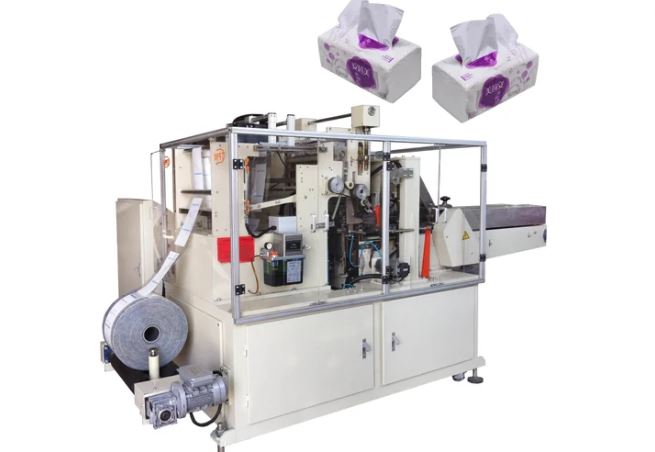

A facial tissue production line is not complete without an effective and reliable packaging machine. This guide will help you choose functional and high quality facial tissue packing machine.

Therefore, before investing in your next tissue packing machine, read this guide.

Working Principle of a Facial Tissue Packing Machine

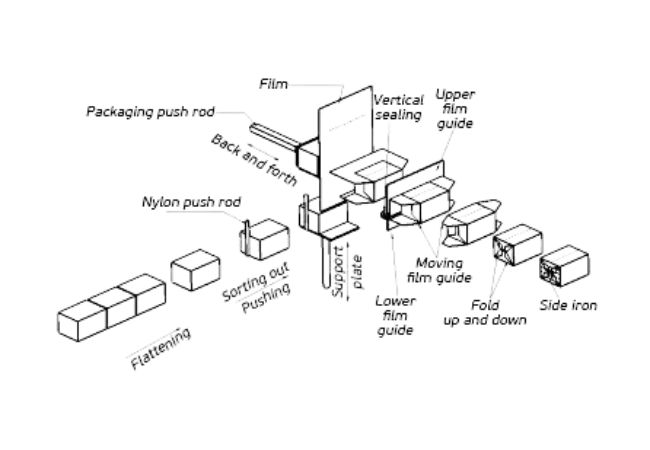

Packaging facial tissue is a step-by-step involving the following key stages:

Step 1: Feeding

In this step, you will feed the facial tissues into the machine through a feeding system. This can be happening manually or through an automatic feeding system.

Step 2: Folding

Thereafter, a folding mechanism will fold the tissue into the appropriate shape and size. This can be a simple zig-zag fold or a more complex multi-fold.

Step 3: Cutting

Afterward, the cutting mechanism will cut the folded tissues into the desired sizes. This can happen either using a rotary cutter or a laser cutter.

Step 4: Sealing

In this phase, you will seal the cut tissue pieces using a sealing unit. The sealing unit can be a heat sealer, ultrasonic sealer, or a tape sealer.

Step 5: Packaging

The final step involves placing the sealed tissues into packets or boxes using a packaging system. Once the packaging process is over, the machine will close and seal the package.

Types of Facial Tissue Packing Machine

These include the following:

- Horizontal Facial Tissue Packing Machines: These machines will produce packets by folding and cutting the tissues in a horizontal orientation. They are suitable for producing flat packets or packets with a single fold.

- Vertical Facial Tissue Packing Machines: The machines produce packets by folding and cutting the tissues in a vertical orientation. They are suitable for producing packets with multiple folds or packets with special shapes or features.

- Interfolding Facial Tissue Packing Machines: These machines produce packets by folding the tissues into a compact interfolded stack, which can dispense through a single opening. They are suitable for producing small packets that are easy to carry and use.

- Overwrapping Facial Tissue Packing Machines: These machines produce packets by wrapping the tissues in a protective material, such as paper, film, or foil. They are suitable for producing packets that are more durable and moisture-resistant.

- Flow Wrapping Facial Tissue Packing Machines: These machines produce packets by wrapping the tissues in a continuous sheet of material. Then it cuts and seals to form individual packets. They are suitable for producing packets with a clean and modern appearance.

- Combination Facial Tissue Packing Machines: These machines combine multiple functions, such as folding, cutting, sealing, and wrapping, into one machine. They are suitable for producing packets with complex shapes or features and for maximizing production efficiency.

- Custom Facial Tissue Packing Machines: These machines are designed and built to specific requirements and specifications, such as specific packet sizes or shapes, or special features or capabilities. They are suitable for producing specialized or unique packets that are not available with standard machines.

Benefits of Facial Tissue Packing Machine

There are several advantages to using a facial tissue packing machine, including:

- High efficiency: A facial tissue packing machine can pack tissues much faster than manual packing, allowing for high production and low labor costs.

- Good quality: The machine can produce consistent and accurate packing, resulting in fewer defects and rejects.

- Minimal waste: The machine can reduce waste by accurately cutting and sealing the tissues to the desired size, thus minimizing waste.

- Improved hygiene: This machine can improve hygiene by automatically handling the tissues, reducing the risk of contamination.

Maintaining a Facial Tissue Packing Machine

Properly maintaining and cleaning of a facial tissue packing machine is important to ensure its long-term functioning and efficiency. Here are some tips to follow:

- Regularly inspect and clean the machine: Regularly inspect the machine for any damage or wear and tear, and clean it regularly to remove any dust, dirt, or debris.

- Lubricate moving parts: Oil the moving parts of the machine, such as the cutting and sealing units, to ensure smooth operation and prevent wear and tear.

- Follow the manufacturer’s instructions: These instructions will help you maintain and clean the machine as per the manufacturers guide to ensure optimal performance.

- Use appropriate cleaning materials: Employ appropriate cleaning materials, such as a mild detergent and a soft cloth, to clean the machine and avoid damaging any parts.

- Shut off and unplug the machine before cleaning: Always make sure to switch off and unplug the machine before cleaning to avoid any accidents.

- Repair or replace damaged parts: If any parts of the machine are damaged or worn out, repair or replace them as soon as possible to prevent further damage or breakdowns.

Factors to Consider in Facial Tissue Packaging Machine.

There are several factors to consider in a facial tissue packaging machine. These include:

- Production capacity: The machine should be able to meet the required production capacity of your business.

- Size and weight: Here, the dimension and weight of the machine should be appropriate for the available space and the handling capabilities of the operators.

- Ease of use: Ensure that the machine is easy to operate and maintain, with clear instructions and simple controls.

- Safety features: The machine should have appropriate safety features, such as guards and emergency stops to prevent accidents.

- Maintenance requirements: The machine should have low maintenance requirements and be easy to clean and service.

- Price: The cost of the machine should be appropriate for the business’s budget and needs.

Troubleshooting a Facial Tissue Packing Machine

Some common problems that may occur with facial tissue packing machines include:

- Jamming: This can occur when the tissues fail to properly feed into the machine, or when the machine is not properly aligned. To address this issue, check the feeding system and realign the machine as necessary.

- Incorrect cutting or sealing: This can occur when you fail to properly maintain or adjust the cutting or sealing units. Solve this by checking the cutting and sealing units and adjust or repair them as necessary.

- Packaging problems: Packaging system that is not properly aligned or when the packaging material is not of the right size or quality causes this issue. To address this problem, check the packaging system and the packaging material, and adjust or replace them as necessary.

- Electrical problems: This can occur when the machine is not properly grounded or when there are issues with the electrical components. To solve this problem, check the electrical system and repair or replace any damaged components.

Safety Precautions When Using a Facial Tissue Packing Machine

Here are some safety precautions to be taken while operating a facial tissue packing machine:

- Follow the manufacturer’s instructions for operating the machine. Make sure to read and understand the manual before using the machine.

- Wear protective gear such as gloves, goggles, and earplugs to protect yourself from moving parts and noise.

- Keep your hands and clothing away from the moving parts of the machine to prevent injury.

- Regularly inspect the machine for any damage or wear and tear, and perform maintenance as recommended by the manufacturer.

- Keep the machine clean and clear of debris to reduce the risk of accidents.

- If you notice any problems with the machine, stop using it immediately and contact a qualified technician for repair.

Conclusion

As you can see, there are many types of facial tissue packing machines available in the market. Whichever machine you opt for, it must guarantee safety, maximum productivity and be cost effective.

At Jochamp, we have many tissue packing machines according to your unique requirements and specification.

More Resources:

Facial Tissue – Source: Wikipedia

Tissue Paper Packing Machine – Source: Jochamp

Tissue Box Packaging Machine – Source: Jochamp