Vertical Form Fill Seal Machine Manufacturer in China

Jochamp has over 15 years of experience in manufacturing vertical form fill seal machines of uncompromising quality and performance. The machines we offer are widely used in the packaging industry for liquids, powders, food, and other products.

- ISO9001, cGMP, CE and SGS certified

- Free sample test available

- Provide lifetime after-sales service

- Suitable for packaging various products

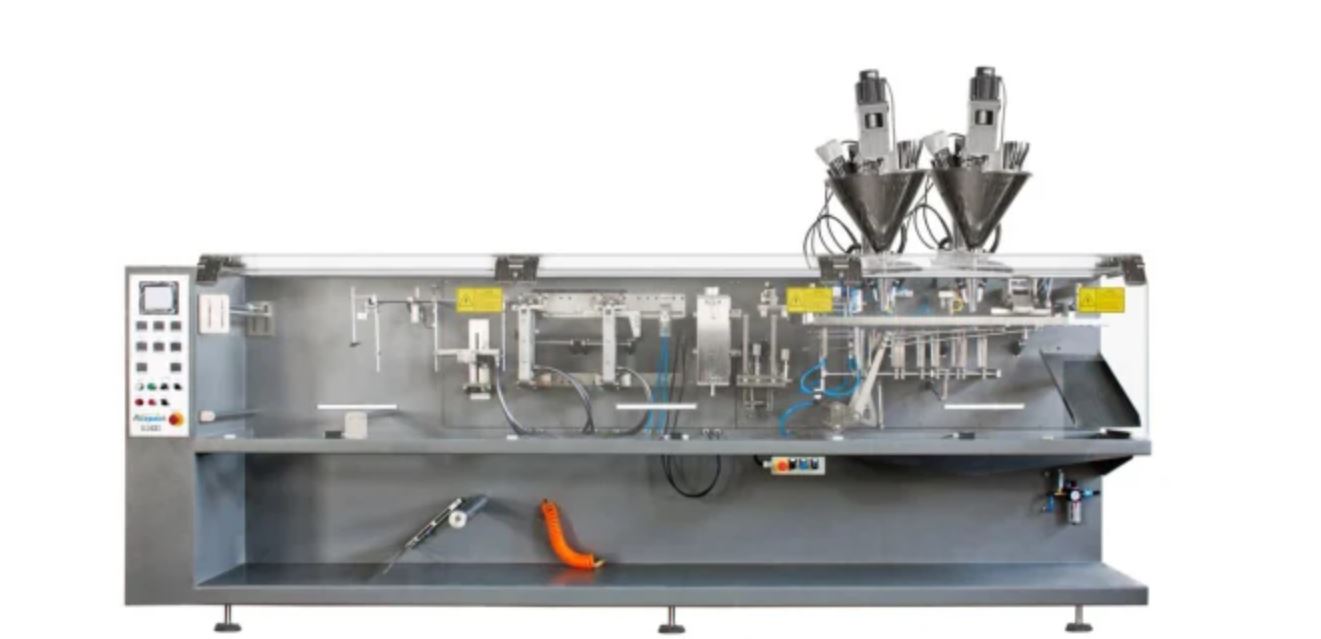

Jochamp Vertical Form Fill Seal Machine

Vertical Filler Sealer or also known as “Tilt Filler Sealer Packaging Machine” is commonly used in the packaging industry for various products such as food, liquids, granules, powders, etc.

In addition, vertical machines roll flat film into plastic bags and fill them with various products such as snacks, confectionery, frozen foods, quick-frozen products, biscuits, bakery products, non-food products and other products. The machine then seals the product and drops it vertically. Vertical machines are capable of handling powerful bags, ziplock bags and other plastic bags. With a single operation, the machine can make bags, seal, pack, and even print dates, codes and other labels.

Some of the features of vertical fill seal machines include high speed production, hygiene, high corrosion resistance, low noise operation, ease of operation, contamination detection, stable seal strength, and more. They can also be customized according to your requirements.

If you have any questions, please feel free to contact us!

Types of Vertical Form Fill Seal Machine

Jochamp Vertical Form Fill Seal Machine Features

The vertical fill seal machine is made of 304-grade stainless steel which is very easy to clean and food-grade. For this reason, they are very hygienic and safe to use in packaged foods such as cheese, frozen products, liquids, etc.

Jochamp Vertical Fill Sealers have excellent corrosion resistance as they are made of naturally corrosion-resistant materials such as stainless steel. Their components can also be surface treated to make them more resistant to corrosion.

The vertical fill seal machine is fully automatic. Because of this, you need fewer workers and labor costs are lower. In addition to this, they also save more energy. Therefore, you will save on energy bills.

The vertical form fill seal machines are made from high-quality and durable materials such as polytetrafluoroethylene and 304-grade stainless steel. Their accessories, components, and systems are also durable and can provide a long service life.

Jochamp Vertical Form Fill Seal Machine Advantages

- Professional manufacturer with rich experience – For more than 15 years, Jochamp has been focusing on developing and manufacturing all types of vertical form fill seal machines.

- Foreign imports of CNC system – The vertical form fill seal machines are using internationally known brands of accessories and electrical appliances such as Mitsubishi, Siemens, Panasonic, Schneider, and many more. They are also designed with a fully automatic system for easy operation. Moreover, the parts of the machines are durable, have low loss, and great quality.

- Offers customization services – Jochamp has the ability to customize the vertical packing machines according to what you want. You can tell us your required materials, features, and specifications, and we will make it all possible for you!

- Excellent after-sales service – Here at Jochamp, we have over 20 after-sales service teams. Aside from that, we offer a lifetime after-sales service. We can give you guidance on how to maintain and install the machines. Also, we can provide regular after-sales care.

Various Bag Styles

The vertical form fill seal machines from Jochamp form any kinds of bags or pouches such as:

- Wide top bag

- Flat bag or pillow bag

- Zip-lock bag

- Block-bottom bag

- Gusset bag

- Quattro pack

- Chain bags

- Three-sided-seal bag

- Punch-hole bag

- Hem seal bags

- Stand bag

- Brick shape bag

Moreover, the vertical form fill seal machines can form any size and shape of bags or pouches. They can also be added with any type of hole such as euro or round.

How it Works?

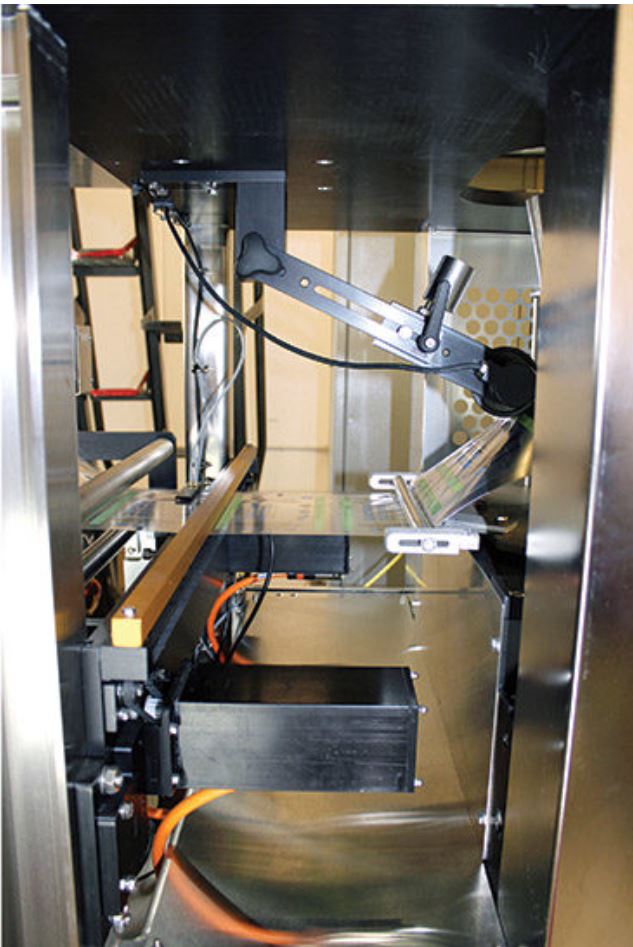

- Film Transport and Unwind – The vertical form fill seal machines use a rolling stock and pull them off by the transport belts. Then, the power unwinds wheel will drive the film roll.

- Film Tension – During the unwinding process, the film will be unwound from the roll. Then, the film will be passed over the dancer’s arm or a series of rollers to transport the film.

- Optional Printing – The film then moves through the printing unit. Thermal printers and ink-jet printers are commonly used. The printer can print dates, graphics, logos, registration marks, and other labels on the film.

- Film Tracking and Positioning – After printing, the film moves through a registration light eye that detects registration marks on the film and helps keep the film in the correct position so it can be cut at the correct location. Then, there are tracking sensors, which also detect the position of the film as it passes through the vertical packaging machine.

- Bag Forming – This is the process of turning the film into any type of bag.

- Bag Filling and Sealing – The machine will fill the bags with products and seal them. Then they will be dropped.

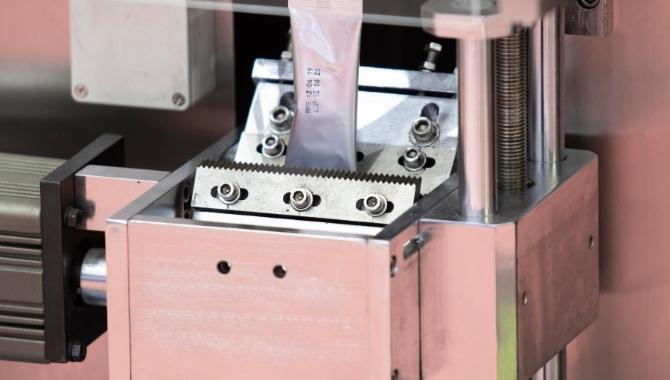

- Bag Unloading – The machine has a sharp knife inside the heat-sealing jaws to cut the bag. When the heat seal is opened, the bag will fall out.

Why Choose Jochamp Vertical Form Fill Seal Machine?

Jochamp offers a wide range of vertical form fill seal machines to meet customers’ requirements, machines such as cup filler pouch packing machines, linear weigher packing machines, auger filler packing machines, multi-head weigher packing machines, sachet filling machines, and many more.

Whether the products are foods, powder, stick-shaped, deep-frozen, granules, liquids, or non-food products, the vertical form fill seal machines from Jochamp can pack all of them. All of our vertical machines are certified by ISO, SGS, CE, and cGMP.

Also, they are composed of touch-screen Mitsubishi PLC computer, Siemens frequency changer, SMC pneumatic components, SICK sensor, and other advanced technology so they will have excellent and high-speed performance. They can also have optional components such as an automatic film correction motor, heat transfer printer, and many more.

Jochamp can also custom design our vertical form fill seal machines to your specific requirements. We have been offering customization services for over 15 years. Also, we have lifetime after-sales service and a 1-year quality guarantee for all of our vertical packing machines.

If you want to know more about our customization services and vertical form fill seal machines, do not hesitate to contact us!

Jochamp Vertical Form Fill Seal Machine

The vertical form fill seal machines have a lot of applications. They can be used for packaging any kinds of food, non-food, liquid, or solid products such as:

- Liquid such as ketchup, milk, sauce, oil, jam, shampoo, and many more

- Powdered products such as coffee powder, milk powder, sugar, etc.

- Any kinds of dried fruits

- Granules such as coffee beans, nuts, corn flakes, cashews, chips, and more

- Baked goods such as cookies, brownies, small bread, etc.

- Biscuits, crackers, snacks, etc.

- Stick-shaped products

- Non-food products such as bolts, nuts, screws, and so on

- Pet food

- Tiny toys

- Deep-frozen products

- Flower seeds, vegetable seeds, and other seeds

The vertical form fill seal machines from Jochamp comes with many different features such as:

- High-speed packing

- Bag-making, filling, sealing, packing, & printing date or labels in one operation

- High corrosion resistance

- Hygienic and easy to clean

- Space-saving

- Safe for food and drug contact

- Easy to operate

- Energy-saving

- Reduces the defective rate

- Diverse range of bag types

- Low noise operation

Vertical Form Fill Seal Machine for Various Applications

The linear weigher packing machines are commonly used for packaging food, non-food, and semi-free flowing food products. They are used for quantitative weighing and packing of products. Also, they can pack quickly, efficiently, and accurately.

The sachet filling machine is commonly used in the packaging of granular products such as seeds, condiments, sugar, instant powdered drink, liquid products such as vinegar, shampoo, soy sauce, and other products. Bag-making, sealing, filling, cutting, and weight-measuring can be done by the sachet filling machine.

The single lane stick pack machine has stable, reliable, and easy operation. It is designed for packing granule, liquid, or powder products such as coffee powder, ketchup, vinegar, soy sauce, and more. Also, it can produce narrow and long pouches.

The auger filler packing machines can be used for quantitative filling and packing of fine granular and powdered products such as food additives, milk powder, veterinary drugs, compound seasoning, and so on. They are widely used in the chemical industry, food industry, medical industry, and agricultural industry.

Related Product

Vertical Form Fill Seal Machine: The Ultimate Guide

It is important to know whether vertical form fill seal machine is good for your packaging industry or not. A reason this guide explores everything about VFFS machines. From parts, working principle, features, specification to benefits – you will find all information right here.

A vertical form fill seal machine is vertically structured equipment you can use to pack products.

vertical form fill seal machine

The machine makes packages from films and fills the products in it then seals the package.

A lot of industries use this type of equipment to package a variety of products that can either be in their liquid forms such as milk, or their solid form.

Industries such as the medical and pharmaceuticals, food industry (both pet and human), and the cosmetic industry use this kind of packaging method.

The packaging industry has evolved in so many ways and there are a lot of machines that one can use. Form filling and sealing is a process that uses a specific material to make a certain kind of pouch that has been sealed.

There are two ways that one can fill and seal a product. The vertical form fills sealing and the horizontal form fill sealing are the two ways to fill and seal. As per their names, the horizontal form fill seal machine fills and seals products in a horizontal plane. The product is then cut on each side then is released.

The vertical form fill seal machine uses a vertical plane to fill and seal products. The products are filled from bottom to top and then sealed on both ends. The machine then cuts the upper part and the lower part.

Deciding on which machine to use between the two is not very difficult. You need to know which type of product will be packaged using the machine.

The vertical form fill seal machine is commonly used for free-flowing products that need to stay in one place. Liquid products or products with gel-like consistency such as milk or ketchup are made with the vertical form fill seal machine.

For the horizontal form fill seal machine, solid products such as candy bars are mostly recommended. A vertical form fill seal machine is not very big and hence takes up less space compared to the horizontal form fill bigger seal machine.

There is no major difference when it comes to the working and how the machines are made or work.

horizontal form fill seal machine

The following parts make up the VFFS machine;

- Cross sealing jaw

- Forming tube

- Film unwind

- Film pull belts

- Vertical jaw

- Film registration

parts of vertical form fill seal machine

The first thing the vertical form fill seal machine does is to feed the roll film over the forming tube.

Next, roll film makes the pouch or bag. Additionally, the forming tubes create the shape of the film. It ensures it is the right size and then seals the bottom part.

It also seals the vertical seam formed by the two edges of the film. Also, the width of the package is also made by the forming tube while the length is determined by the bagging machine.

The forming tube can easily be changed if one wants to make changes to the width of the packaging bag. When it comes to sealing, the most common ways are the lap seal and the fin seal.

To make a fin seal, the edges are brought together by the forming tube, the inside surfaces are sealed together. A lap seal comes about when two edges overlap each other and the back of the top sealing to the front of the bottom are sealed together. The second step involves now filling the bag that was made in the first step.

A filling machine is then joined to the bagging machine and the bag is filled with the product.

The third step is where the bag with the product is sealed at the top, the process is completed and the bag is cut and then dropped. A tear notch and some dates may also be added depending on the type of product.

When using any machine it is very possible to encounter some issues that may arise due to some faults on the machine. Most of the time they do not need experts to fix them. Rather they require a few adjustments to the machine parts.

The following are some of the issues one may encounter with the vertical form fill seal machine;

- Film feed fault

- Film not tracking well

- Temperature of the jaw is not in the range

- Machine does not restart

- Film eye mark error

- Jaw jam

- Bad horizontal cross seals

- Jaws not working

- The printer does not work

- Low air pressure

- The machine does not power up

- Bad vertical seals

- Film unwind fault

The vertical form fills seal technology is widely used especially in the food packaging industry. Besides, the vertical form fill seal technology has many benefits over the other packaging methods and they include;

- Its operational costs are low.

The vertical form fill technology uses very high speeds during the whole process hence reducing the operational costs.

Also, the vertical form fills seal technology allows one to make use of a lot of different materials. The choice of material one uses is determined by the type of product being packaged.

- The bags made from the machine are quite cheap compared to the ones that had already been made.

- You are assured that your package has been secured well and is airtight when using the vertical form fill seal technology.

The vertical form fills seal technology is very versatile. You can make a wide range of bag shapes with it and it is quite easy to make changes to the bag shape.

- The machine is easy to clean because of its open design.

Single web systems use one roll of material compared to dual web systems which use two rolls of material. The material in a dual web system is put into the equipment from separate ends.

Additionally, the product is filled from the upper part and the down part and sides of the bag are secured together using heat. Also, the single web system is commonly used in food applications compared to dual web systems and is mostly utilized in medical device products.

Vertical form fills seal machines can operate in either continuous or intermittent motion. Intermittent motion machines work on the basis that vertical bag seals occur when the film is moving and horizontal seals happen when the film is not in motion.

intermittent motion VFFS

For applications that do not require speed, intermittent motion machines are the best option. Continuous motion machines work based on making both vertical and horizontal bag seals while the film is moving.

These machines require a reciprocating sealing jaw motion and work at the maximum possible speeds. Continuous motion machines have faster cycle times compared to intermittent motion ones because of their high speeds.

Continuous motion machines are highly recommended for products that require a lot of care since they are delicate and fragile.

continuous motion VFFS

Intermittent motion machines are suitable for products that are not fragile and don’t get damaged easily. There is a chance of making a lot of packages using the continuous motion machine. This is because of its control over the cross jaw along the vertical plane over the cross jaw.

Vertical form fill seal machine is one of the machines that is used worldwide because it is applicable in many industries. The following are some of the industries that use the vertical form fill seal machine;

- Food industry

- Cosmetic industry

- Pharmaceutical and medical industry

- Detergent industry

Moreover, the vertical form fill machine makes packages such as milk, dry noodles, cocoa, candy jars, detergents, and many more.

There are several very distinct vertical form fill seal machines and all of them have different features depending on the manufacturer. The list below is the most common features you can find on a vertical form fill seal machine;

- The temperature control in a vertical form fill seal machine is inbuilt

- It has a modular make

- Has bilingual interfaces

- The main material used on it is stainless steel

- It has a high operating speed that surpasses 150 packages every minute

- It has a touch screen integration

- Energy and carbon footprints are kept to a minimum

- Compatibility with virtually any small-medium bag packaging. Larger machines are capable of handling even larger bagging sizes.

- The vertical form fill seal machine has automatic edge guidance and film tracking systems

Normally, the bag to use with a vertical form fill seal machine mostly depends on the product that will be in the bag. Some of the most common types of bags you can use include:

1. Zip bag

zip bag

2. Punch-hole bag

3. Flat bag

4. Gusset bag

5. Chain bag

6. Wide top bag

7. Hem seal

8. Three-sided seal bag

9. Quattro pack

10. Block-bottom bag

block bottom bag

11. Doy style bag

Net weight fillers weigh products before filling them into a package while the auger filler does not weigh the product, they are volumetric. Using a net weight filler ensures the products are filled to their exact amount.

auger filler VFFS

With auger fillers, the package does not fill to their exact amount especially when the package has an irregular shape. When using a net weight filler, products are handled with caution. With the auger filler, there is no caution.

The products are handled harshly.

Besides, the production operation of a net weight filler is quite slow compared to an auger filler which is very fast. Net weight fillers emit a lot of dust while the auger filler produces little to no dust. The auger filler can allow for the addition of dust collectors.

The features of volumetric filler vertical form fill seal include;

- It has a stainless steel makeup

- It has an interface that is quite easy to use

- One can easily and quickly make changeovers

Sealing in a vertical form fill seal machine is one of the most important steps. Sealing ensures that the product retains its freshness and it does not pour out of its package.

The most common sealing technologies in vertical form fill seal machines are ultrasonic sealing and heat sealing.

Ultrasonic sealing utilizes vibrations to bring about friction. It is mostly used on products that cannot be used with heat such as ice creams or chocolates. Heat only comes about in the middle of the film layers when using ultrasonic sealing.

Heat sealing is the most suitable and effective way of sealing a package. This method uses heat which is the best way to ensure the seal is secure. The heat sealing method cannot be used on products that are heat sensitized since they may melt.

- Its operational costs are low.

Vertical form fill technology uses very high speeds during the whole process hence reducing the operational costs.

The high speeds also ensure a lot of electricity is not utilized.

- Vertical form fills seal technology allows one to make use of a lot of different materials.

The choice of material one uses is determined by the type of product being packaged.

- When using the vertical form fill seal machine, you have the option to label and print your products.

It has the label and print features if there are details you may want to add to your package.

- You are assured that your package has been secured well and is airtight when using the vertical form fill seal technology.

The machine ensures that there is no tampering with the package, especially the ones that require airtightness to be fresh and crispy.

- Vertical form fills seal technology is very versatile. You can make a wide range of bag shapes with it and it is quite easy to make changes to the bag shape.

- The machine is easy to clean because of its open design.

For all your vertical form fill seal machines, contact us now.