to seal the package. It is reliable and costs less.

c) Induction Sealing: electro-magnetic field generates heat used to seal the package using sealing jaws

A Pouch Cartoning machine that has been well maintained tends to have a long lifespan and efficiency of operations.

Some tips that can be observed in the proper maintenance of the machine include:

a) Regular Maintenance Schedule

This is the best method of practice for ensuring a prolonged machine lifespan.

Regular and periodic maintenance ensures the best production with the machine having an excellent general effectiveness.

The maintenance schedule should entail a thorough inspection of the machine and lubricating all moving parts.

Parts that wear and tear easily should also be regularly changed regularly with their stock readily available.

b) Understand Machine Part List

After acquiring The Pouch Cartoning machine, a list of spare parts should be requested from the OEM.

The list is then categorised according to their wear for easy strategic planning of the parts inventory.

The categories can be high wear parts bearing a brief life cycle and medium wear parts with an extended life span.

The final category is the Low wear parts that require no changing with minimal chances of failure.

For your pouch cartoner machines, contact us now.