Pharmaceutical Packaging Line Manufacturer in China

JOCHAMP has profound experience in pharmaceutical packaging line production. We provide all types of machines in one line for dry and liquid pharmaceutical products. These are pharmaceutical grade machines work perfectly and efficiently.

- Compact and ergonomic design

- High degree of automation

- Whole line safety protection

- Cost-effective option

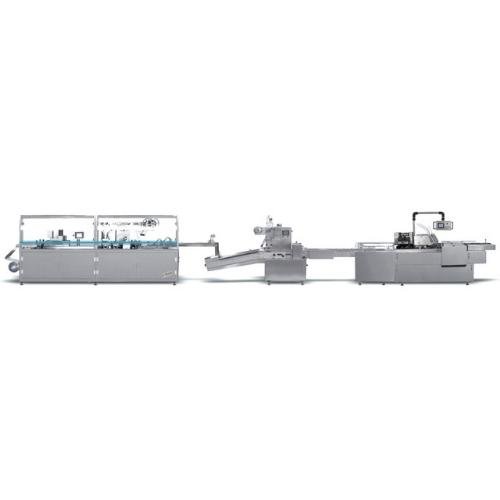

JOCHAMP Pharmaceutical Packaging Line

The packaging line is a vital part of the process and packaging of goods in the pharmaceutical industry. It consists of complete pharmaceutical packaging processes such as labeling, cartoning, case packing, and palletizing. Our company designs and manufactures different custom-built packaging lines for your project.

In Jochamp, pharmaceutical packing lines are constructed to minimize mechanical particle formation while also facilitating batch changes, line voids, and machine cleaning. Its functional layout has a high level of safety for optimal ergonomics and operator stations. This packaging line provides extra care in the distribution and packaging of products.

With in-depth knowledge in this industry, JOCHAMP takes pride in reliable and quality pharmaceutical packaging line production. We support different production requirements and offer a turn-key solution. Our team obtain the core skills, experience, and expertise needed in this field.

Message us today for more details!

Jochamp Pharmaceutical Packaging Line Features

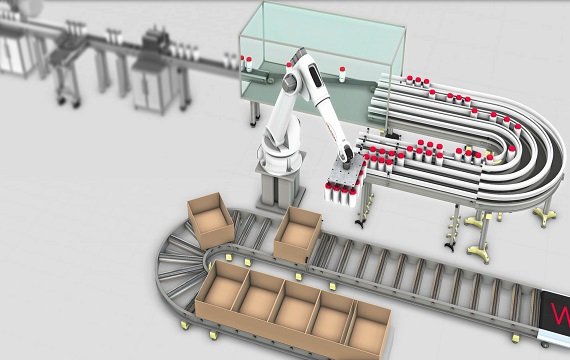

For a fully integrated production line, JOCHAMP can produce a turnkey system that includes assembly and packaging solutions on the same line.

Our flexible pharmaceutical packaging line can process different product presentations. We provide a wide choice of infeed and sorting solutions for both small batch and high-speed packaging line.

All packaging lines are compliant with various authentication such as CE, SGS, ISO9001, cGMP certification, etc. It uses high-quality materials and branded components.

You can guarantee an easy and safe to use machine for your packaging process at JOCHAMP. Designed with a high degree of automation, highly efficient, and intelligent.

One-Stop Provider

JOCHAMP provides one-stop pharmaceutical packaging lines with complete packing processes such as labeling, cartoning, case packing, and palletizing. Some are the following:

- Capsule Packaging Line

- Tablet Packaging Line

- Syrup Packaging Line

- Vial Packaging Line

- Powder Packaging Line

- Liquid Packaging Line

- Stick-pack and sachet packaging lines

- Dry pharmaceutical products packaging lines

Pharmaceutical Packaging Lines Applications

No matter what your industry, Jochamp can provide accurate machines for your pharmaceutical packaging needs. Below are some of the pharmaceutical products, our line is capable of packaging:

- Antibiotics

- Vaccines

- Steroid hormones

- Human blood-plasma fractions,

- Salicylic acids

- Basic vitamins

- Aspirin, pills,

- or any other medicines/drugs

Features and Advantages

JOCHAMP supplies pharmaceutical packaging lines that can work with small batches to high production volumes in various product formats pharmaceutical products. Our packaging lines have the following advantages:

- Ensure high production reliability and efficiency.

- Modular, ergonomic design packaging lines

- Fast changeover with reproducible settings

- Large range of formats

- user-friendly machine operation

- Organized and have optimum access to production and HMI

- Comprehensive traceability through serialization

- Extensive controls can be made based on the applications

One-Stop Pharmaceutical Packaging Line Provider

JOCHAMP is your one-stop automated pharmaceutical packaging solution provider in China. We have 15 years rich experience in R&D and manufacturing of packaging lines for your business. In every step of production, we imply meticulous quality control, from raw materials to machine assembly, and testing.

Our range of pharmaceutical packaging line has a compact design that maximizes the use of factory space. It operates and packages consistently, allowing for a perfect match production process. These are designed with simple concepts, making it easy to use as possible.

Moreover, pharmaceutical packaging lines are compliant with various certifications such as CE, SGS, ISO, CGMP and more. It uses electrical appliances and accessories of internationally renowned brands, such as Siemens, Schneider, SMC, Mitsubishi, Panasonic, etc. Thus, you can guarantee a high performance, high accuracy and high-efficient packaging process for any products.

At JOCHAMP, we welcome unique requirements to satisfy your needs. Please contact us immediately for your special request. We have a cooperative service team willing to help you.

JOCHAMP Pharmaceutical Packaging Line

JOCHAMP is an expert in the custom design and manufacturing of pharmaceutical packaging lines. We are dedicated to providing high-functional equipment for packing clean or sterile pharma products. Our company cooperates with pharmaceutical manufacturers worldwide and now expanding to the medical and biotech industries.

Our team uses various advanced techniques to create a specific design packaging line according to your request. Whether you need a packaging line for liquid, powder, or solid pharmaceutical products, we can provide an unmatched quality system for that.

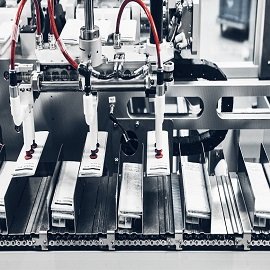

Jochamp has a wide range of custom pharmaceutical packaging machines that can be integrated into your existing packaging line. It may include but is not limited to:

- Syringe Packing Machine

- Ampoule Packing Machine

- Pill Packaging Machine

- Swab Packing Machine

- Ointment Tube Filling Machine

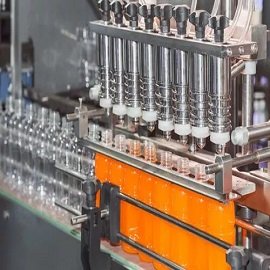

- Syrup Filling Machine

- Herb Packaging Machine

- Dry Syrup Filling Machine

Custom Packaging Line Based on Your Pharmaceutical Products

Dry pharmaceutical packaging machines increase the overall quality appearance of the products. It offers better branding and packing that promote business success. Jochamp is your leading manufacturer that can custom packaging lines based on your requirements.

Liquid pharmaceutical packaging machine from Jochamp provides a high level of protection required. It is designed with an automatic in-feeding system, and the operator manages its performance.

Pill packaging machines offer consistent performance for all types of large-scale and small-scale industries. Made from renowned brand components and materials, guarantee excellent durability for a longer operation.

Jochamp manufacture herb packaging machine according to your specifications. Get a spectacular, energy-efficient, and high-quality packaging machine. It is equipped with intelligent options and can perform well precise packaging work.

Related Product

Pharmaceutical Packaging Line: The Ultimate Guide

There are many pharmaceutical packaging line in the market today. A reason this guide will walk you through vital information on pharmaceutical packaging line. Whether you want to learn about machine design, features, benefits or uses – al information you are looking for is right here.

It refers to packages and packaging processes for a wide range of pharmaceutical preparations and products.

The process involves all operations from the production through drug distribution channels to the end user.

It offers economical means of providing protection, presentation, containment, identification information, convenience, and compliance for drug.

pharmaceutical packaging

Hence, in healthcare sector, pharmaceutical packaging is quite essential in keeping prescribed medication and drugs safe from contamination and bacterial growth.

Essentially, there are three main types of pharmaceutical packaging actuated in a typical drug packaging line.

However, different machines are used in pharmaceutical packaging lines to ensure each drug is properly packaged.

The notable equipment used in pharmaceutical packaging line includes the following;

Blister Packaging Machine

It is a drug packaging machine that closes the package inside and allows the blister to join the lining material, usually by heat sealing.

This equipment can pack capsules, tablets, and Dragees using aluminum and thermoforming materials through flatbed forming and alternating motion flat sealing.

Blister forming during drug packaging is split into flat-plate and drum types.

Flat-plate type generally performs better than drum type.

blister packaging machine

Besides, this equipment is often integrated with other machines like printer, boxing machine, inserting machine, etc., to save cost and labor.

Strip Packaging Machine

This is a high-quality equipment featuring a temperature controller and high pressure for sealing roller to enhance performance.

It has an adjustable film feeding system and adjustable conveyor making it highly efficient.

You can use heat-resistant materials such as Teflon on this equipment to provide excellent sealing without issues of film melting.

strip packaging machine

Moreover, it features an automatic wastage film collecting component, making it ideal for applications requiring minimal manual intervention.

Tablet Packaging Machine

This machine comes with several features like a high-performance counter, making it ideal for precise tablets, pills, and capsules cunning.

It has a lustrous design and conventional controls, making it aesthetic equipment.

You can also find it in dual nozzles of stainless steel material for constant filling and counting.

accounter tablet packaging machine

Besides, it supports variable counting speed and comes with a dust accumulating unit designed to protect its accuracy.

Vertical Tablet Packing Machine

This drug packaging equipment is known for its quiet operation with a precise and compact structure and logical design.

It exhibits comparatively stable operations and often leads to low malfunction.

Some of its features make it suitable for different processes such as automatic counting, measuring, filling, and bag marking.

vertical tablet packing machine

Automatic Pouch Packing Machine

It is notable drug packaging equipment that forms higher seal strength, better pouch appearance, and less leakage.

Ordinarily, this fully-automatic pharmaceutical packaging machine forms the stand-up pouch first before filling it with the drug and sealing it.

automatic pouch packing machine

It is mostly suitable for a wide range of products in liquid, powder, paste, solid, tablet, and viscous liquid nature.

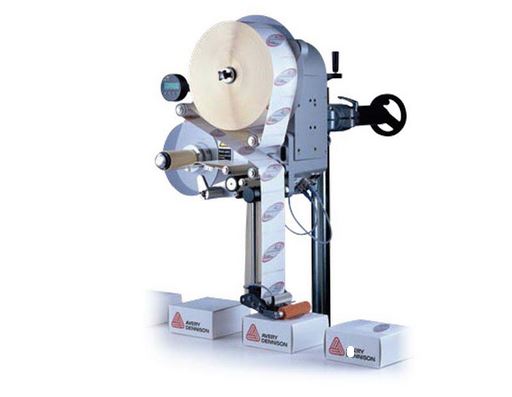

Label Applicators

The design of this equipment allows it to apply pressure-sensitive labels directly to pharmaceutical containers, packages, and bottles.

Typically, it features applicators, which are loaded with labels then applied to the products accordingly.

label applicator

These applicators function differently depending on the specific design.

Wipe on, air blow, and tamp blow are the commonly used label applicators in pharmaceutical packaging lines.

Cartoning Machine

This equipment is designed to form cartons by erecting, closing, folding, side seaming, and sealing them accordingly.

Once the pharmaceutical products, in this case, are filled into the respective cartons, the machine triggers its tabs to apply adhesive and close both ends of the carton.

Cartoning machines used in pharmaceutical packaging line are available in two main categories; horizontal and vertical orientation.

cartoning machine

Horizontal cartoning machine picks a single piece or stack of folded carton, erects, and fills them with products horizontally.

Vertical cartoning equipment erects a folded carton, fills it with product vertically through an open end, and closes it flaps using adhesive.

Leak-Detection Equipment

It is a highly-advanced machine with several in-build frequency sensitivity detector computers, visual probes, and ground probes among others.

The design allows it to detect any form of leakage on packaged pharmaceutical products before cartoning.

leak detection equipment

It is an important machine in pharmaceutical packaging line because it prevents the products from contamination and leakage that would lead to wastage.

Labeling Machines

They come in different designs depending on the specific pharmaceutical product, packaging materials, and container.

These machines help in correct labeling of drug packages, which is essential for serialization, tamper-evident labels, and track and trace codes.

labelling machine

The common labeling machines often used in pharmaceutical packaging lines include;

- Double-sides labeling equipment

- Bottle labeling machines

- Hard film overwrappers

- Automatic vial and ampoule labeling machines

- Wrap-around labelers

- Top sticker labeling machine

In contemporary pharmaceutical production and packaging, this equipment is vital in enhancing overall efficiency.

Some main benefits that make it a worthy investment in a typical pharmaceutical production setting include the following;

1) High production throughput

Ideally, most operations of this packaging line are usually automated hence tend to increase the overall production volume.

Of course, this is beneficial because it ensures supplies is always available whenever required.

2) Time-efficient

It is fast thus can fill and pack several pharmaceutical products in containers, bottles, or respective packaging materials within shortest time.

Moreover, some customizations often integrated into this line, like multiple heads, capping, and labeling features, increase speed accordingly.

3) Reduces unnecessary bottlenecks

Automation of different functions of this equipment reduces several human errors common for different bottlenecks during operation.

Thus, the reliability of production process makes the equipment a worthy investment, especially in an industrial setting.

4) Cost-effective

A typical pharmaceutical packaging line minimizes running costs significantly.

Its automated processes ensure the use of limited human labor, which cuts operating and related costs.

Besides, it is energy-efficient, thus guaranteeing lower utility bills in the long run.

5) Highly versatile

You can use this packaging line to pack different types of pharmaceutical products.

Ordinarily, it can pack tablets, capsules, vials, ampoules, and a wide range of powder and viscous liquid drug products.

6) Protection

The machines used in this packaging line exhibit excellent sealing abilities ensuring moisture-proof and contamination-proof products.

7) Dosage accuracy

The settings of different variables in this equipment enhance dosage accuracy and reduce accidental drug overdose incidents.

CIP, primarily, entails various activities combining to properly clean the entire or part of this packaging line without necessarily dismantling the system apart.

Drugs are quite sensitive, thus the need to ensure they have kept contamination free throughout the entire production and distribution cycle.

Some notable reasons why CIP system is fundamental in pharmaceutical packaging lines include the following;

Increases Product Safety

CIP system automates cleaning to minimize chances of human error likely to contribute to an unsafe product.

Besides, it also reduces contamination risks with its monitoring sensors.

Enhances Employee Safety

The automation process of CIP system implies that employees will not be subjected to chemicals since it offers cleaning solutions within the system.

Moreover, employees do not need to dismantle the machines to clean them.

Saves Time

Without an effective CIP system in place, the packaging process can be quite slow.

Cleaning such equipment would require stopping the machine, dismantling the parts, cleaning and restoring the components.

The entire process would be time-consuming and, in many instances, quite inconvenient.

Utility Savings

Ordinarily, the system reuses water through a repeatable cycle control.

Of course, this is important since it allows you to save a considerable amount of money you would otherwise spend on utility bills.

Enhances Product Quality

Repeatable and reliable cleaning results in sustainable product quality and consistency.

Therefore, there will be fewer or zero product recalls, which ultimately builds formidable brand confidence.

Different pharmaceutical companies use various types of materials for packaging other drugs.

Besides, continuous research and development broaden the spectrum of options.

However, the commonly used materials used in pharmaceutical packaging lines include the following;

Glass

It has been used for several years in packaging a wide range of pharmaceutical products and provides various benefits.

Most glasses used in this packaging line are transparent, durable, and tough.

However, amber glass tends to be used more frequently than clear glass since the former protects drugs from potential UV rays.

Also, you can label and identify them easily, and they come in various shapes and sizes.

Glass is primarily inert, facilitating more comprehensive protection of the pharmaceutical product.

Also, this material has a lower risk of interaction with leachable substances.

Three types of glass materials used in pharmaceutical packaging line include the following;

- Type I: Ultra-resistant borosilicate glass

- Type II: Surface-treated soda-lime glass

- Type III: soda-lime glass

Plastic

It is quite a versatile material used in packaging different pharmaceutical products.

Plastics used in this packaging line are lightweight, flexible, and can be used for pharmaceutical packages of different sizes shapes and hard-to-break.

Several types of plastic materials are used in pharmaceutical packaging line, which includes the following;

- PET – PET or polyethylene terephthalate is a common thermoplastic polymer resin used in single-use drug packaging solutions.

- HDPE – HDPE or high-density polyethylene refers to a thermoplastic polymer derived from monomer ethylene. It has a high strength to density ratio, making it an ideal plastic material for pharmaceutical packaging.

- PP – PP or polypropylene is a synthetic resin formed by polymerization of propylene. It is relatively soft and flexible thus considered safer for drug packaging.

The only major shortcoming of plastic in pharmaceutical packaging is the possibility of the material interacting with product by transferring leachables.

It is always vital to ensure you look into some notable elements when buying or assembling a pharmaceutical packaging line.

The fundamental aspects you must look into to get the most suitable one include the following;

Automation Mechanism

This is an important element to consider since pharmaceutical packaging line consists of different machines designed for different operations.

Technically, most operations of this equipment are automated to limit human involvement in the packaging process and enhance efficiency.

Thus, considering the type and level of automation system of this packaging line is vital since it allows you to determine whether it suits your production needs.

Besides, the automation mechanism determines the pharmaceutical pack cycle and ensures consistency.

Some components that come in handy in automation systems include cameras, sensors, vacant rankle cavities, and temperature sensors.

In the long run, automation mechanism plays a fundamental role in improving efficiency, reliability, and performance of the packaging line.

Design Features And Specifications

When choosing this packaging line, ensure you go for one with relatively advanced features and specifications.

The significance, in this case, is to enable it to adapt easily to the pharmaceutical packaging settings during production.

Factors like faster changeovers of parts and simple operation are also important in determining the efficiency and reliability of this equipment.

The Drive Unit

Commonly, pharmaceutical packaging lines operate in different cycles depending on the type of product.

Thus, such cycles are dependent on mechanical movement of portable sections within the packaging line.

You should, therefore, look into and ensure you pick a drug packaging line with a decent drive component.

Ensure it features a distinctive recurrence step-less speed processes and servo traction.

Such a packaging line allows framework synchronization and speed variance to improve efficiency.

Moreover, the equipment should be able to shape different packs, fill products, seal, and carton the various drug products accordingly.

Usually, the actual quality standards for a wide range of pharmaceutical packaging line depend on the specific target market.

Even so, the main ones often used in a wide range of these machines include the following;

Food And Drug Administration

Commonly abbreviated as FDA, it refers to an agency tasked with protecting public health by ensuring safety, security, and efficacy of human and drug products and devices.

FDA-approved equipment thus means its effects have been reviewed and determined to provide benefits outweighing its potential risk.

It is a necessary quality standard for this equipment since it approves its safety for use in handling pharmaceutical products.

International Standards Organization

ISO is generally a wider alliance of various public guidelines bodies.

Specifically, ISO 13485:2016 pinpoints the requirements for equipment manufacturer’s quality management system (QMS).

Hence, it provides quality standard certification for this equipment that guarantees its conformation to various required elements.

It approves the admiration framework, documentation technique, and fabricating process of the equipment to comply with the required standards.

ASTM International

ASTM International develops and publishes controlled accord technical standards for drug packaging line systems.

It is a critical quality standard because it promotes safety and efficiency in pharmaceutical drug handling within the machine.

IEC 60601

This is a series of technical standards that promotes safety and essential performance of a wide range of pharmaceutical equipment.

It is considered mandatory in most markets, including the EU, US, and Canada, to show proof of safety and performance.

cGMP

These are primarily the Good Manufacturing Practices as prescribed by the FDA.

This drug packaging line is designed to enhance packing of different pharmaceutical products, which need high standard levels.

Hence, cGMP provides the systems guaranteeing the right design, regulation, and control of such machines and their processes.

Moreover, it implies the equipment complies with updated systems ideal for improving performance and efficiency.

For longevity and efficiency, proper and timely maintenance of drug packaging line is fundamental.

The ideal elements to look into when maintaining this equipment include the following;

Adhering To Strict Preventive Maintenance Schedule

Maintenance schedule for this equipment is designed to prevent major disasters and minor problems.

These preventative maintenance measures include; daily machine inspection, checking and changing wear parts regularly, lubricating moving parts, and keeping wear parts in stock.

Proper Planning For Upgrades And Obsolescence

The equipment and software need upgrades and, sometimes, replacements when a certain device or component becomes obsolete.

Hence, consider getting necessary equipment upgrades by formulating a proactive replacement or upgrade for your packaging line.

Know Your Spare Parts List

Get the list of OEM recommended spare list to make it easy for you to purchase when in need.

It prevents unnecessary downtime and inefficiencies due to unfamiliarity with the spares each time the machine is down.

Combine With Autonomous Maintenance Chores

Pairing more in-depth tasks related to drug packaging line maintenance with easier, task-based activities is recommended.

It allows you to become familiar with the equipment due to repeated maintenance tasks since you can easily detect when something is amiss before scheduled maintenance.

The URS of a typical drug packaging line is quite intensive given that it factors in different machines used in the packaging process.

However, the general URS element for this equipment include the following;

- Introduction (A brief overview of information on the equipment)

- Overview (Intended use, capacity, space availability, accuracy, cleaning needs, material quality, etc.)

- Operational requirements (control system, functional requirements, safety, power, environment, operation, other conditions)

- Compatibility and support (Utilities, availability, supporting documents)

- Abbreviations

- References

- Approval

Ordinarily, this drug packaging equipment is highly versatile.

Therefore, it means you can use it to pack a wide range of products, which include the following;

- Vials

- Ampoules

- Capsules

- Tablets

- Blister

- Syrup

- Powdered drugs

- Chewing gum

For all your pharmaceutical packaging line, contact us now.