Without the right information, finding a suitable dry syrup filling machine can be a challenging task.

This guide discusses all fundamental aspects of dry syrup filler. Whether you want to learn about specification, features, classification of working principle; they are all in this guide.

What Is Dry Syrup Filling Machine?

Dry syrup filler is an electromechanical equipment that fills syrup powder and seals packaging. They can fill powder in bottles, cans or sachets.

Parts Of Dry Syrup Powder Filling Machine

These powder filling machines have many parts and components. The number of parts will depend on the design and configuration of the machine.

Let’s look at some of the most common parts:

· Hopper

It is the hopper which holds all syrup powder you want to fill in tins or bottles.

· Filling Heads

The filling heads carry your powder products from the hopper. They take it into the packages for filling process.

· Mechanical Drive System

You may find a dry syrup powder filling machine with either rotary or linear mechanical drive system. The system will determine the direction of movement of the parts of your machine.

The mechanical drive system of your rotary machine has conveyors, gears, and mechanical motors.

· Sensors

They will ensure your packages are placed properly in the machine. Sensors will also make sure that the quantities you fill in are accurate.

They will always send a signal to your machine on what function to carry out.

· PLC Control System

You will use PLC control system in controlling how your products are filled into containers. Touch screens in the machines will help you operate it with ease.

· Measuring Cup

You will use the measuring cup to achieve accurate fills of your products into packages.

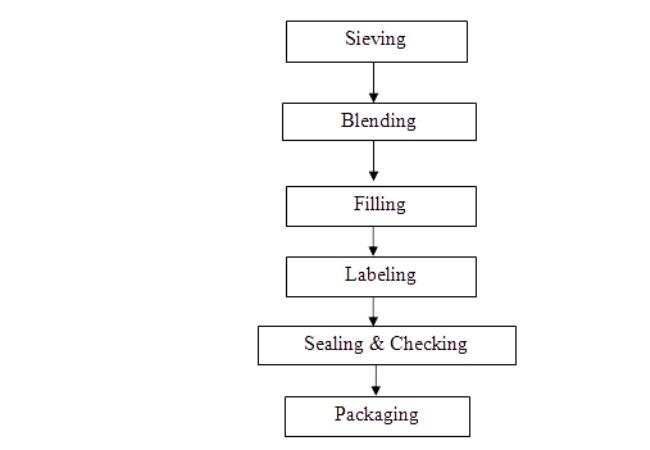

Dry Powder Filling Process In Syrup Packaging Machine

Steps you will use in dry powder filling process include:

- First, you will need to add a huge amount of your product to the hopper of the machine. Also, you will feed packages to the syrup packaging machine.

- Once this is done, the empty packages will be moved and put below the filling head.

- Your syrup packaging machine will then determine the quantity required in each package.

- The filling head will then dispense given quantities of the product into each package.

- After this, the packages will proceed for sealing at your sealing station.

Benefits Of Dry Syrup Powder Filling And Packaging Machine

There are many benefits of powder fillers in pharmaceutical industry such as:

· Speed and Elimination of Manual Labour

It will make your work easier as you will not need to use labour in filling up packages. This will ensure that your products are generated at a high speed.

· Enhanced Production Capacity

The machine enables you make a lot of dry syrup powder. This will enable you to meet the growing needs of your organization.

· Can be Customized to Suit your Needs

Another benefit of the machine is that it is versatile and you can use it to meet various filling needs. It will also enable you to fill different types of packages faster and with ease.

It is important to reach out to manufacturers of the machine and select the type suited for your organization.

· Safe and Easy to Use

You can assemble the machine with ease. This will make sure that your operations run at a faster speed.

· Eliminates the Risk of Contamination

The machine will ensure that your product is free from the risk of contamination by bacteria and dirt. This is because it has high precision control measures.

· No Product Wastage

Your machine a cutting-edge technology that ensures accuracy in filling your packages. It will make sure that the filling process is regulated to achieve the best results and eliminate product wastage.

Types Of Dry Syrup Filling And Packaging Machines

It is important to ascertain the function you would like the machines to serve to select the most suitable one. They include:

Rotary Dry Syrup Powder Machine

You can use it to package your powder products. It works best when your bottles have a square and rectangular shape and are about 100mm in height and 85mm in diameter.

This machine will help you pack so many packages per minute. This will depend on your bottle’s size and diameter and the type of powder.

It has an automated system for you to switch on and off. It is made from AISI 304 material which ensures its durability.

Auger Dry Syrup Powder Filling Machine

With auger filler, even at high speed, the dosing will be accurate. This machine will ensure that you fill containers of between 5 to 200 grams.

It has sensors that will automatically stop filling once they detect that you have not fed any containers. The stainless-steel body ensures that your machine is free from corrosion and stable.

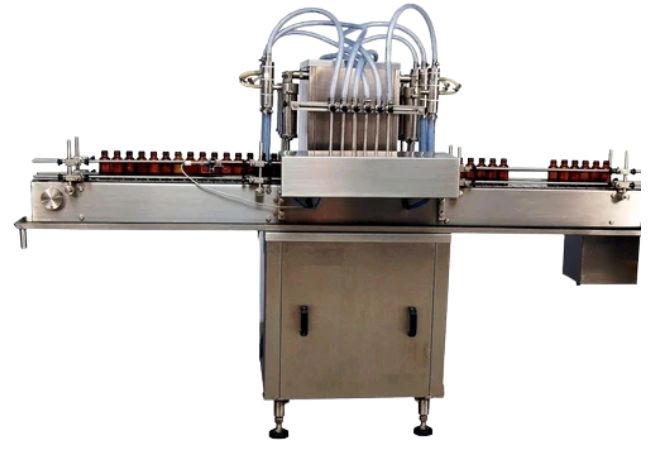

Inline Dry Syrup Powder Filling Machine

These machines have a single lane for feeding in ad removing products. When using them, you will need to have a bigger operation space.

They make it easy for you to identify product movements and inspect the work station.

· Automatic High-Speed Rotary Dry Syrup 16X8 Powder And Capping Filling Machine

This machine will ensure that your functions are achieved at a faster rate as it has a feed star wheel and capping.

· Single And Double Head Auger Dry Syrup Powder Filling Machine

Double-head auger dry syrup powder filling machine is suited for varying container shapes.

Single-head auger dry syrup powder filling machines use a single head in filling your packages. They will ensure that your fills are accurate and carried out at a very fast rate.

The machine will also help you achieve a smooth sequence of operations.

· VFFS Dry Syrup Powder Filling Machine

VFFS can handle a range of syrup powders. The machine will assist you in creating pouches from flat plastic film rolls.

Additionally, they will seal these packages by using the appropriate sealer equipment.

Capsule-filling machines will help you in filling your small packages. You can use them in filling pharmaceutical products.

· Manual Dry Syrup Powder Filling Machines

You will be required to manually weigh the filled containers and determine the number of products to fill. Additionally, you will manually have to switch the machine on and off during and after an operation.

· Semi-Automatic Dry Syrup Powder Filling Machines

They look like fully automatic machines but there are some tasks which you will need to manually execute. They possess a control system for packaging and measuring your dry syrup powder.

· Fully Automatic Dry Syrup Powder Filling Machines

They have incorporated elements of the latest technology to help you fulfill your needs efficiently. Most of your operations like feeding, weighing, and measuring are done by the machine.

You will not need to have an operator to physically monitor every step of the machine. Fully automatic dry syrup powder filling machines can fill up a wide range of products.

automatic dry syrup powder filling machines can fill up a wide range of products.

Powder Filling Mechanism In Dry Syrup Powder Filling Machine

There are several mechanisms that you can use in a dry syrup powder filling machine. They include

· Auger Powder Filling Mechanism

You can use this mechanism in filling dry syrup powders at a fast speed. It is the most commonly used mechanism.

· Vacuum Powder Filling Mechanism

This mechanism will make it possible for you to fill dry syrup powder into containers without using an auger and agitator. It will ensure that your products remain in their original state as they will not need to be broken down.

· Volumetric Cup Powder Filler

It is suitable when you want to handle free-flowing powder products. Volumetric cup powder filler has a structure that is compressed to eliminate mechanical damage.

You should note that volumetric cup dry powder filler cannot fill irregularly shaped products.

· Net Weight Powder Filler

They have weighing features to enable you to fill products using accurate quantities. It is the only mechanism which will measure your products prior to packaging them.

How Bulk Density Affect Efficiency Of Dry Syrup Filling Machine

Bulk density refers to a mass of powder that takes a fixed volume. It tends to affect the efficiency of the machine as it will impact the packaging and storage space of your product.

When there is a low bulk density, you will need a larger velocity for the machine to package your products. It increases the volume of your products thus overworking the machine in the process.

Applications Of Dry Syrup Powder Filling Machine

· Food And Beverage Industry

Dry powder filling process suitable for floor, salt, sugar and coffee packaging. They may require minor adjustments to suit any of these applications

· Chemical Industry

Powdered chemicals you can package include fertilizers, detergents, pesticides, and veterinary medications.

· Pharmaceutical Industry

You can use the machine for powdered drugs, medicines, and packing cannabis.

· Cosmetics Industry

In the cosmetic industry, you may use a dry syrup powder packaging machine for baby powders and cosmetic detergents.

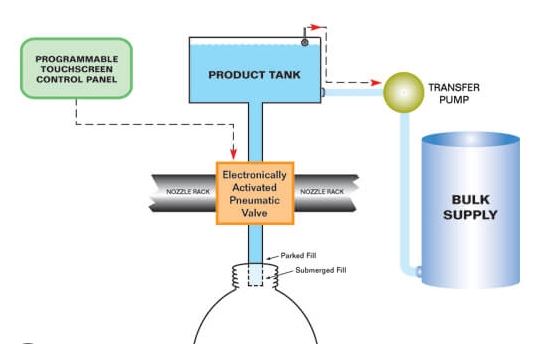

How Liquid Syrup Filling Machine Compare To Dry Syrup Filling Machine.

You can use liquid filling machines in packaging syrup products. They tend to provide you with fast and accurate product-filling functions at an affordable cost. They also ensure that your products are safe and not wasted.

You can use dry syrup powder filling machine in packaging volumes of powder into your packages. It can help you fill up several containers with products per minute. This rate will depend on the type of powder, the volume required, and the diameter of the container.

Conclusion

As you can see dry powder filling process requires an effective and reliable machines.

Depending on your powder filling requirements, you can choose a dry syrup filling machine with suitable dosing. More importantly, buy all your machines from reliable and trusted manufacturers.

More Resources:

- Cough Syrup Cartoning Machine – Senary Lin

- Filler In Packaging – Wikipedia

- Powder Packaging Machine – Jochamp