Coffee Capsule Packaging Machine

JOCHAMP is a leading coffee capsule packaging machine manufacturer that provides lifetime after-sale service and one-year quality assurance. Our machine can be customized to your specific requirements.

- Provides precise packaging

- Excellent sealing performance

- Quick delivery

- Free sample test

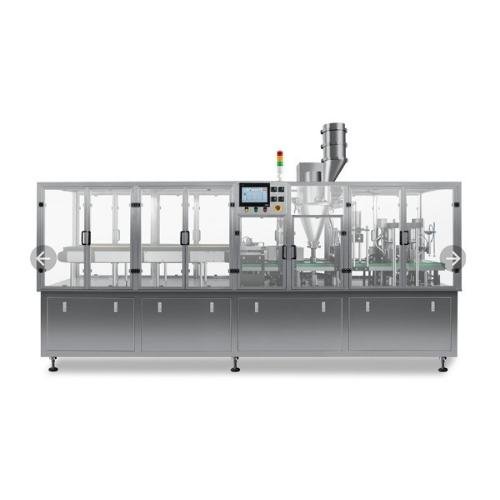

JOCHAMP Coffee Capsule Packaging Machine

The coffee capsule packaging machine is manufactured specifically for powder products and different coffee products required to be sealed and filled. These products include milk powder, cocoa powder, tea powder, and many more. JOCHAMP coffee capsule packaging machine adopts branded components from Omron, Siemens, Panasonic, and many more.

JOCHAMP is a trusted packaging solution provider in China with over ten years of experience. All our machinery is certified with international standards such as ISO9001, CE, cGMP, SGS, and more. Customized machines are guaranteed in terms of materials, design, features, and any specifications. JOCHAMP coffee capsule packaging machine is made of high-end raw materials such as stainless steel or aluminum and can be anodized to enhance durability.

Various Models of Coffee Capsule Packaging Machine for Your Choice

Different Coffee Capsule Packaging (4)

Coffee Capsule Packaging Machine Advantage

Our coffee capsule packaging machine is easy to operate because most of them are automatic. Just provide the important ingredients and let the machine proceed.

The machine’s maintenance provides minimum cost and is simple to maintain. It is important that the moving parts of the machine are clean and lubricated regularly.

Unlike manual coffee capsule packaging, automated coffee packaging machines can save time efficiently. It can also save labor costs, unlike manual packaging machines.

Our machine is flexible enough to adjust easily and produce any types of packages that vary in terms of packaging abilities and size. The machine is speedy to change over.

Numerous Customize Option

The coffee capsule packaging machine is custom-engineered in JOCHAMP. We can produce the machine based on your own design that fits your powder and coffee granule packaging needs. JOCHAMP has experienced engineers to assist in every stage of the design process.

Being a leading manufacturer in China, we can design every model’s performance, size, and capacity to match your unique production situations. JOCHAMP is trusted by most coffee capsule packaging industries worldwide. So, we have rich experience in handling any mechanism. We can provide a packaging machine for K-cup, Nespresso, Dolce Gusto, and Lavazza depending on your needs.

Coffee Capsule Packaging Machine Design

At JOCHAMP, we can make customized coffee capsule packaging machines to meet customers’ requirements. These machines have basic functionality that we called as “stations” or workstations, such as:

- Grab Cup/Dropping Cup Station: Placing cups in two ways – a manipulator grab cup or dropping cup.

- Detecting Station: Detects no-cup no filing.

- Filling Station: Ensures precise filling. The weight of the filling can be modified to client requirements.

- Film Roll/Precut Lid Station: Plastic film roll and precut lids are the sealing materials available.

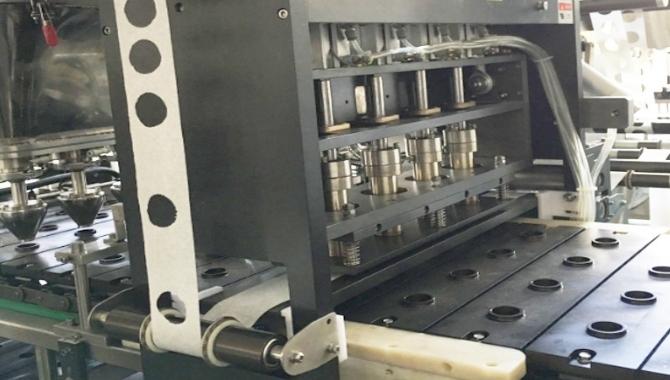

- Heat-Sealing Station: The set of heat-head and heat-tube are built into our machines to ensure the sealing tightness.

- Discharge Station: The finished products proceed onto the conveyor belts.

Details of JOCHAMP Coffee Capsule Packaging Machine

- Cup Falling Device: It allows the cup to fall one by one. Our machines adopt the technique of vertical spiral filling which has high precision, quick filling speed, and a large volume of filling.

- Put and Suck Foil Device: The machine is commanded by air cylinders that can release foils and vacuum suction. The coffee capsule packaging machine has a silicone suction cup.

- Sealing Device: The device can be adjusted in different variations of temperature, ranging from 0-400℃. Our machine adopts copper sealing heads.

- Printing Device: We utilize oil printing so that the letters or numbers will be printed on the materials.

Coffee Capsule Packaging Machine Supplier

JOCHAMP has been a leading manufacturer of packaging machines for coffee capsules. All parts of the machines are fabricated from 304 stainless steel and have advantageous features. The features include a multi-language version of the PLC touchscreen.

Additionally, optional features are available from us and can be customized based on our customer’s needs. Our machine is furnished with imported pneumatic and electrical components from the famous brand – Mitsubishi, Omron, Schneider, Siemens, and many more. We also accept your customized machines matching specific brands if needed.

For more information about the JOCHAMP coffee capsule packaging machine, please don’t hesitate to contact our team!

JOCHAMP Coffee Capsule Packaging Machine

- Reliable, faster, and well synchronize design

- Frequent loading of the cup is not required

- Outstanding sealing quality

- Clean filled edge of the cup and no products are sucked out inside the cup

- Outstanding filling accuracy

- Downstream sorting is convenient, boxing or bagging

JOCHAMP coffee capsule packaging machines can be customized to configure any shape of capsule cups, such as:

- Lavazza blue

- Personalized cup shape

- Nespresso capsule

- Mycup, Melitta

- Filter installed K-cups

- Different types to be specified

Why Choose JOCHAMP Coffee Capsule Packaging Machine

Our coffee capsule packaging machine is built in compliance with international quality standards. Our machines are fully certified by the following:

- cGMP, CE

- ISO9001, SGS

At JOCHAMP, all our machines are manufactured with a quality control process. We own a comprehensive line of the testing facility and raw material inspection.

JOCHAMP can manufacture coffee capsule packaging machines according to our customer’s requirements and other specifications. We have a strong R&D team to provide our clients with customized solutions.

Related Product

Coffee Capsule Packaging Machine: The Ultimate Guide

If you are in the coffee packaging industry, you should consider coffee capsule packaging machine. With this machine, you will package all types of coffee capsules. A reason this guide will help you choose the best coffee capsule packaging machine.

It is a special machine which is designed to fill and seal coffee products, especially coffee powder into coffee capsules that are mainly pod-shaped.

coffee capsule packaging machine

High Speed Working Ability Level

Coffee capsule packaging machine is very fast during the packaging process. Speed is set based on the efficiency to be met.

A high efficiency level will produce more products or capsules over time.

Flexibility

Since it can be used to package different liquids, powder products and even grains, this makes it more flexible in the long run,

Processing company will use such factors while purchasing machines so that the cost of purchasing other machines is kept low.

It is able to fill the capsules and then seal them at ago.

High Efficiency Level

High number of packaging products is done within a specific time frame.

This is less costly compared to employing workers who cannot work all the time as the machine can work all day.

Quality Assurance

Compared to human labour, a packaging capsule maintains high quality of products for exportation.

Highly maintained hygiene is key to human health, a factor for all food packaging industries.

Reliability

Due to its ability to work on different products other than coffee products like tea powder and other soluble powders, it is way reliable to, especially companies having different products for packaging at ago.

Safer To Use

Having been made of mainly stainless steel, it is safe due to the rotating parts.

An operator will not easily be affected with the moving parts as they are well enclosed and safely designed.

Easy To Adjust Speed When In Use

A variety of frequency level control is applied based on the speed needed to make the machine run.

It can be reduced or increased based on the amount of products to work on or the number of capsules to work on within a given period of time.

High Accuracy Level

Different kinds of capsules are used in the process of coffee filling, yet the machine can work on all the types as the process is done with no mistakes detected.

Filling the capsules is highly accurate and quality of the product is maintained.

Maintenance is Less Costly

Since it is a simple machine, cleaning its parts and maintenance during parts repair or replacements is easily achievable.

Its parts can easily be accessed and managed based on the deformity included.

Easy To Detect Defect Or Disorder

Having an alarm response, the machine can easily detect the level of the supply of the gas within it.

An alarm can also detect the presence of any disorder for instance the fail of its components while in use hence aid in accuracy of its actions.

Coffee capsules are cylindrical in shape while coffee pods are rounded in shape.

Coffee capsules are packed in vacuum space while coffee pods are just filled in a single like dose filter in order to obtain a brewed coffee.

Ccoffee capsule

Coffee capsules does not allow external reactions with humidity or oxygen, hence highly hygienic as compared to coffee pods.

Coffee pods are usually sealed a pressed between two papers that allow air, hence reactions with the coffee, creating a low hygienic environment.

Coffee capsules are tightly enclosed hence offer a very long period of storage in different environmental conditions.

Compared with the coffee pods they are much exposed to the environment hence riskier as they are susceptible to humidity changes.

Coffee capsule packing requires machine for the operation to be effective compared to coffee pods which can be done manually.

coffee pods

Convenience

Capsules are measured based on size and shape, hence can be used to pack different materials at ago due to their nature.

Quality Assurance

Coffee is packed in a very skilled and technical way to avoid any contamination with other environmental factors.

Affordable

It is easy to purchase coffee capsules than the machine itself. Coffee capsules are cheap and can easily be packed within a short period of time and stored for export or later use.

Longevity Of The Capsules

Capsules have a longer shelf lifespan. A factor that offers long period of its product lifespan too.

Office Use And Quality

Capsules are best for office use due to their packed manner.

It is easy to use coffee capsule in making a drink in a short period of time while in office.

Different Varieties

Capsules can be packed of different flavours and additives, a factor that meets market value and competitiveness with other products like tea powders.

Money Saving

Making coffee using coffee capsules is easy and does not require technical skills. It saves cash for hiring workers to prepare coffee for you.

Time Saving

The use of coffee capsules is way fast and easy, hence saving time to especially office employees.

Easy To Use

Coffee capsules can easily be used by any person. The seal is pulled off as the coffee powder is exposed.

Recycling Ability

Capsules can be recycled when need be.

Coffee powders incompletely used in the capsules can always be reused went well kept.

Nespresso Capsules

Most of the original capsules are made of aluminium, though the compatible capsules are made of plastics of food grades.

- Capsules are compostable.

- Capsules are 30mm high and 37mm wide.

- Also, they possess a V shape.

Nespresso capsules

Dolce Gusto Capsules

Both original and compatibles capsules are made out of soft materials at the same time the hardy plastics.

Dolce gusto capsules

Dimensions are of 36mm high and 54mm wide.

Lavazza Capsules

Capsules are made up of only soft plastics, both originals and compatible ones.

Capsules comprise 27mm height and 47mm width.

lavazza capsules

Caffitaly Capsules

Capsules from original design are made of softy plastics as the compatible ones are made of both the soft and hardy plastics.

caffitaly capsules

Also, they possess a dimension of 25mm height and 45mm width.

Framed Aluminum Shield

Aluminium being a high quality element, it offers protection to the machine components as it has does not corrode.

Aluminium frame provides high strength to the machine due to its ability to withstand tough situations.

A Configuration Of Stainless Steel For Product Surface

Products being processed are passed through a stainless still surface which allows for quality maintenance and prevention of product sticking to the surfaces.

A stainless steel surface also serves different product nature for instance liquid and powder without creating a sticky surface.

A Rotating Plate Made From An Anodized Surface Of Aluminium

Aluminium offers high quality and reliable protection as it is not susceptible to corrosion.

Fast And Mechanically Made Parts

Such parts offer very fast and efficient mode of working for the capsule packaging machines.

Other parts of the machine are not much complicated, hence making it easier for the machine operator to easily run the machine effectively.

Mechanically designed products are always reliable and flexible.

Conversion Frequency

A device which is motorized is used to offer the indexes to the machine, a factor to offer accuracy of the products from the machine.

A Control Unit With A Touching Screen.

Every activity happening in the machine is well controlled and monitored via te screen. Any changes are made via the screen, making the work fast and efficient.

Magazine Which Is Horizontally Designed Cup

It offers a key factor in carrying of an empty cup.

A Mechanically Designed Clamping Cup

A mechanical cup is way better and effective compared to a vacuum system of sucking.

A Motorized Serve And Adjustment Of The Volume

A high motorized server is key is used to offer efficiency and quality performance as there is an adjustable volume to create a clear and smooth working principles.

Mechanical Type Of Lid System Sucking

Positioning of the lid sucking system is important in offering high quality products.

A mechanical surface offers strength and durability compared to other elements.

Mechanical Edge Type Cleaning

After every filling is done, the machine edge is subject to mechanical cleaning for maintenance and durability.

Device For Sealing

A sealing type of device should adapt itself to offer quality work in the filling process.

Presence of Cup and Lid

Without the presence of either of the two, the machine will not carry out the filling and sealing process completely.

Open Machine Doors

A capsule filling and sealing machine will automatically stop the interlocks once an open door is detected

Discharging Conveyor

A conveyor will do the sorting of the product, after which it will pack.

Some of the most common parts include:

Control Unit

It comprises of a screen monitor made of a screen touch.

Control and monitoring of all the machine operations is done and observed at this point.

Any defect or failed part is detected and shown over the screen.

Filling Point

It comprises of a cup that holds the coffee when fed to the packaging machine.

It acts as the receiving head point.

The receiving cup has a certain diameter based on the machine model, hence capable of holding a measured weight or size of the coffee to the packed using the machine.

Accuracy of filling depends on the customer specifications of the coffee.

Sensing Point

It comprises of sensors that detect all the operations of the machines. Any default is sent to the screen as the alarm response is received.

Sensors also detect the presence or absence of fillings to the receiving cup.

Power Point Or Heat Sealing Point

A given voltage is preferred for the machine to run effectively and efficiently.

A certain heat is offered to effectively seal the capsule for testing and ensuring proper tightness is achieved by the machine.

Air Cleaning System Point

Air is important when cleaning the machine, at the same time it cools the running parts due to the heating process.

Film Rolling Point

It is the main part where different sealing types are distinguished. There is the use of precup lids and also use of film roll from plastics.

Glass Cover

It provides a clean environment for working.

Discharge Point

Packed products are expelled from the machine to the conveyor belt.

Conveyor Belt

It offers movement services or receives packed products from the coffee packaging machine.

Livewire Or The Operator

Any given machine must be run by an operator. He is responsible of operating all the activities within the machine.

Every single operation is majorly done by use of the control screen part.

Electrical Parts

Supply of power and signals to different machine parts is done by the electrical parts.

Signals in the operating parts are monitored at the screen level.

coffee capsule filling and sealing machine

Step 1: Feeding Machine With Coffee Capsules

Capsules to be used for packing are fed on the machine through use of a conveyor belt.

Capsules appear differently based on size and shape.

Step 2: Feeding Inner Filters

Before coffee powder is fed to the machine, the inner filter layers are fed to the machine, though the process is optional based on the working principle.

Step 3: Sorting

It is an optional step as sorting is done on the packing capsules.

Step 4: Filling The Coffee Powder Based On Weight

Coffee capsules are designed in different ways to pack weights of different sizes. Weights are filled to the capsules as per the customer specifications.

Step 5: Powder Pressing

Coffee powder is pressed to enough the capsule holds the required weight to the maximum. Pressing of the capsule offers assurance of the packing level of the powder.

Step 6: Filter Paper Feeding

Covering the coffee powder offers protective layer that reduces risks like spilling.

Step 7: Foil Paper Feeding

Foil paper in help with the seal through heating is majorly a top covering way to maintain quality.

Seals might as well be designed in a way that the product name, type and other components it contains are printed on.

Step 8: Discharge of the Capsule

After sealing, a coffee capsule is expelled from the machine through the help of a conveyor belt.

A conveyor belt offers movement services to and from the machine.

Proper And Continued Lubrications

Moving parts of the machine must always be well lubricated to avoid friction which causes wearing of the involved parts.

Lubrications provide effective movement of the movable parts of the machine.

Dry Cleaning The Machine

A coffee capsule packing machine should be kept dry and clean in order to avoid filthy condition which causes corrosion to the main parts of the machine.

Cutting Parts To Retain Sharpness

Cutting parts used to cut film should be maintained sharp to increase the efficiency and performance of the machine in the long run.

Blunt cutting parts are not effective to the work piece, which can create delays in the operations.

Replacement And Repair Of Affected Or Broken Parts

Repairing parts that are worn out increases efficiency of the machine as the operating system is maintained.

Replacing is key to avoid injuries and offer long term viable solutions.

Regular Machine Check Ups

For any defects based on the machine operations, a regular check-up is required to avoid injuries and poor machine performance.

Skilled Operator

An operator must be skilled to avoid mismanagement of the machines.

Skilled personnel will offer proper management of the machine, set the machine in a very professional way and control the unit performance based on the speed prescribed by the manufacturer.

Some of the most common technologies include;

Rotary Coffee Capsule Filling Technology

It is an automatic designed method that packs and seals the coffee capsules.

Also, it can deliver up to 900 capsules per hour, hence very fast and efficient.

Rotary machines are designed to offer speed and an assurance of customer specifications.

All operations within the system are controlled and are adjustable based on the product and the procedure in place.

Sensors

It comprises of sensors that are infrared that do not allow filling or sealing without a cup.

Automated Dropping Cups

Automated dropping cups are also controlled by the one-time screen control unit too.

Control Unit

A touch screen is used to control all the activities occurring in the machine operational system.

Flushing With Nitrogen Before Sealing

Nitrogen offers preservative nature to the coffee powder.

Glass Covering Of Device

It provides quality maintenance to the machine and a clean working environment.

Air Cleaning System

An air cleaning system that cools the running engines is always kept with air circulation.

Cooling system provide adequate environment for engines.

Opening Door Detection

Opened doors will automatic cause the machine to stop.

Stainless Steel Machine Covers

Machines covered with stainless steel element are durable and offer less maintenance costs due to the availability of the hard cover.

That is less susceptible to bending or cracking when subjected to massive hits.

Automated Sealing

Coffee capsule machines automatically seal the capsules in a very fast and single manner, hence high efficiency level of the machine.

Other Machines:

Drip Coffee Bag Packing Machine

For all your coffee capsule packaging machine, contact us now.