JOCHAMP Drip Coffee Bag Packing Machine

Get a flexible and versatile drip coffee bag packing machine for your business. It can produce coffee bags or tea bags with string and labels.

- Easily integrated into your existing packaging line

- Safe and hygienic design, FDA approved

- Equipped with touch-sensitive controller

- High-quality and reliable performance

Custom Drip Coffee Bag Packing Machine

Our drip coffee bag packing machine can produce high-quality packs such as drip coffee bags, tea bags, etc. It offers the accurate operation, and stability of the machines’ performance, and ensures hygiene products output. This machine can work with various packing materials such as paper/plastic, filter paper, plastic/aluminum/plastic, paper/aluminum/plastic, etc.

Jochamp manufacture superior quality packing machine with hygienic and food sanitary standards. The parts and accessories are made from internationally renowned brands such as Schneider, Siemens, Panasonic, etc. It has low maintenance costs and provides a high return on investment. These are equipped with an automatic conveyor system, touch-sensitive PID temperature controller, servo driven, controlled by touch screen and PLC technology. You can ensure easy-to-operate equipment for your projects.

JC-19 Drip Coffee Bag Packing Machine

This machine is a special model specially designed for drip coffee pods. It uses ultrasonic waves to seal the three sides of drip coffee bags such as nylon, Degradable Bio mesh (PLA), NWF, PET and other materials. After the drip filter bag is formed, there will be a transfer device to pack the drip filter bag into the bag and seal it.

- Ultrasonic sealing, fast sealing speed and firm sealing

- The inner bag length is controlled by servo motor to ensure consistency

- Using PID to adjust the temperature controller, the temperature is controlled more accurately

- PLC motion controller with HMI

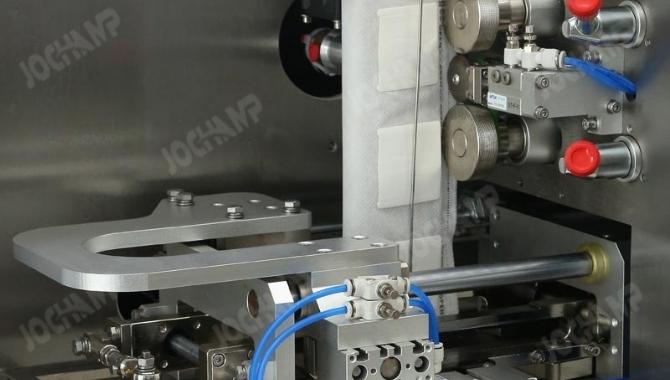

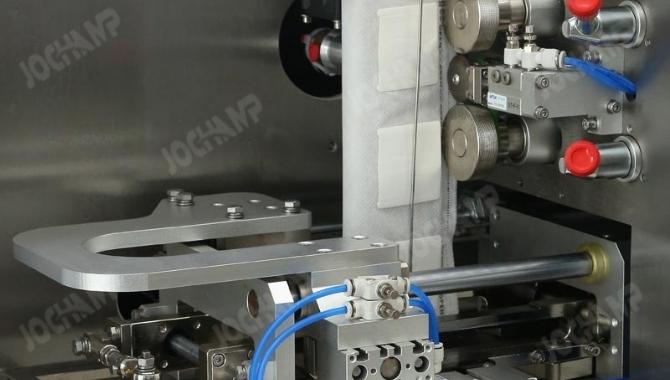

- All accessible material parts are made of SUS304 stainless steel to ensure the hygiene and reliability of the product

- Siemens, Omron, SICK, SMC, Mitsubishi and other internationally renowned brands of electrical appliances and accessories

JC-19

- Technical Parameter

- Features

- Optional

| Model | JC-19 |

| Packaging Materials | Paper/plastic,plastic/plastic, plastic/aluminum/plastic, paper/aluminum/plastic, filter tissue |

| Packaging capacity | 1-5g |

| packing speed | 30-60 bags/min |

| Label size | Width: 40-55mm Length: 20-24mm |

| inner bag | Width: 50-90mm Length: 50-75mm |

| outer bag | Width: 85-120mm Length: 75-100mm |

| power supply | 220V /50HZ/ 3.7KW |

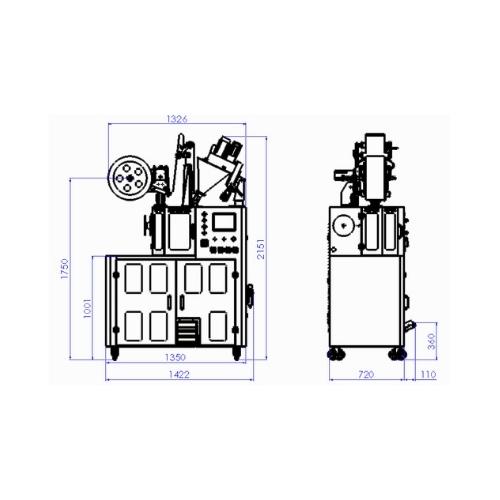

| Dimensions | (L×W×H)1200×900×1900mm |

| Total Weight | 400Kg |

- Ultrasonic sealing, fast sealing speed and firm sealing

- The inner bag length is controlled by servo motor to ensure consistency

- Using PID to adjust the temperature controller, the temperature is controlled more accurately

- PLC motion controller with HMI

- All accessible material parts are made of SUS304 stainless steel to ensure the hygiene and reliability of the product

- Siemens, Omron, SICK, SMC, Mitsubishi and other internationally renowned brands of electrical appliances and accessories

easy tear

add nitrogen

batch printing

Fully enclosed security door

Drip Coffee Bag Packing Machine Benefits

- Provide beautiful and clean bags

- Pack drip coffee bags with thread and label

- Easy to maintain, clean, install and disassemble

- High-precision auger filler

- Intelligent control software

- Durable and simple structure

- Stable working performance

- High speed and capacity up to 3600 bags per hour or customized

- Integrated with a 3-side ultrasonic sealing and cutting technology

Customized for Your Business

Jochamp specialized in developing unique and advanced packing machines. We provide OEM services that can boom your brand. You can choose and custom:

- machine metal structure

- color

- dimension (L*W*H)

- integration

- speed

- custom logo

- package range

Related Products

Drip Coffee Bag Packing Machine: The Ultimate Guide

Probably, you are looking for highly efficient and reliable drip coffee bag packing machines in the market. A reason this guide explores all vital aspects of drip coffee bag machines. From features, parts, benefits, filling options to working principle; you will find all information about drip coffee bag packing machine here.

Presently, drip coffee bag packaging equipment is available in two main variants that include the following;

drip coffee bag packing machine

Semi-Automatic Unit

It is a type where human power is involved in some of its operational aspects.

Ideally, this means that you have to manually carry out some inputs of this machine, whereas others are automatically actuated.

It forms the drip coffee bags, fills and seals them accordingly.

Usually, this drip coffee bag packer is relatively affordable but tends to be somewhat less efficient than a fully automatic unit.

It may need more operators, which in the long run makes it somehow less cost-effective.

Fully-Automatic Unit

Almost all the functional parameters of this machine variant are fully automated, as the name suggests.

Essentially, it requires less or no human interaction in making, filling, sealing, and packing the drip coffee bags.

Hence, the entire packaging process of the drip coffee bags using this machine is highly accurate, reliable, and fast.

automatic drip coffee packing machine

It features a modern, highly advanced touchscreen control panel to regulate its different functions.

Additionally, it comes with a collection unit where the packed drip coffee bags are cut and collected for subsequent cartoning.

Investing in this machine presents a wide range of benefits to your overall drip coffee bag production process, such as the following;

Faster Production Speed – The features of this machine allow it to pack the drip coffee bags relatively fast within shortest time possible.

Increased Production Throughput – Since it is speedy, it implies you can easily use it to pack several drip coffee bags depending on your production demands.

Consistency – This machine guarantees uniformity in drip coffee packaging, which is essential in attaining accuracy and improving quality.

Cost-Effective – Since the machine rarely uses human labor, it means you will easily reduce running costs and expand your profit margin.

Versatility – Other than packing drip coffee bags, you can also use it for packaging different products such as drip tea bags among others.

Easy-Maintenance – It requires less maintenance, and this is vital since it exhibits high reliability and cost-efficiency.

The main parts and components of this machine include the following;

Frame – It supports the entire machine’s parts and components and ensures it offers relevant stability during packaging.

Hopper – This is a funnel-shaped component located at the upper part of the machine for letting the product for subsequent packaging in drip bags.

PLC Touchscreen Panel – It displays various machine operations and controls different parameters to ensure packing efficiency.

Bag Feeder – This part is designed for laying the bags in a predetermined quantity for subsequent drip coffee filing.

Roll Film Bar – It is used for sealing the drip coffee bags once the product is filled.

Photoelectric Sensor – This is an inbuilt light emitting device that actuates a light beam to sense the presence or absence of bags in the machine during filling and sealing.

Printer – It is used for printing different information concerning the product on the surface of the packaging material.

Control Keys – They are buttons located at a central point on the machine for activating or neutralizing various functional parameters of the machine.

Dust-Proof Shield – The essence of this component is to safeguard the machine from imminent dust, dampness, and loose objects of any type.

Universal Wheels – They assist the equipment in easy mobility when moving it from one point to another.

parts of drip coffee bag packing machine

It starts the process with a roll of filter bag film that are filled quantitatively with the drip coffee.

A non-reusable single-serve hanging ear drip coffee bag then comes out.

During operation, the inner bag is pulled off from the rolling stock by film transport belts.

The film runs smoothly under control of a stepper motor.

Dancer arm moves up and down to ensure the film is under stable tension.

Photoelectric probe then ensures the roller pulls the film to the correct position to enable sealing device to cut in the right spot.

The auger filler releases the measured coffee powder into each bag, enabling the ultrasonic sealing devices to seal and cut the inner bag.

Naked drip coffee bag then falls into the outer-wrapping section of the machine.

Clamping parts moving up and down, pulls the outer bag roll film into the bag-forming device.

Once the inner bag drops, the independent horizontal and vertical seal bars move forward as they apply pressure on film, bond, and bond film layers.

The finished double chamber drip coffee bag finally drops on a conveyor belt and then is transported to the supporting equipment.

Some important factors to always look into when buying this machine include the following;

Usability – Ensure the specific model you choose is easy to operate and can easily be integrated into other supporting equipment.

Specifications – Most modern coffee bag packing machines feature a wide range of advanced features. Thus, it is vital to ensure you choose one with specifications that meet your packaging demands.

Size – Often, your available floor space determines the ideal size of machine to procure. Ensure you go for the right size that fits well in your floor space.

Application Demands – If your demands require high-volume packaging, it would be ideal to choose a faster and more efficient machine.

Price – Usually, different factors determine the overall cost of purchasing this machine. Thus, it becomes imperative to ensure you pick one that guarantees value for money.

This machine features the following technical specifications;

- PLC and HMI control for simple operation and easy to customize for the user

- Touch-sensitive temperature control device

- Faster packaging speeds of up to 36,000 bags per day

- Simple design construction that is easy to replace and maintain

- Excellent adaptability to numerous types of laminated films

- Auger filler with high accurate dosing, easy to clean and disassemble

- Three-side ultrasonic cutting and sealing technology produces neat and attractive drip coffee bags

- Stable and durable working performance

- Ability to pack coffee in rectangular bags with string and label

The common packaging styles used by drip coffee bag packing machines include the following;

- Standard drip coffee bag

- Rectangular drip coffee bag with outer cover/envelope

- Drip coffee bag with outer cover/envelope

- Rectangular drip coffee bag with tag and thread

A typical drip coffee packaging equipment has three main filling systems as follows;

Volumetric Cup Filling System – This filling mechanism enables the equipment to fill the drip coffee bags uniformly via a time-reliant filling standard.

Auger Filling System – It is a filling system where a precise drip coffee product is filled in the bag based on predetermined settings.

Load Cell Controller Filling System – This drip coffee bag filling system uses gravity, vacuum, or pressure to determine the filling efficiency.

Here are the notable elements that determine the efficiency of this particular machine;

a) Packaging bags – Some bags can endure and support high volume fills, such as quad seals and flat bottom seals.

Other bags are also pre-made, whereas some are pre-made during packaging process.

b) Drip coffee packaging process – Ordinarily, a fully automatic unit offers higher efficiency than a semi-automatic unit when packing this type of coffee in drip bags.

c) Status of coffee – Using a packaging machine with degassing value ensures the coffee stays fresh for long.

Oxygen, light, and moisture often compromise the freshness of this product in the long run.

d) Packaging bag size – Some drip coffee bags tend to be small, while others are large. In essence, the

This drip coffee packaging equipment may come with a lot of different accessories to facilitate the overall efficiency and reliability of the process.

The notable ones you are likely to find in this machine include the following;

- Material infeed conveyors

- Metal detectors

- Checkweigher

- Tear notch

- Bag deflator

- Package collator conveyor

- Screw air compressor

- Nitrogen generator

- Vacuum conveyor

- Special vertical sealing mold

drip coffee bag packing machine accessories

Occasionally, you will encounter a few problems when working with drip coffee bag packing equipment.

Some of these problems and how to troubleshoot them include the following;

Failure Of Package Bags To Feed

This error implies the bags are not feeding properly or consistently.

Some possible ways of solving it include cleaning the sensor, replacing or repairing vacuum generator, and checking if hose is damaged.

Defective Bag Seals

It causes wrinkled, weak, and uneven package seals.

To troubleshoot this, you will ensure the sealing bar temperature, and pressure are correct, and the bag is centered or level in grippers.

The basic routine maintenance processes of this machine include the following;

Thorough Cleaning – It is ideal to ensure you clean the equipment properly and thoroughly after using it. This ensures the machine stays clean and averts different parts from corroding.

Lubricating – All the contact moving parts should be lubricated properly using recommended lubricants to reduce friction likely to lead to faster parts wearing out.

Replacing Worn Out Parts – All worn-out parts should be replaced by recommended OEM parts to enhance efficiency and reliability.

More Resources:

Coffee Powder Packaging Machine

For all your drip coffee bag packaging, contact us now.