Garlic Packing Machine Supplier in China

JOCHAMP customizes packing machines for garlic products with high speed and accuracy. We design these machines according to your desired packaging and other required specifications.

- Fully automated equipment

- High-precision automatic weighing

- Reaches safety standards

- Comes with replaceable parts

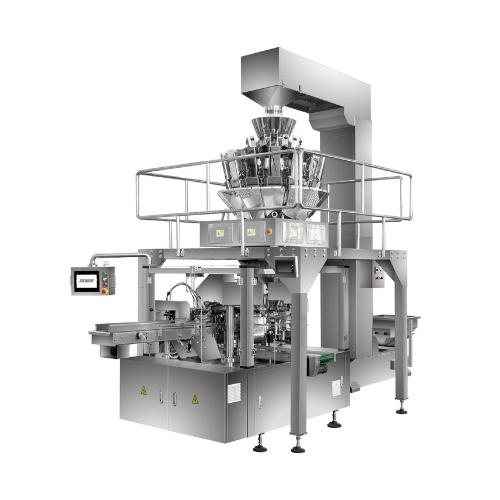

JOCHAMP Garlic Packing Machine

The garlic packing machines defines as flow wrapping equipment. They feature durable packaging capacity and are helpful for various applications. These machines have more excellent performance than pillow packing equipment. Moreover, packing machines for garlic are convenient to operate and more advantageous.

Jochamp owns advanced CNC equipment utilized for every manufacturing process. Our professionals conduct strict quality controls from raw materials to machine assembly and testing. We also provide after-sale services for feedback.

Don’t hesitate to contact us right away!

Types of Garlic Packing Machine

Different Garlic Packaging (3)

How Garlic Packing Machine Work

First, garlic is poured into the vibrating feeder and lifted to the weigher top. The computer component weigher measures the garlic based on the set weight. Then as garlic moved into forming machine, packaging films are assembled and sealed. After that, the finished product runs into metal detection, ensuring the absence of metals.

Inaccurate weight or overweight packed garlic will be excluded, while the suitable packaging will come into the disc sorting table. And finally, the workers arranged the finished garlic bags into the boxes from the sorting table top.

Garlic Packing Machine Properties

Jochamp expertly manufactures packing machines for garlic products with advantageous properties, such as follows:

- High-Accuracy (Appropriate combination selection; a combination of high-speed and accuracy)

- Easy Operation (Easy to operate and maintain microcomputer and touch screen controls)

- Proper Locating (Proper pull film positioning with electric eye tracking and trademark locating)

- Small Space (Optional weighing part design, which reduces machines height and saves more space)

- Quick Return Investment (Retains raw materials and increases production)