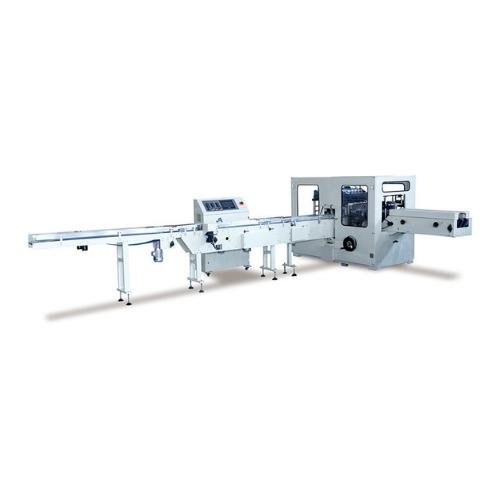

JCT-250 Automatic Single Piece Wet Wipe 4 Side Packing Machine

The machine is modified from the horizontal form fill seal machine, making it suitable for the production and packaging of single-piece wet wipes. Its functions include folding the raw material, then cutting, bagging, adding liquid, and sealing. Its maximum speed can Reach the fastest 120ppm.

- Maximum speed 120ppm

- Fully automated production

- High-precision metering pump, adding liquid error ± 0.01ml

- With wet wipes parent roll folding mechanism

- Material exhaustion shutdown alarm

JCT-250

- Technical Parameter

- Features

- Optional

| model | JCT-250 |

| package style | Four-side seal |

| Packaging Materials | CPP,PE,BOPP |

| wet wipes material | 30-120g/㎡ clean paper, wet strength paper, spunlace non-woven fabric |

| Raw material core diameter | Φ75-80MM |

| Package (finished) length

width |

40—175mm

40—110mm |

| Folding method | Up to 10 folds vertically, up to 40 folds horizontally |

| Dosing range | 0-10ml |

| packing speed | 80-120 pieces/min |

| total power | 5KW |

| Power Type | Three-phase four-wire 380V |

| machine noise | ≤64.9dB(A) |

| Gas source | 0.6-0.8MPa |

| Air consumption | 300-500ml/min |

| Machine size | 3800mm×2600mm×1800mm |

| machine weight | About 1100kg |

- Maximum speed 120ppm

- Fully automated production

- High-precision metering pump, adding liquid error ± 0.01ml

- With wet wipes parent roll folding mechanism

- Material exhaustion shutdown alarm

- Independent PID temperature control system

- Cold and hot two edge sealing structure

- Intelligent color mark tracking and compensation system to ensure packaging consistency

- Intelligent packaging material tension controller and correction system

- Full 304 stainless steel body cover, corrosion resistance, easy to clean

- All food-grade and pharmaceutical-grade product contact surfaces ensure the safety and hygiene of wet wipes

- Comply with GMP requirements, passed CE, ISO9001 certification

- Intelligent fault prompt

- PLC control system and man-machine interface

- Siemens, Omron, Mitsubishi, SICK, SMC and other internationally renowned brands of electrical appliances and accessories

- Safety door function

- Open design, easy to clean and maintain

- A few tools to adjust the design, it only takes 15 minutes to switch products

hole puncher

easy tear

date printing

2-4 stations optional

Nitrogen flushing device

Remote system inspection, maintenance and upgrades

Docking cartoner