Flow Wrapping Machine

Flow Wrapping Machine also called flow wrapper (HFFS) or horizontal flow wrapping machine. Chinese flow wrapping machine manufacturers are used to calling it an automatic pillow packing machine. It is a continuous packaging machine with a very strong packaging capacity and suitable for various specifications for food and non-food packaging.

Jochamp offers customized design flow wrapping machines for various industries. By adopting servo motor control, touch screen, and PLC control system; our machine makes the operation easier. The flow wrapper machine consists of distributing conveyor, production aligning conveyor, and pillow type packing machine, we have different designs for distributing conveyor intercepting, sunken, and so on. It can be used not only for the packaging of unbranded packaging materials but also for the use of pre-printed roll materials for high-speed packaging.

Multiply Flow Wrapping Machine For Your Choose

The JCD-1600 series flow pack packaging equipment is designed and manufactured for the packaging of small products such as candy, and more.

Our JCD-800Q series wrapping equipment is designed for stretch packaging for products such as coffee, instant noodles, bubble gum, nougat, haw jelly, and more.

The JCD-660A automatic horizontal flow wrapper was developed for the packaging of products with small pieces attached like sesame cakes, donuts, bagels, etc.

The JCD-660 automatic horizontal flow packing machine is designed for coated products such as chocolate, wafer biscuits, cakes, and more.

JCD-630W horizontal wrapper equipment is a flexible piece of machinery designed for the packaging of products such as hamburgers, instant noodles, household products, medical products, and so on.

DXD300 plus could package single or multiple products of various types including biscuit, chocolate, and cakes as well as cards, daily necessities, etc

Jochamp Flow Wrapping Machine Sample Package (6)

JOCHAMP MACHINERY- China Leading Flow Wrapping Machine Manufacturer & Supplier

- 2 years warranty support

- Servo motor control, touch screen, and PLC control system

- All our flow wrapper machines are CE, IOS9001, SGS certified

- Has an excellent team of 10+engineer, 15+ sales, 20+ after-sales

- Factory

of course, we are a professional manufacturer of packaging line solutions. We can provide overall packaging solutions based on the flow wrap machines. Including the connection with the front-end production line, product distribution, and factory layout, you can leave it to us.

Powder and liquid materials are not suitable for flow wrapper (HFFS), please use vertical packaging machine (VFFS) to package your products.

Flow wrapper has limitations, we produce different types of flow wrappers to get better adaptability. At the same time, you need to adjust or replace the mold for product conversion.

Depending on the proficiency of the machine operator, you generally need 10-30 minutes to adjust the machine.

To a certain extent, you can change the pattern of the seal, single-pack or continuous-pack, and perforate.

We recommend that you turn on the machine for 23.5 hours, and the remaining 30 minutes are used for necessary maintenance of the machine to ensure the best service life of the machine.

Flow Packing Machine – Definitive Guide

Flow wrapper is mainly used for single or multiple solid packaging. It is also called a horizontal flow wrapping machine (HFFS), which is a type of plastic film packaging machine. Chinese flow wrapper manufacturers and users are used to calling it an automatic pillow packing machine.

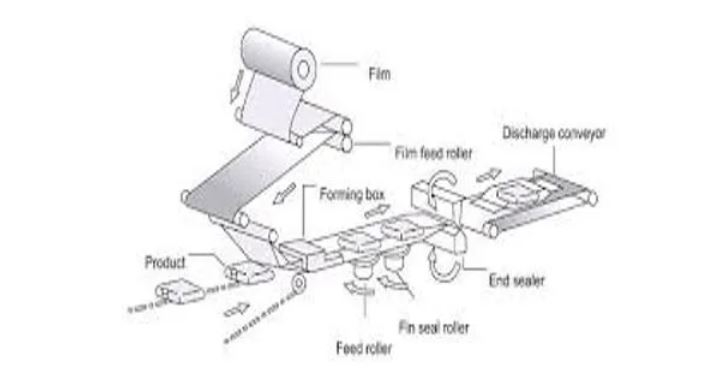

Flow wrapper operation process

The flow wrapper adopts positioning sealing and cutting during packaging. In packaging production, due to the positioning color code printed on the packaging material, the error between the stretching of the packaging material and the mechanical transmission, the packaging material is predetermined. Sealing and cutting parts may deviate from the correct position and cause errors.

In order to eliminate errors and achieve the purpose of correct sealing and cutting, packaging design must consider the problem of automatic positioning. To solve this problem, the design of a continuous photoelectric automatic positioning system was completed according to the positioning standard of packaging materials. According to the error compensation working mode, the continuous photoelectric positioning system is divided into two types, front and rear, brake type, and synchronous transmission of two transmission systems.

Simply put the job of the flow wrapper is to wrap the product with a layer of film, like this:

1. Advantages of flow Packaging Machine

When you need to pack and mark a large number of the same products, a flow wrapper machine can help you pack efficiently. Unlike carton or shrink packaging, flow wrapper packaging can block air, and the product shelf life will be longer. Besides, film packaging can effectively block dust, and the packaged products are easier to place.

The contribution of nitrogen in the food field is great, as a leading flow wrapping machine manufacturer, we have added this technology to the flow wrapper to fill the food with nitrogen at the same time so that the food can be stored for a long time. For some long-term mass-produced products, such as chocolate, candies, biscuits, etc., we can provide professional packaging solutions to improve the automation level and productivity of the factory.

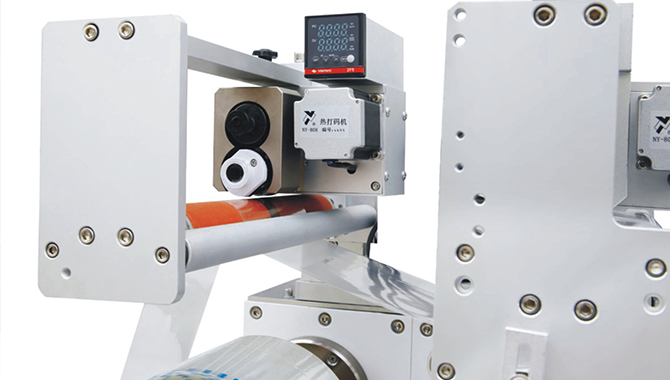

The information that needs to be printed such as the production date and batch number is essential for the packaging of some products. In the application of flow wrapper, we can directly add this function. For some special products, such as shisha tobacco, plasticine, nougat, etc., we can even use dedicated mixing, cutting, and packaging production lines. For products that require secondary packaging, our flow wrapper can be customized to connect some machines, such as cartoning machines.

2. Limitations of Flow Wrapping Machine

This machine is suitable for solid-shaped products and is not as suitable as a vertical packaging machine in the applicability of powder packaging. And the form of direct liquid filling is completely unsuitable.

In many cases, product upgrades represent cost expenditures. Although the price of standard machines has dropped to a certain extent every year, for some special customized packaging lines, the cost of expenditure is still considerable.

I have to say that in some food applications, such as chocolate and biscuits if smart packaging is used, the area that needs to be occupied will be huge. Technology pushes people forward. They can’t be perfect, but the convenience they bring us is huge.

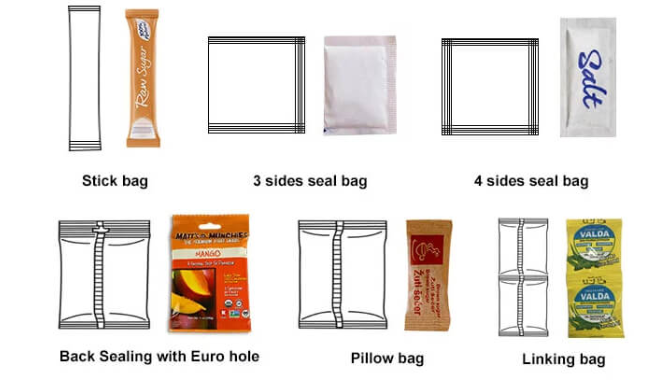

3. Several styles of Flow Wrapper Packaging

Here are several sealing forms that the flow wrapper can change through the modification of the tool.

1) The most common form of sealing tooth-shaped sealing

As it is conducive to consumers to open the package quickly, tooth-shaped sealing is the most common sealing form in the current market. This sealing method is completed by a combination of a toothed cutter and a striped sealing seat.

At the same time, under the condition of the same tool seat, the toothed knife can be replaced with a flat knife, which is also a very common packaging method.

2) Packaging with holes

Some products need to be hung on the shelf for display, so we need to punch a hole in the packaging. It is not difficult to achieve this kind of packaging, we only need to open a hole on the knife holder and equip it with a punching mold. And the shape of the hole can be different.

Airplane-shaped hook hole

Flow wrapper holder with round hole shape

3) Seal pattern

The edge-sealing effect with texture can not only improve the aesthetics of the package but also the sealing performance will be greatly improved. We usually have parallel lines, but there are actually many kinds of lines.

Usually, we recommend the best packaging form based on the customer’s product or packaging material. Generally, in some general scenarios, customers can customize the sealed form according to their preferences.

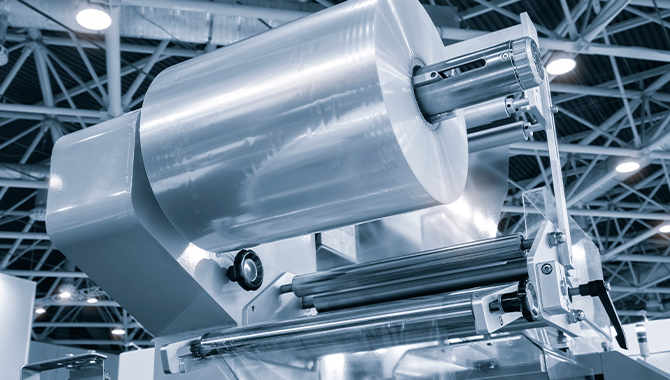

4. The Material used in the Flow Packing Machine

In addition to the machine itself, the materials used in the packaging are also critical, which involves the stability of the machine, the aesthetics of the product, the cleanliness, the aesthetics of the packaging, and so on. So what kind of packaging materials can be used for flow wrapper?

The general pillow packaging machine uses 7 kinds of films: OPP film, CPP film, OPP composite PE, OPP composite CPP, PT composite PE, aluminized film, paper film (laminated film).

Next, we will score some major materials:

| Material | Feature | The main Purpose | |||||||

| Moisture Resistance | Air Barrier | Oil Resistance | Low Humidity Resistance | Transparency | Anti-UV | Formability | Heat Sealability | ||

| KOP/CPP | ★ | ★ | ★ | ○ | ○ | ○ | ○ | ★ | bread |

| PT/CPP | ★ | ★ | ★ | × | ★ | × | × | ★ | pastry |

| OPP/KPT/PE | ★ | ★ | ★ | ○ | ★ | △ | × | ★ | Sauce |

| OPP/CPP | ★ | ○ | ★ | ○ | ★ | × | ○ | ★ | moon cake |

| Nylon/CPP | ★ | ★ | ★ | ○ | ○ | ○ | × | ★ | moon cake |

| OPP/PE | ★ | ○ | ○ | ★ | ★ | × | ○ | ★ | Biscuits, instant noodles, medicine (tablets) |

| PET/PE | ★ | ★ | ★ | ★ | ★ | × | ○ | ★ | Steamed, frozen, rice cake |

Note: ★ is excellent; ○ is good; △ is fair; × is bad; the friction coefficient of all packaging films is the highest 7

After intuitive comparison and understanding of the characteristics of the packaging film, we can choose the film that suits our products. For example, packaging food and medicine generally requires airtight film. At this time, OPP, PET, and aluminized film will be better choices.

5. Packaging film width and unit price calculation

Taking opp/CPP packaging film as an example, you first need to understand the length, width, and thickness of the product (unit is mm). Such as product: length 65mm width 50mm thickness 5mm.

Then the formula for calculating the length and width of the packaging film required by the product:

Packaging film length: product length + product thickness + horizontal seal 30 = film length

65+5+30=100mm.

Packaging film width: (product width + product thickness) × 2 + vertical seal 30 = film width

(50+5)×2+30=140mm.

It can be concluded that the length and width of the film used in the product are: 100mm+140mm.

Based on this indicator, we use a formula to calculate the unit price of the packaging film.

At this point, first, convert the above calculation result of film length and width into m

Film length × film width × 0.00005 × packaging film price per ton = single packaging film unit price

0.1(m)×0.14(m)×0.00005×4300USD=0.003USD/unit

(Note: 0.00005 is 5 c)

First, convert the price of 4,300 a ton into a unit price of one kilogram

4300USD/ton=4.3USD/kg

Unit price per kilogram ÷ unit price of a single packaging film = packaging quantity per kilogram

4.3÷0.003=1433

Total number of products ÷ number of packages per kilogram = total number of kilograms of packaging film to be purchased

Set the total number of products to 1,000,000

1000000÷1433=700kg

The total kilogram quantity of packaging film that needs to be purchased × the unit price per kilogram equals = the total price

700×4.3=3010USD

PS: The above price is an assumption, please refer to the actual price

6. How to Choose the Right Flow Wrapping Film?

Finding the right type of film and how to use the film is as important as choosing the packaging method. Flow packaging can hold many types of products; from candy bars to medical devices, flow packaging provides a wide range of benefits for production managers. Factors such as cost-effectiveness, minimal waste and high output make flow packaging the first choice for packers.

Although it is important to determine whether flow packaging is the correct packaging technology for your product, it is equally important to choose the correct film. The flow packaging process wraps the product in a transparent or printed polyolefin, polypropylene or laminate film to form a three-sided sealed package to produce a light and flexible package. When considering the type of film used in flow packaging, there are several factors to keep in mind.

- Double membrane-running double membrane on one machine is both efficient and flexible.

- Selection -a balance should be struck between quality, performance, efficiency and cost. You should always choose films based on product and packaging characteristics.

- Feature questions to consider-should you consider oxygen transfer rate (OTR), water transfer rate (WTR), or modified atmosphere packaging (MAP)? Or is this application just a cover or group of products/products?

- Further factors-sealing method, throughput, preferred packaging style, product heat sensitivity, quality, budget, output, and required sealing jaw profile are factors to consider when choosing the correct film.

- Product Type-There are many products suitable for flow packaging. For example, in-store production bags, baked goods, bagged boxes (for films containing products inserted into folding cartons or boxes); cooking bags, over-packaged products (such as bell peppers), candy and candy packaging, or meat, poultry And seafood packaging.

There are a variety of commonly used flow wrap films:

- Polypropylene series (PP)-This kind of film is usually used in snack foods, candies, baked goods, etc. It can be transparent, printed or opaque. It is combined with the coating to help protect the film and the product. The protective effect of PP on moisture and oxygen is limited.

- Polyethene series (PE)-PE includes low-density, linear low-density and high-density films. Low-density film and linear low-density film have similar characteristics: good transparency, high flexibility, and can be heat-sealed using a special sealing system. Both low density and linear low-density films are used in the stretch and shrink packaging, bags, pizza, baked goods and other similar applications. High-density polyethene has low transparency and is used together with EVA to package frozen foods, biscuits, bread bags, cereal box liners, etc.

- Polyester film (PET)-Polyester film is usually combined with other films as an outer layer. Potato chips and pretzels in metalized packaging or culinary packaging are common uses. PET lamination provides lightweight, water resistance, heat reflection and ultraviolet light. It preserves freshness and flavour while having the scratch resistance properties of retail and transportation.

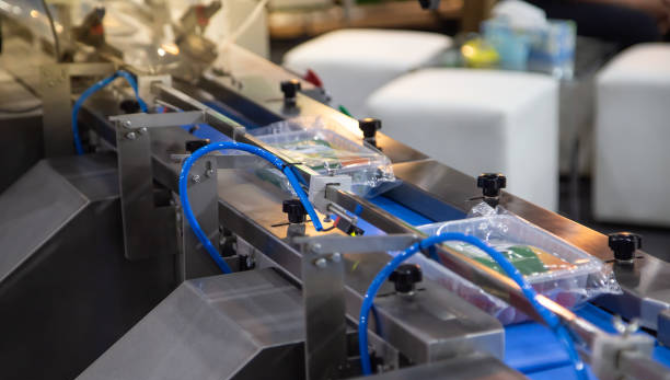

The Right Seal

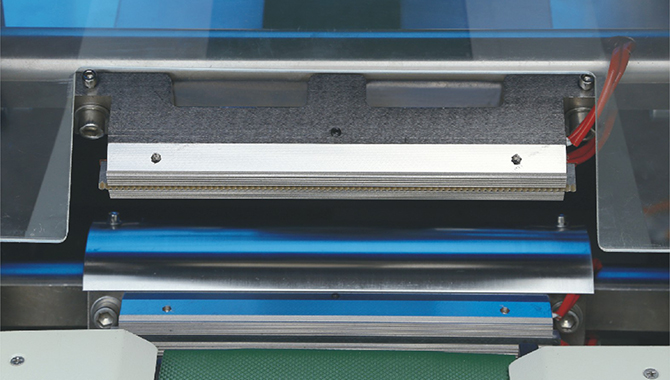

- Three common sealing elements-they are time, temperature and pressure. Changes in one element affect another element.

- Jaw seal-In addition to the sealing element, the type and method of jaw seal also need to be considered. There are many types to consider, and each type has its own unique advantages and disadvantages.

- Flow chart packages performance-when variable changes, it needs to be adjusted. Seal jaw wears, material changes or changes, sealing time or equipment speed changes are variables that need to be considered.

- Hot and cold film sealing-the use of hot or cold film sealing depends on individual product characteristics, material cost constraints, production throughput (capacity/speed), required seal strength or integrity and required film barrier properties ( Ultraviolet rays, oxygen, etc.).

- Cold Seal-This kind of seal is created by pressing the film together using a substrate and adhesive layer. Cold sealing cannot protect the product like heating sealing, and it is more susceptible to environmental factors. However, heat-sensitive products, such as chocolate, need to be cold sealed.

- Heat sealing-Heat sealing is the best choice for high integrity sealing. The temperature range is the key: the wider the effective range, the less chance of seal failure.

7. Things to note when purchasing packaging film

When purchasing packaging film for your flow wrapping packaging, there are some things you need to know first.

- Choice of packaging film thickness

Generally, we recommend the use of packaging film with a thickness of 3.0c-8.0c. Based on product characteristics, such as food, we generally recommend a film thickness of 8.0c.

The thickness of the film is very important to the sealing performance and packaging strength. A film that is too thin is easy to break, and a film that is too thick is not easy to seal.

- Tracking the printing of color marks

For the packaging effect of the product, we usually use printed film or transparent film. But in actual application scenarios, not all machines are applicable. For example, the reverse stretch film flow wrapper (using the packaging film as the driving force to pull the product forward) must be applied to the packaging film with color code printing. If there is no color code, the cut-out bag will be different in length.

- Color of the color code

Our common color code is black. This is to better distinguish the color code tracker when packaging on the flow wrapper. Therefore, the color of the color code is not necessarily black but should have a stronger color than the color of the packaging film

8. Conclusion

Everyone is familiar with flow wrapper equipment. This equipment has been manufactured and launched on the market since the 1970s. I believe that people are more willing to buy more intelligent flow wrappers with innovative ideas.