High Speed Case Sealer Manufacturer in China

Jochamp high-speed case sealers can accommodate both double-wall and single-wall flutes, as well as most case sizes. You can find the right standard or custom equipment that can seal up to 25 cases per minute or more here. Message us today!

- Maintenance free

- Keep cases perfectly square

- Oil-less air cylinders

- Produce greater profit margins

JOCHAMP High Speed Case Sealer

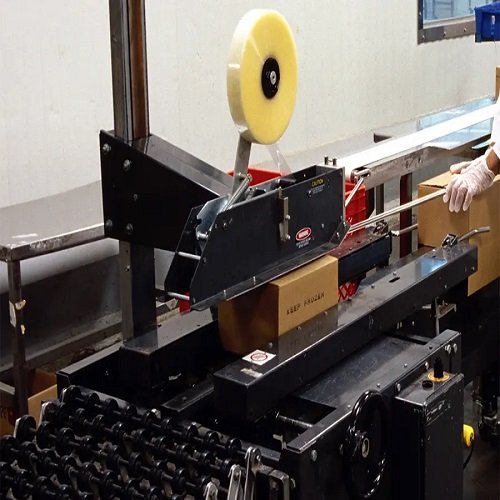

Jochamp High-Speed Case Sealer is a piece of packaging equipment that offers a reliable and efficient way of folding and sealing the top lids of your packed cartons. Hand-held tape guns are no longer necessary with high-speed case sealers. These machines can overcome fragile corrugate and case manufacturing differences. It improves product appearance, by professionally sealing cartons in a clean and neat way.

Jochamp manufacture automatic and semi-automatic types of high-speed case sealer for you to choose from. It delivers flawlessly squared and sealed cases. It can be easily adjusted to handle various case sizes and types. Whether you pack various box sizes or a single standard box, Jochamp got you covered. Jochamp will work with you closely to design a superior quality case sealing system for your projects. Message us today!

Why Choose JOCHAMP High Speed Case Sealer

The machine’s simple design makes it simple to operate and changeovers are quick. It will always yield square cases that protect products better.

Don’t let malfunctioning equipment get you down. Our innovative design compensates for case variances and prevents clogs, allowing your line to keep going.

Our machines were built with safety in mind. From safety shields and curtains to interlock shut down switches, it is designed thoroughly for cautious operation.

All our high-speed case sealers have unmatched performance and technology. Our expertise and knowledge make us leaders in the industry.

Ultra High-Speed Case Sealer

If you require a case sealer at maximum speeds, you can trust Jochamp’s high-speed case sealers. It is mechanical equipment automatically times cases. This also folds all four flaps efficiently. The case sealer applies glue and compression to securely close cases.

It provides speeds up to 25 cases per minute that increase throughput. The continuous motion design is the key to its operation. All movements are PLC-controlled and evaluated by non-contact sensors. These guarantee a clockwork precision and dependable shift-to-shift operation.

High Speed Case Sealer Features

Our range of high-speed case sealers offers various benefits and features such as:

- UL approved electrical parts

- Achieves speeds to 25 cases per minute

- Rugged construction and heavy-duty frame

- Made for uniform applications

- Bottom one edge seal or top edge seal

- 1 bottom driven belt and 1 top belt

- Cost-effective and reduced energy consumption

- High visibility, easy access guard doors

- Withstand high-pressure washdowns

Custom High-Speed Case Sealers

To satisfy your unique requirements, Jochamp provides custom high-speed case sealers with various specifications. We will make the best machine that ensures a more secure carton closure. Many options are available for:

- speeds, power supply

- case sealer types and dimensions

- closing process

- machine frame and magazine

- machine performance data communications

One-Stop Solution for Your Packaging Requirements

Jochamp is a professional high-speed case sealer manufacturer in China. We have 15+ years of OEM manufacturing experience and consistently provide premium machines to clients worldwide. All our case sealers are built for flexibility and speed. It can achieve speeds of 25 cases per minute or customized.

These machinery are ideal for manufacturing and distribution facilities with various packing lines that need to be merged for sealing. Every box, regardless of structure, can be constructed and sealed with exact 90-degree angles.

Jochamp high-speed case sealer machines are compatible with a variety of tape types. It can be used with either a hot melt glue sealing box or a tape sealing box. The machine’s steel construction is durable and thick, making it operate for a long time with low noise.

For your high-speed case sealer needs, contact us immediately. We produced a case sealer machine to fit your needs and budget.

JOCHAMP supports customizes high-speed case sealers machines. If you don’t find the right machine, you can message us and send your detailed tailored specification. Below is the process:

- Communicate with our team and discuss

- Confirm your requirement

- Contract signing

- Machine production

- Packaging and shipping

- Equipment installation

- After-sale supports

We can provide optional equipment for your high-speed case sealers machine. Some are the following:

- Indexer

- Heavy-duty locking casters

- Conveyor for infeed/outfeed

- Interlocking Security Gates

- Material: stainless steel

- Sensor with a low or no taper

- Kit of spare parts

- Height and/or width adjustments that are motorized

- Upgrade to a high-speed motor (up to 125 feet per minute)

Custom High-Speed Case Sealer for Your Industry

Jochamp can design custom high-speed case sealers for the eCommerce industry. These are made with protective cover and emergency stop equipment to protect safe production. It passed CE, ISO9001, SGS, and other certifications, thus you can ensure a reliable sealing system solution.

For your high-speed case sealer requirements in the distribution industry, you can rely on Jochamp machines. Our machines are thoroughly manufactured and rigorously checked before delivering the process. It is constructed with a reliable and durable motor, a unique smoothing device, adjustable chassis with easy-to-move casters, a high-precision structure and limiter, and more.

A high-speed case sealer for logistics industries is built with flexibility and high efficiency in mind. This is manufactured with a high wear-resistant belt, a high corrosion resistance frame, and better sanitary conditions. We source sophisticated components to ensure almost zero maintenance.

Related Product

High Speed Case Sealer: The Ultimate Guide

If you want to improve efficiency in your case packing systems, then you should integrate high speed case sealer machines. It offer seamless packing solution for all your packaging needs. However, before choosing your next high speed case sealer, read this guide.

It refers to an all-mechanical piece of equipment designed to pace case feeds, fold flaps, apply adhesives and compression and tightly seal cases automatically.

This machine is designed for continuous high-speed operation while functioning with high stability.

Ordinarily, it has a wide range of unique features, ensuring complete case control while automatically feeding cases back to back.

high speed case sealer

Moreover, this equipment is highly versatile and thus utilizes a high-speed distribution component to pack and seal different cases.

In this article, you will learn various aspects revolving around a typical high speed case sealer.

Hence, it lets you get vital ideas of what to expect when shopping for one.

The notable sealing methods that are common in high speed case sealers include the following;

Hot Melt Sealing Technology

This sealing technology entails using a broad range of adhesive systems with different adhesion.

Ideally, this method involves using a synthetic resin, which liquefies when heated and applied using an automated system containing multiple applicators.

It is quite cost-effective, efficient, and fast, thus suitable for large scale case packaging and sealing.

The other advantage of this technique is that it provides application flexibility; thus, you can use it on a large variety of nozzle sizes and material types.

Moreover, it guarantees long-term bonds, professional appearance, higher structural strength, and a unique customer experience.

Some ideal case packaging options that are suitable with hot melting sealing method include;

- Regular Slotted Cartons (RSC)

- Easy Open Techniques on Cartons

- Full Overlap Cartons (FOL)

The major shortcoming of this sealing technology is relatively equipment purchase cost and longer operator training time.

You can learn more about hot melt case sealing machine.

Adhesive Tape Sealing Technology

It is a sealing method that entails using a pressure sensitive nylon-reinforced filament or plastic adhesive tape on case surface directly from tape roller setting.

This technique is most suitable in relatively low volume packaging and sealing solutions where different box sizes are used.

One advantage of using this sealing method is it offers lower equipment purchase and running costs.

Also, it provides complete sealing of flap seams from the surrounding as well as offers lower package size flexibility at lower volumes.

Adhesive tape sealing technique also offers low safety risks to the operators.

However, its major downside is inconsistencies since the tape covers numerous boxes if too close.

It can also encounter several downtimes due to manual reloading after every 2,000 feet of tape.

Ordinarily, the design of a typical high speed case sealer allows its operation to be in a continuous motion.

It implies that all the operational functions of this equipment are monitored by PLC control non-contact sensors.

Generally, this makes it easy for the machine to seal numerous cases within the shortest time possible.

But this is usually dependent on the specific machine features and specifications.

You can find custom high speed case sealers with relatively high production capacity.

The size of the cases also influences the actual production capacity of this particular equipment.

However, most common ones used in various applications have a production throughput of between 25-100 cases per minute.

The common benefits of using high speed case sealer include the following among others;

High Production Throughput

The continuous motion operation design of this equipment allows it to seal many cases within shortest time possible.

As such, it provides consistency, efficiency, and reliability, which are critical in attaining desired packaging solutions.

Enhances Quality Control And Accuracy

Its specifications and working principle allow it to deliver high-quality and accurate results.

Ordinarily, the result of using this machine provides customer-friendly seals that safeguard the products accordingly.

Reduces Running Cost

This equipment is automatic; thus, its operations barely involve use of manual labor.

Furthermore, it is power-efficient, and this enables you to cut utility costs significantly.

In essence, you tend to minimize operating costs considerably when using this specific equipment, which adds to your profit margin.

Easy To Configure

You can configure this machine to meet your particular packaging and sealing needs.

Thus, it becomes easier to attain the best results based on what you case sealing requirements.

Guarantees Safety

Since operations of this equipment are automated, it prevents it from constant and unnecessary downtimes.

Besides, it has different features such as overload protection, which improve the machine’s safety during sealing process.

This equipment also performs quality control evaluations and enables the operator to maintain full control with a manual power override.

User-Friendly

This equipment is quite straightforward to operate and maintain and does not necessarily need in-depth knowledge to troubleshoot.

Of course, this is advantageous because it implies you can use different case packaging and sealing applications.

This equipment is commonly used in large industries where high production throughput is a main concern.

Some common areas you will find include but not limited to the following;

Pharmaceutical Industry

Various pharmaceutical products are usually packaged and sealed into different cases using this particular machine.

It gives a better alternative, especially when packing and sealing different pharmaceutical products in different case sizes.

FMCG Industry

In industries dealing with Fast-Moving Consumer Goods, speed is usually a great concern since the products need to get to the market sooner.

Hence, this case sealer is used since it guarantees the necessary speed that will ensure the products reach the market within shortest time possible.

Food And Beverage Industry

Different food and beverage items are packaged into various cases using this equipment.

Ordinarily, the speed and accuracy that this machine guarantees make it a suitable choice for ensuring you attain best results.

Stationery Industry

In companies that manufacture different stationery items, this machine is used in packaging the various products into respective cases.

Automotive Industry

A wide range of automotive parts are usually packed in their respective cases using the high speed case sealer.

Mostly, such parts require rapid packaging, which is easily attained by using this particular equipment.

Confectionery Industry

Most confectionery products are often produced in masses hence the need to have an equipment that also packs and seals them faster.

This is where use of high speed case sealer comes in handy since it makes it possible to pack the required quantity within shortest time possible.

Hygiene And Personal Care Industry

It is widely used in packaging different types of personal care and hygiene products.

Some items packed using this machine in this industry include toothpaste, detergents, cotton pads, toiletries, facial masks, etc.

Ideally, a high speed case sealer is made up of several parts and components, all integrated to produce a single operational unit.

high speed case sealer

In essence, each part and component of this machine is designed to perform a specific function in ensuring the equipment delivers the desired result.

The main components of this equipment thus include the following;

- Tape Head – This transducer device is intended to convert electrical signals into magnetic alternations to enable correct case adjustment.

- Conveyor System – It contains belts and metal rollers that assist in effective movement of cases from one station to another within the equipment.

- Control Buttons – They are helpful in opening and closing various control circuits in the machine.

- Encoder – It is a device for receiving uncompressed data and translating values to the binary to perform binary functions.

- Photo-Eye Detector – this device contains an inbuilt light emitting element that triggers a light beam to enable the machine to detect whether there are cases during sealing.

- Tape Roller Setting – It applies the sealing tape during case sealing process to guarantee safety.

- PLC Touchscreen – This screen features a user-friendly HMI module and mainly displays the functional machine variables during case sealing process.

- Electric Panel – It is an enclosure for a wide range of electrical units used in running the equipment.

- Fail-Safe Control Button – It is used as a safety measure to contain hazardous parts by breaking the machine’s circuit and halting power supply.

- Lubrication System – The design of this unit is to ensure contact parts are properly lubricated to reduce friction.

- Product Loader – It is responsible for stacking the items into respective cases before sealing takes place.

- Safety Guard – Minimizes and protects possible damage or injuries likely to arise from the machine or the operator.

Remarkably, the general working principle of a high speed case sealing machine is quite straightforward.

Here are the main aspects involved in the working process of this particular equipment;

Setting Empty Cases In Position

The cases move from the blank case zone through the feeding unit one by one.

Each case opens up at the right angles with the aid of a push plate and the guide rails that direct them to the correct position.

The machine, through a series of push and suction mechanisms, fold the cases to enable them to attain the right shape.

Loading

At the loading zone, the equipment loads the items into each case accordingly.

The loading techniques often vary depending on the actual type of high case sealing machine you are using.

Folding

Once the items are loaded into the cases, they are pushed to the folding zone through the conveyor system.

At this stage, the case flaps are folded through a continuous rotary motion.

Once the flaps are properly folded, the conveyor system then moves them to the sealing zone.

Sealing

At the sealing area, the machine applies the adhesive tape or hot melt sealing technique to ensure the cases are securely closed.

Ordinarily, the pushing plate activates a push on the tongue, allowing it to fasten a lock forming seal.

The equipment then inspects the cases before conveying them to the loading zone.

You can find this equipment in various types but often depending on how it applies the seals on the cases.

The notable ones you are likely to come across in different applications include the following;

High Speed Random Case Sealer

This high speed case sealer variant uses a system that can easily adjust its tape height to seal different case sizes on the fly.

Ordinarily, it features a design construction that enables it to offer top and bottom sealing capabilities at high speeds.

Every case getting into this equipment is determined in height and width; thus, it can easily position folding and sealing system automatically.

high speed random case sealer

This machine variant does not require a set up for continuous runs of different random size cases.

It is easy to operate, cost-effective, self-adjusting, durable, and ideal for packaging products in cases of different sizes simultaneously.

High Speed Uniform Case Sealer

This is a type of high speed case sealing machine variant that uses a fixed tape head suited for specific case sizes on the fly.

Primarily, it implies that the tape head in this machine often requires manual adjustment for every case size with a different height.

Simply put, unlike a random high speed case sealer, a uniform case sealer is designed only for sealing boxes with same height at every specific run.

high speed uniform case sealer

Once you set this machine to specific case size, it folds the upper section flaps and seals the top and bottom sides of the case.

When you need

Therefore, it is mostly suitable when handling cases with similar height dimensions in large-scale production.

It is also fast, accurate, and reliable hence an ideal consideration for industrial applications.

Top And Bottom High Speed Case Sealer

This case sealer variant is known for its production efficiency, dependable service with less maintenance needs.

Ordinarily, it features flight lugs designed to push each case at corner to square it during transfer.

Its flap folders are contoured to fold the flaps gradually at the score line and close them smoothly without any flap overlap.

top and bottom high speed case sealer

The compression section of this equipment is an independent system featuring a dual belt case transfer powered by a motor to guarantee ideal case transfer.

This machine provides a simple changeover, and you can make adjustments from either side of the case sealer.

You can also learn more about top and bottom case sealer machines.

High speed case erector refers to a piece of automated equipment designed to open cases and place them in position awaiting good’s stacking and sealing.

The design enables it to reliably position the knockdowns for precise introduction into the equipment for filling and sealing.

This machine also ensures the bottom flaps of RSC and HSC cases are folded as sealed with hot melt adhesive.

Primarily, the main role of a case erector is to ensure cases are erected and glued constantly and appropriately at high speeds.

high speed case erector

It is quite adaptive, and it is designed to avoid repetitive and wasteful equipment refills, thus minimizing operator involvement at accelerated production rates.

On the other hand, high speed case sealer is primarily designed to pace already erected case feeds, fold flaps, apply adhesive and compression to seal cases tightly.

As such, the main difference between these packaging equipment lies in functional variables.

Case erector opens and glues case flaps at high speeds before moving them to case sealer.

Conversely, case sealer folds the flaps and seal them tightly also at high speed to guarantee safety of the products.

This equipment features different mechanical and operational elements and often depends on the specific design and type of the machine.

However, the typical features of a standard high case sealing machine include the following;

- Fully automatic case feed-pace belt to help feed cases back to back or spaced

- Automatic flap closing

- Low-voltage control circuit transformer

- High quality tape applicator/hot metal adhesive applicator

- Programming logic controller

- Interchangeable hot melt and tape sealing techniques

- Automatic water eliminator

- Maintenance free sealed bearings

- High capacity case magazine

- Top and bottom taping capabilities

- Non-slip belt drive conveyor

- Automatic indexing

- Fault detection and warning light

- Self-centering lid lifter

- HMI operator control panel on both sides

- High speed servo operation

- Emergency stop switches

- RSC, CSSC case ranges

You May Like;

Packaging And Labelling Machine

For all your high speed case sealing machine needs, contact us now.