Pharmaceutical Cartoning Machine

JOCHAMP provides cartooning machines for diagnostic and pharmaceutical products, techno chemical products, medical devices, cosmetics, and the food industry. Our pharmaceutical cartooning machine allows packing pharmaceutical bottles, containers, ampoules, etc.

- Suction box structure compatibility

- Food-grade machine

- Compact footprint

- Secure, fast line clearance

JOCHAMP Pharmaceutical Cartoning Machine

JOCHAMP pharmaceutical cartooning machine can operate either intermittent or continuous motion. It can accommodate 10-30 packages per minute. There are lots of pharmaceutical products packed with our machines such as pharmaceutical bottles, containers, ampoules, inhalers, blister, and sachet bags.

Our dedicated team performs strict quality control to exceed high requirements in the secondary packaging. It ensures the safety of the ampoules, vials, or blisters and complied with GMP. We offer a modular, flexible pharmaceutical cartooning machine for your reference. These machines enable the blister, stick pack system, or sachet to have an effortless expansion into a high-performance, complete production line.

Types of Pharmaceutical Cartoning Machines

Why JOCHAMP Pharmaceutical Cartoning Machine

The machine has digital counting features to ensure accurate settings when the format is need to change.

Enable fast changeover due to excellent accessibility. It also reduces production time due to fast cleaning.

The machine is featuring teach-in techniques for numerous ranges of brochure lengths.

Provides different expansion options to meet your different needs: coding, labeling, conveying, manual folding, glue spraying, and more.

Our Pharmaceutical Cartoner Machine Capability

Today, the demand for health products is increasing. That’s why the healthcare and pharmaceutical industry will never vanish. Meanwhile, the pharmaceutical cartooning machine from JOCHAMP allows efficient and fast packaging of pharmaceutical products. Some health products our cartooning machine allows you to package are:

- Blister Pack:

- Face Masks

- Healthcare Dressings

- Medical Bottles

- Healthcare and Sachet Products

- Soap Products

It’s quite hard to maintain a sterile environment in healthcare product packaging. Thanks to our innovation, our machines are ideally suitable for this kind of cartooning.

Pharmaceutical Cartoner Machines We Offer

Cartoners Available: vertical, semi-automatic, and automatic for pharmaceutical products.

Our series of JOCHAMP pharmaceutical cartooning machines can accommodate numerous cartooning types for pharmaceutical products in a germ-free area. With options for magazine loading, fully automatic, and on-demand operator engagement. No matter what packaging you are into, our cartooning machines are uniquely calibrated to meet your needs.

On the other hand, our vertical cartoner machine is specifically designed for vertical, on-demand carton loading. It is operated automatically through a rotary vacuum system. It can be running on continual or intermittent motion and allows multiple operators at the loading stage.

Why Choose from JOCHAMP?

- Extensive Standing Reputation

JOCHAMP is the most flexible producer of the reliable pharmaceutical cartooning machines in China. Our machines provide versatility and high productivity to pack healthcare liquids and fragile products.

- Healthcare Packaging Machines

JOCHAMP offers custom and standard machines with fill, erect, and seal cartons. They are perfect for any healthcare product work, whether you need blister or pod packs, plastic or glass bottles, sachets, and cartons.

- Bespoke Products and Latest Technology

We have invested in the most suitable computer technology for a quick design process. Our pharmaceutical cartooning machine is tailored to meet the requirements of any healthcare goods or business. JOCHAMP is successful in this industry by understanding product and cartooning handling.

Choose JOCHAMP Pharmaceutical Cartoning Machine

As the population is growing, the health products are also increasing these days. If you are in the pharmaceutical industry that needs reliable cartooning machines, JOCHAMP is the right place! JOCHAMP is a leading healthcare cartoner manufacturer for many years. Our machines can pack different health products efficiently and quickly. We are not just a manufacturer but we also repair the machines we supply to you.

JOCHAMP pharmaceutical cartoner machine is designed to pack a large scale of goods, including sachets, soaps, bandages, and bottles. Most of the healthcare industry can get benefits from our machines. It is fully calibrated, and can accommodate large production and health product preservations like blister or pill packs, filled sachets, and sterile dressing.

If you need to customize your pharmaceutical cartooning machine, please don’t hesitate to contact us. We have friendly staff and professional engineers to assist your custom project.

JOCHAMP Pharmaceutical Cartoning Machine

Our series of pharmaceutical cartooning machines is fabricated for medium and small batch sizes. It can handle packaging in folding cartons. The machine has a modular design to integrate additional functions. We design them through a building block principle. Our machine needs minimum space and requires a few format parts.

JOCHAMP offers a healthcare cartoner machine with different intermittent motions. For parenteral and solid packaging, the machine with P4 and P2 motion is equally suited. They have a 120mm pitch that is perfect for medium and small batches. The machine is characterized by minimal versatility for folding box packaging solutions.

Custom Pharmaceutical Cartoning Machine for Packing Different Products

For liquid medicine packing, our pharmaceutical cartoning machine offers high-speed and accurate operation. It provides safe, hygienic, secure packaging with no contamination and spilling.

We offer blister carton packaging at an affordable cost. It has a compact design, servo-driven, in vertical or horizontal construction. This machine meets the cleaning standards of the food and pharmaceutical industries.

JOCHAMP ampoule cartoning machines feature a compact, quick, and easy to change over. Ideal for small and medium-sized ampoule batches. Offer a high standard of process, dependability, and long service life.

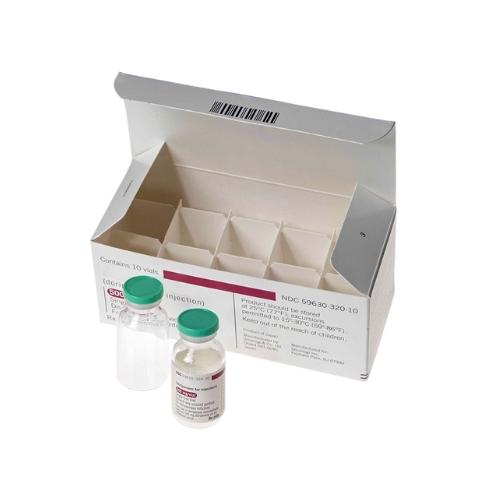

Our pharmaceutical cartoning machine can pack different vials safely and efficiently. Jochamp designs flexible and high-speed vial cartoning machine range to satisfy the most demanding applications Perfect for the production of small to medium batch sizes.

Related Product

Pharmaceutical Cartoning Machine: The Ultimate Guide

With high quality pharmaceutical cartoning machine; you can improves efficiency, safety and reliability in the entire supply chain system in pharmaceutical industry. This guide will help you choose the best cartoning machine for your pharmaceutical packaging line.

Vertical Cartoning Machine In Pharmaceutical Packaging

A vertical cartooning machine is designed to load the cartons in a vertical position.

Usually, the insertion of the product into the carton is done manually or automatically from above the box.

pharmaceutical cartoning machine

Vertical cartoner is suitable for packaging pharmaceutical products that can easily flow through gravity.

This type of cartooning machine comes with the following features;

vertical cartoning machine

A pivoting arm for folding down the two minor flaps and a pushing mechanism which secures the top flap.

Horizontal Pharmaceutical Cartoning Machine

Horizontal cartoner is different from the vertical cartoner in terms of the way the product is inserted into the carton.

Just as the name suggests, the products are inserted into the carton horizontally or from the side of the carton.

The machine can operate in an intermittent or continuous mode and the loading process can be manual or automatic.

horizontal pharmaceutical cartoning machine

It is mostly used for pharmaceutical products that cannot flow freely when placed in vertical position.

Semi-automatic Pharmaceutical Cartoning Machine

This is one that can operate through mechanical and pneumatic mechanisms.

The machine can be vertical or horizontal and involves having to insert the product into the carton manually.

Working with a semi-automatic pharmaceutical cartoning machine makes the work simple.

However, the production speed is low which also means a low throughput and may require more human labour.

Automatic Pharmaceutical Cartoning Machine

Automatic cartoners can be continuous or intermittent and are usually designed with accessory units that can operate automatically.

The machine can form, load, seal and print the cartons automatically.

Automatic pharmaceutical cartoning machine can pack products into cartons laterally and later seal the carton.

The movement of the product from one section of the machine to another is fully automated.

Continuous Motion Pharmaceutical Cartoner

Continuous motion pharmaceutical cartoner is an automated cartoner that operates in a continuous mechanism.

The machine is able to detect the loading of the product into the feeding hopper, and automatically form the machine.

And when the carton has been loaded, sealed, printed and discharged.

Another carton is made ready and the process does not end until the session is over.

The production process is very efficient and saves on labour costs and increases the throughput.

Intermittent Motion Pharmaceutical Cartoner

Intermittent pharmaceutical cartoner involves a movement that advances an object and then holds it at some point.

This machine employs a mechanism that is the opposite of continuous, it stops at some point for carton making to take place.

This stop over slows the whole process down leading to low throughput.

The main purpose for stopping the movement is to allow for the formation of more cartons before a new session begins.

Side Loading Pharmaceutical Cartoner

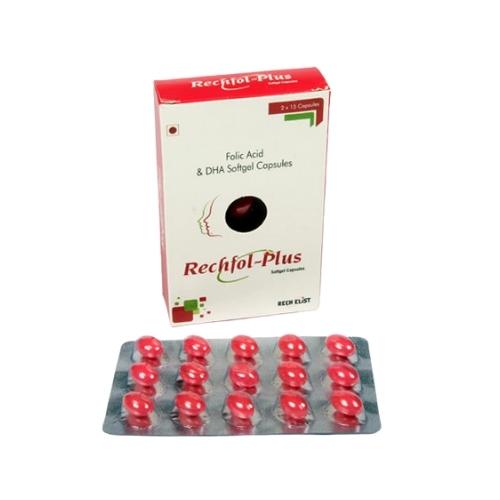

Side loading pharmaceutical cartoner are basically suitable for packing blisters, vials, ampoules and other pharmaceutical products.

Products are loaded into cartons from the sides of the cartons and the process is automated.

The machine is designed to expand sachets, blisters and ensure highly performing production line.

Side loading cartoner has a digital counting feature for accurate setting during format changes.

Top Load Pharmaceutical Cartoning Machine

This is an automatic or semi-automatic cartoner that loads products into cartons through the top of the carton.

Top load pharmaceutical machines employ the same working principle as that of the vertical pharmaceutical cartoner.

The top load cartoner can operate through intermittent or continuous mechanisms to package pharmaceutical products.

Since the machine is very flexible, it can pack various pharmaceutical products like vials, ampoules and other products.

Besides, the machine can also handle varying sizes of the products and make cartons of different sizes.

Bottom Load Pharmaceutical Cartoner

Bottom load pharmaceutical cartoner is best suited for single layer processing speeds.

The machine is made up of a raw forming mechanism and a raw pusher which aid in the loading process.

Cartons are formed automatically by loading them onto the case magazines and are formed through suction grippers.

Through a pneumatic cylinder, the product is pushed from the bottom into the carton and the carton is sealed pneumatically.

The machine also does the sealing and printing of the carton after it has been loaded with products.

Feeding The Storage Hopper

Automatic pharmaceutical cartoners are capable of loading the products and cases into the storage hoppers automatically.

Carton Forming

Once the cases have been supplied to the carton erector, the machine is capable of erecting cartons of various sizes.

Product Loading

At the loading station, pharmaceutical cartoner is designed to automatically or manually load products into cartons.

Loading can take place vertically or horizontally depending on the type of the pharmaceutical cartoner in use.

Sealing

Sealing of the carton after it has been loaded with products is one of the functions of the pharmaceutical cartoner.

There are various ways that a cartoning machine can employ to carry out its sealing procedures such as hot melt seals.

Printing Or Creating Codes

The pharmaceutical cartoner is equipped with a printing section the ensures that instructions for the user are printed on the carton.

This is also an automated process which is controlled through an HMI interface connected to the machine.

Discharge Of The Carton

Once the carton has been formed, loaded, sealed and printed, the machine will proceed to ejection.

The carton is now ready for distribution into the market.

Some of the most common applications include:

Packing Blister Medicine

Blister medicine after being packaged into capsules are loaded into cartons through the semi or automatic pharmaceutical cartoner.

Packing Medicine Bottles

Medicine bottles after they are filled with medicine, are also packed into cartons of various sizes through pharmaceutical cartoner.

Packing Tablets

Tablets can first be packed into bottles before being packed into cartons through a pharmaceutical cartoner.

Packing Ointments

Through the use of pharmaceutical cartoners Ointments are also packed into cartons after being filled into various containers.

Packing Chemicals

Chemicals like acids are first filled into bottles which are packed into the cartons through the pharmaceutical cartoner.

Control System

Every pharmaceutical cartoning machine is designed with a control panel that enables the operator to monitor the whole process.

The control panel is connected to a PLC which can determine the number of cartons, number of products, print and loading.

This part acts as the brain of the machine and all the process of the machine functioning can be controlled and monitored.

An alarm system is also connected to the HMI part and in case of any failure the error will be displayed on the screen.

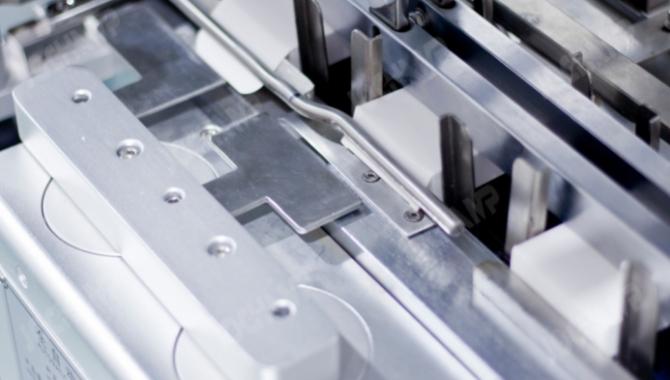

Gearing System

The electrical panel and electric motors are part of the gearing system

Additionally, the electric panel is the part where the mains of the whole system are tapped and the pneumatic system is powered up.

Moreover, the whole pharmaceutical cartoning machine system is connected to the electric panel.

The electric system can be referred to as the heart of the machine.

Electric motor functions to convert electric energy into the mechanical energy which leads to movement.

Also, the electric motors are normally placed and enclosed at the bottom of the machine.

All the moving parts of the machine are connected to this section through support axis and gearing axis.

Lubrication System

A pharmaceutical cartoner being an electromechanical machine, must be properly lubricated.

Lubrication is normally done to the moving parts.

For proper functioning and long service of parts like bearing, gears, belts it is important to prevent contamination, high temperature and moisture.

The lubrication system is automated to ensure frequent lubrication of all the moving components.

Cartoning And Pneumatic System

This is the part that controls the cartoning process and the pneumatic system plays the role of vacuum suction of the blank cartons.

The cartons are kept into the storeroom from where they are drawn one by one.

They erected and sealed at the bottom by a carton erector in place.

Loading Systems

The most commonly used loading options are multi-axis robotic system, two axis robotic system.

With the loading system controlled from the gearing system, the products are loaded into the cartons.

Closing Systems

There are various ways that a pharmaceutical cartoner can carry out its closing and sealing processes.

Tri-seal is mostly used with top load cartoners where the carton is closed with a lid which is sealed at the 3 ends.

Compact right angle meant for multi flap cartons creating a seal at the center where all the flats connect with each other.

Inline top seal creates a seal all around all corners.

Conveyers, Rollers And Rail

Conveyers are interlinked with rollers for the movement of product to take place.

The guiding rail leads the carton to sealing stage from the packing stage.

Safety System

Safety system consists of safety buttons that can cut off power supply to the machine when an error occurs.

Gearing Section

After powering on the machine, a mechanical movement is initiated towards the main drive which is also sent to the gearing parts.

The mechanical movement is transferred to the parts through gearing axis, threaded shafts or support axis.

A reciprocating movement is created at the middle part of the machine.

Through the carton chain, the movement is transmitted to other parts.

Blank Carton Section

The blank cartons stored at the storeroom are unloaded through a suction process and the sucker can absorb damaged cartons.

Feeding Stage

The blank cartons are fed into the carton forming stage through a feeding mechanism depending on the type of pharmaceutical cartoner.

Carton Making

A leaflet folder will fold up the carton as it runs on the conveyer and it is sealed at the right parts through suction and stacker mechanisms.

Packing Stage

Once the carton has been formed and sealed, the machine inserts the products as required through a feeding device.

Sealing Stage

Small torque is on either sides of the conveyer and has a box guide and folding pad.

The big torque is being driven by rotating cranks to move the plate flat.

These two aids in bending and sealing of the carton through hot melt method.

Printing Section

The instructions created through the HMI can be printed on each carton through an in-built printer,

Ejection

The ready carton can be ejected from the machine through a chute system.

The chute system can also determine if a carton is good or bad.

Some of the most common features are:

- In-built features for Product checking

- Stainless steel frame for pharmaceutical products

- Carton pick – up mechanism

- Code embossing on the already packed carton

- Carton erection and sealing by knife blade mechanism

- Leaflet pick-up mechanism

- Operator interface with a touch screen.

- Product insert mechanism

- Carton closure and sealing mechanism

- Carton Discharge through chute mechanism

- Multi packs different products in the same carton can be handled.

Depending on your specific needs and requirements, you may choose a machine with more features.

Although there are broad ways of maintaining pharmaceutical cartoning machines, some of the most common options are:

- Lubrication of the different moving parts of the machine should lubricated every week and do not add too oil.

Too much oil may lead to pollution of the products.

- Conveyer belts on every conveyer must be adjusted every week to avoid any runoffs.

- The operator must be very keen to follow instructions to avoid mis operations which can lead to damages.

- During cleaning, ensure that water does not reach the electric parts as this will cause shocks when the machine is in use.

- Check the screws and moving parts every week if they are loose and adjust appropriately or get an expert.

- When the machine is working be attentive enough to know if there are abnormal sounds or smells.

Some of the most common closing options are:

Pressure Sensitive Tapes

The tapes are obtained from petroleum and cannot be biodegraded

They are easy to apply using a tape gun or dispenser.

The pressure sensitive tapes are transparent and does not need water or any other solvent to enable sticking.

They are meant for lightweight cartons and those that contain inexpensive items.

Water Activated Tapes

These are made of kraft paper and gun adhesive, are brown or white in colour.

This technique applies moisture to the tape when its being applied.

They create a strong bond with the cartons.

The tape can be used with heavy contents, costly items and cartons with tamper-evident requirements.

Glues

The glue used for sealing cartons is the Polypropylene adhesive and it forms a tamper-evident seal.

Glues can be used in companies that operate in fast-paced environment and produce uniform goods in terms of size.

One in a while, your pharmaceutical cartoning machine may fail to operate optimally or as intended. This could be due to any of the following reasons:

- If the machine does not power up; possibly caused by Incoming power problem or main disconnect is off.

- The carton is not formed or ejected after being sucked down; possibly caused by; carton being too hard, position of the guide bar is incorrect, hook spring is deformed, height between the feeding track and the suction head is incorrect.

- The machine cannot reset; possibly caused by;

Safety circuit not reset,

Low air pressure,

Guard doors open,

E-Stop,

Faulty wiring

- Bad seals; possibly caused by Forming tube backstop set improperly or Incorrect distance between film and forming tube.

- Cartons cannot be sucked down possibly caused by;

Cartons not placed in order

Cartons are pasted together

Air pressure at the suction head is not normal

- Cartoner or belt gap shutdown possibly caused by;

Shortage of material

Poor power supply

Carton Sealer For Pharmaceutical Cartoners

The main function is to fold the flaps and to seal the top and bottom of the cartons.

Carton sealer can seal both the bottom and the top, however, when used together with a carton erector, it seals only the top.

carton sealer

The machine is made up of a tape holder, taping mechanism and a conveyer belt.

It works by holding the carton into place through a set of holders while another shaft moves down to tape the box neatly at the top.

Carton sealers only work in one direction.

Carton Erector For Pharmaceutical Cartoners

The main function of the machine is shape up the box, fold the flaps at the bottom and seal.

Carton erector only seals the bottom of the carton

The machine is made up of shafts for carton erection and taping wheel for sealing the bottom.

Carton erector functions by holding the carton through tong-like structures in an upright position giving it the shape and adhesive tape is applied at the bottom.

carton erector

Carton erector can work in two directions vertical and horizontal

Labour Costs Reduction

Every section of a robotic pharmaceutical machine is automated and does not require having to monitor every stage.

High Safety

Safety to the operator and to the consumer of the products because automation eliminates handly of the product by operators.

Quality Services

The robotic cartoner follows a fixed operation procedure and it means no errors incurred unlike manual cartoners that are prone to errors.

Continuous Production

The fully automated cartoning machine ensures high throughput due to the fact that the process is continuous.

More Resources:

Semi-automatic Cartoning Machine

Guidelines For Packaging Pharmaceutical Products

For any questions or inquiries on pharmaceutical cartoning machines, contact us now.