Coffee Powder Packing Machines Manufacturer

Jochamp coffee powder packing machines are easy to add to your existing packaging line. It can perform its operations efficiently. Provide high-quality and safe packaging. Jochamp has the ability to manufacture complete turnkey automated packaging lines.

- Capable for both simple and complex bag styles

- Tested and proven technologies

- Modular and compact design

- Obtain high-speed production

JOCHAMP Coffee Powder Packing Machines

Coffee powder packing machines are manufactured specifically for all kinds of coffee powder. It is equipped with an automatic feeding machine and controls material level. These are more convenient to use, improve production efficiency and reduce labor costs.

Jochamp is a one-stop solution for any type of packing machine. We can build equipment suitable for your specific applications and environment. All coffee powder packaging machines are tested from raw materials to machine assembly before the moving process. It passed CE, SGS, ISO9001, cGMP certification. Supported by 15+ mechanical engineers and 20+ after-sales service teams, you can guarantee a comprehensive service 24/7.

Types of Coffee Powder Packing Machines

Various Coffee Powder Packaging (5)

Suitable Bag Styles

Jochamp packaging machines are specifically developed to meet all of your needs. These are capable of packing different coffee bag styles including:

- Flat Bottom Bag or Stabilo / Quad Seal Bag

- Zipper Pouch, Premade Pouch

- Vacuum Brick Bag

- Gusset Bag, Stick bag, Pillow Bag

Custom Coffee Powder Packing Machine

Custom coffee powder packing machine at low cost. We can custom machine’s packing speed, capacity, machine dimensions, functions, suitable packaging materials, and more. The hygienic and safe metal is used in the construction. The electrical parts and components are built from Siemens, Omron, SICK, SMC, Mitsubishi, and other internationally renowned brands.

With 15+ years of custom packing machine experience, Jochamp guarantee a superior and high-speed machine for your projects. Our team will provide full packaging solutions from machine designing, production, and installation. We will assist you in technical training and after sales service.

Related Products

Coffee Powder Packing Machine: The Ultimate Guide

This article helps you to sort through a wide range of information regarding coffee powder packing equipment.

It provides a straightforward guide to various types of this machine, working principle, and other resources to enable you to take the next steps.

This equipment is available in different types based on the following categories;

coffee powder packing machine

Form Fill Seal Coffee Powder Packaging Machine

Coffee packaging equipment under this category is available in two main types, which include Vertical form fill seals (VFFS) and horizontal form fill seals (HFFS).

The major difference between these two coffee packaging machines is that VFFS performs its operations in a vertical manner, whereas HFFS performs horizontally.

VFFS coffee powder packing equipment is more popular and often used widely due to its lower cost to entry, compact size, and highly adjustable speeds.

form fill seal coffee powder packaging machine

It can also make both simple and complex coffee packaging bags.

Essentially, VFFS coffee packing machine utilizes a special former to form coffee bags from a large roll of packaging film.

It also measures a discreet amount of coffee, thus mostly recommended, especially in a commercial coffee packaging application.

HFFS coffee packaging equipment is relatively fast, accurate, and reduces wastage significantly.

Even so, it is limited to the specific powder coffee it can efficiently package and seal due to its horizontal orientation.

Fill And Seal Coffee Powder Packing Machine

In this category, coffee powder packaging machine are available in two types, which include rotary and inline coffee powder equipment.

Rotary coffee powder packing machine packs the product in a circular manner thus needs less floor space since its starting point is next to its endpoint.

Inline fill and seal coffee powder packing equipment operates in a straight line hence tend to cover more floor space.

fill and seal cofee powder packaging machine

Often, rotary machines are common in most coffee powder packaging applications due to lower cost of entry, more ergonomic design, and better floor space utilization.

Moreover, it is quite fast and accurate, thus essential in coffee powder packaging, especially in industrial applications.

You can also find them in semi and full automatic operations, making it easy to select the most suitable one for your coffee powder packaging demands.

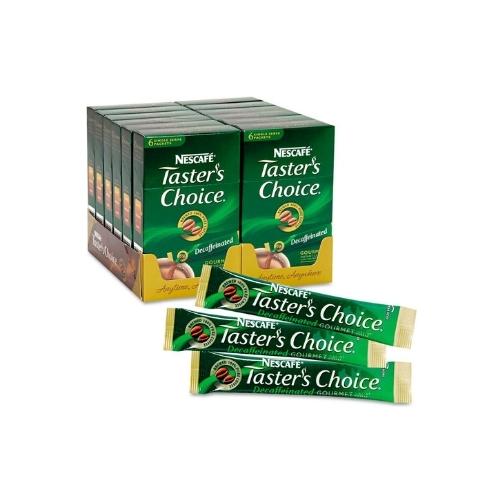

Stick Pack Coffee Powder Packing Machine

Coffee powder packing machines in this category are relatively standard.

Mainly, machines under this category are often distinguished based on the number of lanes you need to meet your throughput demands.

Ordinarily, stick pack machines operate more or less the same as VFFS coffee powder packing machines with slight differences.

stick pack coffee powder packaging machine

It uses a large roll of packaging film split into different lanes of the machine features.

The strips are then formed with small forming collars into stick packs filled with coffee powder and sealed shut.

You can always order change kits with different stick sizes and types.

The remarkable benefits of using a coffee powder packing machine include the following;

Reduced Running Costs

Often, using this machine guarantees reduced operating costs such as labor and other related utility expenses.

Since this equipment is automated, you will rarely require human labor, and this is vital in cutting costs and increasing profit margin.

Minimizes Wastage And Product Rejection

This equipment offers a discreet product quantity based on the specific settings.

As such, it guarantees accuracy and eliminates wastage, which is vital, especially in profit maximization.

High Versatility

You can use this equipment to pack a broad range of powdered products by merely adjusting the packaging material.

In essence, it reduces time wastage and unnecessary costs when you want to pack different products.

Faster Packaging Speeds

Since most parameters of this machine are automated, it implies you can attain the ideal speed based on your preferred settings.

Hence, faster packaging rates are vital in increasing throughput, which ensures you always maintain the supply.

Guarantees Superior Quality

This machine eliminates errors and inconsistencies like over-packing and package damage.

Essentially, most of such inconsistencies and errors usually waste the products and interfere with overall quality.

But using this equipment delivers consistency, which in the long run improves the quality of a product.

Eliminates Repetitive Tasks

Several errors often arise from manual coffee powder packing leading to additional product and packaging material waste.

But using this machine sets the workers free from the imminent monotonous tasks and gives them fulfilling roles.

Better Floor Space Utilization

The design construction of most coffee powder packing machines ensures they are compact hence take up smaller floor space.

In a typical production line, this is a fundamental feature since larger spaces would likely need more expenses.

Ordinarily, the features of coffee powder packaging equipment often vary depending on the specific machine and the model.

You can find custom designs with additional features to ensure they meet your production demands.

Nonetheless, here are the main technical features of standard coffee powder packing equipment;

- Touchscreen control system with an easy-to-understand human-machine interface offering more precise and convenient monitoring and control.

- Full stainless steel framing component and contact parts or stoving varnish for various customer requests, energy saving, and food grade.

- Allows use of various packing materials such as laminated film, plastic film, aluminum foil, non-woven fabrics, and filter paper among other heat-sealed compound materials.

- It comes with auger device making it ideal for packaging different powder products.

- Easy to operate since it also allows direct setting of filling weight on display.

- Multiple lanes hence can package several coffee powder products simultaneously.

- Emergency stop, count capacity, ready bag output, and set capacity to auto stop machine features.

- High precision photocell sensor enhances eye mark printing auto tracking on a film roll for accurate packaging material positioning.

- Automated parameters that enhance the overall efficiency of the coffee powder packaging process.

Notably, this powder packaging equipment offers different filling sealing systems, often based on the type of machine.

The common powder filling methods most of these machines use are as follows;

Volumetric Filling System

This filling method enables the machine to fill packages with uniform coffee powder volume through a time-based filling principle.

Essentially, it involves volumetric fillers dispensing precise and consistent coffee product filling irrespective of discrepancies in package sizes and shapes.

Auger Filling System

It is a filling mechanism where a product is filled to the exact volume in the coffee powder package as a set.

This system is regulated by corresponding pulses from the machine’s auger shaft driven by a servo-motor unit.

As such, the motor metes out a particular predetermined coffee powder amount into the package.

Net Weight Filling System

It uses pressure, gravity, or vacuum to establish the coffee powder filling effectiveness.

The desired coffee powder fill level is determined by the machine, which allows it to fill the packaging bags accordingly.

As far as sealing mechanisms for this machine are concerned, here are the main ones;

Ultrasonic Sealing

This sealing technique uses audile vibrations to produce heat at molecular level inside the coffee powder packaging material film.

Essentially, the audile vibrations trigger the molecules in packaging film material to begin the motion.

Thus, the ultrasonic vibrations form dynamic shear stress that deforms and produces heat due to friction between the contact parts.

Heat Sealing

This system entails sealing the coffee powder packaging material using pressure and heat.

It offers direct material contact that utilizes a continually heated die or sealing bar to apply heat to a specific path for material fusing.

This machine contains different parts and components integrated to provide a single functional unit.

Ideally, some parts often vary from one machine to another depending on the actual design construction and customization.

Here are the primary parts you will find in most standard coffee powder packing machines;

Frame – Usually made of stainless steel material designed to support different components and provide stability.

Bag feeder – It is used for continuously providing packaging bags into the machine for subsequent coffee powder filling and sealing.

Control panel – This component features various parts and devices designed to regulate different operating parameters of the machine.

Pneumatic powder elevator – It uses pressure to raise the coffee powder to the required level for easier filling and sealing into respective packages.

Display window – It showcases various functional parameters of the machine to enhance easy control to attain best efficiency.

Film hanging rod – This part is used for hanging the films used in sealing the coffee powder packages.

Material barrel – It is used for introducing the coffee powder into the machine for subsequent packaging.

Photocell sensor – This is an inbuilt device with a light-emitting feature designed to trigger a beam, which senses the presence or absence of packages for coffee powder.

Turntable – It is common in rotary machine models designed for clamping the packaging bags by ensuring indexing positioning during filling and packaging.

Vibrating tray – It shakes the coffee powder product while conveying the same to packaging bags and sealing phases.

Dust-repellant cover – The primary design for this component is to prevent dust, dampness, and any form of dropping.

parts of coffee powder packaging machine

A typical coffee powder packaging machine works systematically to ensure it fills and packs the product accurately, consistently, and effectively.

Here is a step-by-step process of how it works;

Packaging Bag Feeding

It starts with loading the respective packaging bags into the machine, often manually through the feeding unit.

The machine contains a magazine, which makes it easy to feed such bags.

It also contains a roller that feeds the bags automatically into the equipment for further processing.

Packaging Bag Gripping

Photocell sensor detects the presence of the bag at the extreme end of the magazine.

Ideally, the magazine contains vacuum suction pads with arms that easily grasps and loads packaging bags into a turntable.

Optional Printing

If need be, you may choose to print the surface of packaging bag material with various details or information by setting the printer to execute the action.

Bag Opening and Detection

The magazine’s vacuum suction pads grasp and pull the lower section of the bag to open.

While at it, the bag’s upper section is gripped with an arm allowing it to open fully.

The sensor in this station detects whether coffee powder fills the packaging bag correctly.

Should it fail to sense the bag, filling and sealing phases hardly engage for the ensuing bag.

Bag Sealing

The coffee powder-filled pouch shifts to the sealing station with a pair of hot seal bars combing on top of the bag.

Ideally, the seal bars create a sturdy seal on the packaging bag by bonding the packaging material.

Some vital elements you need to consider when buying coffee powder packing equipment include the following;

Design Construction

A suitable machine should be practical and versatile.

In essence, it is advisable to choose one with a compact structure to minimize floor space.

It is also ideal to go for one that you can easily set up and adjust accordingly depending on different operational parameters.

Model

This machine is available in numerous models with different standard and custom features.

Therefore, it is important to determine the specific one that suits your production demands based on your predetermined throughput.

Type Of Machine

Ordinarily, this equipment is available in semi-automatic and fully automatic options.

Of course, a fully automatic unit offers a better grip on the packaging bag as the product fills into it.

Besides, it is faster and more accurate, thus more appropriate for large-scale coffee powder packaging.

Semi-automatic unit, on the other hand, allows for both manual and automatic inputs during packaging.

It is moderately fast and also relatively accurate.

Technical Features

Most coffee powder packing machines have different technical specifications depending on the model and other related elements.

As such, it is important to ensure what you choose fits your coffee powder packaging demands accordingly.

Packaging Form

Some coffee powder packing machines have different packing styles, such as back seal and three-side packaging form.

User-Friendliness

Modern coffee powder packing machines are more sophisticated since they are integrated with advanced technology.

However, it is advisable to consider a model that features advanced technology and guarantees easy operation for efficiency and reliability.

Cost

You can always find this equipment at different rates depending on various prevailing factors.

Often, the actual price is based on the size, specifications, and model.

Ordinarily, this equipment is somewhat highly versatile, so you can always use it for packaging different powdery products in different industries.

Other than coffee powder packaging, the notable sectors that can use this machine include the following;

Dairy Sector

Powdered milk is among the common products filled, sealed, and packed using this machine.

Hence, you will find this machine in different dairy products processing entities that use it to pack different quantities of powdered milk.

Food And Beverage Industry

A wide range of companies that process food and beverage products also use this machine in packaging such products.

It comes in handy in this industry because it is fast, accurate, reliable, and more efficient, which allows it to add more value.

Pharmaceutical Industry

Different powdered pharmaceutical products can be packaged using this machine.

In essence, this product provides excellent accuracy, reliability, speed, hygiene, and efficiency, making it ideal for packaging such products.

Pet Food Processing

Several pet foods can also be packaged using this particular machine.

It sizes such food products depending on predetermined quantity at preset speeds, thus vital in attaining best results.

A typical coffee powder packing machine is highly efficient and rarely requires regular in-depth routine maintenance.

However, it is recommended to carry out different maintenance processes on this machine occasionally, such as the following;

Breakdown Maintenance Process

This maintenance process is often carried out when the machine experiences a significant breakdown leading to a remarkable downtime.

Even so, this is often quite rare, especially with this kind of machine because of its strong design construction.

Corrective Maintenance Process

It is a type of maintenance process that involves repairing different parts and systems of this machine once they start to malfunction.

Mostly, it is common in fully automatic coffee powder packing units since they highly depend on software and occasional system upgrades.

Routine Maintenance Process

As the name indicates, this maintenance process entails carrying out frequent check-ups on the machine to ensure it functions efficiently.

The notable routine maintenance process on this machine include cleaning, lubricating, and dusting among others.

Preventive Maintenance Process

It is a common type of maintenance approach designed to prevent the machine from an imminent breakdown that would affect packaging process.

Some common types of this process include replacing worn-out parts, reporting malfunctions, and routine inspections among others.

For all your coffee powder packing machines, contact us now.