This guide will answer all your questions about the chocolate packaging process. Whether you want to learn about technology, machines, or the best packaging solutions – you will find the answer here. Find out more by reading on.

1. Is there a difference between the chocolate packaging process and the chocolate packaging process?

Yes, the chocolate packaging process is different from the chocolate packaging process in the following points.

Chocolate Packaging

During the chocolate packaging process, the material used to wrap the chocolate can come into direct contact with the chocolate. This is the initial and main process of packaging chocolate. Then comes the packaging process of the chocolate.

Here, the chocolates are covered in boxes, containers, or other packaging materials, and they are waiting to be dispensed. The chocolate packaging process acts as a storage option for chocolates and protects them from contamination or damage.

2. What are the key aspects of chocolate packaging?

The chocolate packaging process adheres to different stages to ensure that the chocolate is carefully packaged and ready for distribution. Below are some of the key stages in the chocolate packaging process

1) Prepare

This marks the first step in the chocolate packaging process. This stage includes preparing the raw materials for packaging. It also requires you to get the packaging machine ready for use, making sure it is not malfunctioning.

For fully automatic machines, raw materials need to be plentiful, as the process is usually fast. After all these ingredients are prepared and the necessary precautions are taken to improve the safety of using the machine, the packing material is loaded into the hopper of the machine.

2) Bag formation

The formation of the package begins as soon as the chocolate product is used. Shipping systems are often used to help deliver products to the packaging area. Dancing arms and forming collars are the main components of machines that assist in the forming of packaging materials. The chocolate packaging process begins when the collar is formed with the packaging material.

3) Packaging process

Once the packaging material is ready, the chocolate product is packaged to the right size. The design of the machine helps to achieve the desired shape and size of the product. The machine then helps seal the package. To make the seal airtight, glue or heat can be used.

chocolate packing process

4) Discharge

Once the chocolates are packaged, they can leave the packaging area through the unloading area and proceed to the next stage.

- How do you package chocolate? What machines do you use?

Chocolate packaging can be done with a variety of machines. These machines include:

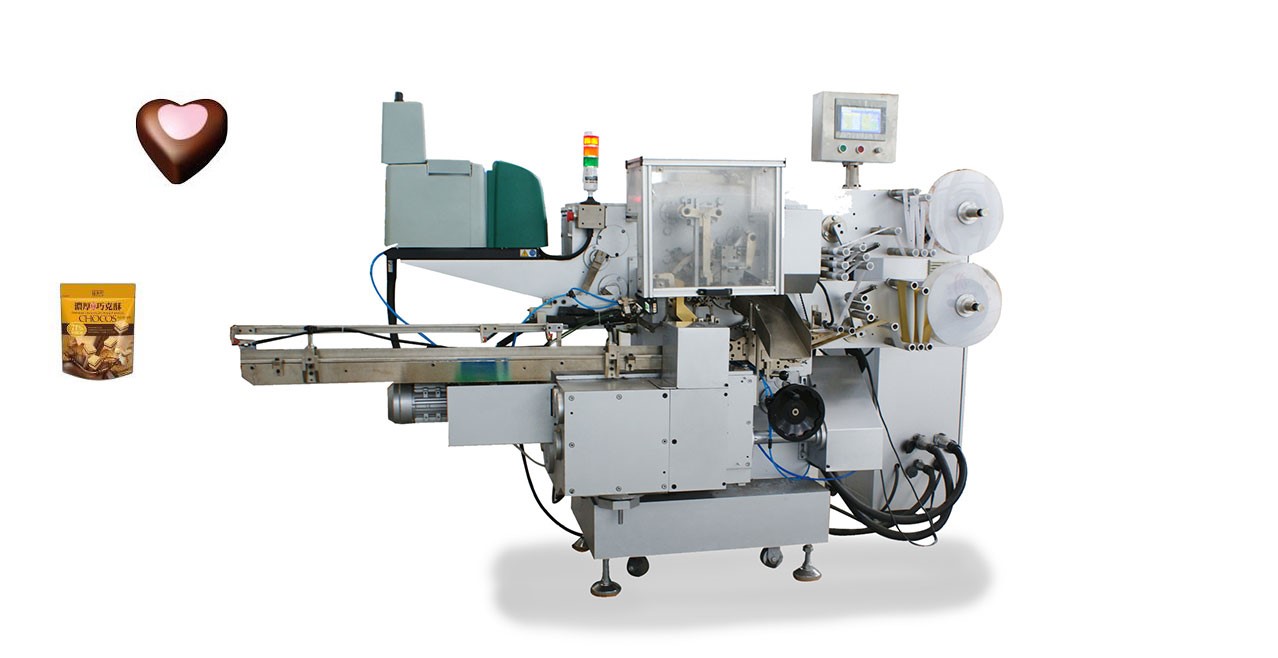

1) Chocolate Folding Packaging Machine

This machine is very useful because it can pack different sized chocolates in envelopes. This is very useful in the chocolate packaging process. However, the machines are expensive and further require huge space for installation.

Chocolate Folding Packaging Machine

2) Chocolate Foil Packaging Machine

If you’ve ever tasted spherical or oval chocolate, this is the machine responsible for the packaging process. It utilizes various foil materials to aid the packaging process. The special feature of this machine is that it is easy to pack chocolates of different sizes.

Chocolate Foil Packaging Machine

Its automation feature improves production efficiency and facilitates mass production. However, the price of this machine is quite expensive. Also, faults take a long time to fix; Therefore, there may be insufficient output due to malfunction.

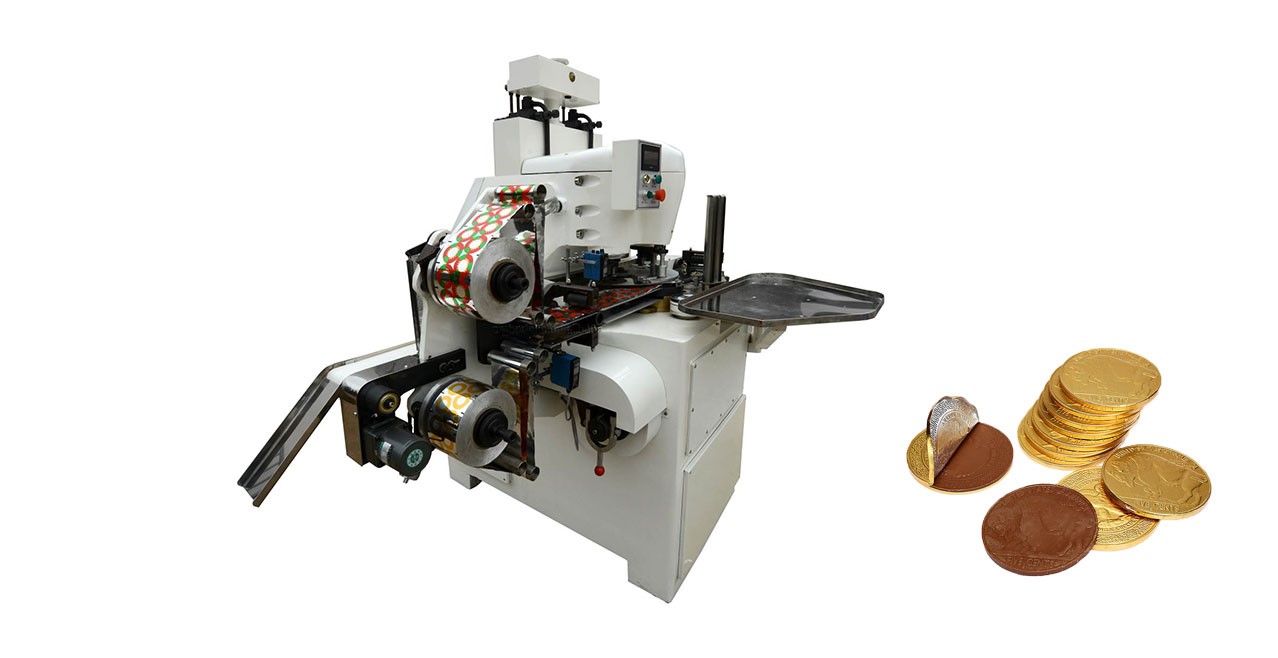

3) Chocolate Coin Packaging Machine

From its name, this machine can pack chocolate in the shape of coins. Their unique design features molds that facilitate the production of chocolates in different sizes.

Similar to the above machines, the cost of the machine is also high and a huge space is required to facilitate the installation of the machine.

Chocolate Coin Packaging Machine

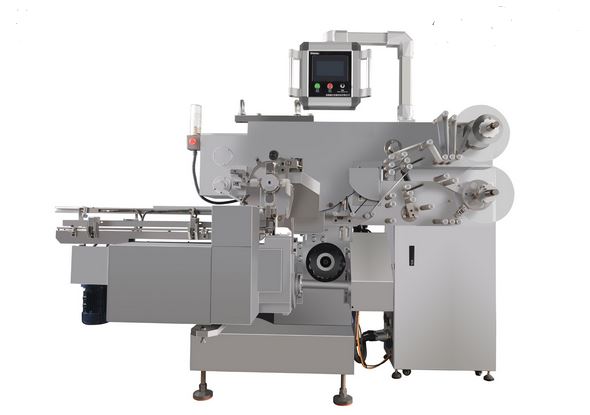

4) Chocolate Bar Packaging Machine

The machine is designed so that it can pack chocolate products from chocolate bars in aluminium or cardboard. Like other machines, it is expensive to purchase and requires a lot of installation space.

Chocolate Bar Packaging Machine

4. Why is the chocolate packaging process important?

Various factors are considered in the chocolate packaging process with the aim of achieving product quality and ensuring consumer safety. Here are some of the reasons that make the chocolate packaging process important.

1) Process Assurance Protection

Chocolate is a product people ingest in the body. The packaging process protects the consumer by ensuring that the product is not contaminated. The process further ensures that the packaging is free from spoilage and degradation effects, from chemical changes.

Physical damage and biological damage can also destroy chocolate. The packaging process requires care to ensure that the product is reliably protected.

2) Create convenience

After the chocolate product is packaged, it is easy to manage and carry. The packaging process also increases the visibility of the product. This makes consumers aware of the size of the product they are buying.

3) Take credible containment measures

The packaging process ensures that chocolate products are in place and protectively sealed until their final disposal, the consumer.

4) Communicate important information

The packaging process includes important information that is beneficial to the packaging material. This information includes expiration dates, ingredients and manufacturing dates. For example, listing ingredients on packaging materials is necessary to help people with allergies.

5) It makes it easier to track production

Through the packaging process, manufacturers can say what yields they have achieved. The packaging process includes printing batch numbers, allowing manufacturers to track production, processing and distribution.

6) Help identify any cases of tampering

Packaging adheres to a unique and defined sealing process. An example of quickly notifying users of any product tampering. The packaging process is to ensure that the final product has not been tampered with. To prevent any tampering incidents, the following measures should be considered.

- Use the strip technique.This technique groups together several products and sales as a single unit.

- Use a unique membrane familiar to the manufacturer to prevent tampering.

- Use detaching closures

- The used graphics cannot be changed back once you open it.

- Use a unique print that cannot be copied anywhere else.

- The chocolate packaging process is also helpful in marketing the product.

Information and graphics embedded in products have a significant ad tech role. Graphics help entice consumers to buy a product. Product information helps to further convince consumers of the benefits of buying this chocolate. This information includes chocolate size, ingredients, quantities, additives, batch numbers and even weight.

5. How to improve the efficiency of chocolate packaging?

Efficiency mainly depends on the type of machine you use, whether automatic or manual. How the machine is operated can also improve efficiency. Below are some practices and measures you can take to help improve the efficiency of your chocolate packaging process.

- Make sure that the chocolate packaging machine is regularly cleaned and maintained after use.This includes removing any debris and contamination that could interfere with machine operation. It helps the machine to operate at the optimum level, thereby increasing the efficiency of the execution process.

- Establish routines that allow you to perform regular inspections of machine parts.This can be daily or weekly. This is crucial as it helps you find any possible causes of failures and resolve them accordingly.

- Be sure to lubricate all moving parts.This helps reduce wear on machine parts. It helps keep the maintenance costs of the machine to a minimum.

- When machine parts wear out, be sure to find easily identifiable replacement parts.It is advisable that you consult with your supplier or manufacturer to help ensure genuine spare parts for your machine.

- Finally, make sure your electrical connections are not faulty.If repair is needed, it should be repaired in time. Lack of care with electrical components can lead to serious hazards such as electric shock or even fire.

6. What are the recommended packaging materials for chocolate?

The chocolate packaging process employs different materials to aid the packaging process. The following is an outline of the materials used in chocolate packaging.

1) Plastic material

This material is preferred as it provides a durable, rigid and leak-proof structure that helps keep chocolate fresh. However, it is not environmentally friendly, thus limiting its use.

2) Paper

Its use is due to its lightweight nature, which makes it easy to carry chocolate. Compared to other materials, it is also more affordable. However, if not carefully lined, the material can easily be damaged by moisture and grease.

3) Aluminum

This is the third material you can use in the chocolate wrapping process. It is a safe material for packaging edible foods, such as chocolate, and is also very light. However, this material also has its drawbacks.

Achieving an appealing appearance that entices customers to buy chocolate, or even the marketing of the product, can be challenging.

7. Can you recommend the best chocolate packaging ideas for marketing?

Chocolate packaging adapts to various types of packaging technologies and is applied in the chocolate packaging process.

They include;

1) Multipack

This packaging idea is to put several chocolate bars in one space. Has an open section for easy access to the chocolate

2) Traffic packet

Packaging styles with hot or cold sealing films fall into this category.

3) Chocolate Tablet

It combines two packaging materials. Thus, the inner and outer packaging films are formed. The outer packaging style has an envelope style with side tabs tucked into the flap.

4) Mixed packaging

This type of packaging has several rows to hold chocolate products. It comes with cardboard and dividers for packaging purposes.

5) Carton Multipack

It combines several chocolate bars into a single carton pack.

6) Display box

This style utilizes an open cardboard box for easy and convenient access to chocolate. The carton can take the shape of an open tray or a folding box with a lid attached.

7) PP film multipack

This packaging concept uses PP film to fully wrap the chocolate. However, it left a tear-off tape to access the chocolate product inside the package.

8. How to be hygienic during chocolate packaging?

Always make sure to clean the machine before and after the packing process. This helps remove any contaminants left on the machine. Ensure that all workers in direct contact with the packaging process wear protective caps, gowns and gloves.

Make sure the workspace is clean. This cleans the work space. Also, make sure that the machine you buy is made of stainless steel. The material is easy to clean and ideal for making food materials.

9. How to incorporate printing into the chocolate packaging process?

It is easier to include printing on chocolate packaging with automatic machines. You just enter information and graphics onto the packaging and the machine makes sure they are printed on the packaging. However, with manual machines, a printer must be integrated to help print the required information and graphics.

10. What should you consider when preparing chocolate wraps?

Here are the key things to keep in mind when preparing for the chocolate wrapping process.

1) Power requirements

The chocolate packaging process relies on a certain amount of electricity supply, which helps drive the process. Failure to observe the requirements to supply these power sources can damage packaging and therefore affect production, and

2) Operating space

The type of machine you use in the packaging process largely determines the operating space. It also depends on your packaging level, so whether it’s a small-scale or large-scale chocolate packaging process.

Therefore, if you are in a large-scale packaging process, the required space is correspondingly large. Make sure there is enough space to accommodate the needs of your chocolate wrapping process.

3) Machine automation level

Automated machines help reduce the number of operators in the packaging process, thereby reducing labor costs. In addition, this contributes to increased efficiency and reliability in the packaging process of chocolate products.

4) Quality Standard

The existence of quality standards helps ensure that products are not harmful to consumers. Therefore, it is important to comply with all international quality standards applicable to chocolate products. These standards are optimally adhered to during production and packaging.

5) Operating cost

It depends on the type of chocolate packaging process you want to achieve. These machines have different prices and different methods of operation. For example, buying a manual packer is cheaper than buying an automatic packer.

6) Integrated

Chocolate packaging machines can accommodate a variety of equipment to help increase the efficiency of the chocolate packaging process. Therefore, it is important to ensure that you get the equipment that your machine comfortably supports.

You can get further clarification from your supplier or manufacturer to get the right equipment to help support your packaging process for your machine.

7) Speed

The type of machine you buy determines the speed. Compared with manual and semi-automatic packaging machines, fully automatic packaging machines operate faster. Therefore, if you have a high demand for chocolate products, you might consider purchasing a fully automatic packaging machine.

11. How to reduce the cost of the chocolate packaging process?

Obtaining a reliable and efficient machine in the packaging process can reduce the cost of the chocolate packaging process. The ideal is to purchase an automatic packaging machine. Although expensive, the machine functions effectively and also guarantees speed, thereby increasing production efficiency.

Also, ensure that the machine is continuously cleaned and maintained to protect it from damaged and worn operating parts. Maintenance avoids the need to replace the whole machine and reduces the cost of the machine. Finally, adapting to lower-cost packaging technologies can help reduce costs. For example, use cold sealing techniques rather than heat sealing techniques to seal chocolate products.

12. What sealing techniques can you use during chocolate packaging?

There are two types of sealing techniques you can apply to help achieve sealing during the chocolate packaging process. This is the cold sealing and heat sealing technology. Heat sealing is the use of heat to help seal chocolate packaging.

Cold sealing, on the other hand, applies glue. No heating required With these sealing techniques, one of the following seals can be applied during the chocolate packaging process.

1) Bands

This method only requires heating or gluing the chocolate after placing it in the package.

2) Foil packaging

The foil material does not require heating to seal the chocolate packaging.

3) Set of packaging

Use more than one packaging material; It is then heated to seal the product.

4) Twisted packaging

This method twists the ends of the chocolate wrapper together to seal the chocolate product.

Other Related Information:

For all your carton folding machine needs, contact us now.