Leading Granule Packing Machine Manufacturer in China

JOCHAMP offers a wide range of granule packing machines with fully automatic and semi-automatic functions. These are widely used for filing and packaging all types of granular foods. It is also available in custom filling machine options.

- Small sachet packaging technology

- High precision and accuracy

- Used for cosmetics, food, pharmaceutical, and more

- Different bag styles such as sachet, stick packet, and pillow

Custom Granule Packing Machine

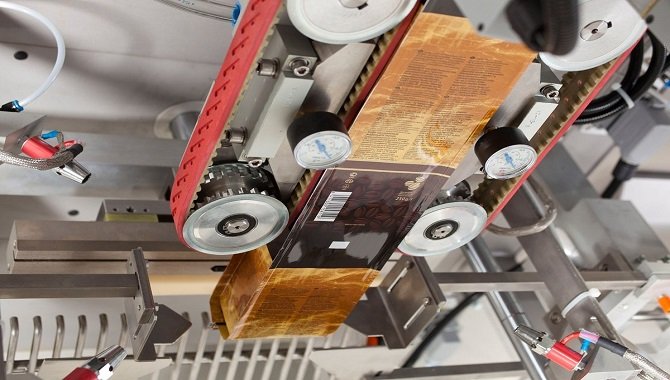

Granule packing machines are widely used for packaging granular foods. It offers a versatile, high-speed, and precision performance. These machines are commonly made from stainless steel construction. It features a hopper and easy-to-remove tooling. Therefore, you can ensure that granular packing machines are easy to clean and maintain.

JOCHAMP is a manufacturer of granule packing machines that can accommodate different types of bags such as three-side seals, back seals, four-side seals, and more. We manufacture these machines according to standards, including ISO9001, CE, SGS, and FDA. Our engineering team can also customize each machine based on your requirements.

Please send us your inquiries today!

Types of Granule Packing Machine

Application Scenarios of Granule Packing Machine (11)

Why Choose JOCHAMP Granule Packing Machine

Our granule packing machines are constructed using stainless steel materials that are certified by CE and cGMP standards to ensure safety.

We designed granule packing machines with cutting position digital input and photoelectric high-sensitivity color tracing to ensure accuracy.

The length of the bags and its packaging speed are adjustable based on your requirements without changing some machine parts.

Our granule packing machines are manufactured with features including strong sealability, clear-cutting patterns, and low noise.

Granule Packing Machine Characteristics

Our packing machines for granular products are manufactured with different characteristics such as:

- Stainless steel body and frame

- PLC controller

- Easy to adjust and install

- Accurate tracking and high speed

- Can print shelf life, production date, and batch number

- Different sealing forms

- Less error

Suitable Packaging Material

JOCHAMP granule packing machine can accommodate stick pack, sachet, or pillow bag with different materials such as:

- Filtering paper

- BOPP thin touch

- Combination of Polyester and PE

- Paper and PE combination

- Polyester

- PT/PE

- PET

- OPP/CPP

- OPP/CE

- Other materials that can be heat sealed

Why JOCHAMP Granule Packing Machine is Trusted by 1000+ Clients

We manufacture granule packing machines that are made from 304 stainless steel materials while meeting safety and health requirements. JOCHAMP designed granule packaging machines with a simple, reasonable design, solid, and compact structure. It also offers high control ability, user-friendly operation, and stable performance. As a professional supplier, JOCHAMP aims to provide the best packaging solution for granular products. Thus, we are customizing each machine according to your requirements.

Please send us your inquiries today!

| Product Type | Packing Machine for Granular Products |

| Machine Material | 304 stainless steel |

| Measuring | Measuring cup, measuring cylinder |

| Packing Speed Per Minute | 30 to 80 Bags |

| Suitable Bag Length | 30 up to 180mm |

| Bag Width Range | 15 up to 150mm |

| Packaging Film Thickness | 0.05 up to 0.08mm |

| Optional Device | Punching device and Air-filling device |

- Photoelectric components

- Bag former

- Plates

- Horizontal and vertical sealing block

- Heavy move wheels

- Stepper motor drive

- Screw feeder of the measuring system

- Machine control center

- Measuring cup device

- End sealing bag cutting device

Why Choose JOCHAMP as Your Granule Packing Machine Manufacturer

JOCHAMP has a professional team that can provide a one-stop granule packaging machine solution.

- Full knowledge of customer’s needs

- Strong production and processing team

- Logistic and Transportation team

JOCHAMP offers effective and timely after-sales services to support your business.

- Offers video about the operation and installation of the machine

- One-year warranty for the machine’s electrical appliance

- Professional engineers to help you if the machine fails

We produce granule packaging machines through different production processes including:

- Component processing

- Quality inspection

- Machine assembly

Related Product

Granule Packing Machine Guide

There are many granule packing machines in the market today. A reason you need an in-depth information that will help you choose highly efficient machine.

In this guide, you will find all vital information you’re looking for about granule packing machines.

granule packing machine

Vertical Form Fill And Seal Machine (VFFS)

Vertical form, fill and seal machine is designed to package products into bags within or outside a production line.

Filling of the products into the bags take place through the top of the bag.

Some of the functions include automatic bag forming, bag filling and bag sealing getting it ready for shipment.

vertical form fill seal machine

With this machine, bag size can be adjusted automatically depending on what parameters are fed into the system the touch screen.

The machine can handle bags up to 200 bags in one minute when working in a duplex line.

Horizontal Form Fill And Seal Machine (HFFS)

Horizontal form fill and seal machine are designed to form, fill and seal the package within the same system.

Filling can take place through hot fill, clean fill or ultra clean fill.

Sealing is done through one of the following; hot seal, ultrasonic or induction seal.

horizontal form fill seal machine

Some of the products that can be packed through this machine include tea, sugar, tablets, peanuts, salt and grains.

Automatic Powder Pouch Packing Machine With Cup Filler

Automatic powder pouch packing machine with a cup filler is designed to fill and pack cups.

When using this machine product and material wastage is minimized.

There are various products that can be packed through this machine including wheat flour, chemical powder, coffee powder etc.

powder pouch packing machine with cup filler

Some of the features found in this machine include stainless steel covering, pneumatic technology, low maintenance.

Automatic Auger Pouch Packing Machine For Sticky Powders

Automatic auger pouch packing machine for sticky powders is a vertical form fill seal system that has a cup filler.

Pouches or sachets are made using film rolls and are hot sealed.

Some of the features include high filling accuracy, contact parts are made using stainless steel since it is corrosion resistant.

Other features include low maintenance, simple to use, automatic pouch size change and coding device.

powder pouch packing machine

Auger filler is connected to a high-speed screw and can be synchronized easily.

Automatic Weigh Filler Packing Machine

Automatic weigh filler machine can handle products such as snack food, poultry, spices, beans, confections, chemicals etc.

Some of the functions performed by this machine include weighing of products and dispensing them into bags, trays, cartons or jars.

weigh filler packing machine

Automatic weigh filler machine can be incorporated into a production line to make the process more efficient and cost effective.

Stick Bag Packing Machine

Stick bag packing machine is designed to perform functions like bag forming, weighing, filling, sealing, counting, cutting, heating and pressing.

Various packing materials can be used to pack items using this machine including PET, paper laminated using PEF nylon.

stick bag packing machine

Some of the features for stick bag packing machine include;

- Bag size can be adjusted automatically.

- Lubrication of the moving parts of the machine is automated.

- Conveyer and ink printer are available as options.

- Machine is provided with a PLC touch screen.

- Stainless steel coating is of required standards.

- Hot sealing is available and the temperature during sealing depends on the customer needs.

Multifunction Automatic Stand-Pouch Packing Machine

Multifunction automatic stand-pouch packing machine can be used for automatic filling of products into stand-pouches followed by automatic sealing.

This machine handles granular and powder products such as beans, coffee, washing powder and candy and liquids like milk and wine.

stand up pouch packing machine

Heat-seal lamination materials like PET/PE/plated AL, NYLON and PET/PE can be used as packing materials.

Multifunction automatic stand pouch packing machine can automatically form, fill, seal, cut and hot press codes.

Bag Former

Bags are formed automatically at this point depending on the parameters preset through the PLC touch screen.

Measuring Cylinder

Measuring cylinder is used for measuring the products before be packed into the bags depending on the parameters preset.

PLC Touch Screen

Various parameters are set up through the PLC touch screen including bag size, speed, language and photoelectric detector.

Film Reel

Film reel loaded on a conveyer belt is used to fix the packaging film during packaging and display it for coding.

Hopper

Products are usually stored into the hopper temporarily before being fed into the bags or the trays having measuring cups.

Conveyer Belt

Conveyer belts aids in the movement of the packing bags from one station to the next within the machine.

The movement is controlled through the electric motors.

Sealing Device

Sealing device is used for sealing the bottom of the already formed bag before it is filled.

Coding Device

Batch number and date can be printed on the already filled and sealed bags through a coding device.

Filling Station

Products are packed into the bags automatically at the filling station depending on the predetermined quantity.

granule packaging machine parts

The first step is to feed the material through the feeding device followed by weighing using the multi-head scale.

Once the material has been fed and weighed, it is then moved to the film reel aided by collar forming device.

After forming the film, the coding device prints codes such as batch number, date and any other content as desired.

From there the film is moved to the bag forming station where it is formed into shape for filling to take place.

At the sealing stage, the sealing device seals the bottom of the bag.

Through the conveyer belt, the bag is moved to the filling station, and after weighing, the product is dropped into the bag.

After filling, the bag to can be moved to the next machine for sealing before distribution.

Granule packing machines are suitable for packaging products such as shrimp strip, puffed food, melon seed, jelly, salt, sugar, peanut and corn.

Granule packing machine can perform functions like bag forming, measuring, bag filling, coding and product ejection.

Various bag sizes and shapes can be formed and filled through a granule packing machine with a simple changeover procedure.

Advanced PLC with a touch screen used for controlling and monitoring the whole process.

Motor and Variable frequency drive used for aiding movement in the whole packaging process.

Color photoelectric sensors for monitoring the filling and sealing processes to avoid errors.

Stainless steel material used for coating parts that get into contact with products.

Coding device available for printing details.

4-sided seal to ensure that the product is safe and secure.

Gas flushing device to increase the shelf life of the product.

An arching technology that can reduce material wastage by preventing agglomeration of material when screw feeding.

Suspension sensor which is independent with a stable transmission of signal to ensure accuracy during weighing.

In agriculture industry the machine is used to package products like fertilizer, pesticide, feed, grains etc.

Within the pharmaceutical industry, granule packing machine can be used for packing products like medicine decoction pieces, medicine granules, and premix.

Another industry that requires this machine is the food industry for packing products like snack food and candy.

Detergents industry uses this machine to pack products like washing detergents and other products.

Other products that can be packed using a granule packing machine include salt, melon seeds, hardware products etc.

For all your granule packing machines, contact us now.