Custom Paper Pouch Packing Machine Manufacturer in China

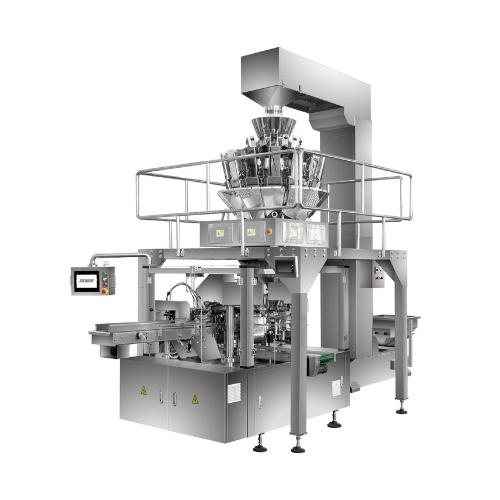

JOCHAMP offers a paper pouch packing machine that is easy to operate and PLC a controlled system. These machines are customizable based on customers’ requirements and applications.

- Paper pouch sealing and filling functions

- Can pack 30 to 40 paper pouches per minute

- High accuracy and precision

- Automatic checking system

Jochamp Paper Pouch Packing Machine

JOCHAMP is a leading paper pouch packing machine supplier that constantly provides high-quality, high accuracy, and excellent performance. These machines can accommodate 200x100mm or 300x350mm paper pouch sizes. Depending on the product to be packed, it can provide a filling volume of up to 10-2500 grams. Our paper pouch packing machines are applicable for packing products such as granules, powders, coffee, milk, nuts, snacks, and more. Here in JOCHAMP, you can find a variety of models and types of this machine. Each machine is tailored according to the client’s requirements. We also guarantee that all our paper pouch packing machine is certified by various international standards such as FDA, ISO, and more.

For customized paper pouch packing machine, don’t hesitate to contact us!

Components of Our Paper Pouch Packing Machine

JOCHAMP offers paper pouch packing machines that are constructed with different components such as:

- Film pulling system and optional printer

- Pouch former and filling & sealing machine

- Pouch cut

- Control cabinet

Optional Paper Pouch Packing Machine Configuration

Our paper pouch packing machines are available in different configuration options such as the following:

- Platform

- Metal detector

- Check weigher

- Filling machines

- Material weighing

- Product conveyor, and more

Paper Pouch Packaging Machine: The Ultimate Guide

If you are looking for any information about paper pouch packaging machine, you will find it right here. From parts, working principle, features, benefits to applications – this guide offers perfect solution to all your paper pouch packaging needs.

It is a piece of electromechanical machine that fills and seals different types of products into paper pouches.

This machine is increasingly becoming popular today due to its simplicity, user-friendliness and excellent aesthetics of the final product.

Whether you are considering adding this unit to your existing packaging line or are new to packaging equipment, you’re likely interested in knowing more about this machine.

paper pouch packing machine

Hence, this article discusses various fundamental elements surrounding paper pouch packer and why you should invest in it.

Ordinarily, this machine offers a wide range of benefits in paper pouch packaging solutions.

Some notable advantages making it a worthy investment include the following;

Time And Cost-efficient

This equipment offers a seamless packaging solution for different products. Thus it saves time and running costs significantly.

Improves Safety

It features a wide range of safety characteristics, which are integral in preventing the machine and operators from inevitable hazards during operation.

Increases Production Volume

Speed is an essential element in a typical industrial process.

As such, this machine uses automated functions that enhance production speed and ultimate throughput.

User-friendly

It comes with an easy-to-understand HMI and PLC touchscreen for easy and convenient control and monitoring of the different operating processes.

Customizable

You can adjust this machine to offer flexible packaging solutions based on your specific production demands. Ordinarily, this is important because it reduces wastage.

Easy To Maintain

The maintenance requirements for this equipment are less demanding given its simple design, construction and components.

It thus ensures reduced time wastage arising from unnecessary machine breakdowns during packaging process.

A standard paper pouch packer comprises numerous parts and components integrated to form a single functional system.

Ideally, each part has a designated function, which ensures the machine accomplishes pouch packaging process seamlessly.

Even so, the exact parts and components are dependent on the actual type of machine since it is available in many variants.

paper pouch packaging machine

Nevertheless, here are the common parts you will find in an ordinary paper pouch packaging machine;

PLC Touchscreen

It is integrated into a user-friendly HMI system designed to display graphics and different functional parameters of the machine.

Ideally, it is the part the operator uses to select and monitor the various operational parameters during packaging process.

Hopper

It is a funnel-shaped unit located at the top section of the machine where the products to be filled in paper pouch are fed into.

Filling Unit

This unit is designed to dispense and fill the products into the various paper pouches before they are sealed.

Drive Mechanism

This system comprises different units that drive the machine and mostly includes a combination of motor and power systems.

Its essence is to ensure unified movement of different machine components to accomplish the packaging process.

Control Buttons

They are used for changing different operating variables such as start, stop, emergency stop etc., based on the specific required operation.

Loading Port

It is the actual section where the ready paper pouches are loaded into the infeed lane to pass into filling and sealing stages.

Conveying Unit

It is designed to move the products from station to station and from completion to assembly awaiting shipment.

Dusting System

Solely for managing and eliminating dust likely to exist within the equipment.

The common parts of this component include a dust hood, dust nozzles and dust collector trough.

Photoelectric System

It discharges a light beam from the in-built light-emitting feature for color marking the paper pouch during packaging.

Interlock Guards

They ensure the machine is safe by reducing or eliminating possible hazards, particularly when unsafe maneuvers occur.

Technically, paper pouch packaging machines are in two categories based on the paper pouch layout; vertical and horizontal configurations.

Vertical layout merely implies that the paper pouch has a vertical structure, and it is more preferred in this technology.

Simply put, paper pouch packaging is a comprehensive process that involves intermittent rotary movement of pouches in different stations.

Here is how this machine works;

Paper Pouch Loading

Preformed pouches are loaded into the bag magazine by a robotic arm and conveyed into the equipment by a bag feeding roller.

The robotic arm grasps individual bags using vacuum suction technique and loads them into the bag gripping section.

Bag Gripping

Proximity sensor detects a bag and allows vacuum bag loader to pick up and transfer the pouch to a set of grippers.

The grippers hold the bag as it moves around the packaging machine to different stations.

Printing/Embossing (Optional)

Printer is placed at this station if printing of embossing is required.

Mostly, the printer is used for placing dates, lot codes and batch numbers on pouches.

Paper pouch packer can use thermal and inkjet printers.

On the other hand, embossing option may be used for placing raised dates or lot codes on the bag seal.

Pouch Forming

The film moves to bag forming after printing.

This process overlaps film edges to shape the pouch accordingly and allows the sealing jaws to close vertical and bottom sealing.

If the pouch doesn’t have a zipper, the vacuum suction opens its bottom part and engages air blower only.

The machine has two sensors that detect presence of a bag.

Hence it only engages the filling and sealing stations upon detecting the presence of the bag.

Besides, it never fills and seals the product if the bag is placed incorrectly.

Instead, the bag stays on the rotary equipment until the next cycle.

Bag Filling And Sealing

Filling is accomplished by joining a bagging machine to a multi-head scale or another filling machine like a volumetric filler or auger, depending on nature of product.

The connected machines are synched electronically to allow the product to drop automatically once the bag is ready.

Filling unit is programmed to ensure correct measurement and release of discrete product quantities dropped in each pouch.

Product Settling

In some instances, loose products need time to settle to pouch’s bottom before sealing; hence the station shakes premade pouch gently to attain that.

Paper Pouch Sealing

The deflator components squeeze remaining air out of the bag before sealing.

Hot sealing jaws close the upper part of the pouch by forming a strong seam from pouch sealant layers using heat pressure and time.

Cooling And Discharge

The seal is strengthened and flattened by a cooling bar.

The finished pouch bag is then released from the packaging machine into a receptacle or conveyor for downline equipment transportation.

Paper pouch packers are available in different types, often based on various aspects, including operation, function, packaging style etc.

However, the notable types used commonly in different industries include the following;

Automatic Paper Pouch Filling Machine

It is a type where all the packaging functions are fully automated; thus, the process hardly requires human involvement.

Automatic paper pouch filling machine

Semi-automatic Paper Packaging Machine

In this machine, most operating variables are automated, but it also has a few functions that require human intervention, albeit a few.

semi automatic paper packing machine

Kraft Paper Pouch Packaging Machine

This type of machine creates the pouch from plain kraft paper for packaging different products.

It comes with different equipment that creates the pouches depending on the preferred or desired design.

Kraft paper pouch packaging machine

Vertical Pouch Packaging Machine

This is a type of pouch making machine that features a vertical structure. It means the products are filled and sealed inside pouches that are in a vertical orientation.

vertical pouch packaging machine

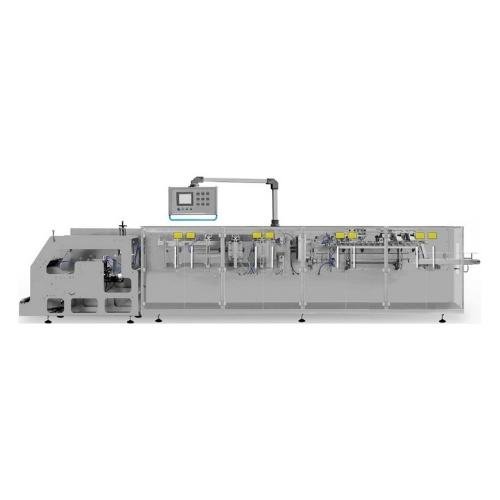

Horizontal Pouch Packaging Machine

It is a pouch making machine with a horizontal structure.

Ideally, this type of machine fills and seals paper pouches designed in a horizontal orientation.

horizontal pouch packaging machine

Rotary Automatic Pouch Packaging Machine

It is a paper pouch packer type with a circular design.

Technically, this machine creates a circular fashion operation; hence it implies the operation starting point is beside the ending stage.

rotary automatic pouch packaging machine

When choosing an ideal paper pouch packer for your packaging needs, here are the fundamental factors you need to focus on;

Operation Mode

Determine the specific equipment based on whether it is fully or semi-automatic.

Ordinarily, the choice here is dependent on your preferred convenience and production demands.

Packaging Speed

Often, it varies from one equipment to another, but it is advisable to choose a machine with reasonable packaging speed rates.

Control Unit

Always go for a paper pouch packer with a digital PLC integrated with a user-friendly HMI for easy and efficient usability.

Design Construction

It is available in different designs such as rotary, inline, vertical and horizontal layouts among others.

Hence, the choice is based on what suits your pouch packaging demands.

Drive System

VFD, servo motor, electronic motors, and vacuum suction are the notable drive mechanisms for different parts of paper pouch packers.

As such, choose the most suitable one depending on what best suits your packaging requirements.

Quality Standards

cGMP, CE, CCC and ISO are some notable quality standard certifications you should always consider when buying this machine.

Machine Material

It is advisable to consider a paper pouch packer made using stainless steel material.

This material is sturdy, durable, easy to maintain and resistant to several unfriendly elements like corrosion.

Occasionally, you may encounter a few challenges when using this machine.

The common errors and ways of solving them include the following;

Failure Of Pouches To Feed

It primarily means the pouches are not feeding into the machine appropriately.

Possible solutions to this error include; cleaning the sensor, adjusting the air valve or solenoid valve, repairing hose and check the vacuum generator.

Defective Pouch Seals

This error indicates uneven, wrinkled or weak package seals.

Troubleshooting tips include; moderating, sealing bar temperature, resetting, sealing bar pressure and centering the bag in grippers.

Failure Of Pouches To Open

It means the packer can hardly open the pouches once they are loaded.

To solve this error, change filters, ensure the timing is correct, ensure bag is loaded properly and check whether solenoid of air valve is in good condition.

The versatility of paper pouch packer makes it a valuable asset in different applications across various industries, such as the following;

- Pharmaceutical sector packages various powdered and semi-liquid drugs

- Coffee and tea packaging

- Food and beverages

- Nutritional products like workout supplements

- Cosmetic and beauty industry

- Chemical industry

The notable ones include the following;

Auger Filling Mechanism

It fills the exact amount of product in the container as required.

Mostly, this system is suitable for filling powdered products into paper pouch packaging.

Net Weight Filling Mechanism

This filling mechanism relies on pressure, vacuum or gravity to fill products into paper pouches.

Primarily, the ideal fill level is determined and set on the machine then the mechanism fills the pouches to the respective level.

In some instances, a vacuum can come in handy to initiate a flow of powdered or semi-liquid products at low or medium speed.

Volumetric Filling Mechanism

In this filling mechanism, the equipment fills containers with a consistent product volume via a time-based filling principle.

Lateral Sealing Mechanism

It entails sealing a tubularly-shaped paper pouch in lateral and longitudinal directions.

Transverse Sealing Mechanism

This sealing mechanism functions to thermally seal the pouch in a transverse direction.

Ideally, this direction is perpendicular to one, which the paper pouch is conveyed.

Paper pouches are available in different configurations, but the common ones include the following;

Pillow Pouches

The design of these pouches entails two flat, sealed panels, which allow you to easily peel in opposite directions when opening.

Sachets

These are relatively small, flat packets with all four sides sealed for single-serve condiments.

Liquid Pouches

They are available in numerous designs but mainly offer clear packaging solutions for different products.

Stand Up Pouches

These are pouches with an oval-shaped pocket at the bottom, enabling them to stand up straight.

Additionally, they have a tear-off tab with a plastic zip-lock underneath for easy resealing.

Gusseted Pouches

They are more or less stand up pouches but with indents on each side.

The indents enable these pouches to create a rectangular or square base with folded-down tops sealed with adhesives and two tabs for resealing.

More Resources:

Cup Filler Pouch Packing Machine

For all your paper pouch packaging machines, contact us now.